Service record Dynamis TSD 3 of 36

2021-05-26

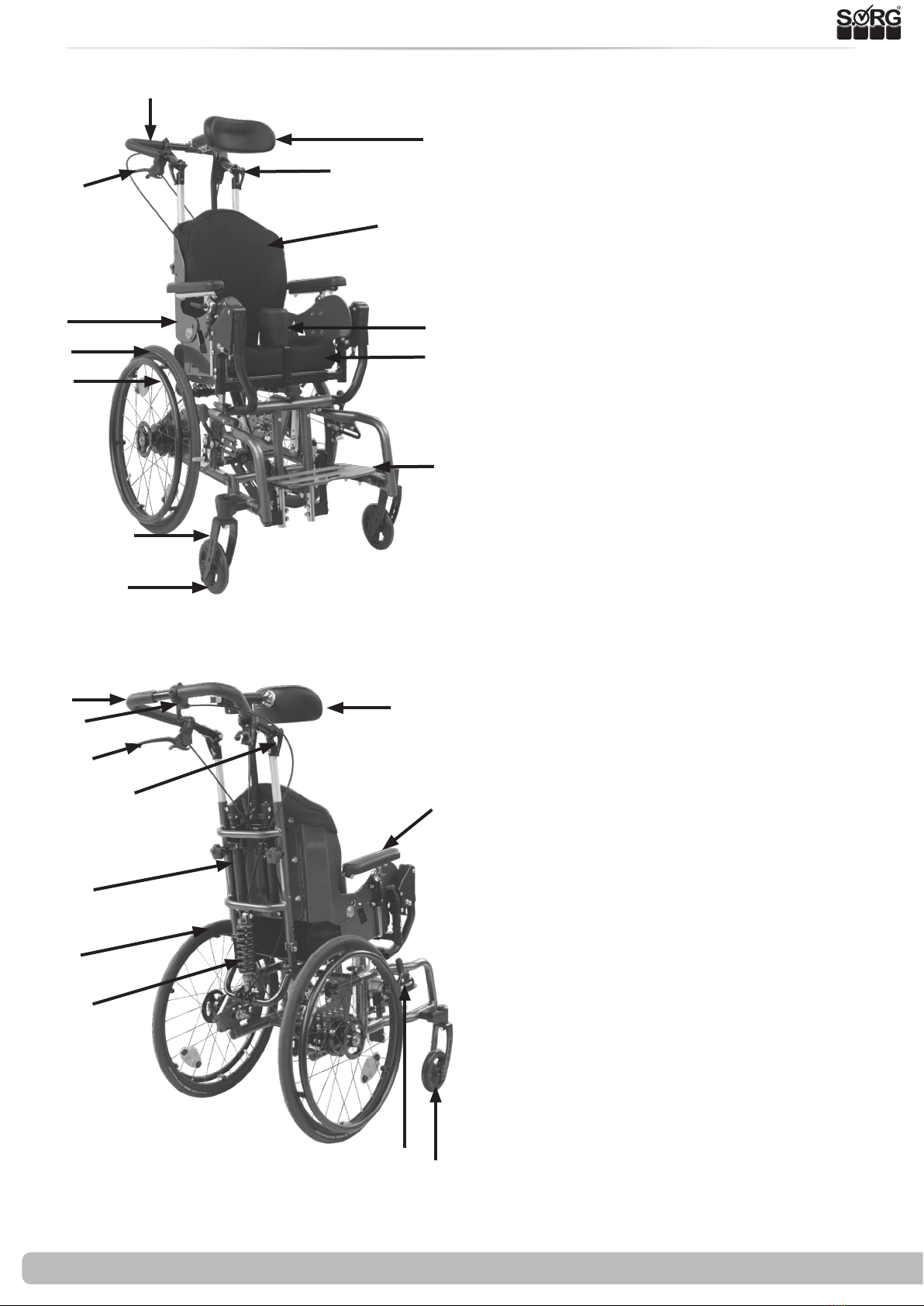

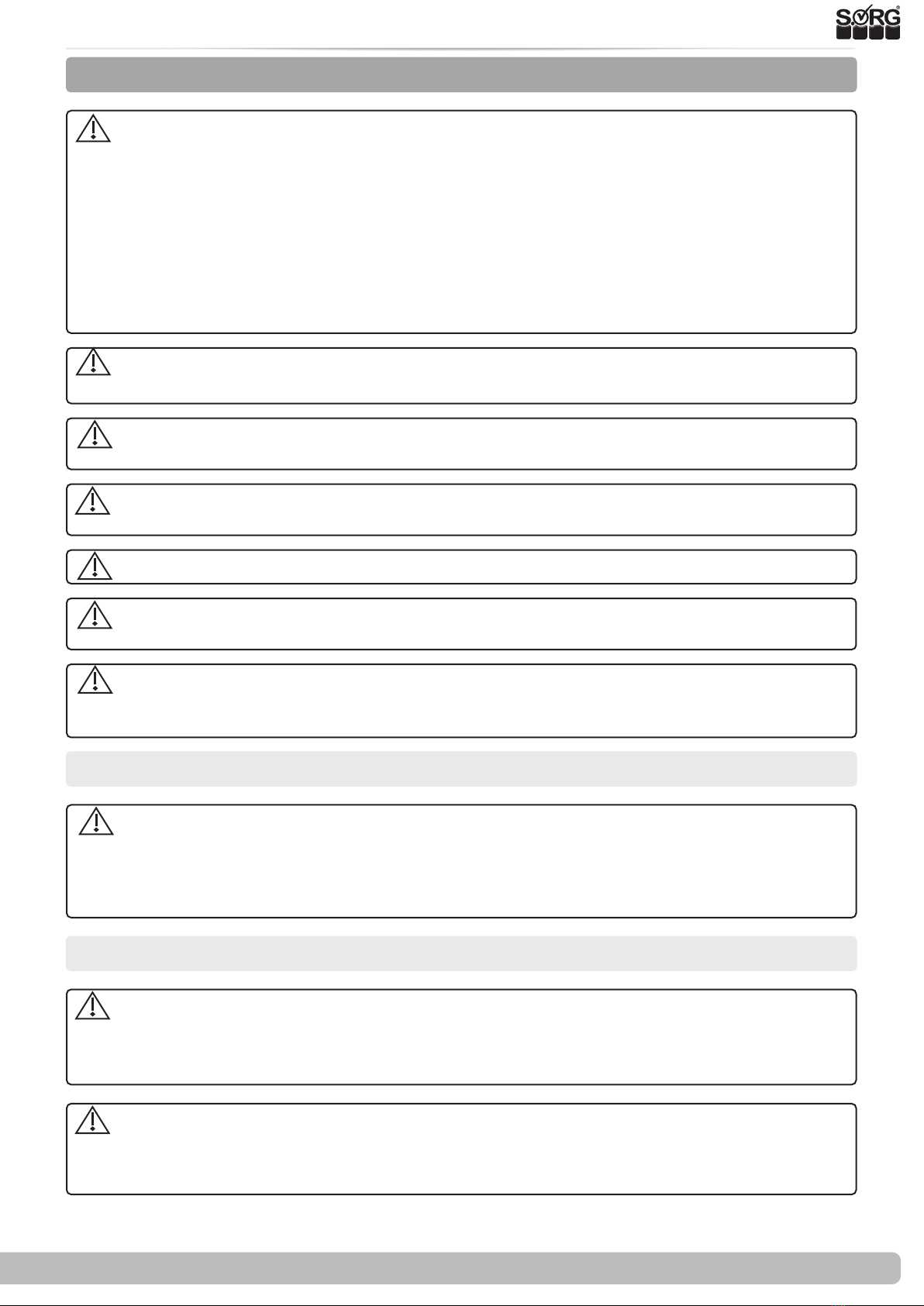

1 Wheelchair overview 4

2 General information 5

2.1 General information service record 5

2.2 Documentation indications 5

2.3 Required torques and tools 5

2.4 Explanation of symbols 6

2.5 General safety instructions 7

3 Assembly groups 8

3.1 Assembly group wheels 8

3.1.1 Wheel position 8

3.1.2

Adjusting the height and position of the

wheel cover when the wheel changes position 9

3.1.3 Moving the wheels WITHOUT camber

adapter (20",22",24") 10

3.1.4 Moving the wheels WITH camber ad-

apter (20",22",24") 10

3.1.5 caster wheels 11

3.2. Assembly group frame 12

3.2.1 Frame widening 12

3.3 Assembly group seat 13

3.3.1 Vertical adjustment of the seat

height 13

3.3.2 Conversion to double gas pressure

spring 14

3.4 Assembly group back 17

3.4.1 Setting dynamic back 17

3.4.2 Setting the rebound speed 17

3.5 Assembly group leg support 18

3.5.1 Adjusting the leg support 18

3.5.2 Adjusting the depth 18

3.5.3 Adjusting the height 19

3.5.4 Presetting the opening angle 19

3.5.5 Height adjustment of the calf support 19

3.5.6 Height adjustment of the footrest 20

3.6 Assembly group ERGO-seat 21

3.6.1 General information about the ERGO-

seat 21

3.6.2 Removing the ERGO-seat 21

3.6.3 Axis of rotation seat part / back part 22

3.6.4 Growth in seat depth ERGO-seat 22

3.6.5 Increase seat width ERGO seat

and back unit 23

3.7 Assembly group brakes 24

3.7.1 Drum brake 24

3.7.2 Knee lever brake 25

3.8 Assembly group frame accessories 26

3.8.1 Anti tipper 26

3.8.2 Step tube 26

3.9 Assembly group headrest 27

3.9.1 Height adjustment 27

3.9.2 Depth adjustment and dynamics of the

headrest 27

3.9.3 adjusting the inclination 27

3.10 Assembly group abduction wedge 28

3.10.1 Depth adjustment 28

3.10.2 Height adjustment 28

3.11 Assembly group lateral support 29

3.11.1 Nomenclature 29

3.11.2 Vertical adjustment 29

3.11.3 Horizontal adjustment 29

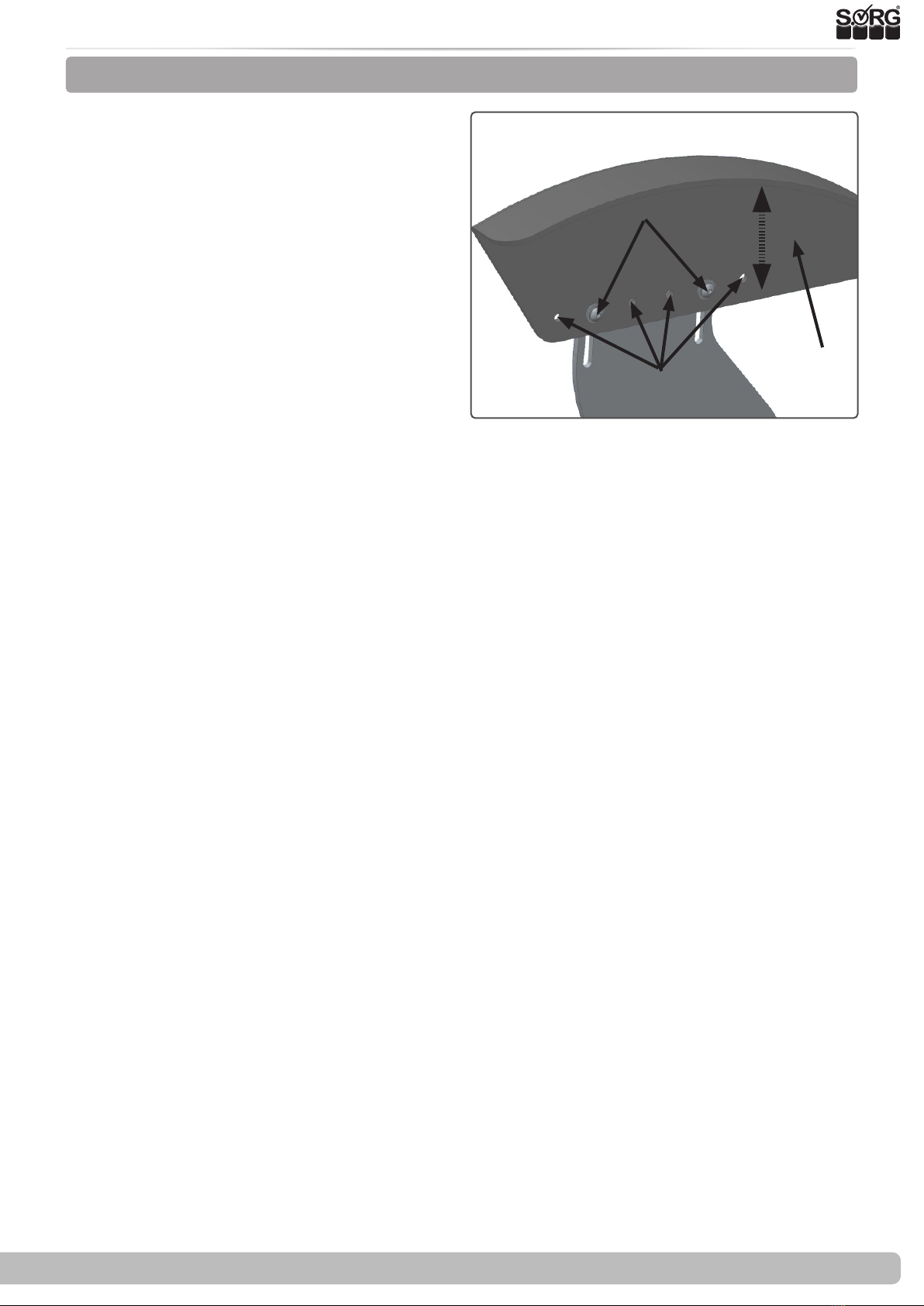

3.11.4 Fine adjustment of the pad holder 30

3.11.5 Adaption to the user 30

4Repairs / maintenance / re-use 31

4.1 Repairs 31

4.2 Spare parts 31

4.3 Cleaning 31

4.4 Disinfection 31

4.5 Storage 31

4.6 Lifespan 32

4.7 Reinstatement 32

4.8 Disposal 32

4.9 Maintenance / Inspection 32

5 Technical data 34

5.1 Data and measurements 34

5.2 Meaning of labels 35

5.3 Declaration of conformity 35

Contents