EN

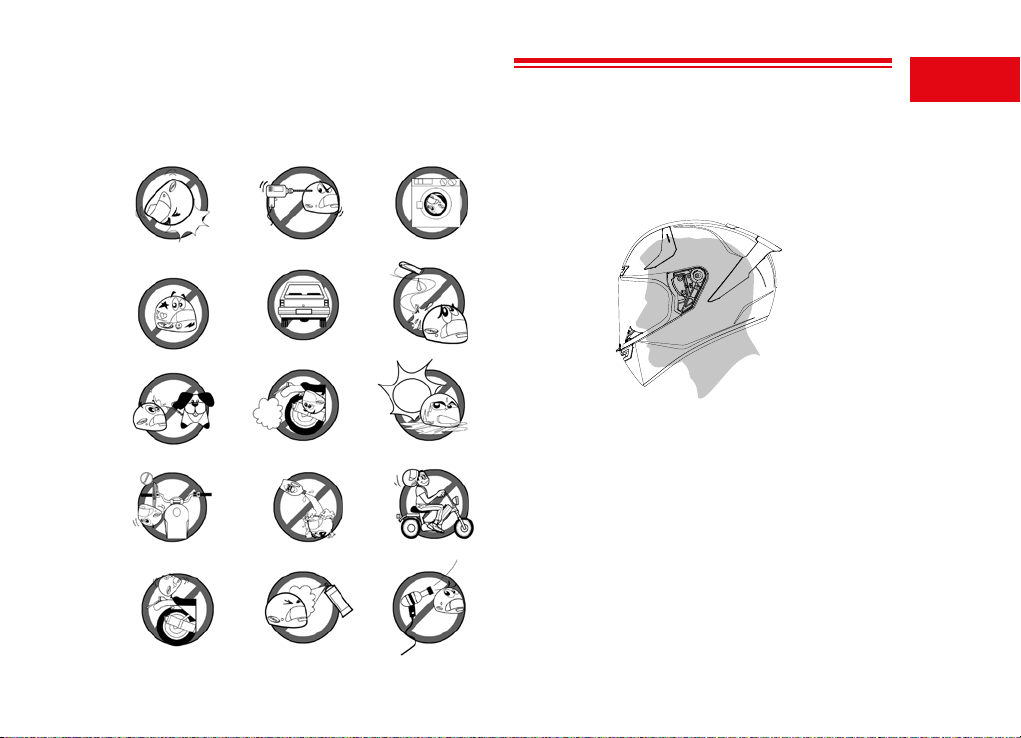

The integrity of the shell and of the inside are essential to assure

maximum performances in terms of safety.

SR-GP was studied to absorb crashes through a partial destruction

of the shell or some of its parts that could be damaged after a crash

even if it is not readily visibly. If the helmet suffers further stress it

might not be able to offer the maximum level of protection.

Do not use a helmet that suffered severe blows even though the

damage is not readily visible; if the helmet is damaged it must

be replaced. It is extremely dangerous to modify the helmet by

sticking or gluing anything on it. Do not cut or punch the helmet’s

shell, do not insert screws or paint it.

Do not change the internal lining of the helmet, particularly never

cut or change the inside polystyrene padding: changes to the

shape of the internal polystyrene shell can affect the safety features

of the helmet.

Damaged visors may limit visibility especially at night and must be

immediately replaced with regularly certified visors according to

the certification regulations in force.

Do not apply paint and/or adhesives on the visor. Do not remove

homologation label from the visor.

Only use original Suomy accessories and spare parts or those

specifically indicated by Suomy for the specific model: this is the

only way to assure reliability, safety and compatibility with the helmet

used.

The use of non original components and/or accessories make the

warranty void (see warranty conditions on page 35) and can affect

the safety requirements.

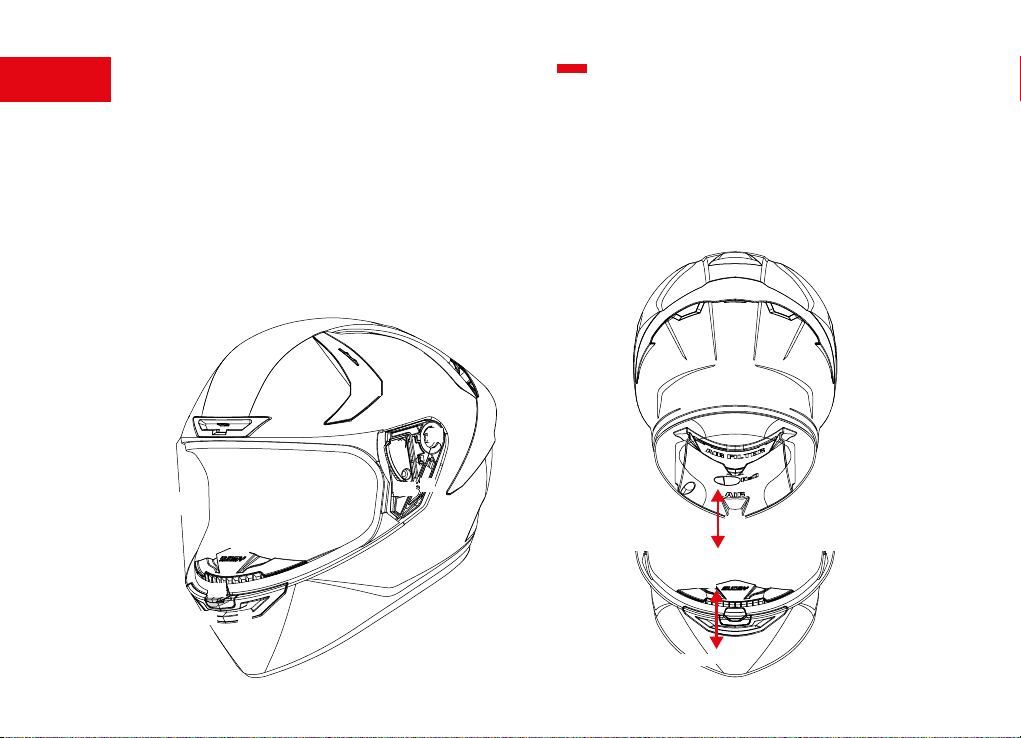

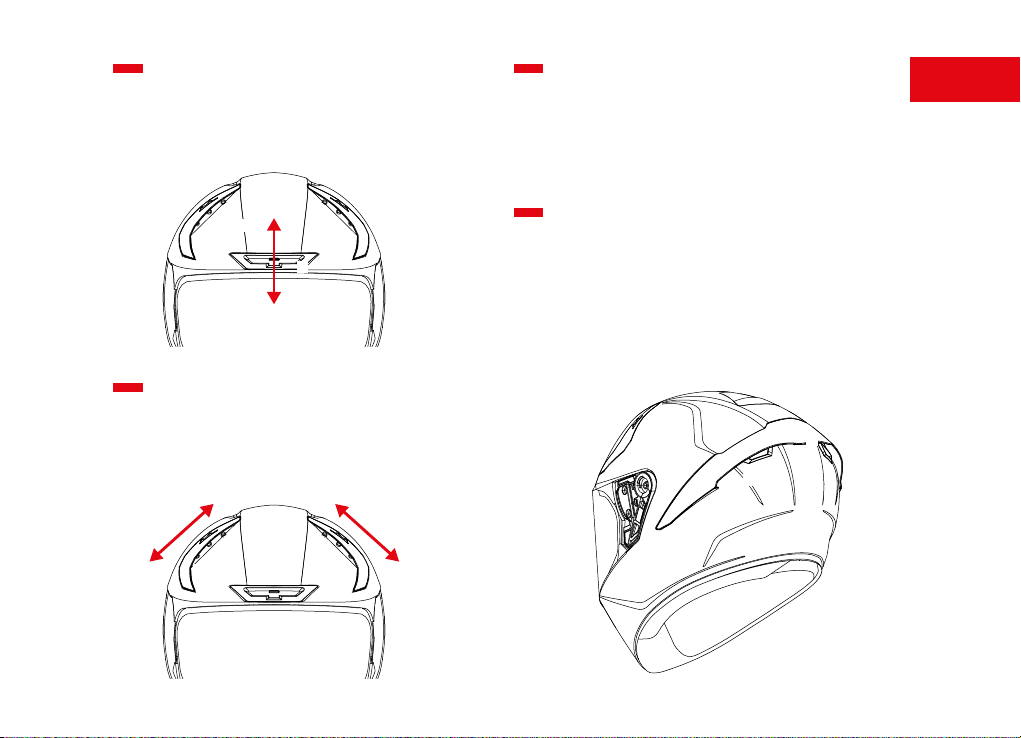

Use

Maintenance

To clean the shell use water and mild soap; let the helmet dry

at room temperature, never expose it to heat.

Cleaning the helmet with solvents, petrol by-products or chemical

substances, the application of stickers or paint could affect the

structure of the shell, thus affecting the safety features, even if the

damage is not readily visible. Do not paint, or apply stickers, petrol

or other chemical solvents to this helmet.

To clean the internal lining, just hand wash at 30°C maximum,

exclusively using mild soap.

To clean the fixed internal lining use a damp cloth and mild soap.

The fabric lining, even if they are part of removable elements, must

not be soaked in water when they are applied to or paired with an

internal padding, either rigid or soft.

Dry the pieces at room temperature, away from sunlight and without

exposing them to heat.

Periodically clean the «D-Rings» system with warm water and mild

soap. Do not use solvents or chemical detergents and do not

lubricate.

Clean the visor as follows:

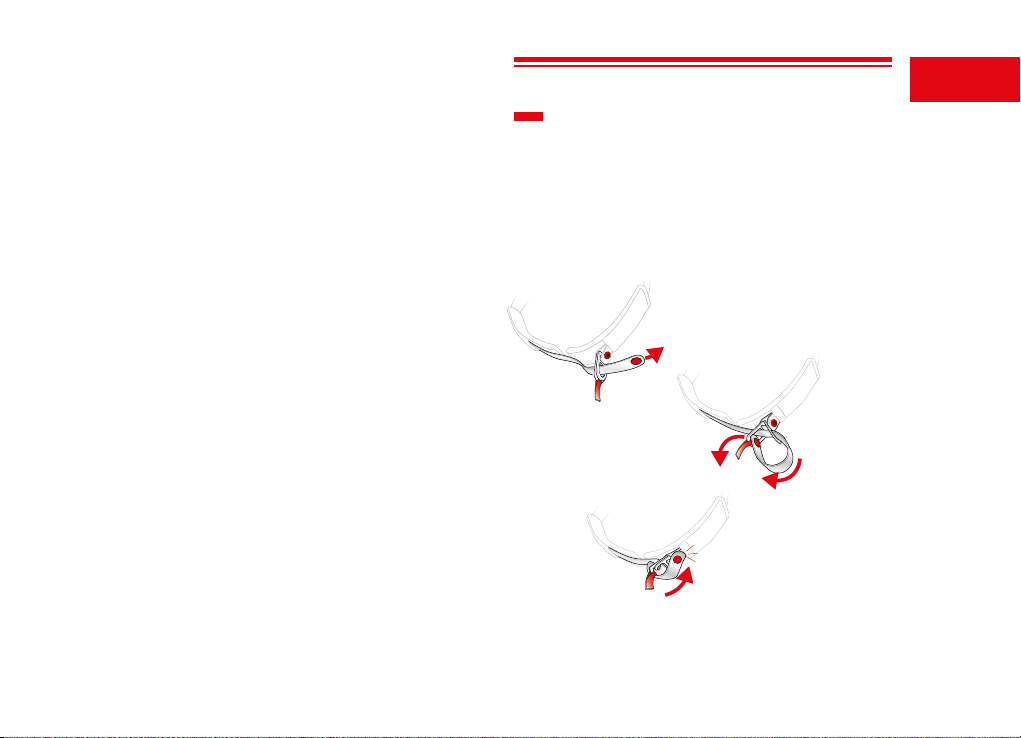

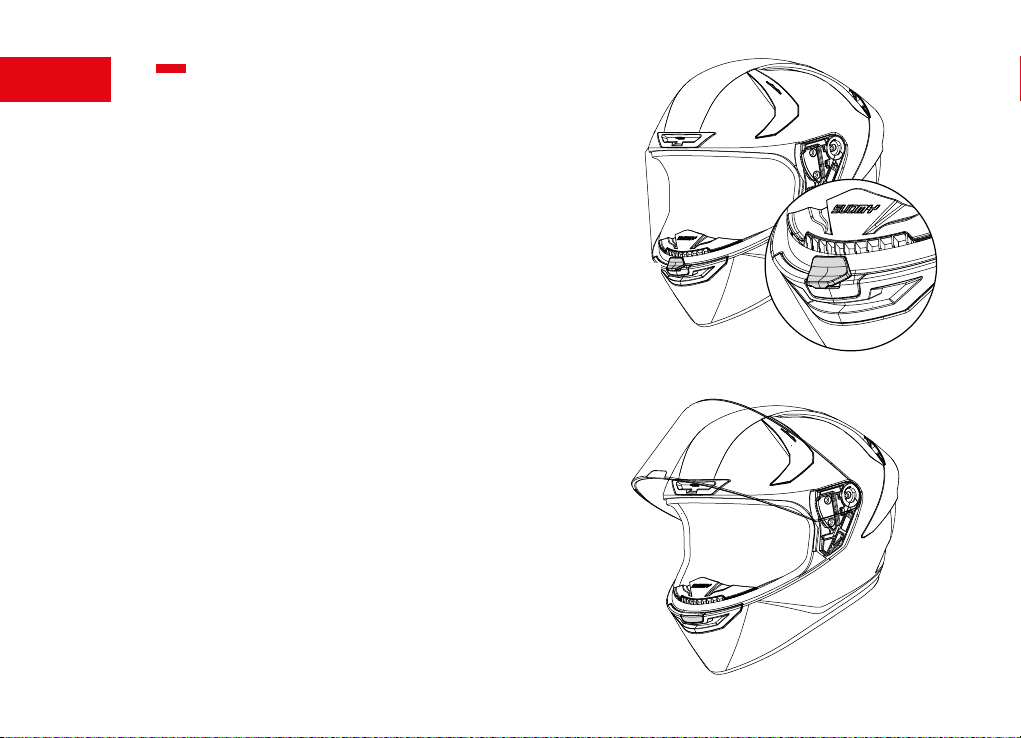

1. Remove the visor from the helmet (see paragraph VISOR -

removal)

2. Rinse it with running warm water only on the outside.

3. Wash the visor with water and mild soap using a soft cloth to

remove the dirt.

4. Rinse with warm water.

5. Dry with a soft and delicate cloth

6. Put the visor back on the helmet (see paragraph VISOR –

Assembly)

Verify that the cloth used does not leave any traces that could stick

to the surface of the visor after washing. Do not use paper cloths to

clean and dry the visor.

Do not expose the visor to heat to dry.

Do not use particular detergents (prepared solutions, creams,

22