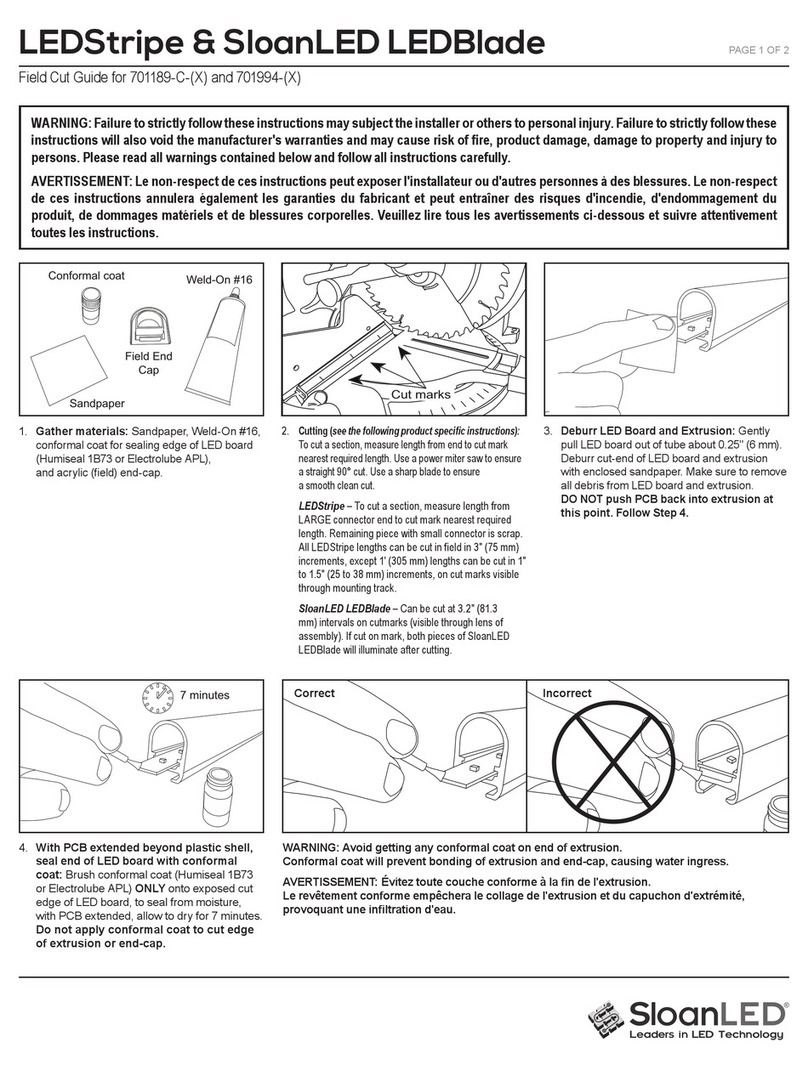

LEDStripe

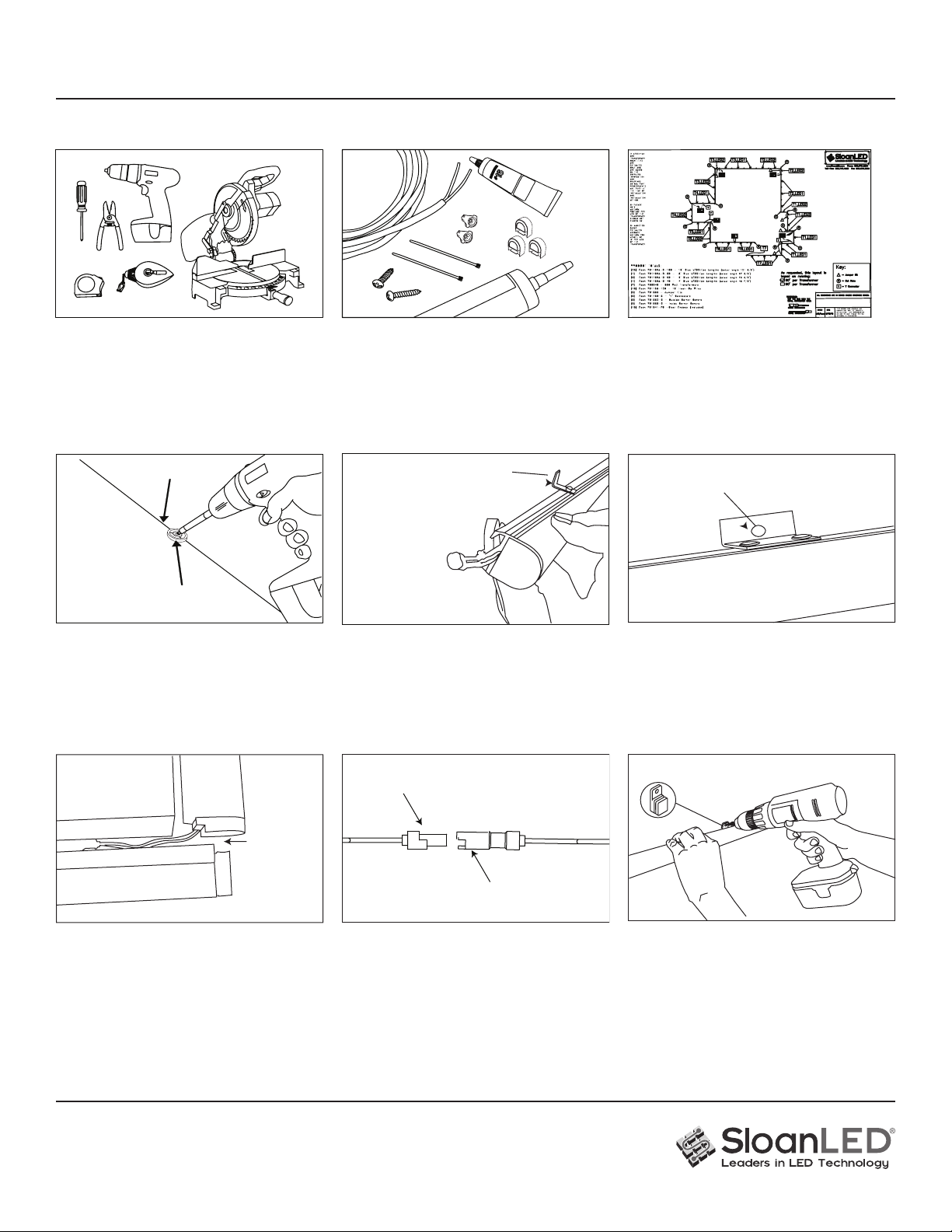

Installation Guide for 701189-C-(X)

PAGE 1 OF 4

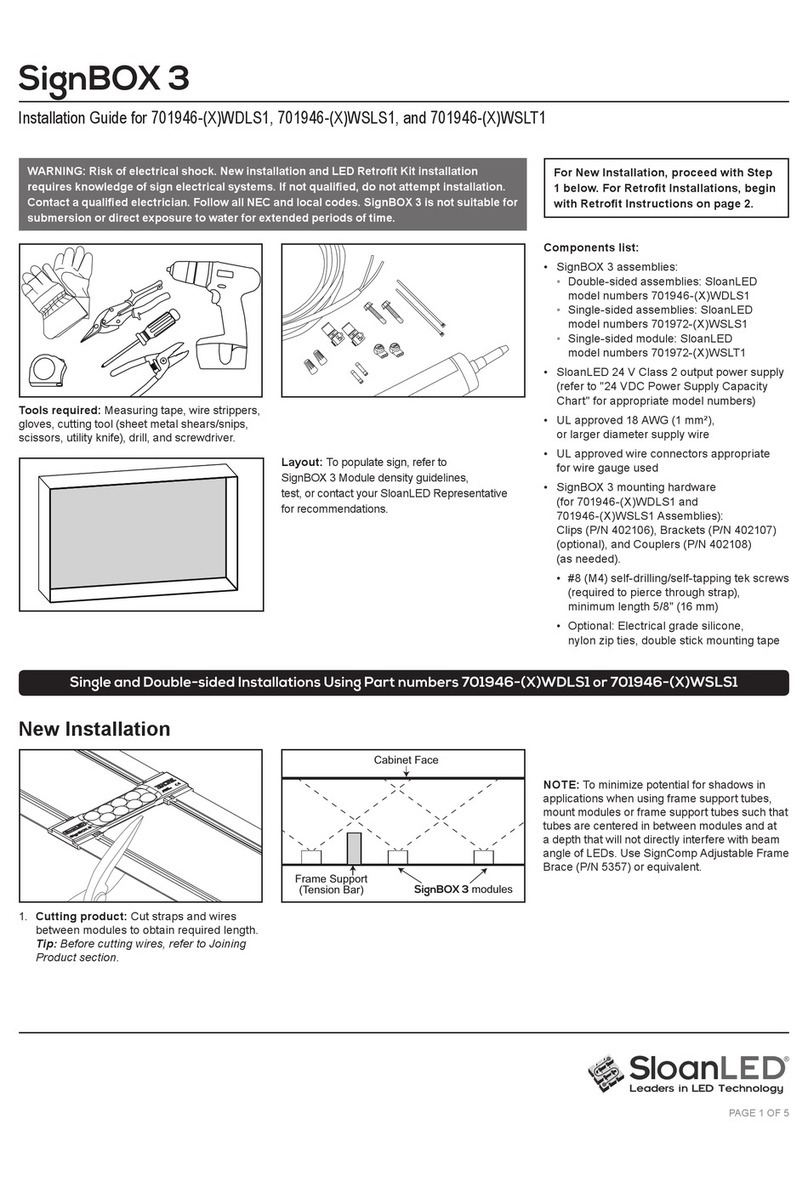

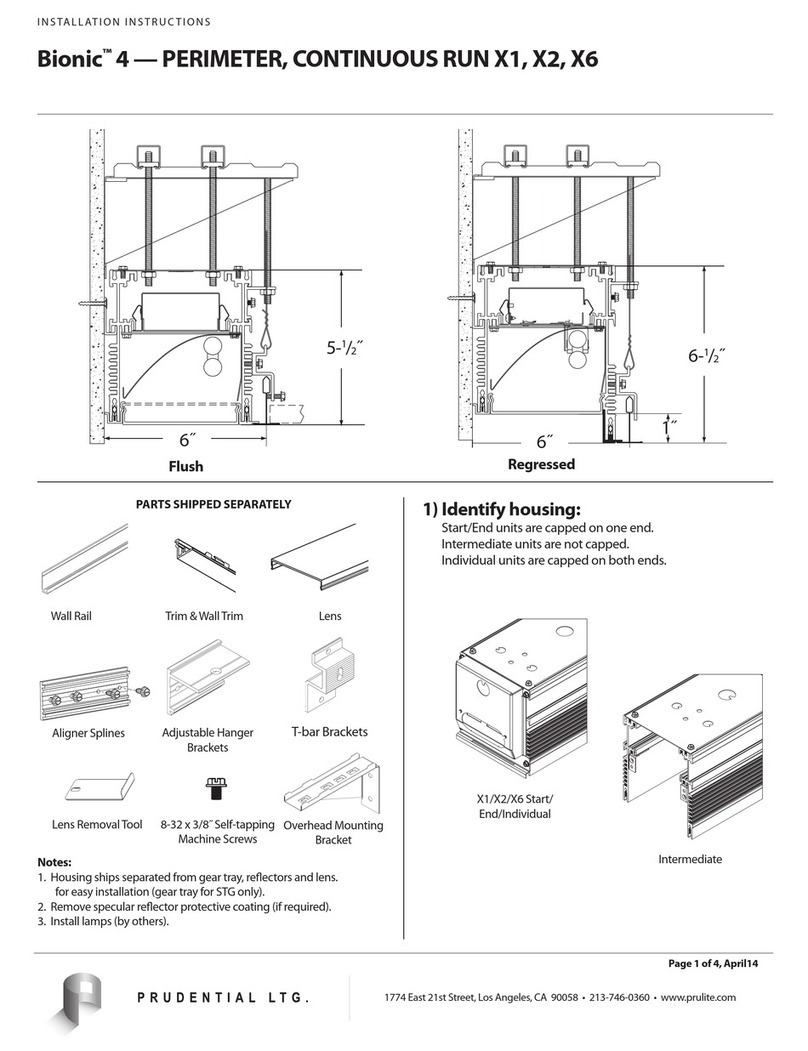

7. Corners: Corners should be installed with

one section slightly overlapping the other

leaving a minimum 0.25" (6 mm) space.

Optional corner covers can be snapped

into place.

8.

Connect pieces together: Make sure that tab is aligned

with locking clip. Once connected, hide wires at the back

of the LEDStripe in the mounting track. Use joint covers to

cover. CAUTION: To maintain the integrity of end caps and

prevent water penetration around wires, do not pull or tightly

bend wires or allow tension between wire connections.

ATTENTION: Pour maintenir l’intégrité des capuchons

d’extrémité et empêcher la pénétration d’eau autour des ls,

ne tirez pas ou ne pliez pas fermement les ls ou ne laissez

pas la tension entre les connexions des ls.

0.5"

(6 mm)

gap

Optional slide and mount rectangle

mounting buttons: (not included) are available

for hard to mount areas. Slide button onto the

back of the LEDStripe and use pan head screw

to secure to the wall.

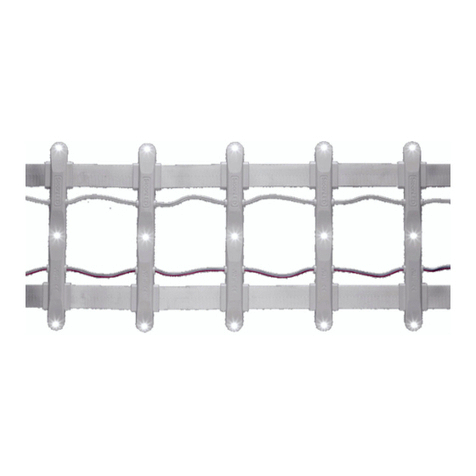

Small connector

Large connector

4. Install mounting buttons: Snap a chalk line on

surface for mounting. Space mounting button 1.5"

(38 mm) from the end of each LEDStripe section and

every 24" (610 mm) on center throughout the length of

each LEDStripe section. For custom bends and tight

corners, see Step 9 for installation, and use a mounting

button every 12" (305 mm).

6. Secure section in place: Use #8 pan head

screws to secure center bracket once all

sections are located on the mounting surface

5. Install LEDStripe sections onto buttons: Slide or Snap

LEDStripe sections onto mounting buttons with center

bracket facing up. NOTE: If installing in temperatures

below 40° F (4.5° C), leave a 0.25" (6 mm) gap between

8-ft (2.44 m) and 10-ft (3.05 m) pieces to allow for

expansion at warmer temperatures.

Secure section in place with #8 pan

head screws through bracket hole

Center bracket points up

Chalk line

#8 pan head screw

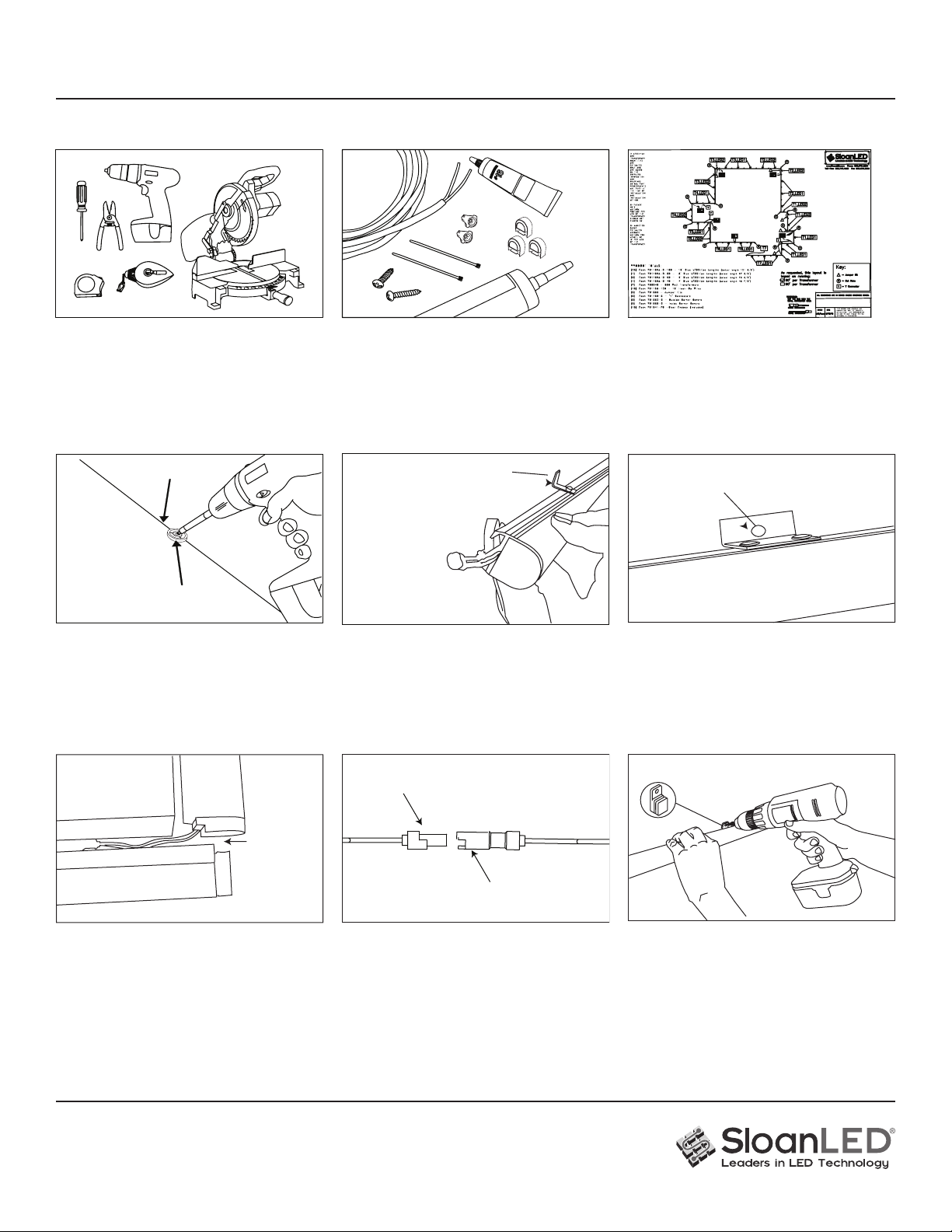

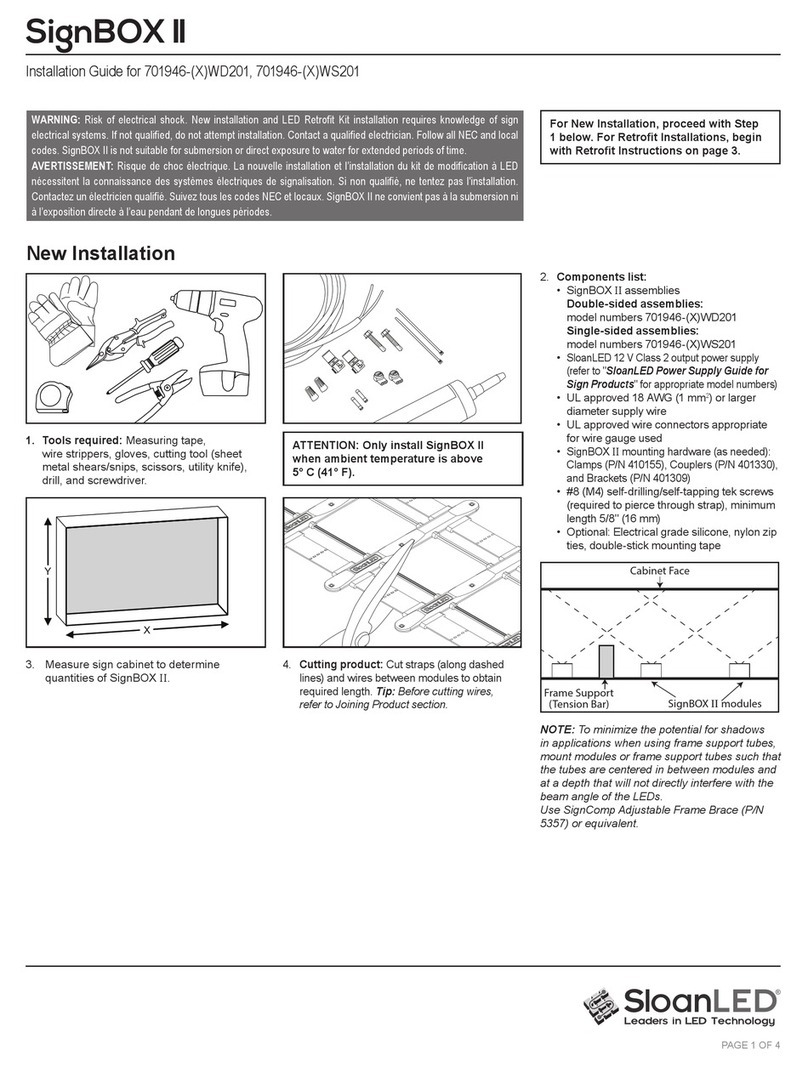

1. Tools required: Cordless drill, drill bits,

#2 Phillips driver bits, wire stripper,

measuring tape, chalk line, marking pens,

miter saw (for custom cut lengths),

Multi-meter.

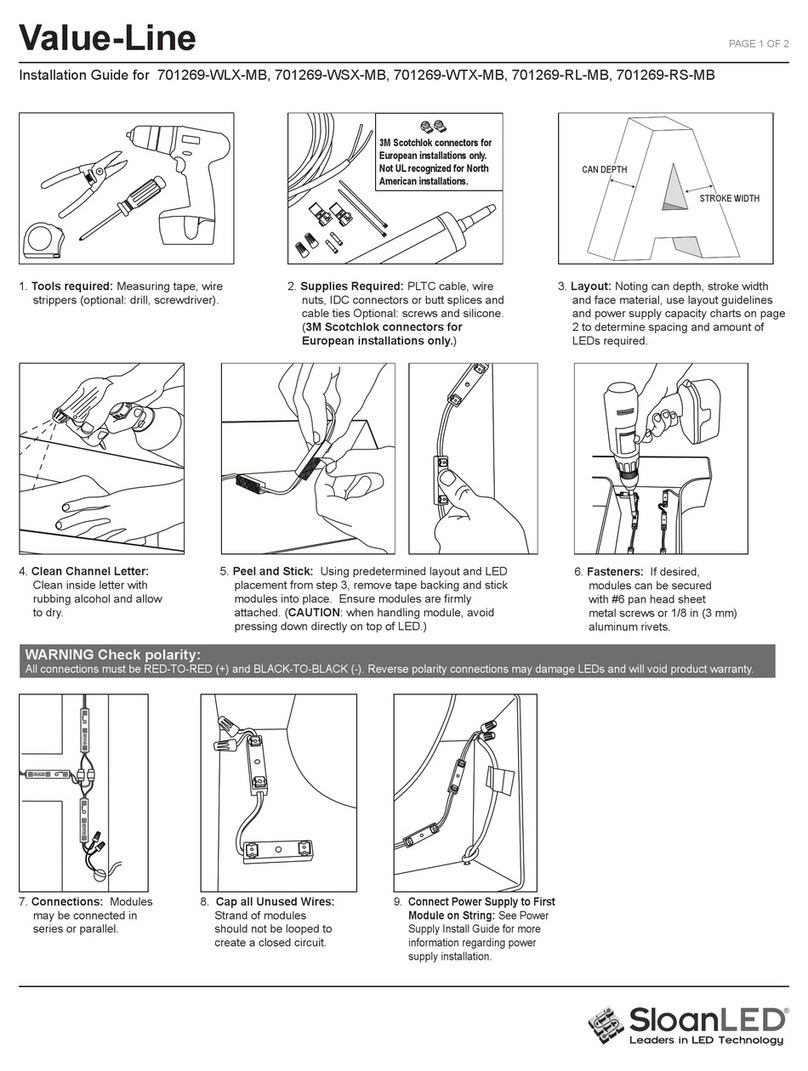

2. Supplies required: Butt splices (22 - 18 AWG,

Red), eld end cap kit, #8 Pan head, Phillips screws,

appropriate thread anchor for the surface it is

mounting to, transformer box, silicone sealant, conduit

and conduit connectors (water tight if mounting the

transformer in a box outdoors), disconnect switch, UL

Listed wet location, sunlight resistant PLTC cable.

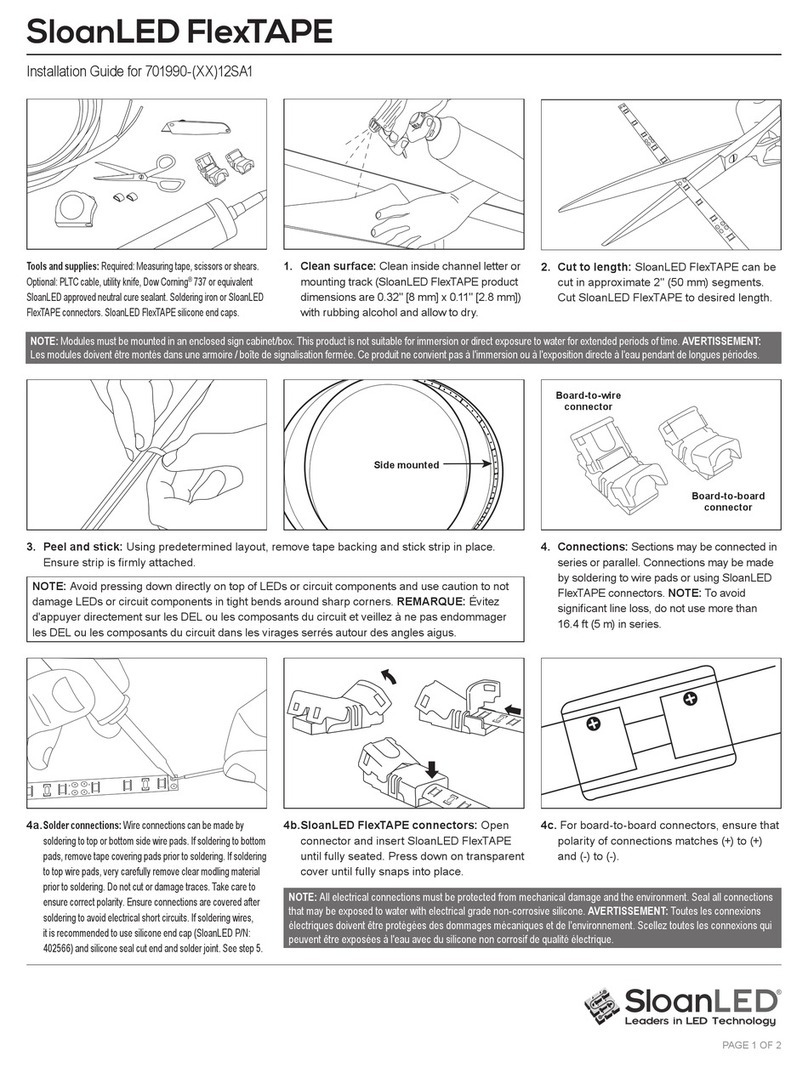

3. Layout: Use an architectural drawing or

layout provided by SloanLED (sample

above) to determine the number and length

of LEDStripe sections and power supplies

required for your installation.

LEDStripe Layout from SloanLED