SignBOX 3 Slim

Installation Guide for 701946-(X)WDLS2

PAGE 3 OF 4

Connecting

Product to

Power Supply

1

1

m

(

3

6

f

t

)

m

a

x

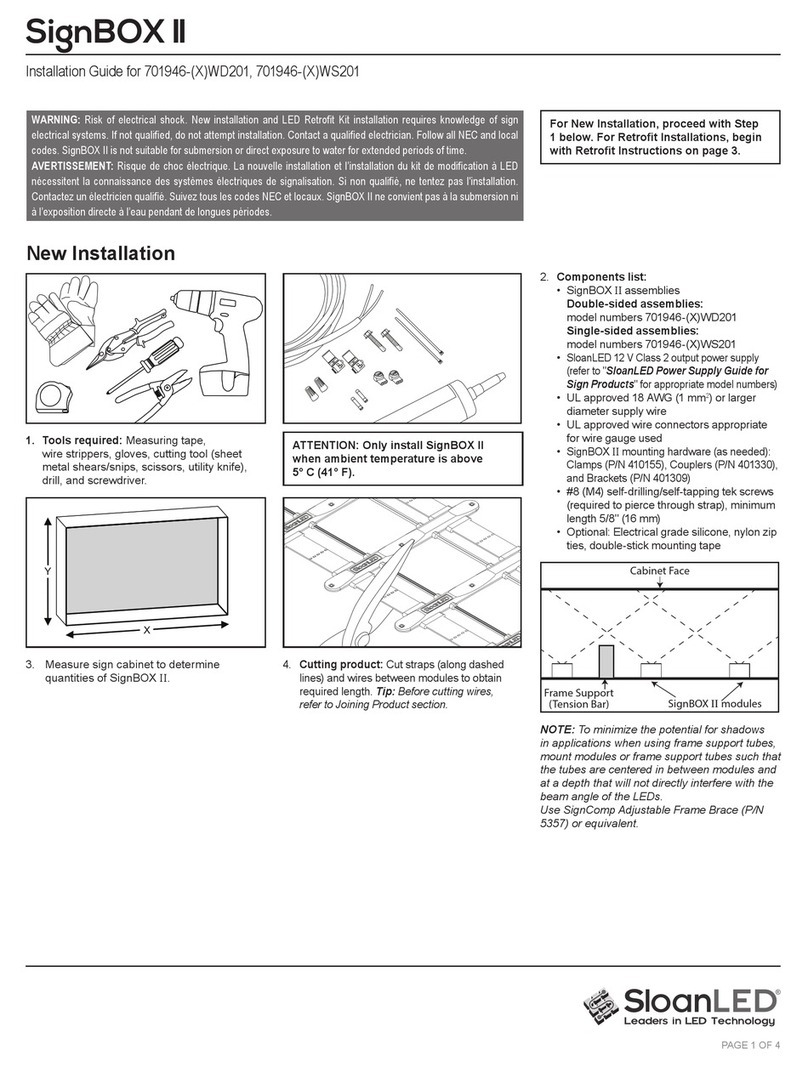

5. Using electrical connectors with appropriate safety agency markings,

daisy chain product as required and connect to power supply as shown

above. CAUTION! Have a licensed electrician connect primary.

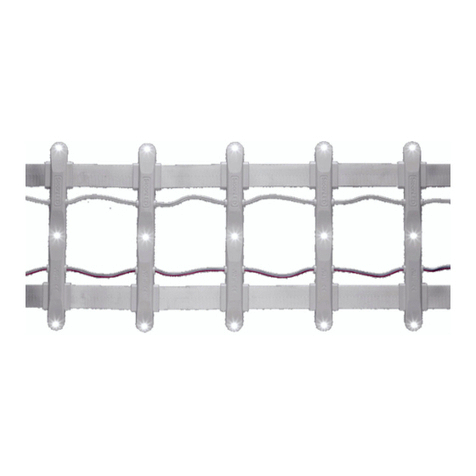

Modules may be connected in series* or parallel. End wires of

SignBOX 3 Slim should be capped and not tied back to power supply.

*For optimal performance, SloanLED recommends connecting

no more than 36 modules in series.

WARNING check polarity:

All connections must be RED-TO-WHITE WITH RED STRIPE (+) and

BLACK-TO-WHITE (-). Reverse polarity connections may damage LEDs

and will void product warranty.

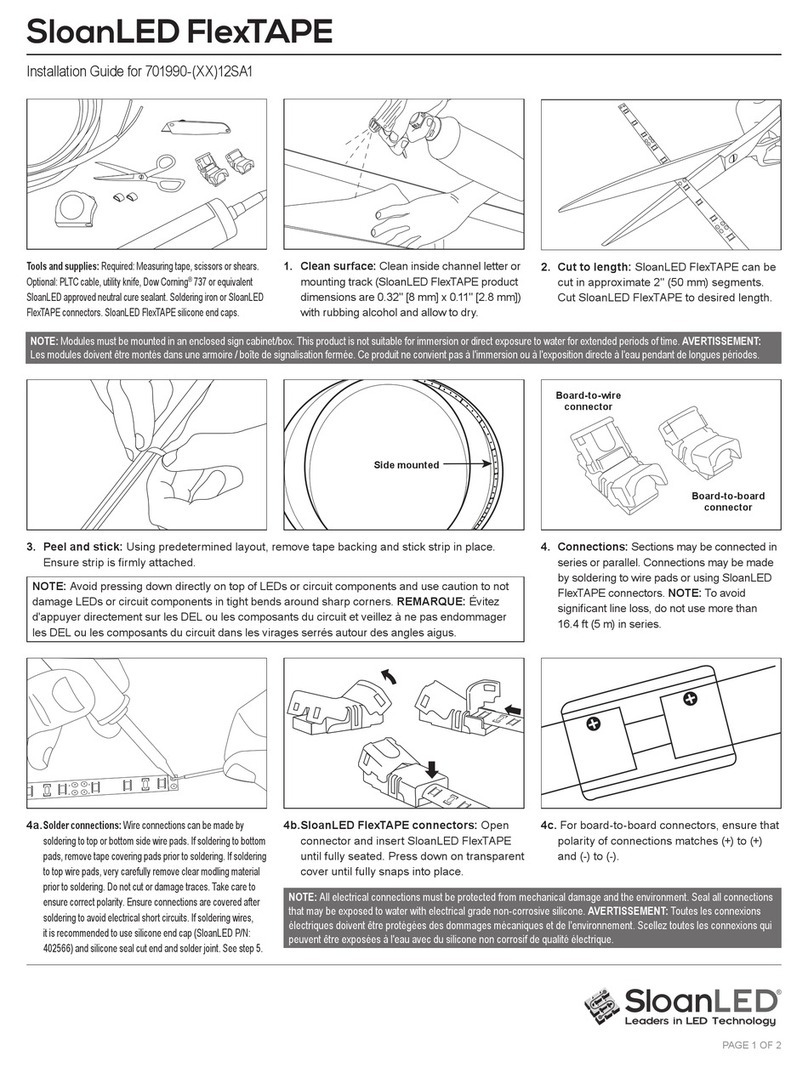

Retrot Instructions for Existing Signs

WARNING: Risk of re or electric shock. Install this kit only in host signs that have

been identied in the installation instructions, and where the input rating of the

retrot kit does not exceed the input rating of the sign. Installation of this LED retrot

kit may involve drilling or punching of holes into the structure of the sign. Check for

enclosed wiring and components to avoid damage to wiring and electrical parts.

CAUTION: Turn o power to sign before inspecting or removing existing light source. Power must remain o while installing LED product.

1. Identify sign to be retrot and ensure branch circuit supplying existing sign are within voltage range for LED power supply.

Refer to components list (page 1) and "24 VDC Power Supply Capacity Chart" (page 4).

2. Remove existing lighting equipment intended to be replaced, such as neon or uorescent, and all power supplies, transformers, or ballasts.

Remove existing neon and all standos to leave an empty sign cabinet. NOTE: All materials removed must be disposed of in accordance with

applicable local or national regulations.

3. If required by local or national regulations, install a new disconnect switch.

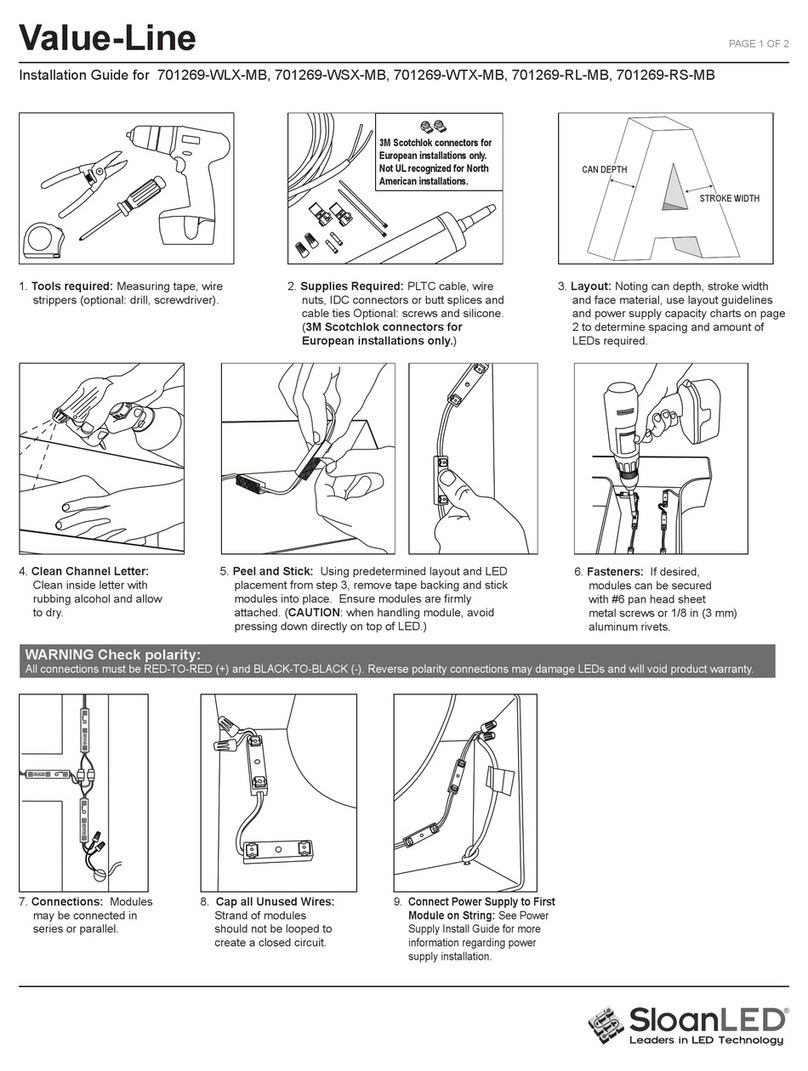

4. Determine suitability and structural integrity of existing sign after removal of existing lighting equipment. If retrot does not require the making

of any new holes, do not make or alter any open holes in an enclosure of wiring or electrical components during kit installation. If existing holes

are present in a wet or outdoor location sign, repair and seal any unused openings in the electrical enclosure.

Openings greater than 12.7 mm (0.5") diameter require a metal patch secured by screws or rivets and caulked with non-hardening caulk.

Smaller openings may be sealed with non-hardening caulk.

5. Clean inside of sign using non-oil based cleaner. Follow all manufacturer’s instructions and ensure inside of sign is dry before proceeding with installation.

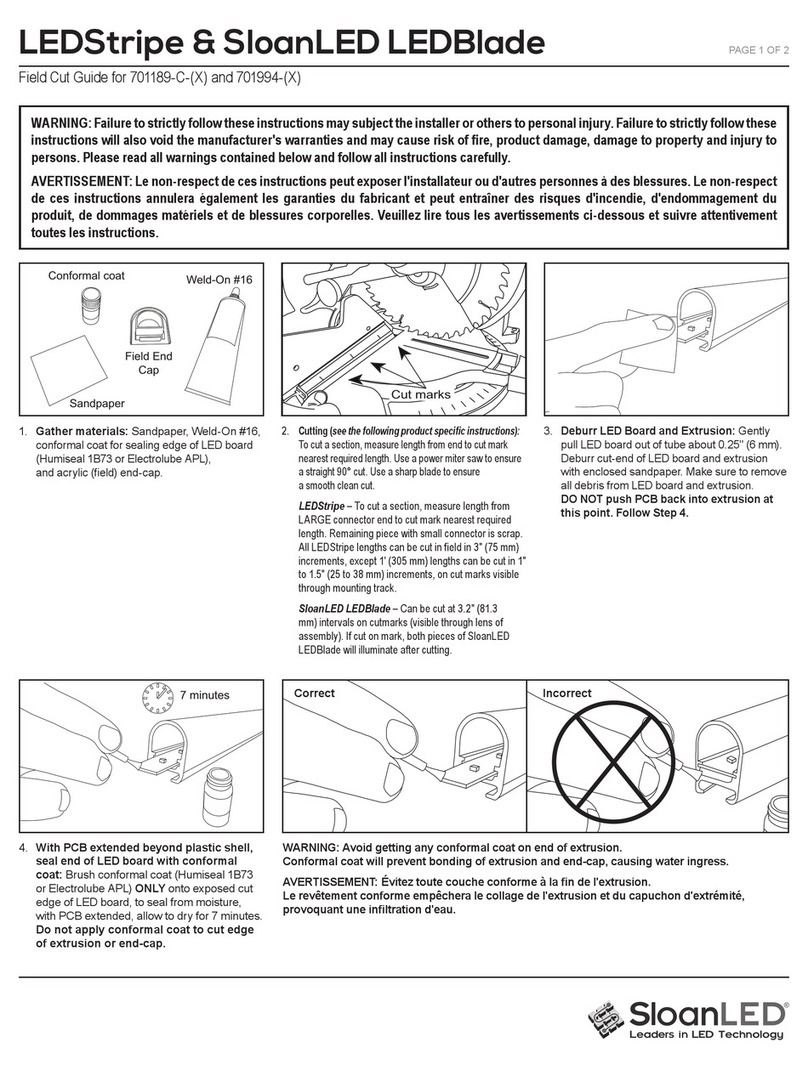

6. To populate sign, refer to SignBOX 3 Slim density guidelines as well as power supply capacity chart (page 4) to determine appropriate number of

modules and power supplies. A list of acceptable power supply models is shown in the supplemental "SloanLED Power Supply Guide for Sign Products".

7. Follow all instructions on pages 1 and 2 under "New Installation" to properly install LED modules.

8. Connect modules to power supply output as shown on page 3 under "New Installation".

9. Connect power supply input as outlined in power supply installation guide in accordance with local or national regulations.

Refer to power supply install guide included with power supply for details.

10. If required, install disconnect switch in accordance with local or national regulations by qualied personnel.