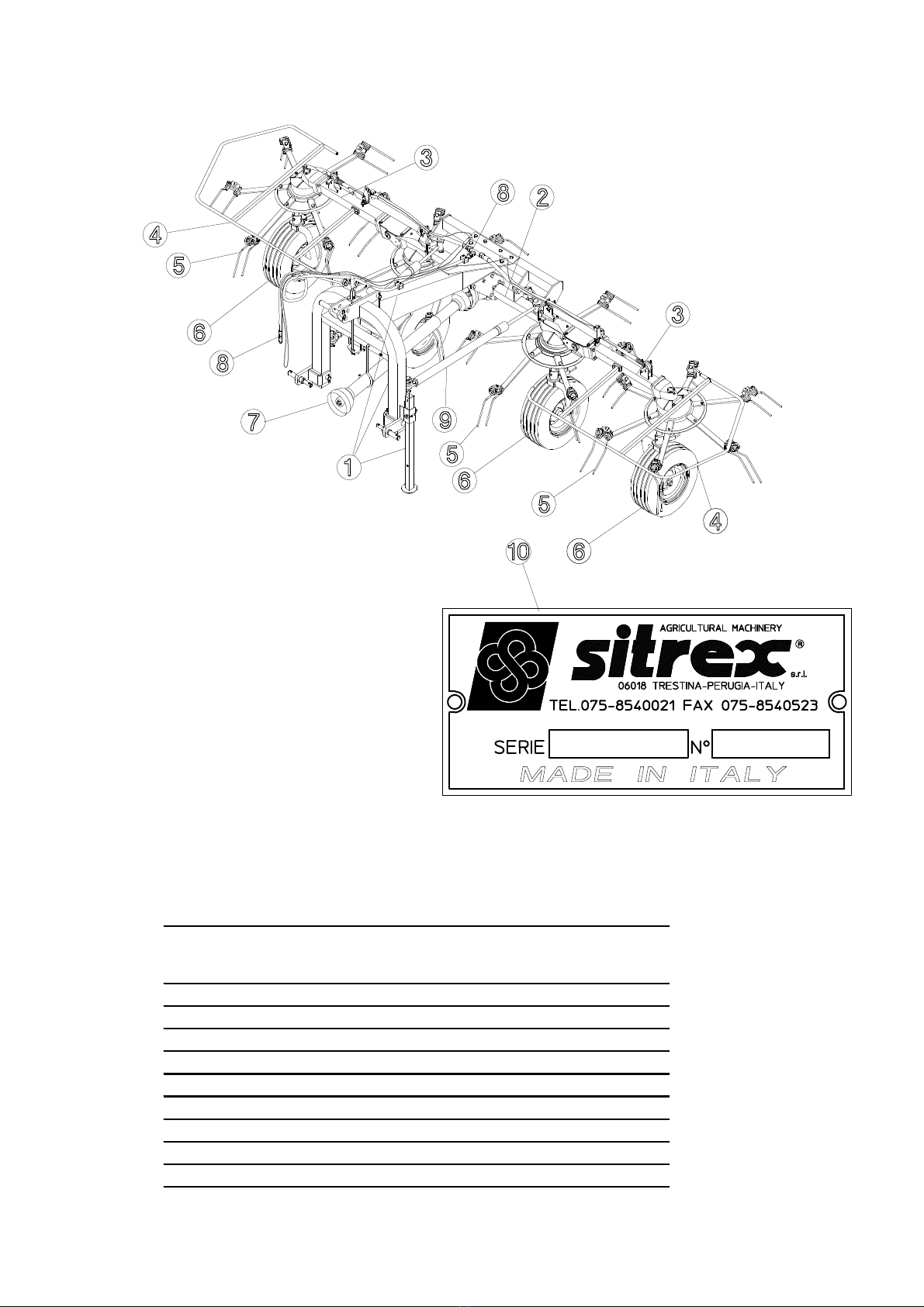

10

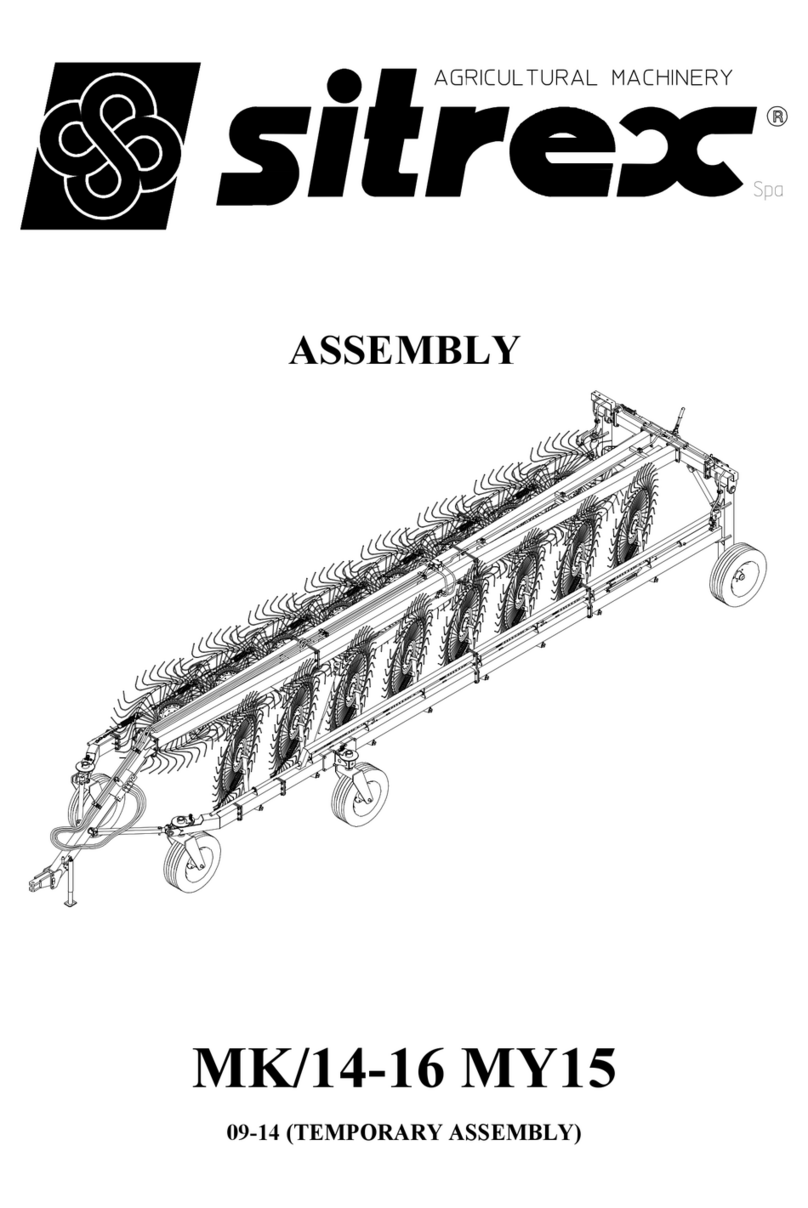

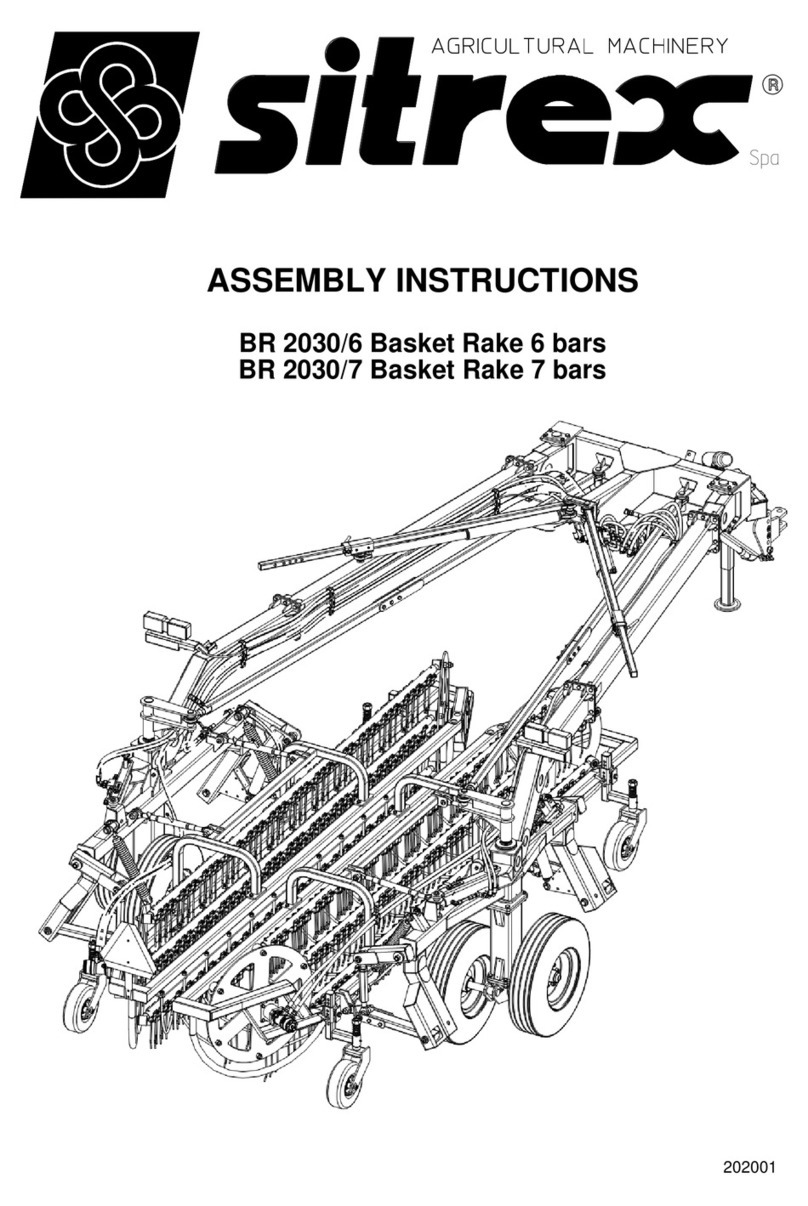

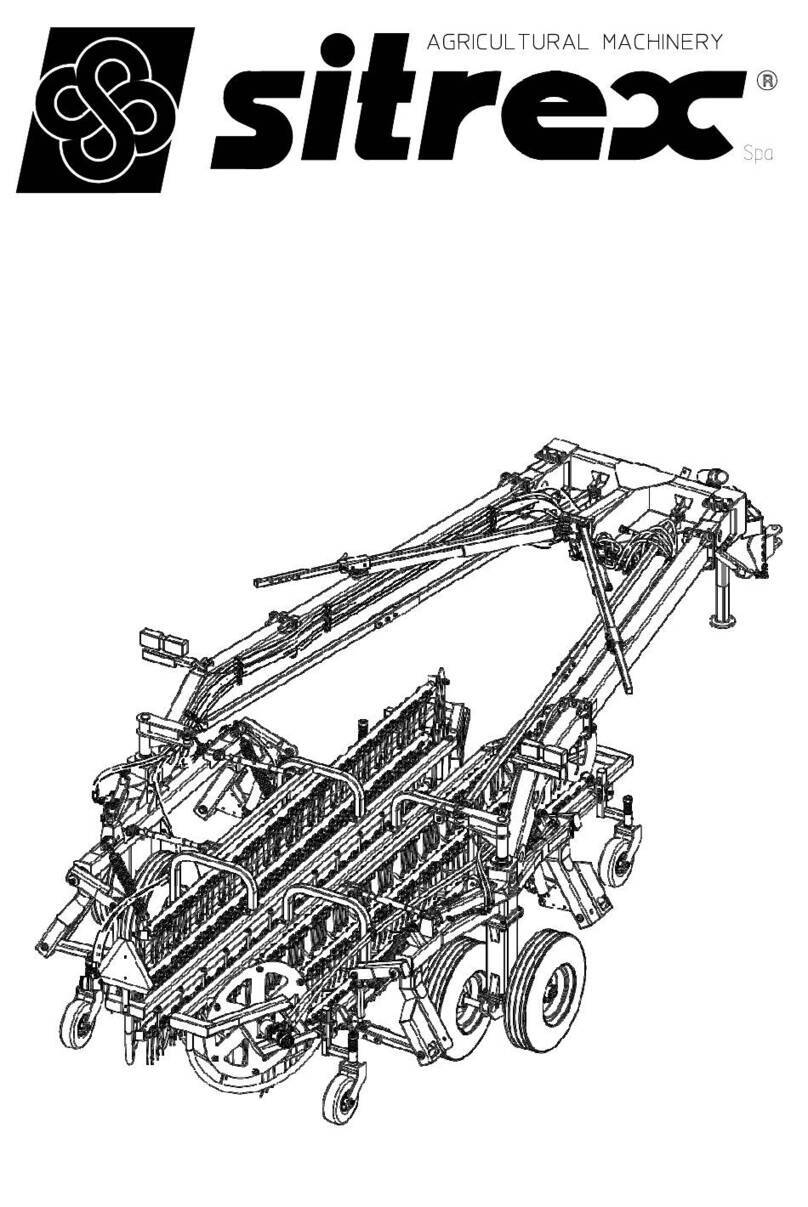

ASSEMBLY INSTRUCTIONS

Assembly is highly dangerous and must be carried out in strict accordance with the

following instructions. We recommend that qualified personnel perform assembly.

We also recommend that assembly be carried out on a flat, solid surface, in an open

area with no people (particularly children) nearby who could be severely injured if

they were to touch or move any parts of the machine.

Assemblers must provide suitable lifting mechanisms and supports for stabilizing the

partially assembled units, so as to prevent them from falling and causing damage or

injury. The steps for assembly are illustrated in following. Depending on the

experience of the assemblers and the tools available, it is not necessary that the

instructions be followed in the exact order given here, but the safety precautions

described above must always be followed carefully and scrupulously.

ASSEMBLY SEQUENCE:

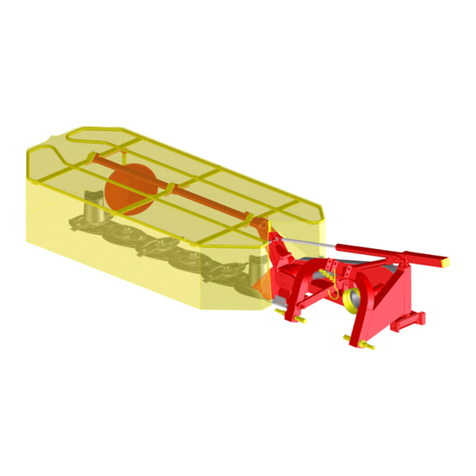

SUPPORTS AND WHEELS ASSEMBLY

1)

Mount the grease nipples 1 onto their seats on the hubs 2-3 (RH - LH).

2) Remove the spring pins 8 from the wheel supports 4-5 (RH-LH) and remove only

the upper shims 7.

3) Mount the wheel supports 4-5 (RH - LH) to their respective hubs 2-3 (RH - LH).

To do this, you must pull back lever “A” and then insert the upper pins of the wheel

supports 4-5 into the seats provided for them on the hubs 3-4. Then place the upper

shims 7 on the parts of wheel support pins 4-5 that protrudes from the seats of the

hubs 2-3 and secure the whole assembly in place with the spring pins 8. Position the

pins “A” on the central seats “B” provided for them on the hubs 2-3.

4) Attach the large hay guards 9 to the wheel supports 4-5, followed by the wheels

10, the small hay guards 11 and the washers 12 and fasten with the nuts 13.

In this steps, you will use:

Item 1: 4 grease nipple M6

Item 6: 4 shims ø30.5x39.8x0.5 (or 1) (ø1.2”x1.57”x0.02” (or 0.04”)

Item 7: 4 shims ø30.5x39.8x0.5 (or 1) (ø1.2”x1.57”x0.02” (or 0.04”)

Item 8: 4 spring pins ø6 x 45 (0.24” x 1.77”)

Item 12: 4 flat washers ø17 (0.67”)

Item 13: 4 nuts M16