PRESSURE SENSORS

DP5/DPH

Head-separated

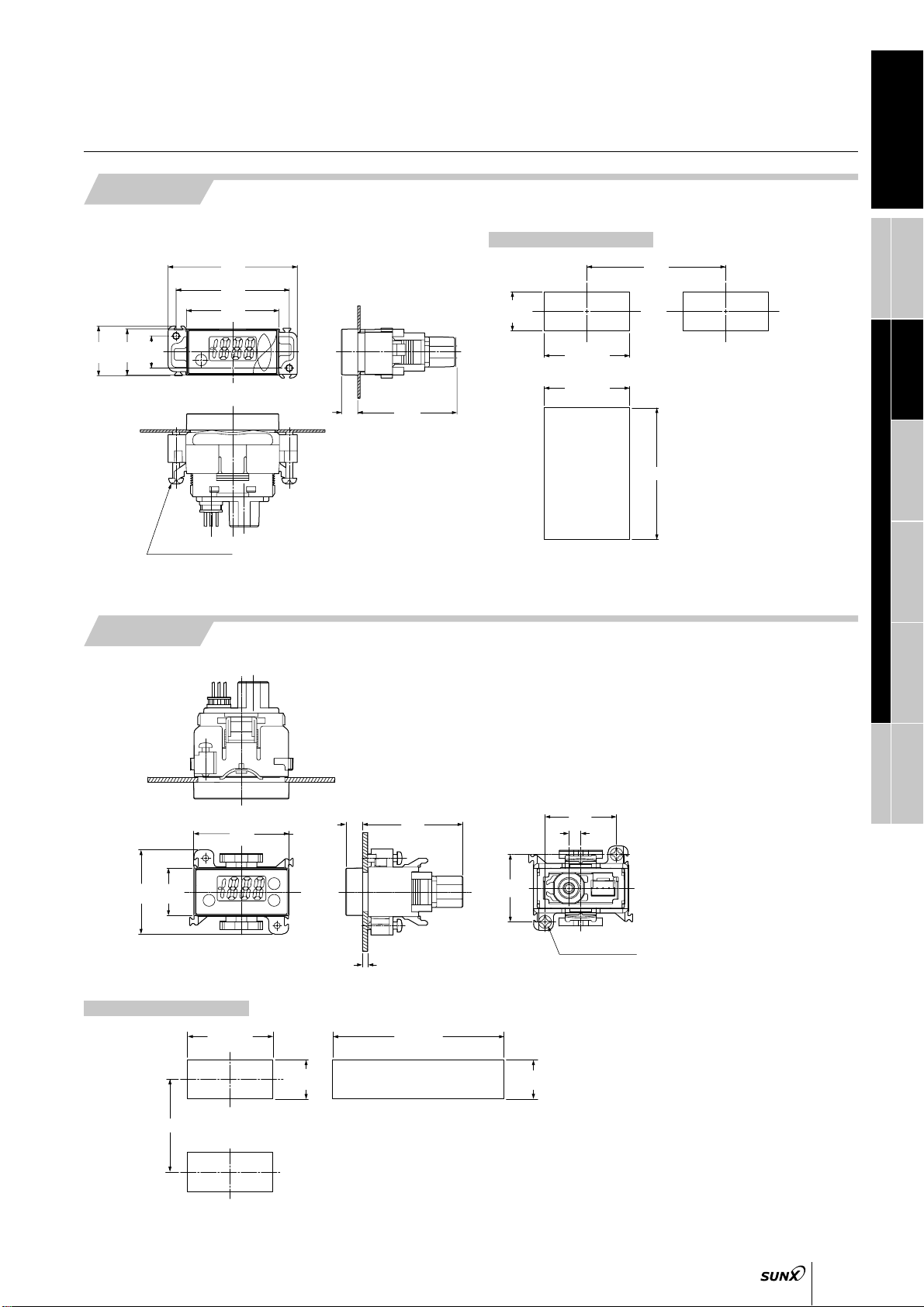

DP4DP2DP3DP-M Digital Display

PE

LED Bar Display

DP4

783

Gauge pressure

0 to 101.3 kPa 0 to 1.000 MPa 100.0 to 100.0 kPa

5.1 to 101.3 kPa

0.052 to1.033 kgf/cm

2

, 0.051 to1.013 bar

0.74 to14.70 psi, 38 to760 mmHg

1.5 to29.9 inHg

490 kPa 1.470 MPa 490 kPa

Non-corrosive gas

1 digit (however, variable in hysteresis mode)

Within 0.2 % F.S. 1 digit (within 3 digits)

12 to 24 V DC % Ripple P-P 10 % or less

40 mA or less

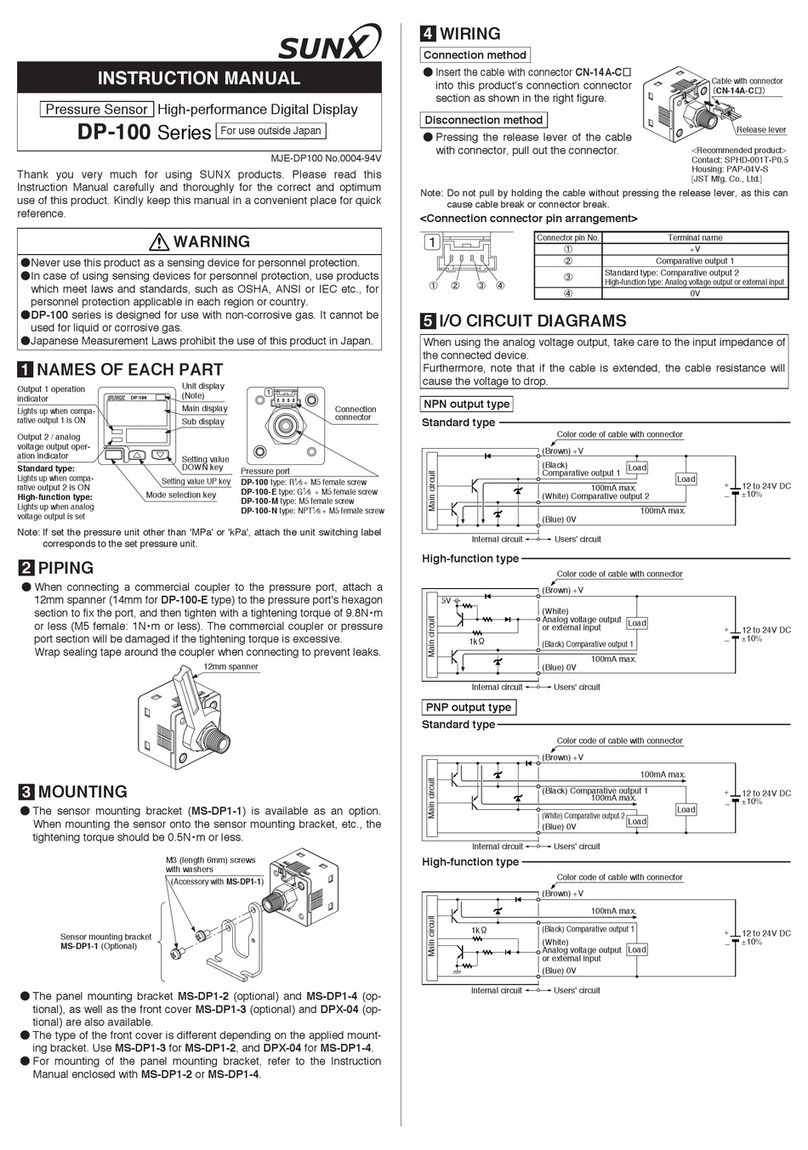

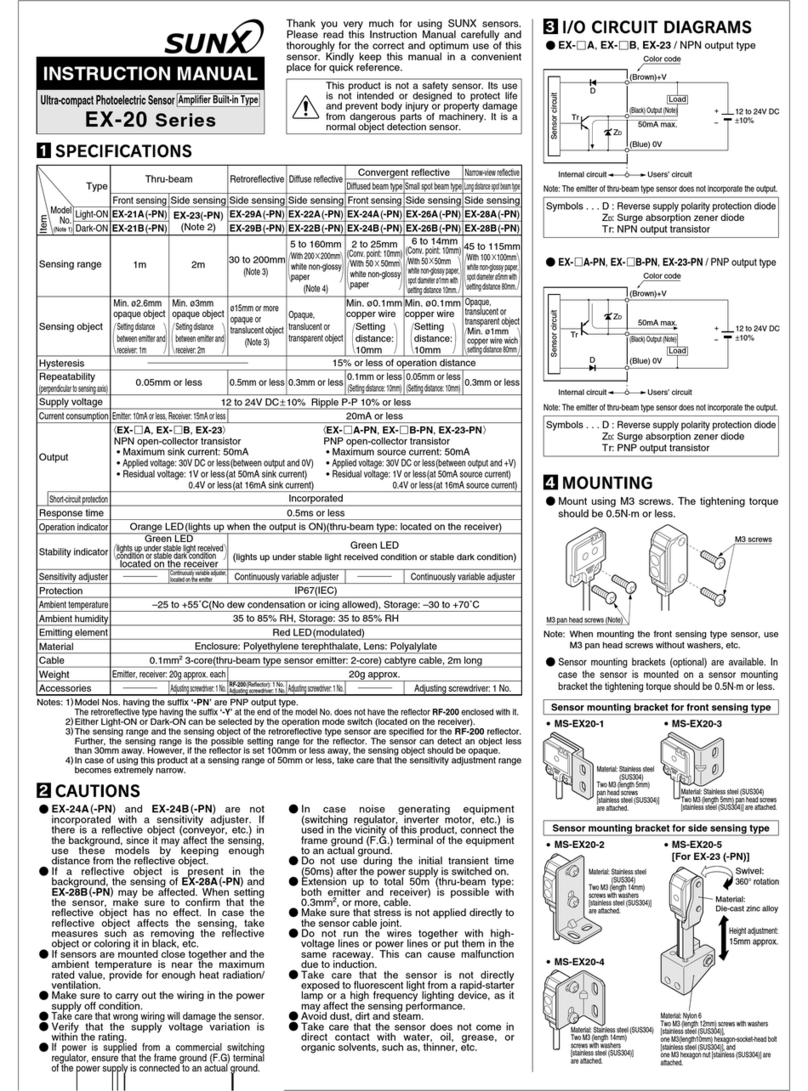

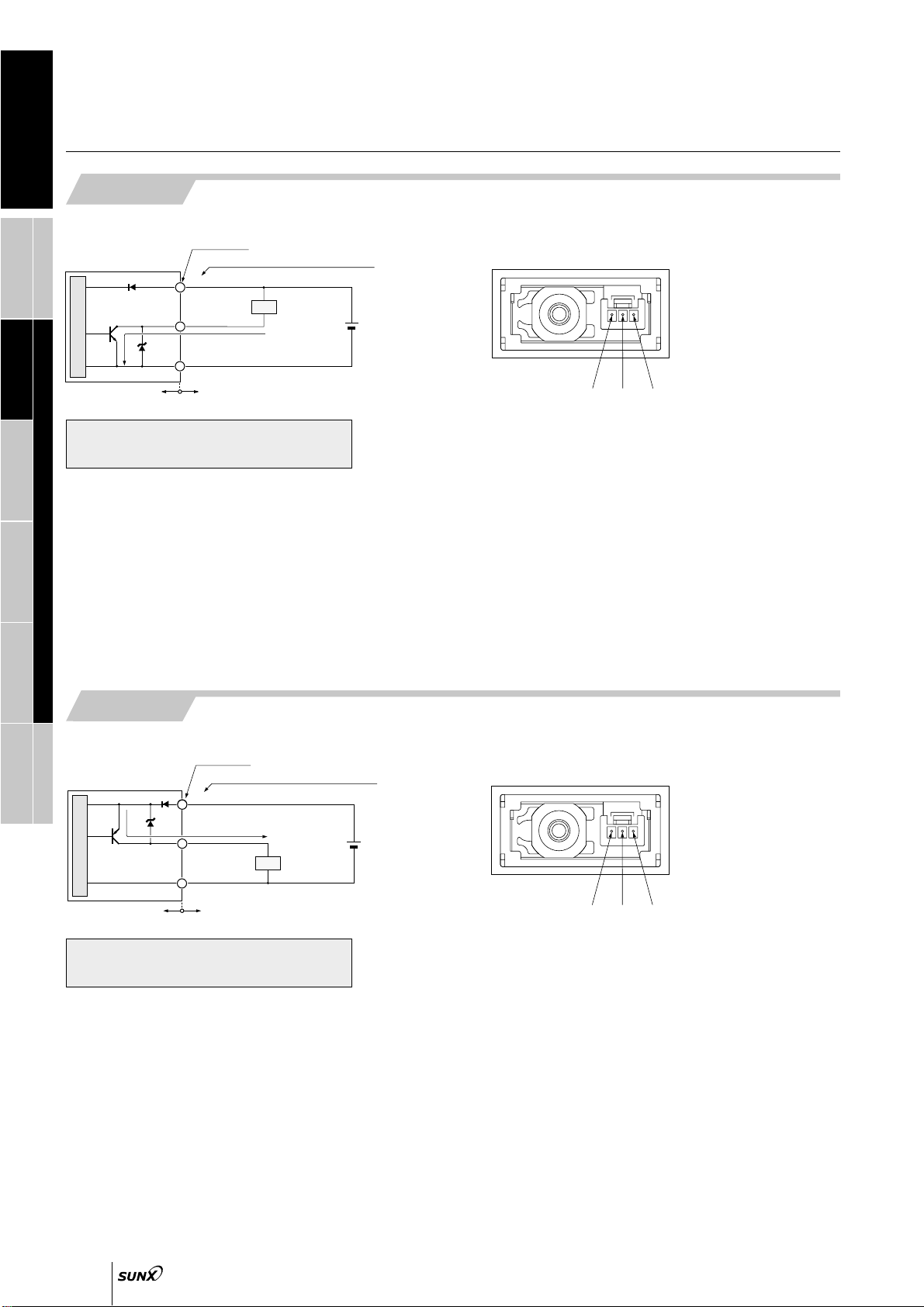

<NPN output type>

NPN open-collector transistor

• Maximum sink current: 100 mA

• Applied voltage: 30 V DC or less (between output and 0 V)

• Residual voltage: 1 V or less (at 100 mA sink current)

0.4 V or less (at 16 mA sink current)

DC-12 or DC-13

NO / NC (selectable by key operation)

Equipped with 4 types of modes: Hysteresis mode, window comparator mode, automatic sensitivity setting mode,

forced output mode (selectable by key operation)

Incorporated

2 ms, 16 ms, 128 ms, 512 ms or less (selectable by key operation)

31/2digit LCD display (with red and green backlight)

(Sampling rate: 256 ms, 512 ms, 1,024 ms selectable by key operation)

5.1 to 101.3 kPa

0.052 to1.033 kgf/cm

2

, 0.051 to1.013 bar

0.74 to14.70 psi, 38 to760 mmHg

1.5 to29.9 inHg

Bar display in steps of 14 % F.S. approx.

LCD segment is red when the output is ON, and green when the output is OFF

3 (Industrial environment)

IP40 (IEC)

0 to50 C 32 to122 F(No dew condensation), Storage: 10 to60 C 14 to140 F

35 to 85 % RH, Storage: 35 to 85 % RH

EN 50081-2, EN 50082-2, EN 61000-6-2

1,000 V AC for one min. between all supply terminals connected together and enclosure

50 MΩ, or more, with 500 V DC megger between all supply terminals connected together and enclosure

10 to 150 Hz frequency, 0.75 mm 0.030 in amplitude, or 5 G in X, Y and Z directions for two hours each

100 m/s2acceleration (10 G approx.) in X, Y and Z directions for three times each

Over ambient temperature range 10 to40 °C 50 to104 °F: within 2 % F.S. of detected pressure at 25 °C 77 °F

Over ambient temperature range 0 to50 °C 32 to122 °F: within 5 % F.S. of detected pressure at 25 °C 77 °F

M5 female thread

Front case: ABS, LCD display: PET, Rear case: PBT [M5 threaded part: Brass (nickel plated)]

Connector

0.16 to 0.32 mm2 (AWG#25 to 22)

"1.2 to "1.8 mm "0.047 to "0.071 in

Tin plated, soft, twisted copper wire

Extension up to total 100 m 328.084 ft (less than 10 m 32.808 ft when conforming to CE marking) is possible with 0.3 mm

2

, or more, cable

30 g approx.

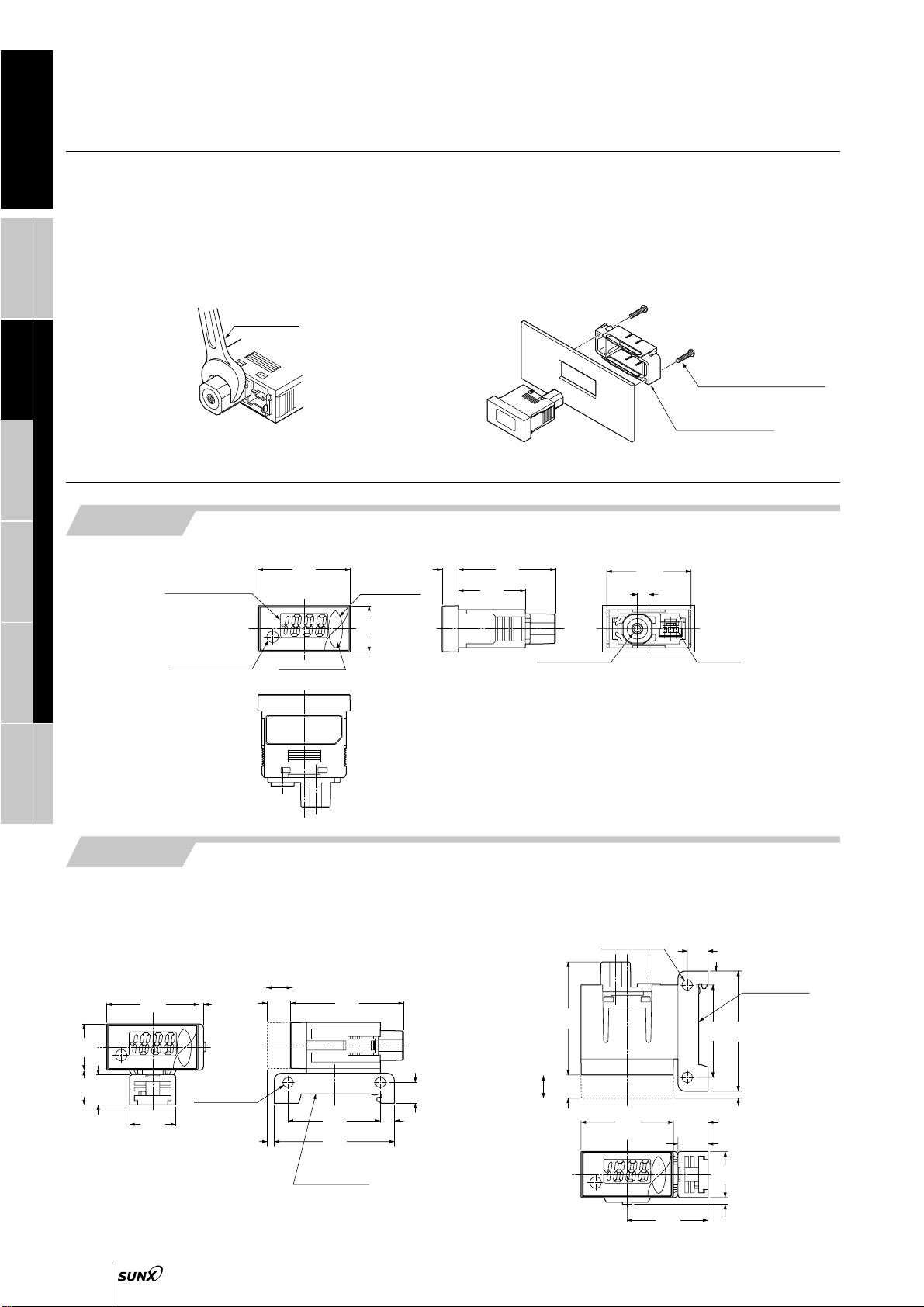

Panel mounting bracket (MS-DP-1): 1 set, Pressure unit label: 1 pc.

Connector: 1 set (Housing: 1 pc., Connector pin: 3 pcs.)

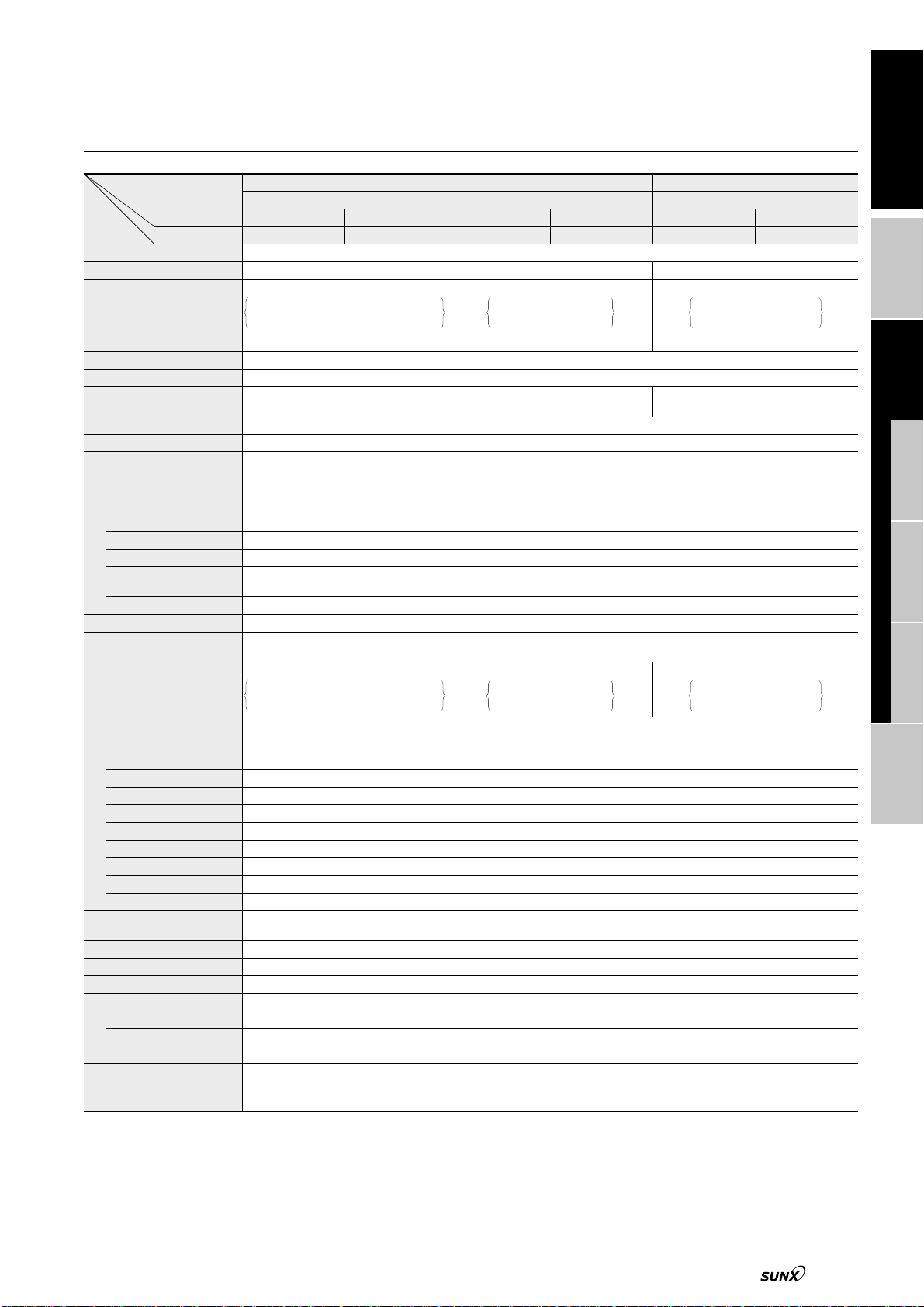

SPECIFICATIONS

10

15

<PNP output type>

PNP open-collector transistor

• Maximum source current: 100 mA

•

Applied voltage: Same as supply voltage (between output and

V)

• Residual voltage: 2 V or less (at 100 mA source current)

Within 0.2 % F.S. 2 digits

(within 6 digits)

Type of pressure

Rated pressure range

Set pressure range

Pressure withstandability

Applicable fluid

Hysteresis

Repeatability

Supply voltage

Current consumption

Output

Utilization category

Output operation

Output modes

Short-circuit protection

Response time

Display

Displayable pressure range

Analog bar display

Operation display

Pollution degree

Protection

Ambient temperature

Ambient humidity

EMC

Voltage withstandability

Insulation resistance

Vibration resistance

Shock resistance

Temperature characteristics

Pressure port

Material

Connecting method

Conductor cross-section area (Note)

Lead wire diameter

Wire material

Cable extension

Weight

Accessories

Suitable cable

Environmental resistance

Vacuum pressure Positive pressure Compound pressure

101 kPa type 1 MPa type 100 kPa type

NPN output PNP output NPN output PNP output NPN output PNP output

DP4-50 DP4-50P DP4-52 DP4-52P DP4-57 DP4-57P

Type

Item Model No.

Note: If the wiring is longer than 5 m 16.404 ft, use a cable with a diameter of 0.3 mm2or more.

0.050 to 1.050 MPa

0.51 to 10.71 kgf/cm2

0.50 to 10.50 bar

7.2 to 152.2 psi

0.050 to 1.050 MPa

0.51 to 10.71 kgf/cm2

0.50 to 10.50 bar

7.2 to 152.2 psi

101.3 to 105.0 kPa

1.033 to 1.071 kgf/cm2

1.013 to 1.050 bar

14.68 to 15.22 psi

101.3 to 105.0 kPa

1.033 to 1.071 kgf/cm2

1.013 to 1.050 bar

14.68 to 15.22 psi