Service Record Jump alpha 3 of 36

2019-07-16

Table of content

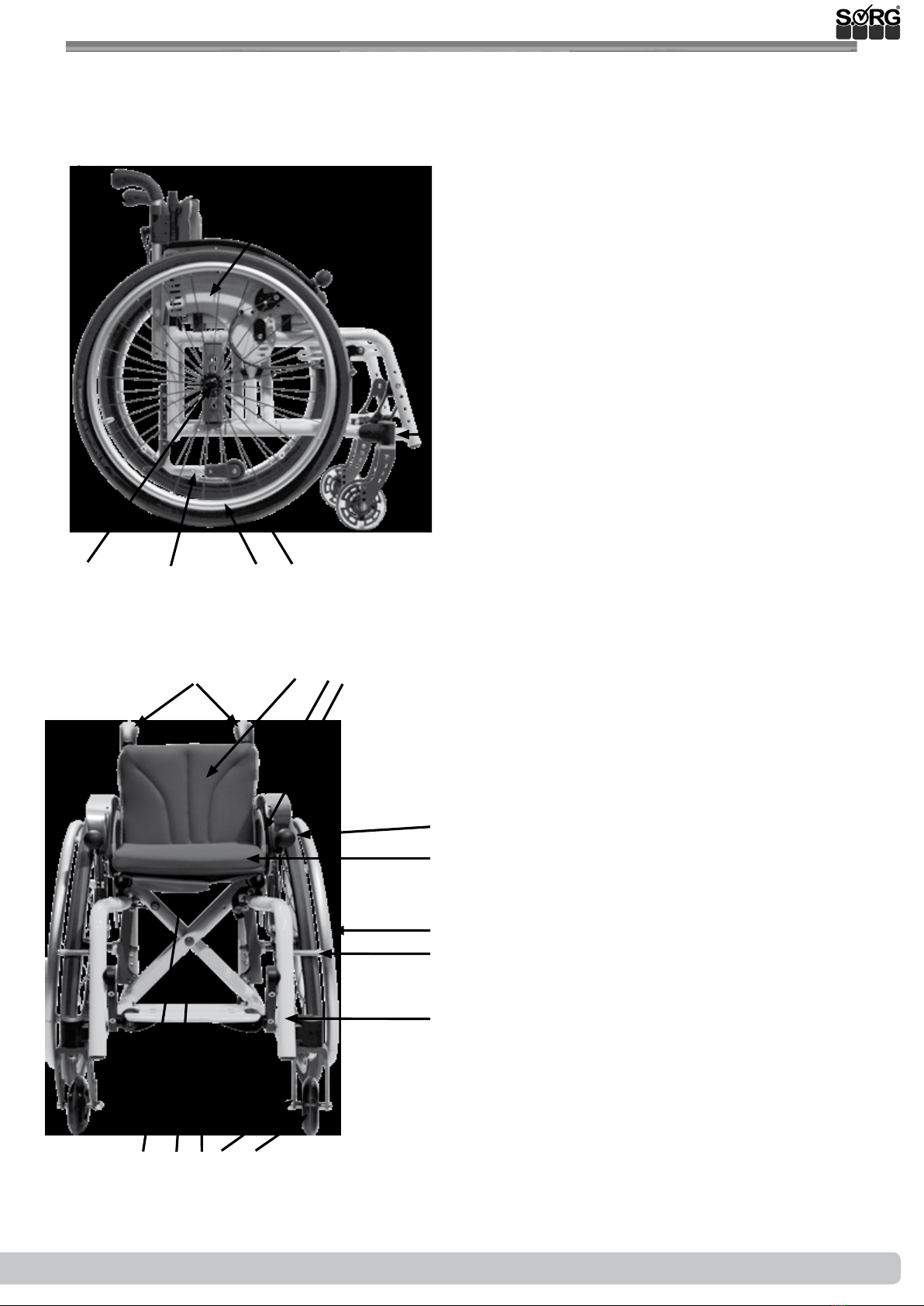

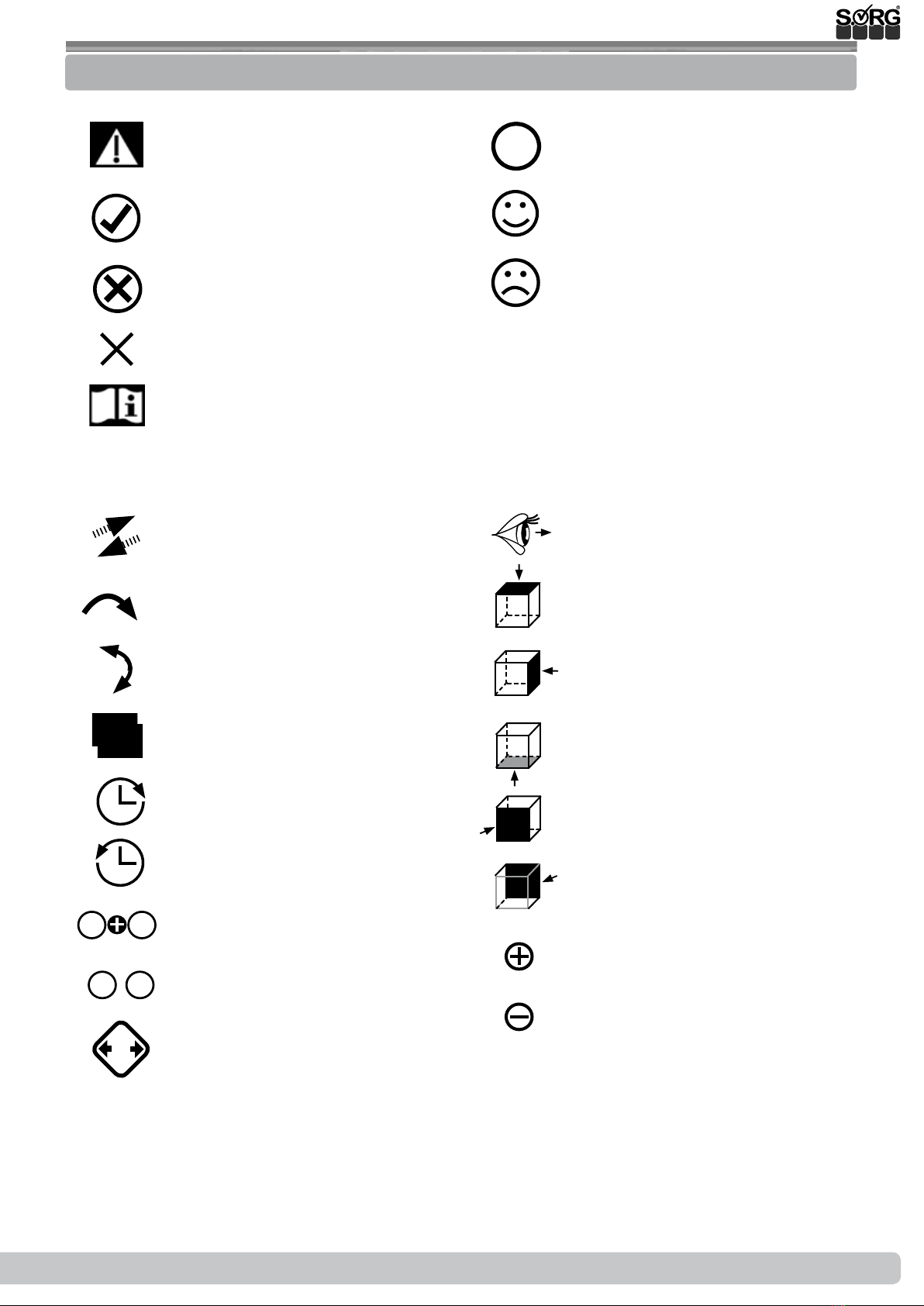

1 Wheelchair overview 5

2 General information 6

2.1 General indications 6

2.2 Documentation indications 6

2.3 Required torques and tools 6

2.4 Explanation of symbols 7

2.5 General safety instructions 8

3 Assembly groups 9

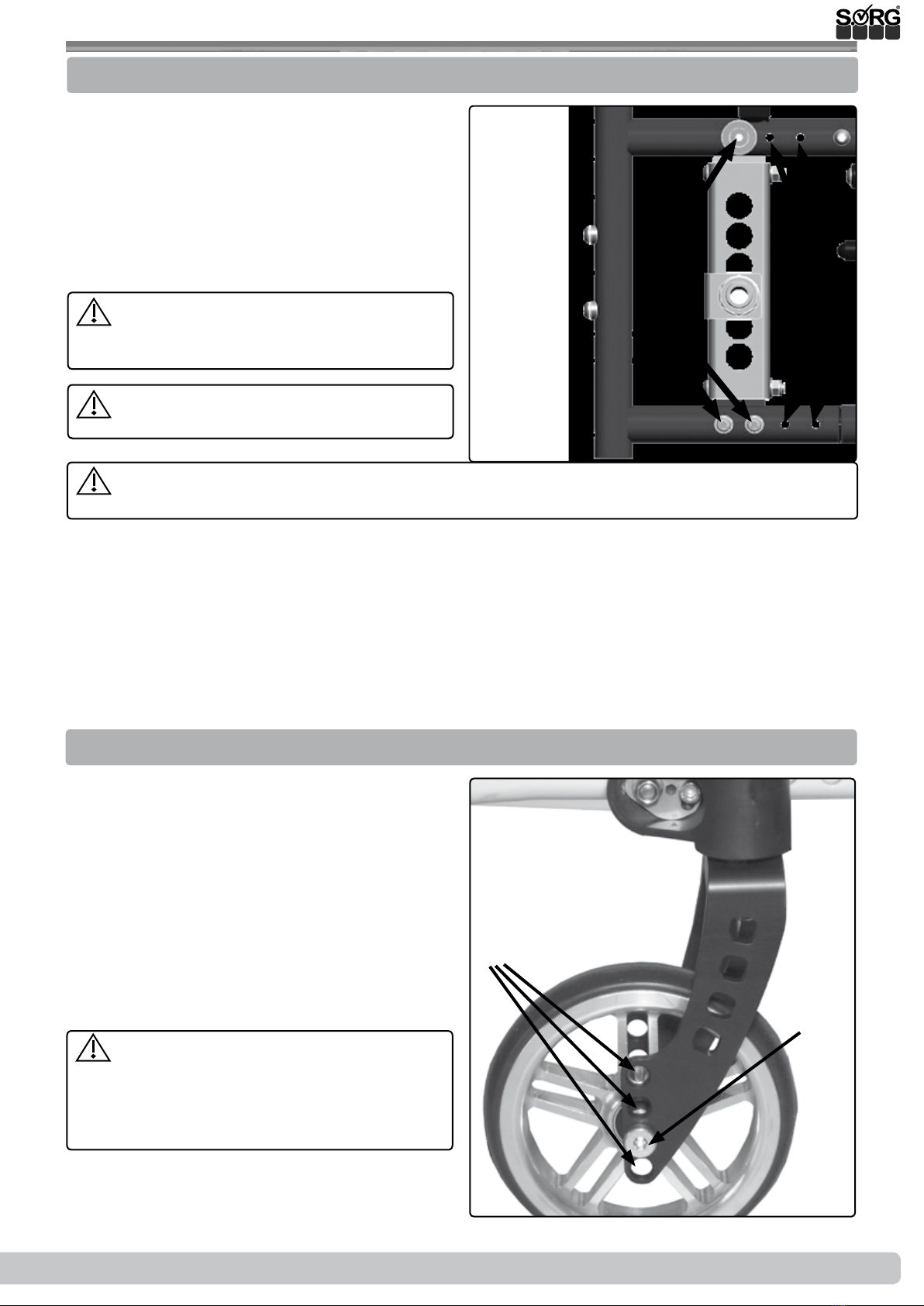

3.1 Assembly group wheels 9

3.1.1 Centre of gravity 9

3.1.2 Seat height in front 9

3.1.3 Seat height in back, seat slant 10

3.1.4 Steering head slant 10

3.1.5 Replacing/ displacing the caster

adapters and casters 11

3.1.6 Camber 11

3.1.7 Rear wheel track balance 12

3.2 Assembly group seat 15

3.2.1 Changing the seat cover 15

3.2.2 Extending the seat depth with a

seat cover 15

3.2.3 Retightening the seat cover 15

3.2.4

Changing the seat depth of the SitzFix

15

3.2.5 Chaning the seat width 16

3.3 Assembly group leg support 17

3.3.1 General Information Leg supports 17

3.3.2 Leg support outer attachment,

folds up sideways 17

3.3.3 Leg support 18

3.3.4

Divided foot plate, folds up sideways

18

3.4 Assembly group side guards 19

3.4.1 Setting side guards 19

3.4.2 Skirt guard on the side guard 19

3.4.3 Armrest on the side guard 20

3.5 Assembly group brake 21

3.5.1 General information brake 21

3.5.2 Standard wheel lock 21

3.5.3 Cable brake 22

3.5.4 Drum brake 22

3.6 Assembly group anti-tipper 23

3.6.1 Height setting 23

3.6.2 Length setting 23

3.7 Assembly Group tipping lever 24

3.7.1 Mounting 24

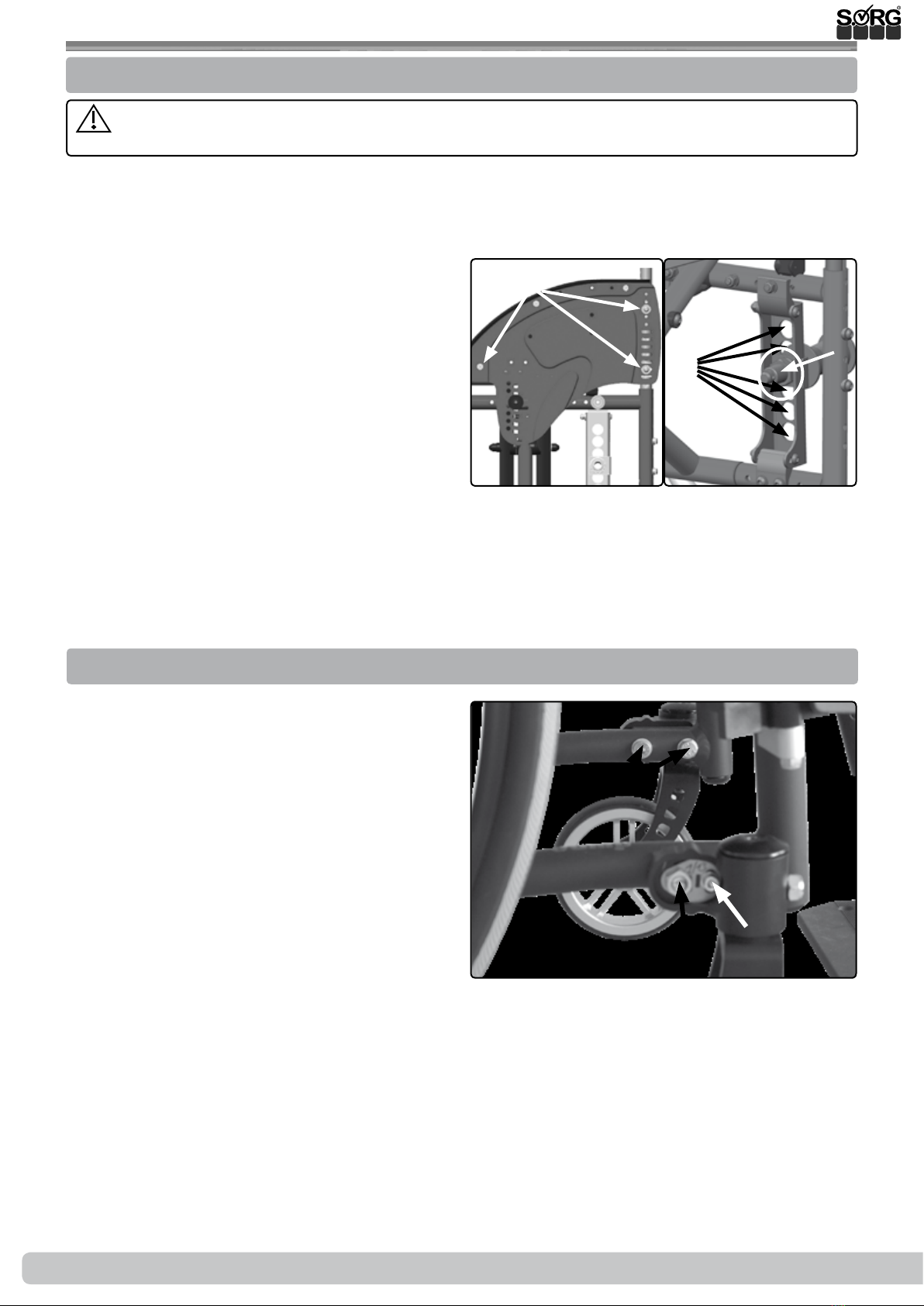

3.8 Assembly Group back 25

3.8.1 Adjustable back cover 25

3.8.2 Firm curved back plate 25

3.8.3 Stabiliser bar 25

3.8.4 Setting the back angle 26

3.8.5 Extension on the standard backs 26

3.8.6 Extension on backs with angle

adjustment or setting 26

3.9 Assembly Group Truss Pads 27

3.9.1 Classication 27

3.9.2 Vertical setting 27

3.9.3 Horizontal setting 27

3.9.4

Fine adjustment of the truss pad holder

28

3.9.5 Adjusting to the user 28

3.10 Assembly Outdoor Front End 29

3.10.1 General Information 29

3.10.2 Widen 29

3.10.3 Extend 29

4 Repairs and maintenance 31

4.1 Repairs 31

4.2 Spare parts 31

4.3 Maintenance 31

4.4 Disinfection 31

4.5 Storage 31

4.6 Reinstatement 32

4.7 Disposal 32

4.8 Maintenance/ Inspection 32

5 Technical specications 34

5.1 Daten und Maße 34

5.2 Meaning of labels 35

5.3 Declaration of conformity 35