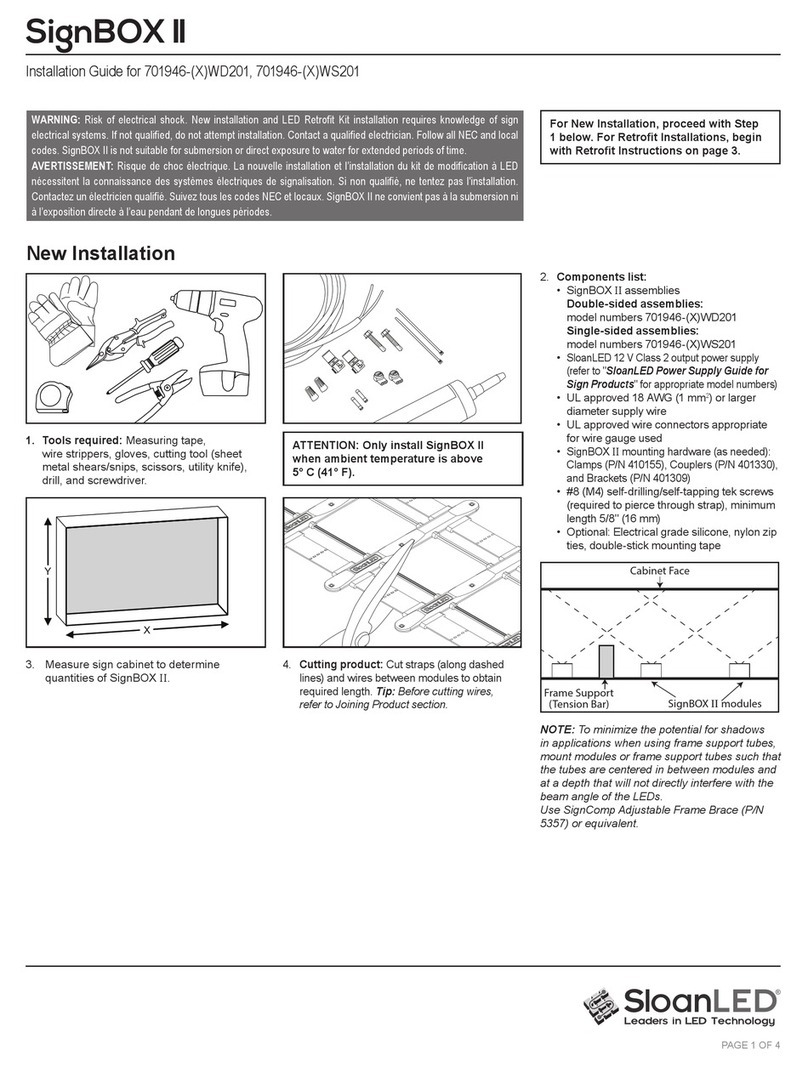

LEDStripe & SloanLED LEDBlade

Field Cut Guide for 701189-C-(X) and 701994-(X)

PAGE 2 OF 2

SloanLED Headquarters

5725 Olivas Park Drive, Ventura, CA, USA

888.747.4LED (888.747.4533) • info@SloanLED.com

SloanLED.com

SloanLED Europe b.v.

Argonstraat 110, 2718 SN Zoetermeer, NL

+31 88 12 44 900 • Europe@SloanLED.com

P/N 701661 Rev G 2021-04-14

Customer service and technical support

For LEDStripe installation video, please visit SloanLED.com/LEDStripe.

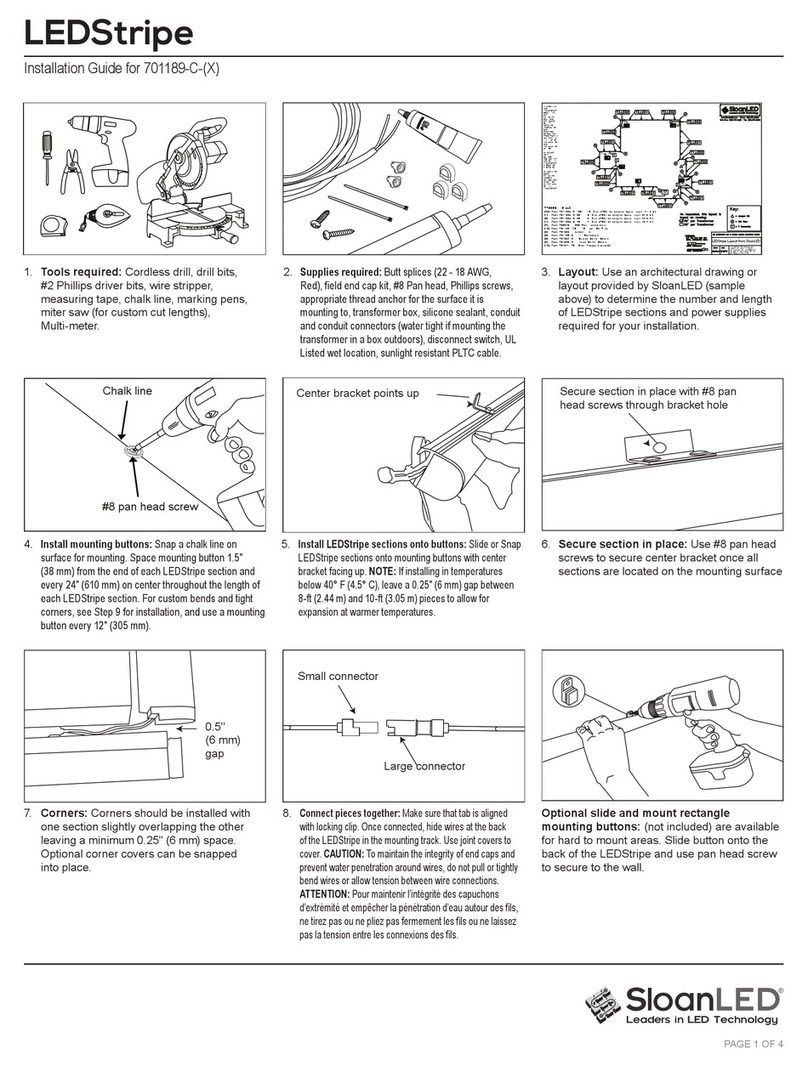

7. Apply Weld-On #16: Apply Weld-On #16 in a generous continuous bead to both cut end of LEDStripe extrusion

and bonding surface (crosshatched area) on end-cap. See diagram above. Do not use silicone or other solvents/

adhesives.

Hold cap

to edge

8. Fit end-cap to cut edge: After applying Weld-On #16,

immediately press end-cap onto extrusion. Ensure

end-cap is aligned, covers entire extrusion opening,

and is completely seated against extrusion.

Apply constant pressure to end-cap for 5 minutes.

ExtrusionExtrusion

LEDStripe SloanLED LEDBlade

End capEnd cap

5. Push PCB back into extrusion: After conformal coat

has dried for at least 7 minutes, press circuit board as

far into tube as it will go. Gently pull on connector as

necessary to fully seat circuit board.

6. Clean extrusion: Ensure end of extrusion is clean

and free of any foreign material. If any conformal coat

adhered to extrusion, gently sand off. Avoid sanding

edge of LED board.

WARNING: It is important to follow and review the safety instructions

and SDS for Weld-On #16 solvent cement packaging and Humiseal

1B73 or Electrolube APL conformal coats. Follow all safety instructions

on Weld-On #16 packaging.

Humiseal 1B73 MSDS available at http://www.humiseal.com/

Electrolube APL MSDS available at https://electrolube.com/

Weld-On #16 MSDS available at http://www.ipscorp.com/

AVERTISSEMENT: Il est important de suivre et de revoir les

consignes de sécurité et la FDS pour les emballages de ciment

à solvant Weld-On # 16 et les couches conformes Humiseal

1B73 ou Electrolube APL. Suivez toutes les instructions de

sécurité sur l'emballage Weld-On # 16.

Humiseal 1B73 MSDS disponible à http://www.humiseal.com/

Electrolube APL MSDS disponible sur https://electrolube.com/

Weld-On # 16 MSDS disponible à http://www.ipscorp.com/

WARNING: Field end-cap must create a water tight seal. All debris must be removed to promote a good end-cap bond and to avoid electrical failure. Use of other types of saws and/

or use of a dull blade may lead to chipping or cracking of the extrusion or create a cut that cannot be sealed resulting in product failure. Ensure extrusion bonding surface is clean.

Contaminants or any adhesive other than Weld-On #16 on this surface may lead to poor bonding, water ingress, and product failure. Product failures resulting from failure to strictly

follow eld cut instructions are not covered by any product warranty.

AVERTISSEMENT: Le capuchon d'extrémité de champ doit créer un joint étanche à l'eau. Tous les débris doivent être enlevés pour favoriser une bonne adhérence du capuchon

d'extrémité et pour éviter une panne électrique. L'utilisation d'autres types de scies et / ou l'utilisation d'une lame émoussée peut entraîner un écaillage ou une ssuration de

l'extrusion ou créer une coupe qui ne peut pas être scellée, entraînant une défaillance du produit. Assurez-vous que la surface de liaison par extrusion est propre. Les contaminants

ou tout adhésif autre que Weld-On #16 sur cette surface peuvent entraîner une mauvaise adhérence, une inltration d'eau et une défaillance du produit. Les pannes de produit

résultant du non-respect des instructions de coupe sur site ne sont couvertes par aucune garantie du produit.

NOTE: Strong tape can be used to maintain

pressure on end-cap for curing period.

9. Second bead of Weld-On #16: Remove strong

tape after the 5 minutes curing period. Apply a

generous continuous second bead of Weld-On

#16 around the entire seam where the end-cap is

bonded to the extrusion.

SAFETY WARNING: Failure of eld end-cap to

maintain a water tight seal may lead to water ingress

and product failure. Product failures of this type could

result in electrical shock and/or re and damage to

the product and materials which may come in contact

with the product. Electrical shocks may cause injury.

MISE EN GARDE DE SÉCURITÉ: le fait de ne pas

maintenir un joint étanche au niveau du capuchon

d'extrémité peut entraîner une pénétration d'eau et

une défaillance du produit. Les pannes du produit de

ce type peuvent entraîner un choc électrique et / ou un

incendie et endommager le produit et les matériaux

qui peuvent entrer en contact avec le produit. Les

chocs électriques peuvent provoquer des blessures.