Getting started with the touch sensing evaluation kit UM0671

6/23 Doc ID 15330 Rev 4

Display options

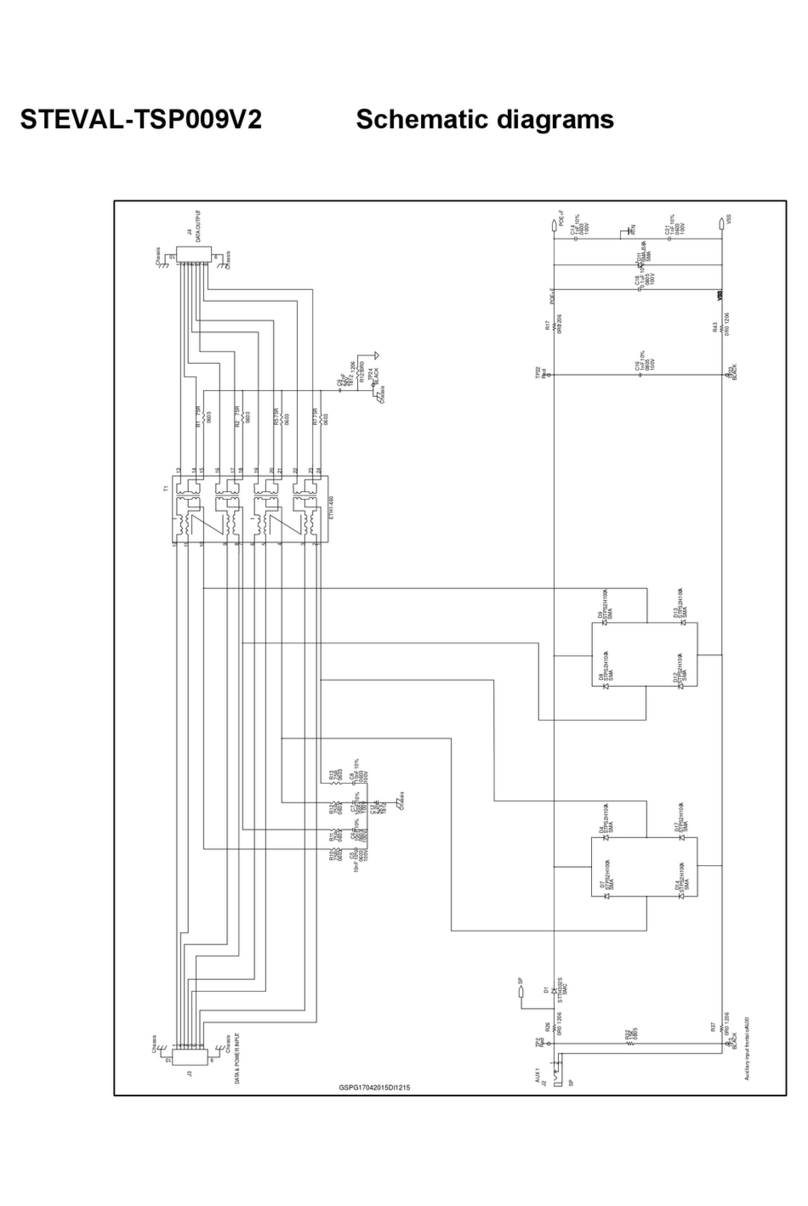

Use the joystick to navigate through the sub-menus as shown in Figure 3 to do the following:

1. Display the state of keys (K1, K2, K3, K4 and K5) and slider on the same screen.

2. Display only the state of the selected key (Kx) (Idle or Detected).

3. Display the signal value and the reference threshold of the selected Key (Kx).

4. Display the number of samples rejected by the noise filtering system.

5. Display the state of the slider (Idle or Detected).

6. Display the signal value and the position of the slider.

7. Display/change slider resolution (default is 4 bits, may be set to up to 7 bits).

Parameter setting options

Use the joystick to navigate through the sub-menus as shown in Figure 3 to set the following

options:

1. Detection time-out

This feature automatically recalibrates keys after a fixed duration of continuous touch

detection. This prevents the keys from becoming 'stuck on' due to foreign objects or

other sudden influences. This is known as the detection time-out feature.

After recalibration, the keys will continue to operate normally, even if partially or fully

obstructed.

Infinite timeout (detection time-out value = 0) is useful in applications where a

prolonged detection can occur and where the output must reflect the detection

regardless of its duration.

2. De-bounce filter

The de-bounce filter reduces the effects of low frequency noise on key states. This

mechanism requires a specified number of measurements that qualify as detections

(and these must occur consecutively) or the detection will not be reported.

In a similar manner, the end of a touch (loss of signal) also has to be confirmed over

several measurements. This process acts as a type of “de-bounce” mechanism against

noise.

The typical value is equal to 2.

3. Low power mode

To reduce device power consumption, this feature inserts a low power mode window

between each key acquisition period.

This window duration is programmable with the following typical values (in

milliseconds): 0, 1, 2, 4, 8, 16, 32, 64, and 128.

4. Detection Exclusion System

The Detection Exclusion System (DES) prevents multiple keys from responding to a

single touch. This can happen with closely spaced keys.

Once a key is considered as “touched”, all other keys are locked in an untouched state.

To unlock these keys, the touched key must return to an untouched state.

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.