2

SUMMARY

1. Introducon ...................................................................................... 3

1.1 Safety .................................................................................................................... 3

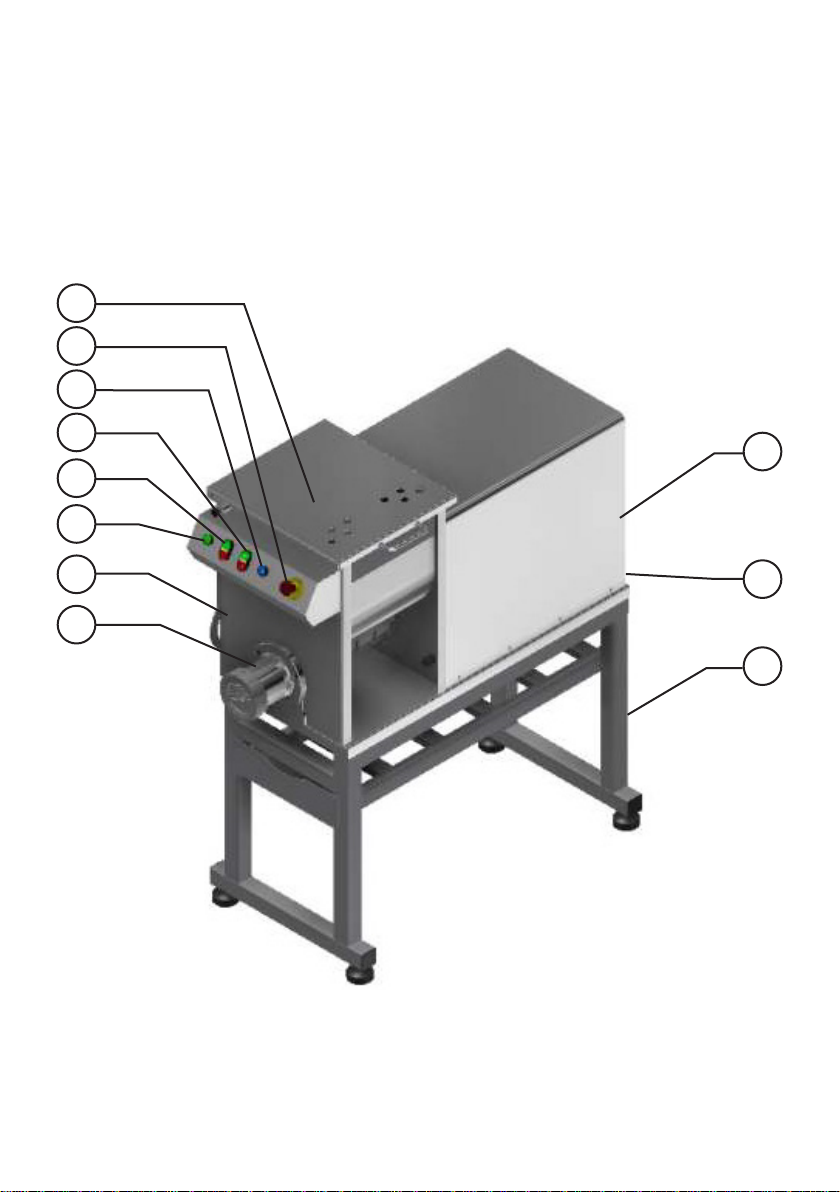

1.2 Main Components ................................................................................................. 5

1.3 Technical Characteriscs ........................................................................................ 6

2. Installaon and Pre Operaon ...........................................................6

2.1 Installaon ............................................................................................................ 6

2.2 Pre Operaon ........................................................................................................ 8

3. Operaon .......................................................................................... 8

3.1 Starng the operaon............................................................................................ 8

3.2 Operaon Procedure ............................................................................................. 9

3.3 Safety System ....................................................................................................... 9

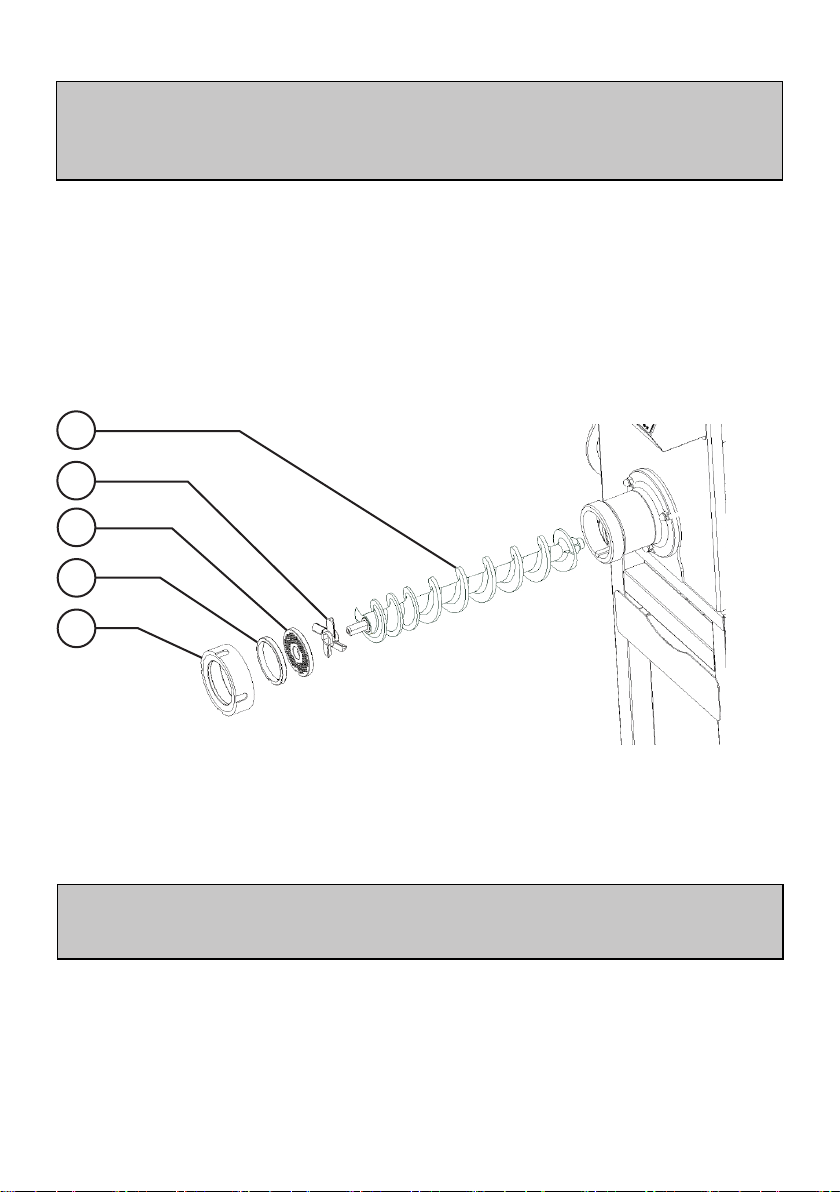

3.4 Assembling of the mouth internal components.....................................................10

3.5 Cleaning and Sanizang ......................................................................................10

3.6 Cauons with Stainless Steels ...............................................................................11

4. General Safety Noons.................................................................... 12

4.1 Basic Operaon Pracce .......................................................................................13

4.2 Cauon and observaons before Turning on the Appliance...................................13

4.3 Roune Inspecons ..............................................................................................14

4.4 Operaon .............................................................................................................14

4.5 Aer nishing the work ........................................................................................15

4.6 Maintenance ........................................................................................................15

4.7 Advice ..................................................................................................................15

5. Analysis and Problems Solving......................................................... 16

5.1 Problem, causes and soluons..............................................................................16

5.2 Sharpening of Knives ............................................................................................16

6. Observed Standards......................................................................... 18

7. Maintenance ................................................................................... 18

8. Electric Diagram ............................................................................. 20

220V Triphase 60Hz ............................................................................. 20

380V Triphase 60Hz ............................................................................ 22