HOT

E00

7

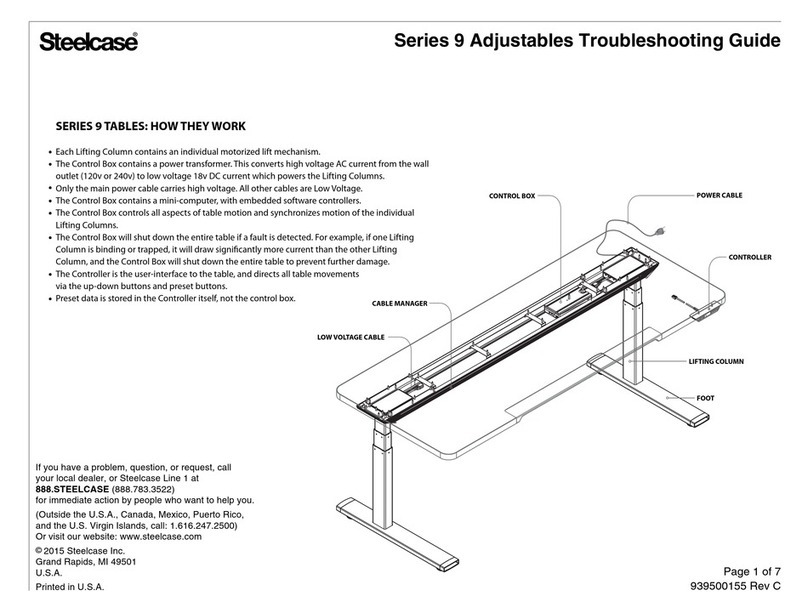

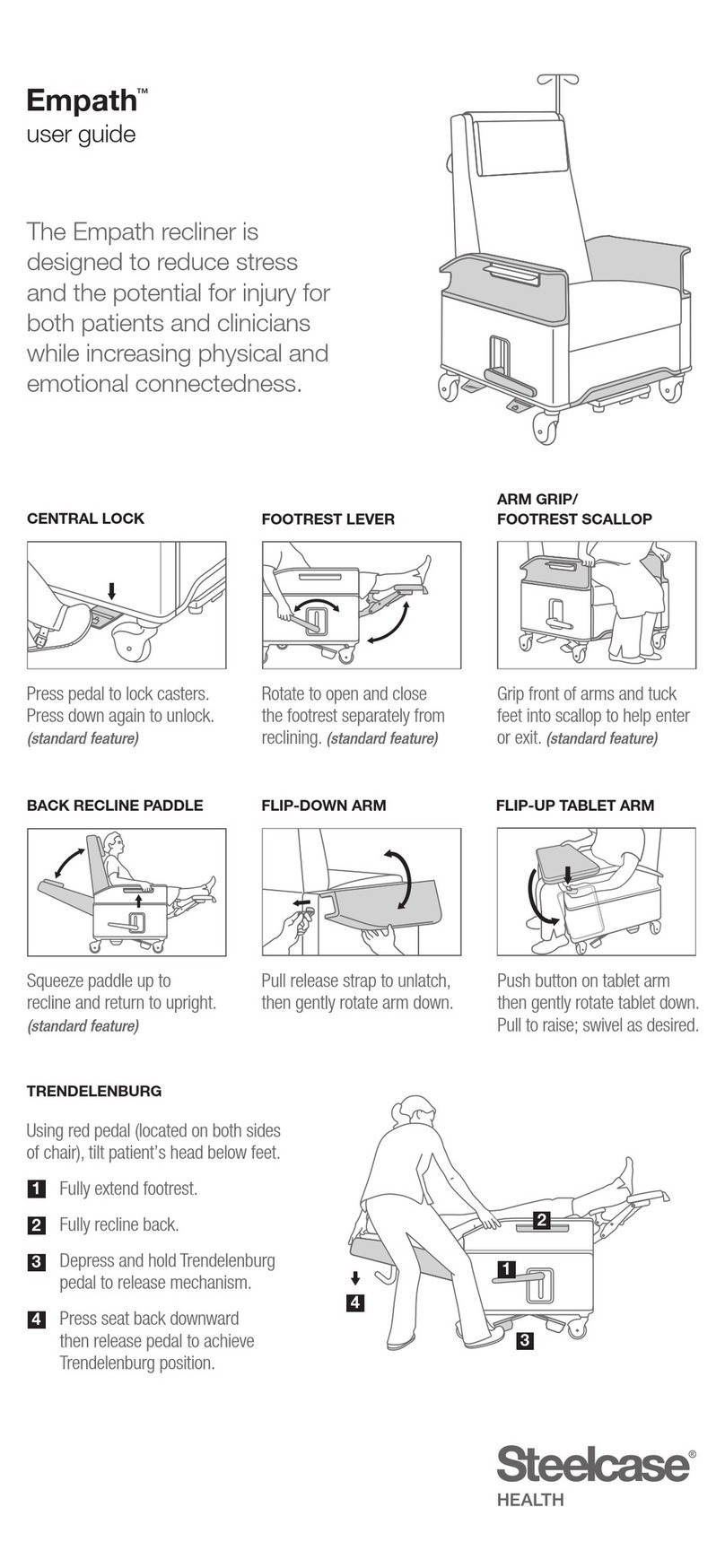

OLOGY BENCH ERROR CODES

Error codes are only available with the Digital/Preset Controller

ERROR

CODE NAME DESCRIPTION POTENTIAL CAUSE SOLUTION/TROUBLESHOOTING

HOT Overheating The Control Box incorporates

overheating

E00 Internal error, Channel 1 Relay sticks, MOSFET defect

E01 Internal error, Channel 2 Relay sticks, MOSFET defect

E02 Internal error, Channel 3 Relay sticks, MOSFET defect

E12 Defect, Channel 1 Short circuit, impulse timeout

E13 Defect, Channel 2 Short circuit, impulse timeout

E14 Defect, Channel 3 Short circuit, impulse timeout

E24 Overcurrent, Motor M1 Over current on channel

E25 Overcurrent, Motor M2 Over current on channel

E26 Overcurrent, Motor M3 Over current on channel

E48 Overcurrent, Over current on group

Motor Group 1

E49 Overcurrent, Over current on group

Motor Group 2

E60 Collision Protection Collision detected

E62 Overcurrent, Control Box Control box over current over

all motor groups, or SMPS

overload

E36 Plug Detection in Lifting Column not detected on

Motor Socket M1 channel

E37 Plug Detection in Lifting Column not detected on

Motor Socket M2 channel

E38 Plug Detection in Lifting Column not detected on

Motor Socket M3 channel

E61 Lifting Column Changed Lifting Column has been

changed

E55 Synchronization Lost, Synchronization Lost, Motor

Motor Group 1 Group 1

E56 Synchronization Lost, Synchronization Lost, Motor

Motor Group 2 Group 2

E67 High Voltage Over voltage

E70 Motor Configuration Motor Configuration Changed

Changed

E71 Anti-Pinch Configuration Anti-Pinch Configuration

Changed Changed

E81 Internal Error CRC flash

CRC EEPROM

Data not saved at power off

HW initialization

FW-driver initialization

Wait until the HOT error message is no

longer displayed. May need to wait for

entire remaining 18 minutes of 20-minute

duty cycle period.

Try soft reset (unplug, wait 5 sec, plug

back in); if this does not solve the issue,

re-initialize the Control Box. Verify function

of Control Box via troubleshooting steps.

Replace Control Box if faulty.

Control box fault, or fault at

connectors

Exceeding the Duty Cycle;

hot environment

Verify low-voltage connections are

properly made, and that pins / connectors

are not damaged. Test Lifting Columns

per troubleshooting steps, and proceed

through rest of steps if Lifting Columns are

not faulty.

Lifting Column fault, or fault

in Low-Voltage Cables, or at

connections to Control Box.

Remove excessive loads, remove any

obstructions. The Lifting Columns

may need to be re-synchronized.

After this, verify proper function. If not

functioning properly, proceed through

troubleshooting steps.

Desk is overloaded, or

Desk has hit an obstruction.

Check connections for damage / proper

attachment. Check Low-Voltage Cables for

damage. Proceed through troubleshooting

steps.

Low-voltage connectors

disconnected, or not

connected properly;

Lifting Column fault.

Re-synchronize Lifting Columns.Lifting Columns have lost

synchronization.

Verify power at outlet is normal using

another device. If power is abnormal,

disconnect from source. Try soft reset /

initialization of Control Box if power is normal.

Internal fault, or power

supply too high

Try soft reset (unplug, wait 5 sec, plug

back in); if this does not solve the issue,

re-initialize the Control Box. Verify function

of Control Box via troubleshooting steps.

Replace Control Box if faulty.

Control box fault, or fault at

connectors.

The display reads HOT.

The display reads E + an error code.