10 of 32 Service Record Mio (Design 2018)

Service Record Mio (Design 2018) 2019-07-16

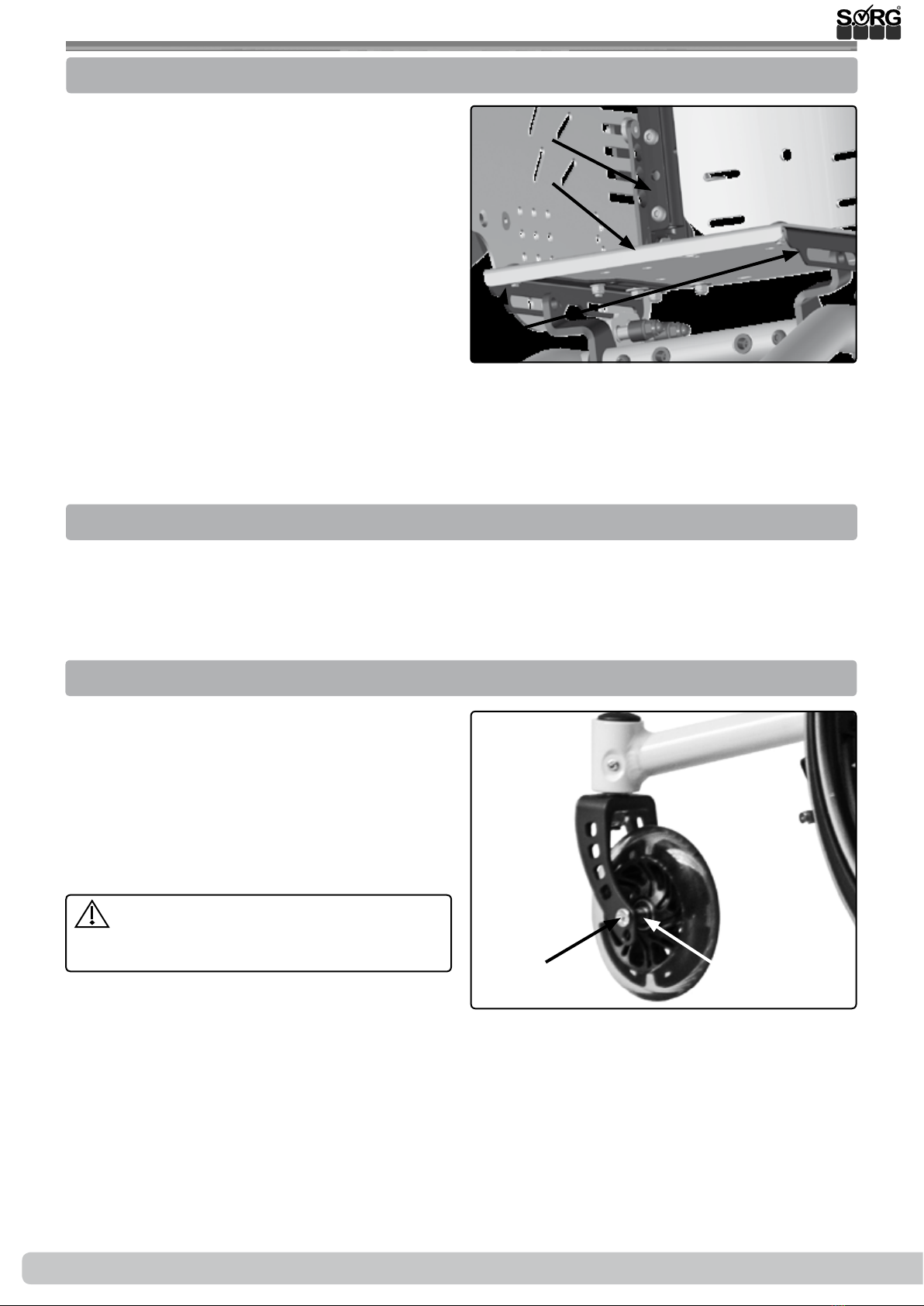

3.2.2 Widening the seat

3.2 Assembly group seat

(1) To increase the seat width by 20 mm / 2

cm, you must remove the rear wheels, prevent

the wheelchair from rolling away and proceed

as follows:

• Completely remove screw connection

between seat plate and seat support

brackets,

• Completely remove screw connection

for depression

• Completely remove side guards,

• Move spacer bushes.

(1) Remove seat plate

• Remove both screws (D) on both sides.

• Leave the seat support bracket (A) con-

nected to the side panels.

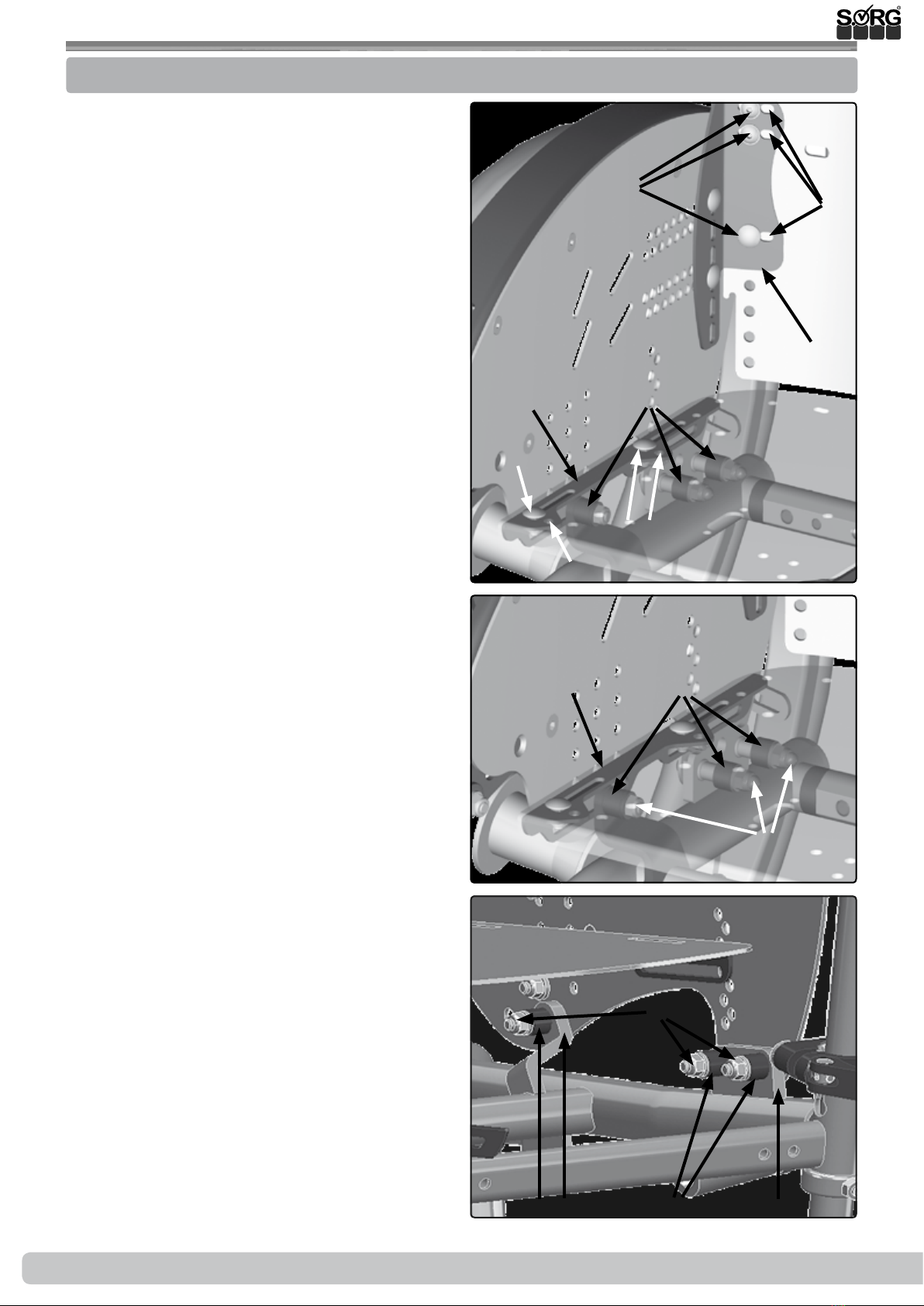

(1) Remove the depression

• Remove all screws (E) on both sides.

• Leave the rear support brackets (C)

connected to the side panels and remo-

ve only the back of the rm curved back

plate

(2) Remove side guards

• Remove all screws (A) on both sides.

• Leave the seat support brackets (B)

connected to the side panels.

• Remove the spacers (C).

(3) Moving the spacers / widening of the

wheelchair

• The wheelchair is delivered by us in

such a way that the spacers (A) neces-

sary for the seat broadening sit on the

inside.

• Move the spacers (A) between the side

panel (B) and the brackets (C).

• Replace all screws (D) and turn them

tight.

After the seat widening sit the spacers (A) on

the outside between side panel and side panel

holder.

(1) Insertion of the depression

• Use the screws (E) to screw the depres-

sion back into the new holes (F).

• Check all screw connections.

• To change the seat height / seat angle:

• Completely remove the screws of the

seat support bracket on both sides,

• Bring the seat plate into the desired

position,

• Reinstall screw connections and tighten

tightly.

(A)

(D)

(F)

(F)

(D)(F)

(C)

(E)

(B)

Seat plate shown trans-

parently

(3)

(C)(C)(A) (A)

(D)

(B)

(A)

(C)(B)

(2)

(1)