2

INSTRUCTION

1. Quality T7075 Aluminum Main Chassis.

2. Quality T7075 Front and Rear Shock Towers.

3. SWORKz S35-3 BBS Race Shock System.

4. High Performance CNC machined Crown Gears and Pinion Gears.

5. F/R Full CVA Drive Shafts.

6. Aluminum Adjustable Front and Rear Lower Plastic Insert Toe-In system.

7. Double Protection Bumper Design.

8. Sealed Front and Rear Arms design.

9. Adjustable Front Upper and Lower Suspension Arm System.

10. S350 Falcon II Pre-painted and Pre-Cut Body Shell (For EP Buggy) is included.

11. 2.4G Radio System (SW-T2 Radio t for AA battery).

12. Comes standard with SWORKz SE-100 100A 1/8 BL ESC (Made by HobbyWing)

13. SWORKz SP-2150 3670 BL MOTOR for 1/8 RTR motor system.

14. SWORKz SES-2S steering servo (with 12kg metal gear) made by the world famous brand SAVOX.

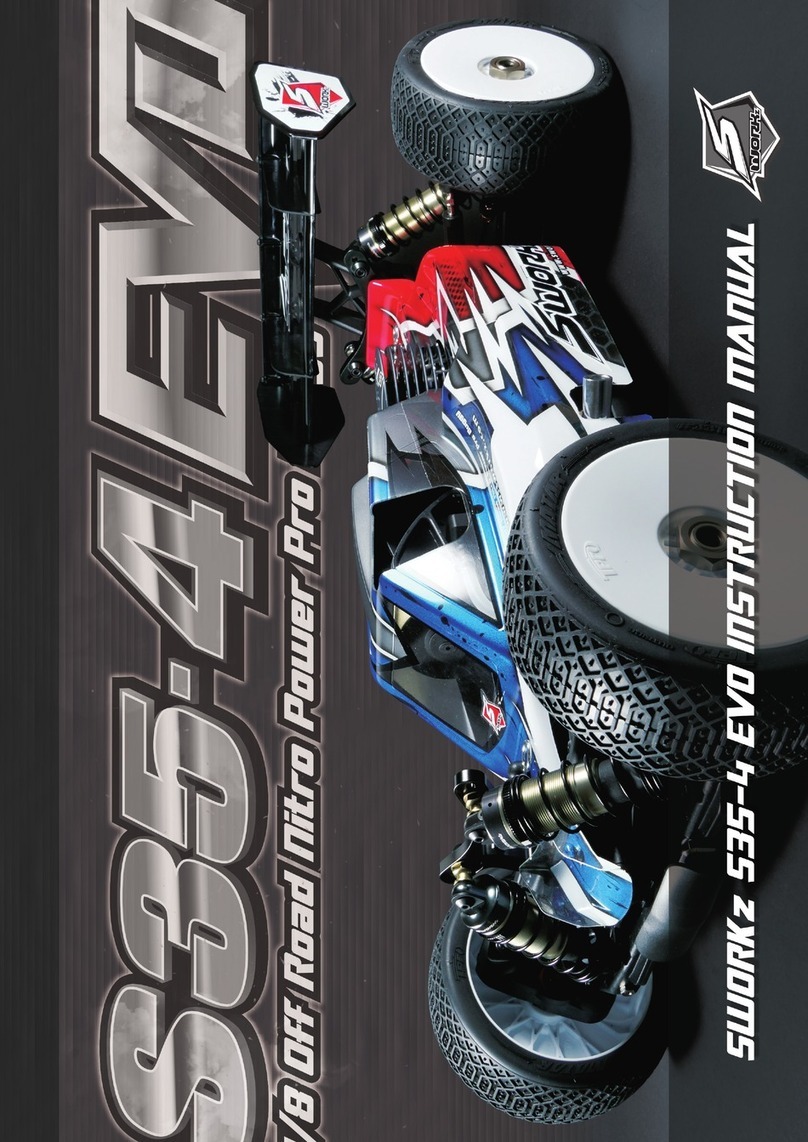

Introducing the new APOLLO II Pro Electric RTR 1/8th scale o-road professional ready to run

buggy from SWORKz. The 1/8th APOLLO II EP buggy is a Pro RTR based on the pro S350 but

with an updated S35-4E buggy center layout.

The APOLLO II EP Buggy incorporates many of the race-inspired features from the S35-3E and

S35-4E Pro Kit. This buggy provides precise feedback, a nimble and balance feel that will suit

drivers of all levels. The SWORKz design team put their eorts into proper weight distribution

for the APOLLO II EP Buggy. Proper weight distribution proved to be instrumental to the setup

during the testing phase of the APOLLO II EP Buggy.

The SWORKz APOLLO II Pro EP RTR buggy comes standard with many high quality parts

like a T7075 aluminum chassis (with the same S35-4E chassis hard coating process), front

and rear shock towers. It also has S35-3E Pro Kit's 16mm BBS Racing Shocks System, High

Performance Crown and Pinion Gears and oil lled dierentials providing traction and balance

on multiple o-road surfaces.

The APOLLO II EP buggy uses the S35-4E center new designed Motor mount makes it possible

to change very easily the motor or adjust the play of the gears.

The pivot ball steering system gives the driver sharp and accurate turning feedbacks. The

APOLLO II EP buggy comes with a race inspired base set up that is easy to drive.

The APOLLO II EP set comes with high quality electronics from HobbyWing (SWORKz SE-100)

100A 1/8 BL ESC and an S-ePOWER SP2150 BL 3670 MOTOR.

The SWORKz SES-2S steering servos (with 12kg metal gears) are made by SAVOX. This RTR

also includes a 2.4G Radio System.

A pre-cut painted body shell is also included.

APOLLO Kit Features: