3

3. INSTALLATION AND PRE-OPERATION

3.1 Placing

Your appliance must be posioned and leveled on a dry and

rm surface with a preferable height of 850 m.

3.2 Electrical Installaon

The feeding cable has 3 pins, and the central pin is for

grounding. It is mandatory that the 3 pins are turned on

before turning on the appliance.

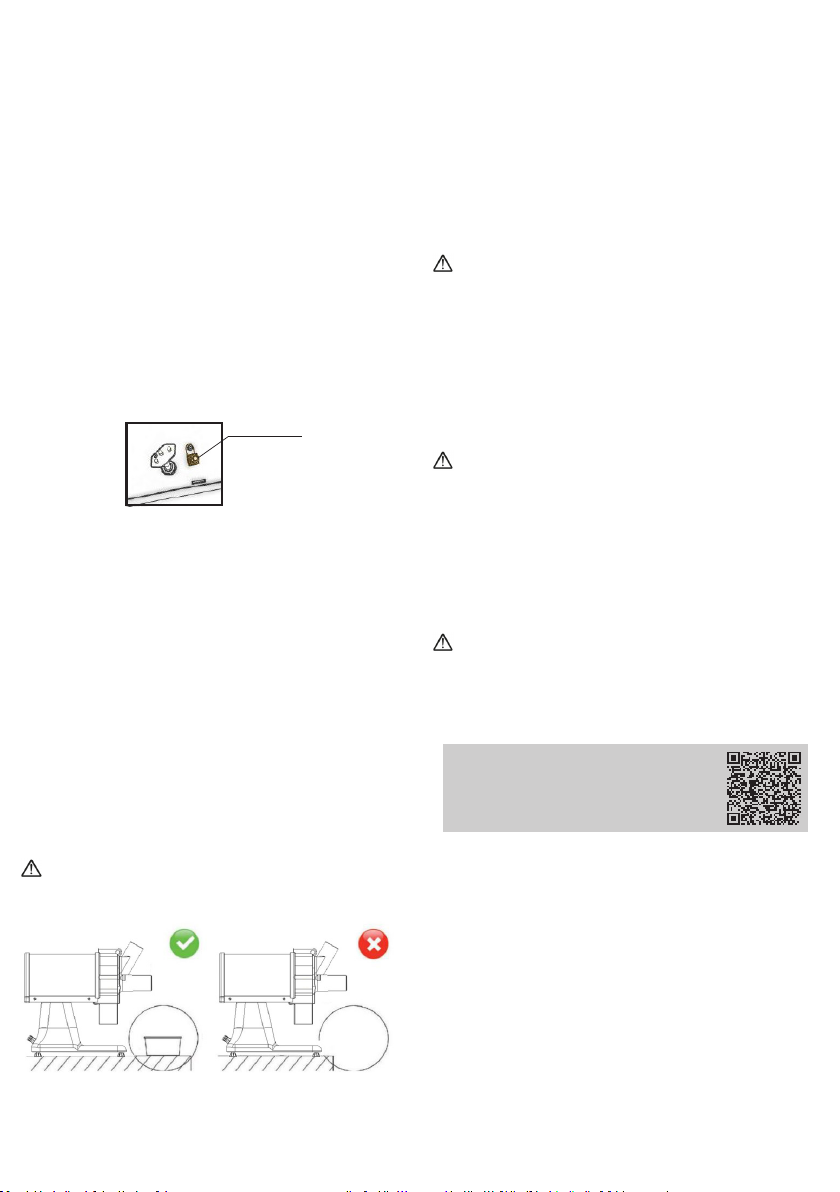

3.3 Equipotencial terminal

The Picture presented below indicates the external

equipotenal terminal.

It must be used to guarantee that there is no potenal

dierence between dierent equipment connected to the

power grid, diminishing the risk of electric shocks.

The disnct equipment must be turned on one to the other

by their own equipotenal terminals.

3.4 Safety System

For the safety of the operator, this appliance has 3 devices

that are capable of turning o the machine and prevenng

accidents.

a– The rst one turns the machine o automacally

when removing the feeding nozzle. When returning to the

posion, the machine doesn´t work again.

b– The second device interrupts the operaon of the

machine when the pushing boom is on, opening the

feeding nozzle. When the pushing boom returns to its

posion, the machine starts automacally to work

c– The third one turns o the machine motor in the case

of overheang. Wait for some me unl the machine cools

down and turn it on again on the turn on buon.

4. OPERATION

Never operate this appliance when close to the border

of the work surface.

• Check if the appliance is rm to the working area.

• Before using the appliance, it is necessary to wash all

the components that have contact with the product

that will be processed, with water and neutral soap.

4.1 Turning on the Appliance

Before turning on the equipment, check the following

procedures:

- Check if the feeding mouth is closed and correctly locked;

- Check if the pushed is correctly posioned inside the

nozzle.

To start the appliance, press the Turn ON Switch so that the

appliance starts working.

4.2 Feeding Procedure

Under no circumstance, use the instruments to push

the product to be processed to the Feeding Nozzle No.

02 (Picture 01), much less the hands. Use the pusher No.

01(Picture 01) to make the referred operaon.

The Ice Crusher is a machine that Works in high velocity, and

it also needs the feeding to be fast.

To feed it, li up the pusher No. 1(Picture 01) e put the

product to be processed inside the feeding nozzle No. 02

(Picture 01) pushing it down, with the help of a pusher.

The product leaves because of the gravity. The cleaning

of the interior of the box and the outlet nozzle , Exit Nozzle

and the exit Nozzle to avoid obstrucon.

5. CLEANING

Step 1: Turn the plug from the outlet;

Step 2: Make the disassembling of the removable parts;

Step 3:Wash the removable parts with warm water and

neutral.

Never use water jet directly to the appliance.

Step 4: When washing the disc, handle it with care. Never

throw the disc against other objects, to preserve the blades.

Step 5: Wipe the Box and the Disc with warm water and

neutral soap.

6. MAINTENANCE

The maintenance must be a group of procedures that have

the objecve of keeping the appliance in it best condion of

operaon. Increasing its life expectancy and safety.

* Cleaning – Check the item 5 Cleaning of this Manual.

* Electrical wiring – Check all the cables to avoid deterioraon

and all the electrical contacts about their ghtening and

corrosion

* Contacts – Turn on and o boom,, emergency boom,

reset boom, electric circuits, etc. Check the appliance so

that all the components are working correctly and that the

operaon is working normally

* Installaon – Check the installaon of your appliance

according to the item 2 Installaon and Pre-Operaon of

this manual.

* Life expectancy of the appliance – 2 years, for a normal

Terminal

Picture 02

Picture 04

Scan the QR Code to get informaon

about special care with stainless steel.