GENERAL INTRODUCTION - WARRANTY

3

CHAPTER 1

GENERAL INTRODUCTION - WARRANTY

1.1 INTRODUCTION

The user of the lawn mower (later referred to as the "machine") is responsible for his own safety as well as

that of the people in proximity of it.

It is therefore crucial that the user has detailed information on the use and maintenance of the machine and

on how to connect it correctly to a tractor.

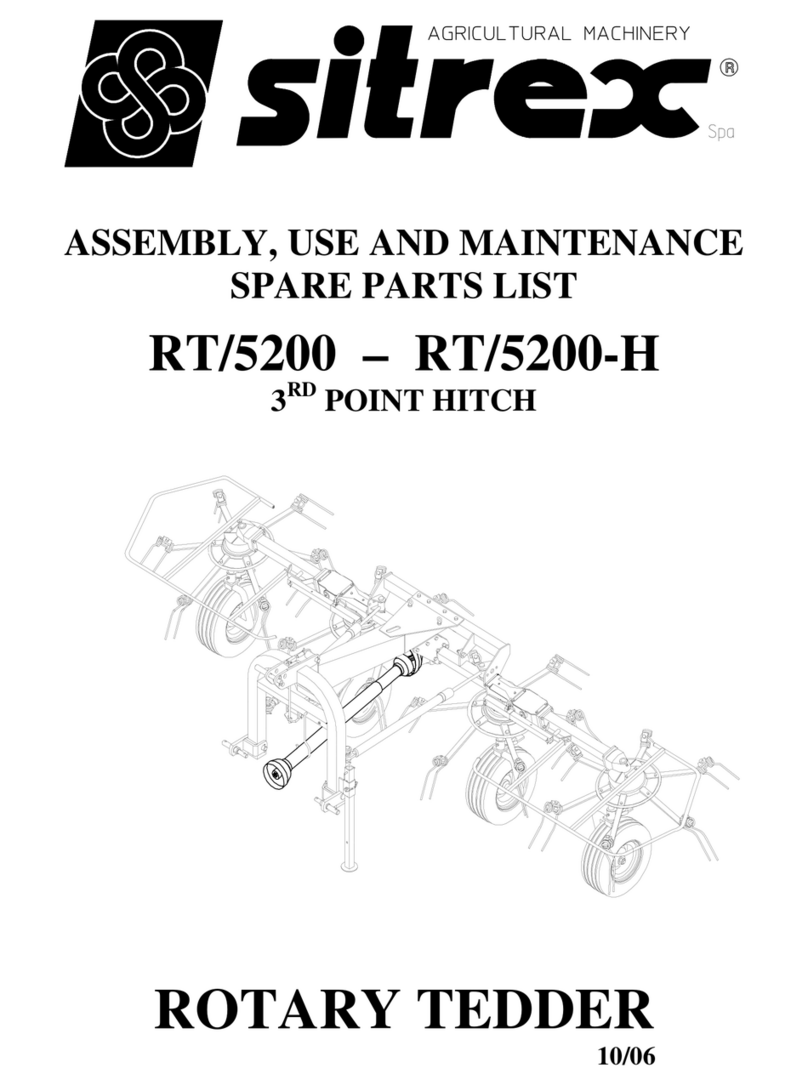

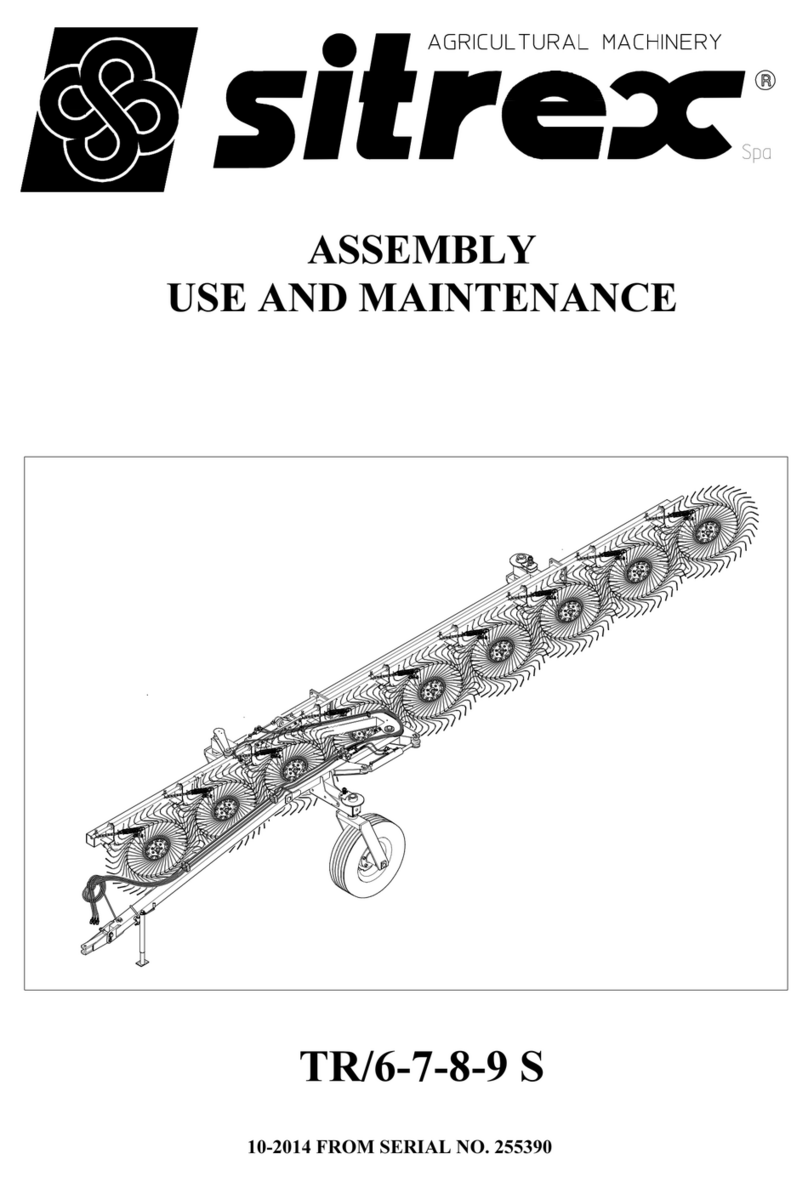

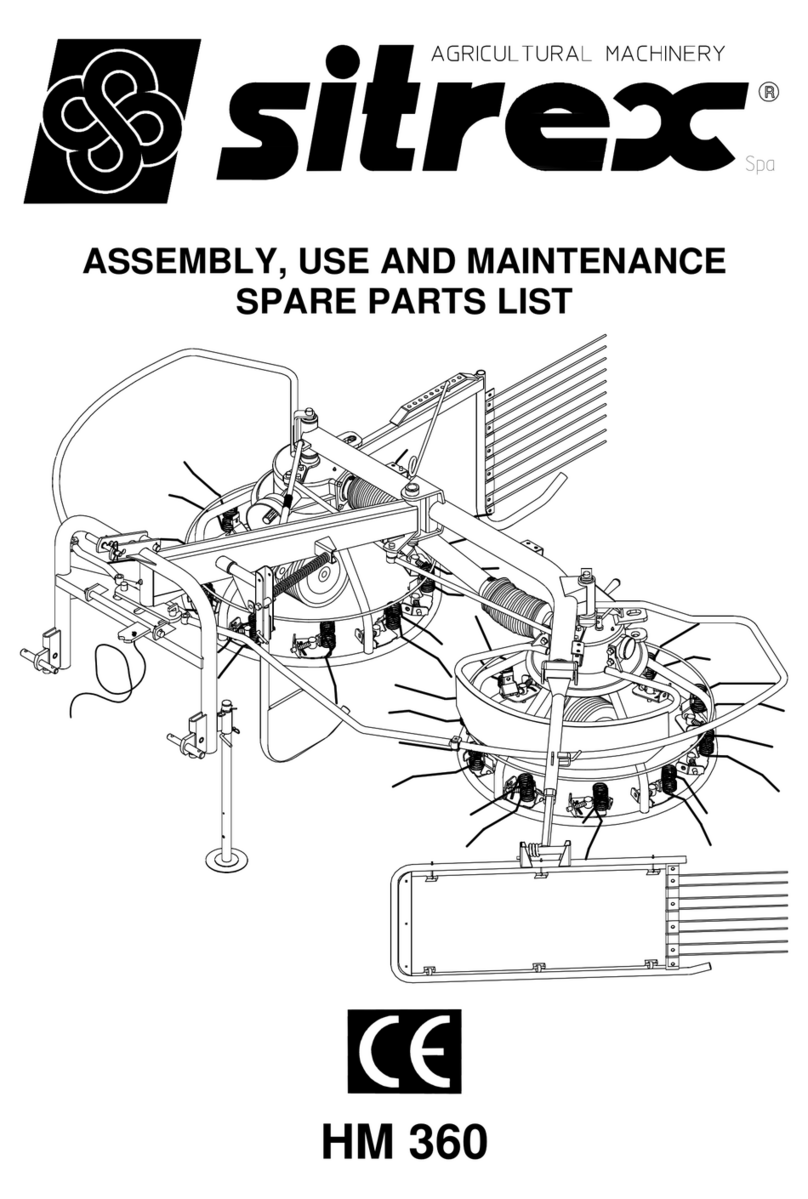

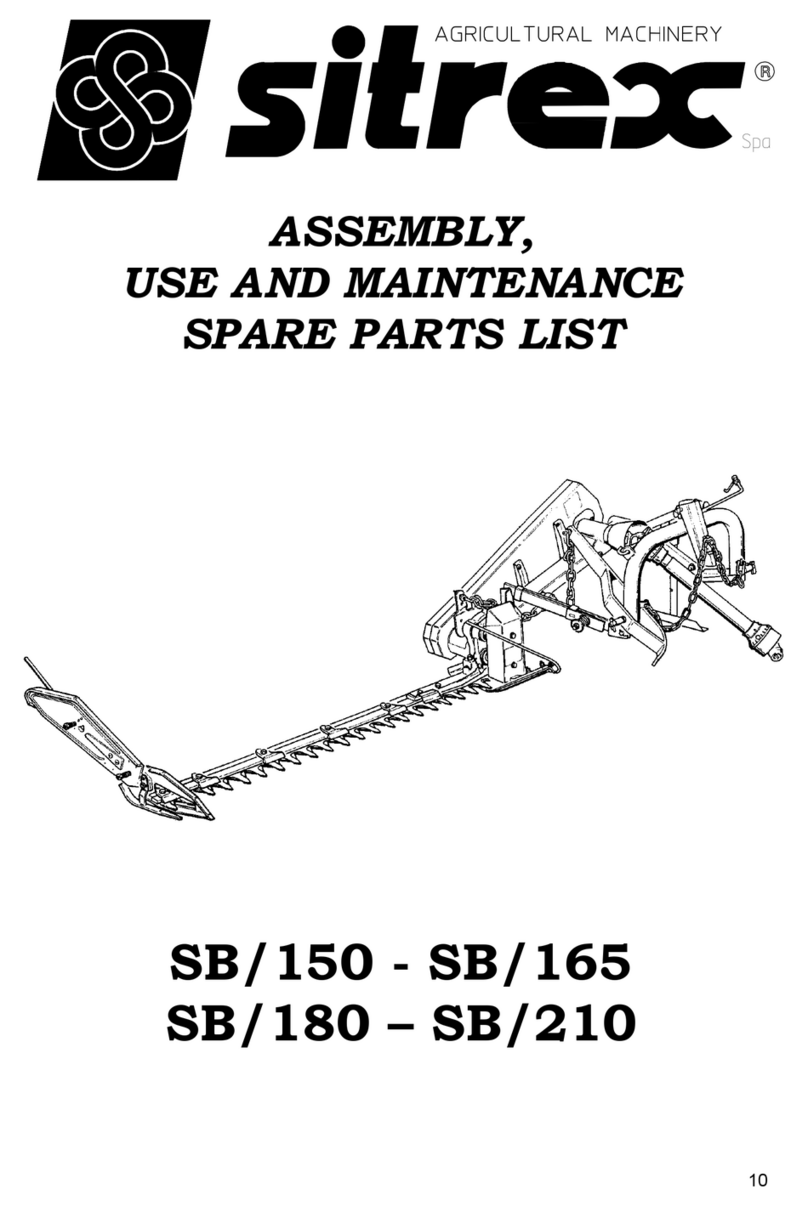

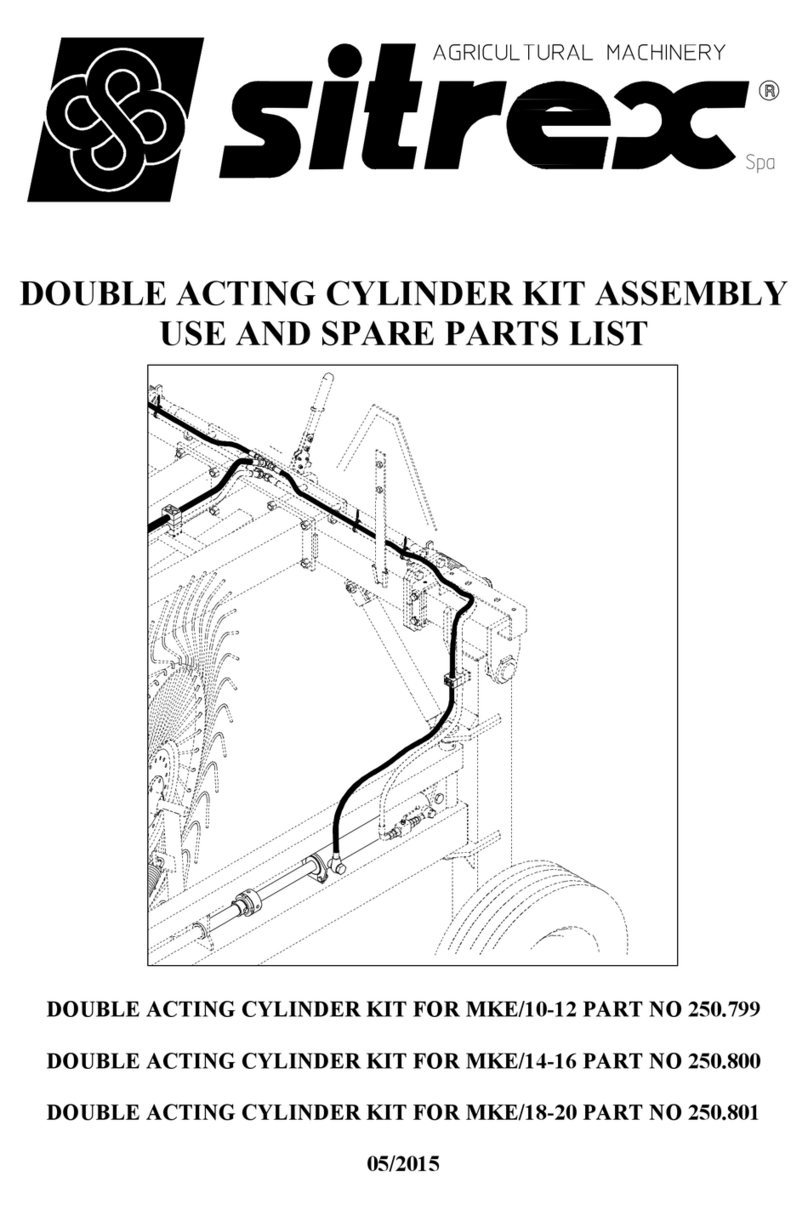

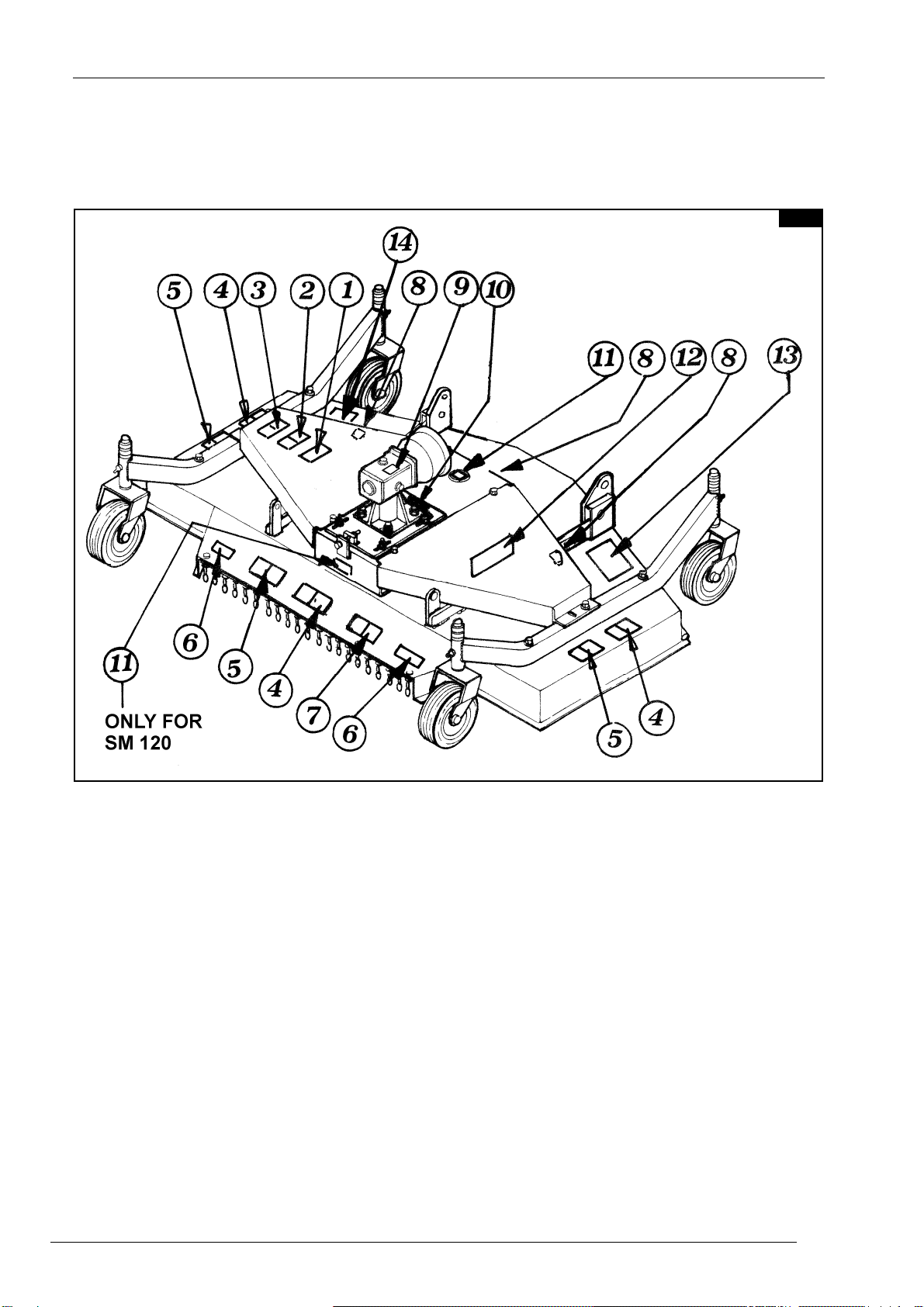

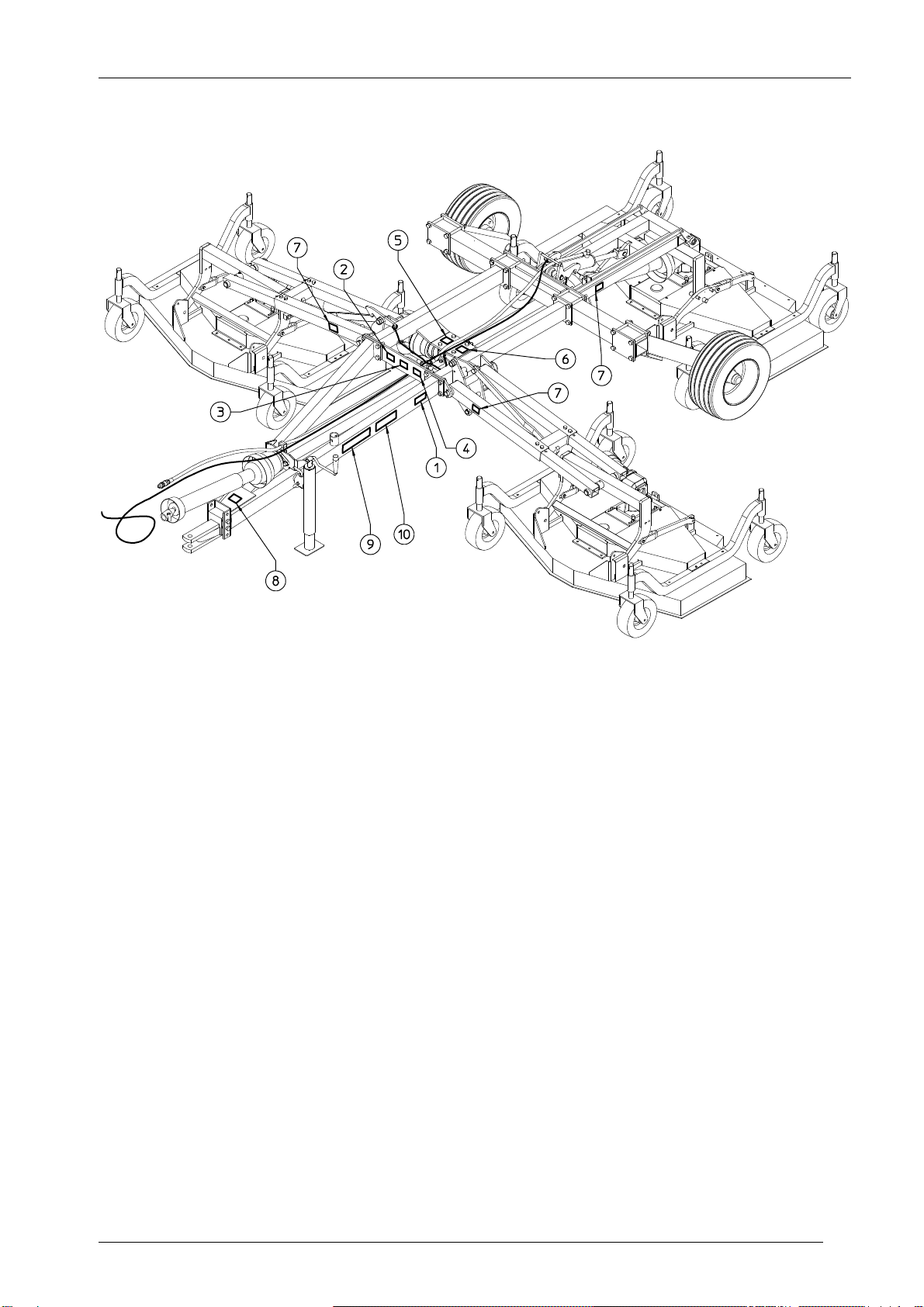

This machine can operate only through a Cardan shaft attached to the power takeoff of an agricultural tractor

equipped with a draw-bar and a hydraulic system. This manual is intended both for the operator and those

responsible for maintenance. Essential instructions and procedures to follow during use and maintenance of

the machine are conveyed through drawings and text.

The user is responsible for ensuring that the machine is connected to the tractor and is operated in com-

pliance with current legal provisions.

The machine must only be operated and maintained by persons who have read this manual. The manual

should always be kept to hand. It is particularly important to read CHAPTER 3 on general safety instructions.

These instructions must always be heeded.

If you are in any doubt, contact the Assistance Center or your nearest dealer.

1.2 WARRANTY

On delivery, check that the machine has not been damaged during transport and that all the attachments are

present. Claims must be made in writing to the agent within 8 days of receipt.

The manufacturer warrants new machinery at the time of delivery to the original purchaser to be free from

defects in material and workmanship if properly set up and operated in accordance with this Operator's Ma-

nual.

The manufacturer undertakes to repair or replace free of charge any defective part which should be returned

by the purchaser (freight prepaid) and found to be defective by inspection authorized by The manufacturer

during the warranty period.

This warranty will be valid for 12 (twelve) months from the delivery of goods to the original purchaser.

In case the customer is not in a position to return the defective part to the manufacturer, the manufacturer

cannot be held responsible for any cost due for repair or replacement of any part of the machine, he will only

supply the part(s) required for the repair and/or replacement.

The warranty is null and void when it is evident that the machine has been improperly used or repaired or

however repaired without authorization.

The manufacturer undertakes no responsibility for any obligation or agreement reached by any employers,

agents or dealers, which are not in compliance with the above warranty. The manufacturer cannot be held

responsible for the consequent damages. This warranty substitutes any other warranty, express or implied,

and any other manufacturer's obligation.

NOTE:

ALL WARRANTY WORK OR REPAIRS MUST BE APPROVED BY THE MANUFACTURER BEFORE WORK BEGIN.

ANY WORK OR REPAIRS MADE BEFORE APPROVAL MAY NOT BE COVERED UNDER WARRANTY.

PLEASE NOTIFY YOUR SALES & SERVICE DEPARTMENT OF THIS POLICY.