. . . . .

S

IGNIFICA N T

F

EATURES

AND

R

EQUIREMENTS

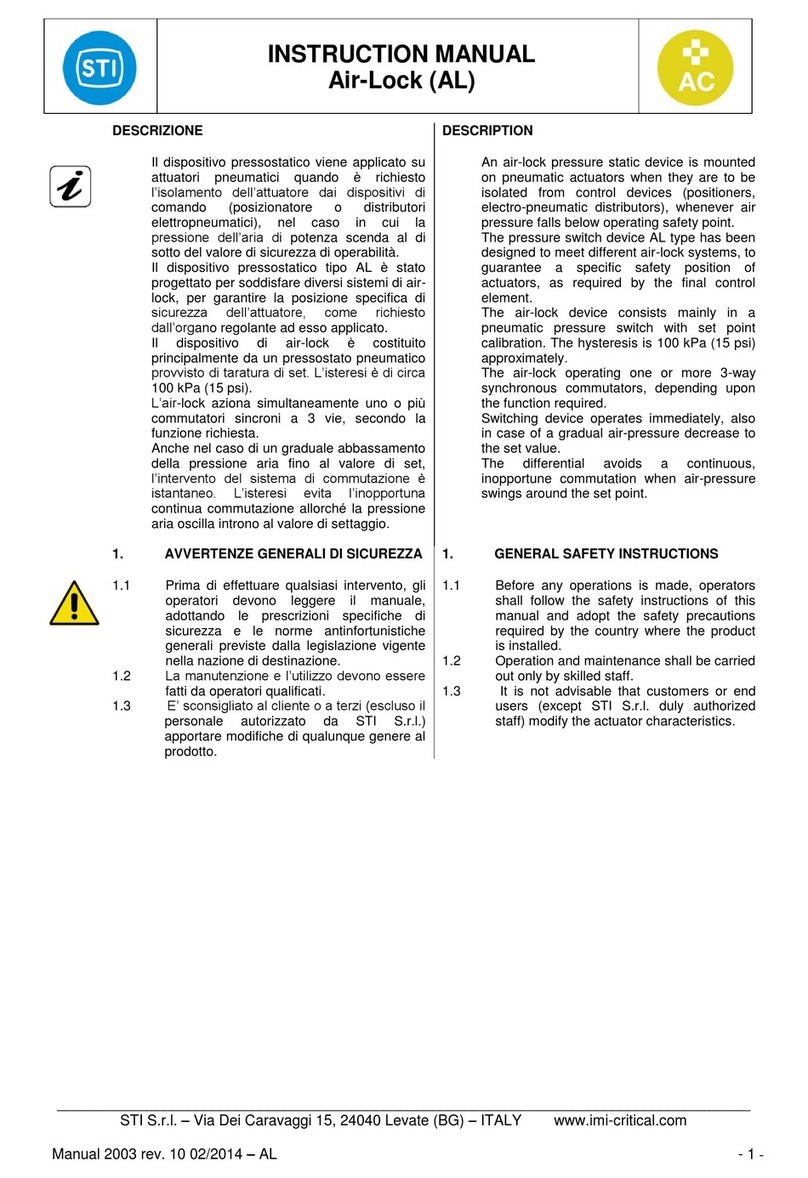

Employer Responsibilities

BeamSafe II Installation and Operation Manual

•The machine on which the BeamSafe II is installed must be capable of stopping motion

anywhere in its stroke or cycle. Do not use the BeamSafe II on a power press with a full-

revolution clutch.

•The BeamSafe II does not offer protectionfrom flying objects.

•Do not use the BeamSafe II on any device with inconsistent stopping time or

inadequate control devices or mechanisms.

•Do not use the BeamSafe II where the environment, such as severe smoke, particulate

matter, or corrosive chemicals, may degrade the efficiency ofthe BeamSafe II.

•When the BeamSafe II is utilized as a safety device, the employer has the responsibility

to ensure that all applicable federal,state and localrules, codes and regulations are satisfied.

•All safety-related machine control circuit elements, including pneumatic, electric or

hydraulic controls must be controlreliable. Control reliable is defined as:“...the

device, system or interface shallbe designed, constructed and installed such that a

single component failure within the device, interface or system shall not prevent

normal stopping action from taking place, but shallpreventa successive machine cycle...”

•Additional guarding such as mechanical guards may be requiredifthe BeamSafe II

does not protect all points of entry into the hazardous area.

•All brakes and other stopping mechanisms and controls must be in proper working

order. If the machine stop mechanisms and associated controls are notworking

properly, the machine may not stop safely even though the BeamSafe II is functioning

properly.

•The OMRON STI test procedures must be performed after any maintenance is performed on the

machine controls or the BeamSafe II. The test procedure is contained in this manual.

The user must perform (at leastevery three months, more oftenwith continuous use)

the preventive maintenance procedures recommended in this manual.

•Do not perform any test or repairs other than those outlined in this manual. All

electricalwiring must be installedinaccordance with local electrical codes and regulations.

•The user must follow allprocedures in this manual for proper operationof the

BeamSafe II.

•The enforcement of these requirements is beyond OMRON STI’s control. The employer has the

sole responsibility tofollow the preceding requirements and any other procedures,

conditions and requirements specific to his machinery.

WARNING!

!

Despite inherent safe design measures, safeguarding and complementary

protective measures adopted by the user, residual risk may remain in any

installation. Potential risks are strictly under the control of the end user

and may include severe injury or death.

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

3© OSTI 0510 PN99235-0020 Rev. E

Original Instructions

. . . . .