2

INSTRUCTION

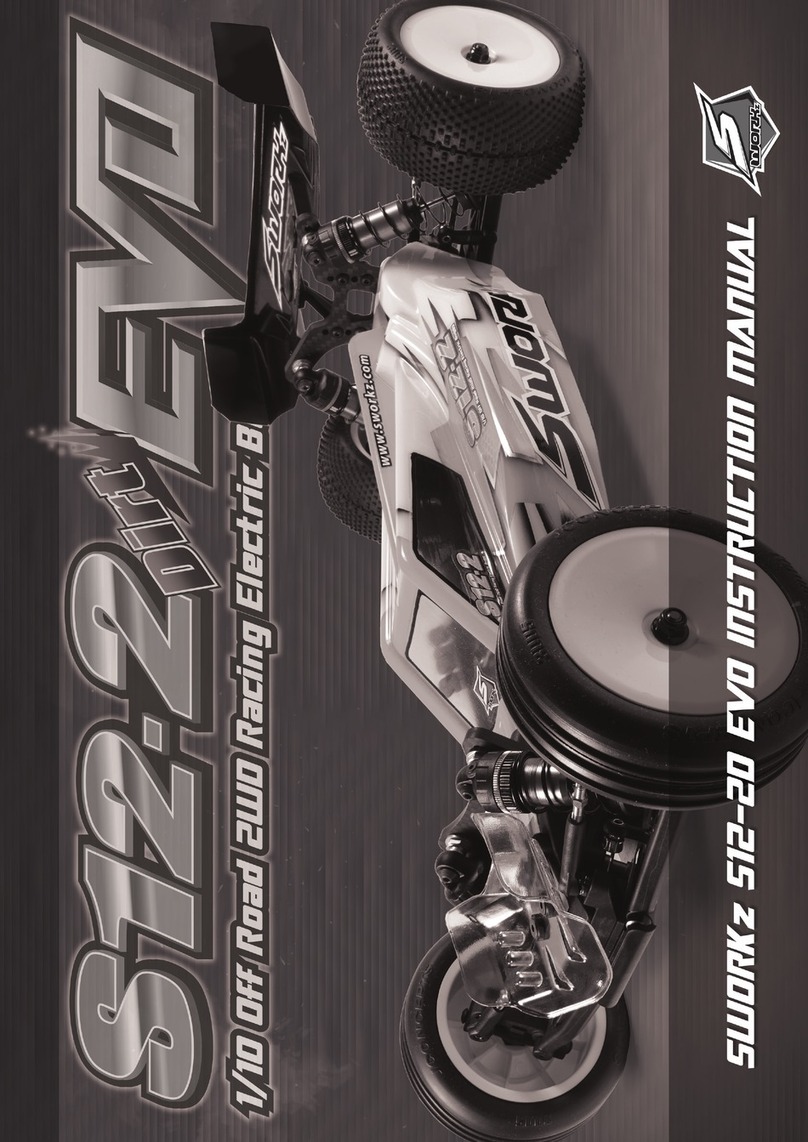

The SWORKz S35-T2 1/8 Nitro Truggy is designed for pure racing. The geometry of the car provides great

corner speed with exceptional traction and easy driving control.

The S35-T2 features a T7075 hard anodized and lightened aluminum wide layout chassis that was tested by

our factory pilots to guarantee best performance.

The newly developed Truggy HET differentials are included and provide traction that was not possible

before.

The new S35-T2 comes with a longer shock layout in the front and rear. The construction of the shocks is

adapted to that new optimized layout. The smart holder for shock spring plates makes it almost impossible

to lose them anymore.

The steering geometry, with new Ackerman and steering plates, gives the driver a feeling of total control

over the SWORKz S35-T2.

With the new toe-in plates, which now contain square inserts, you can adjust the geometry of your

SWORKz S35-T2 to fit every track layout and track condition. The lower arms are made of a newly

developed composite material and t perfectly to the new chassis. Side guards were redesigned as well.

With the new lightened wing support you can adjust various positions and the angle of the wing to give

your SWORKz S35-T2 the best stability on the track. Together with the “Speed Rhinoceros III” body shell,

perfect aerodynamics is achieved.

Another new development in our SWORKz S35-T2 is the totally new rear hub. Made from composite

materials combined with 2 carbon plates gives you the possibility for various setups.

There are many changes and smart ideas put into your new SWORKz S35-T2 that makes the car a real

winner.

The secret of a modern racing car is the possibility to adapt the setup to every track for top pilots but also

have a standard setup that works on most tracks for hobby pilots.

The SWORKz S35-T2 represents these two characteristics in perfection.

The SWORKz development team focused on using materials corresponding to the highest quality

standards when designing the car. You will nd only 100% SWORKz quality in the S35-T2 kit.

Congratulations on your purchase of the new SWORKz S35-T2 1/8 scale o-road racing Truggy pro kit and

thanks for trusting in SWORKz.

Please read this manual carefully, before you start to build and drive your SWORKz S35-T2. This manual

contains step-by-step instructions to helping you completing, preparing and ne tuning your Truggy for

racing. Updates, setups, and product news will be posted on all SWORKz digital media.

As always, if you should ever have any questions or need help with your SWORKz products, please feel

free to contact our ocial SWORKz dealers and distributors.

S35-T2 Kit Features:

• New T7075 Hard Anodized, Lightend Aluminium Chassis

• New Wide Chassis Design

• New Design Shock Towers

• New Shock Caps

• New Fixed Shock Spring Holder

• New 3mm Updated Rear Shock Studs

• New Ackerman Plate

• New Steering System

• New Servo Saver Aluminium Part

• New Servo Saver Fixable Nut

• New Servo Saver Plate

• New Servo Saver Post Locking Design

• New Steering Balls

• New Steering Knuckle Plates

• New Updated Toe-In Plates with Square Inserts

• New Lightweight Wing Mount

• New Side Guards

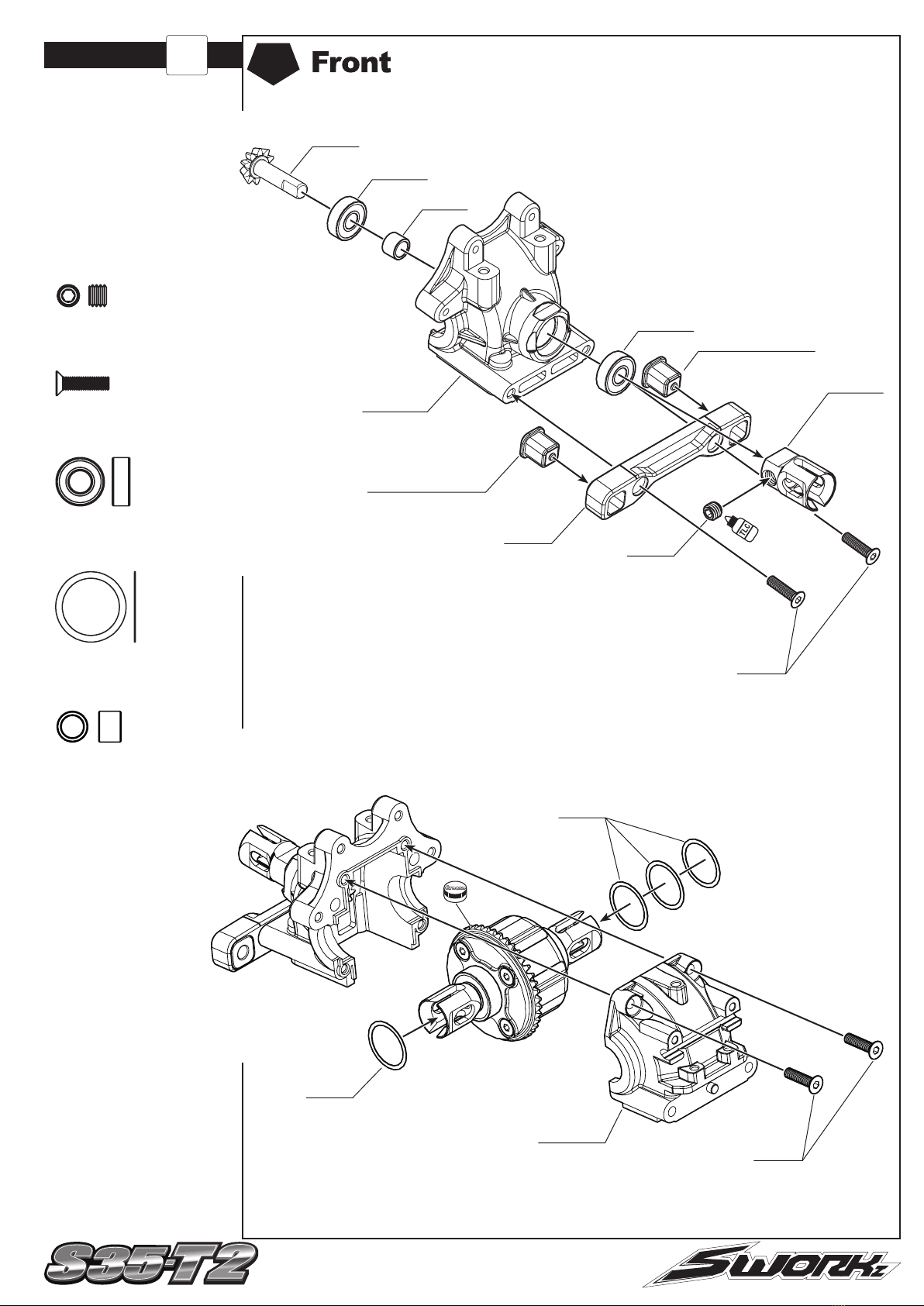

• New Lower Front and Rear Arms

• New Front Upper Arms

• New Body Posts Front and Rear

• New Composite Rear Hubs with Carbon Plates

• New Multi Adjustable Ball System for Rear Upper Arms

• New Anticlock Screws for Shocks

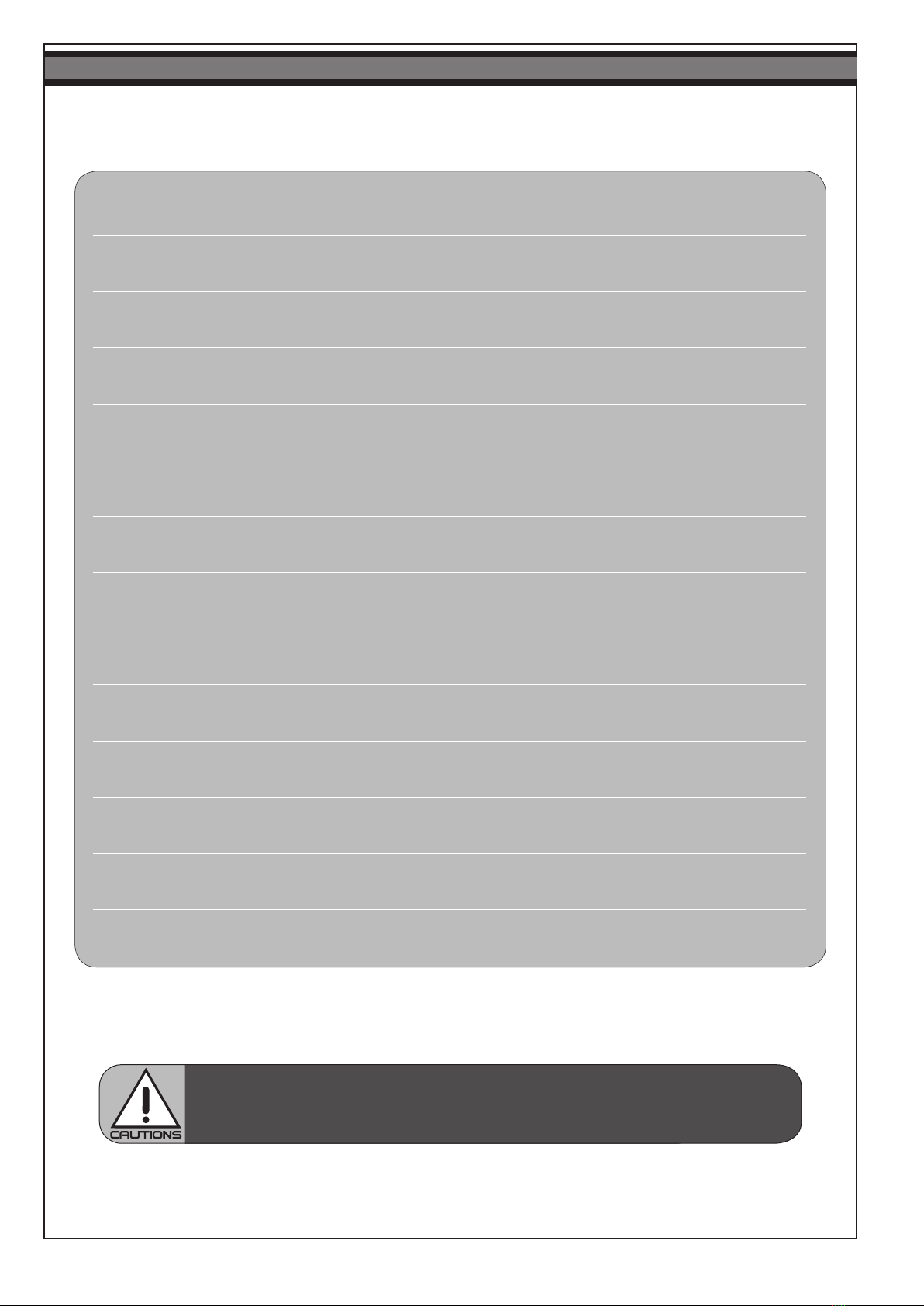

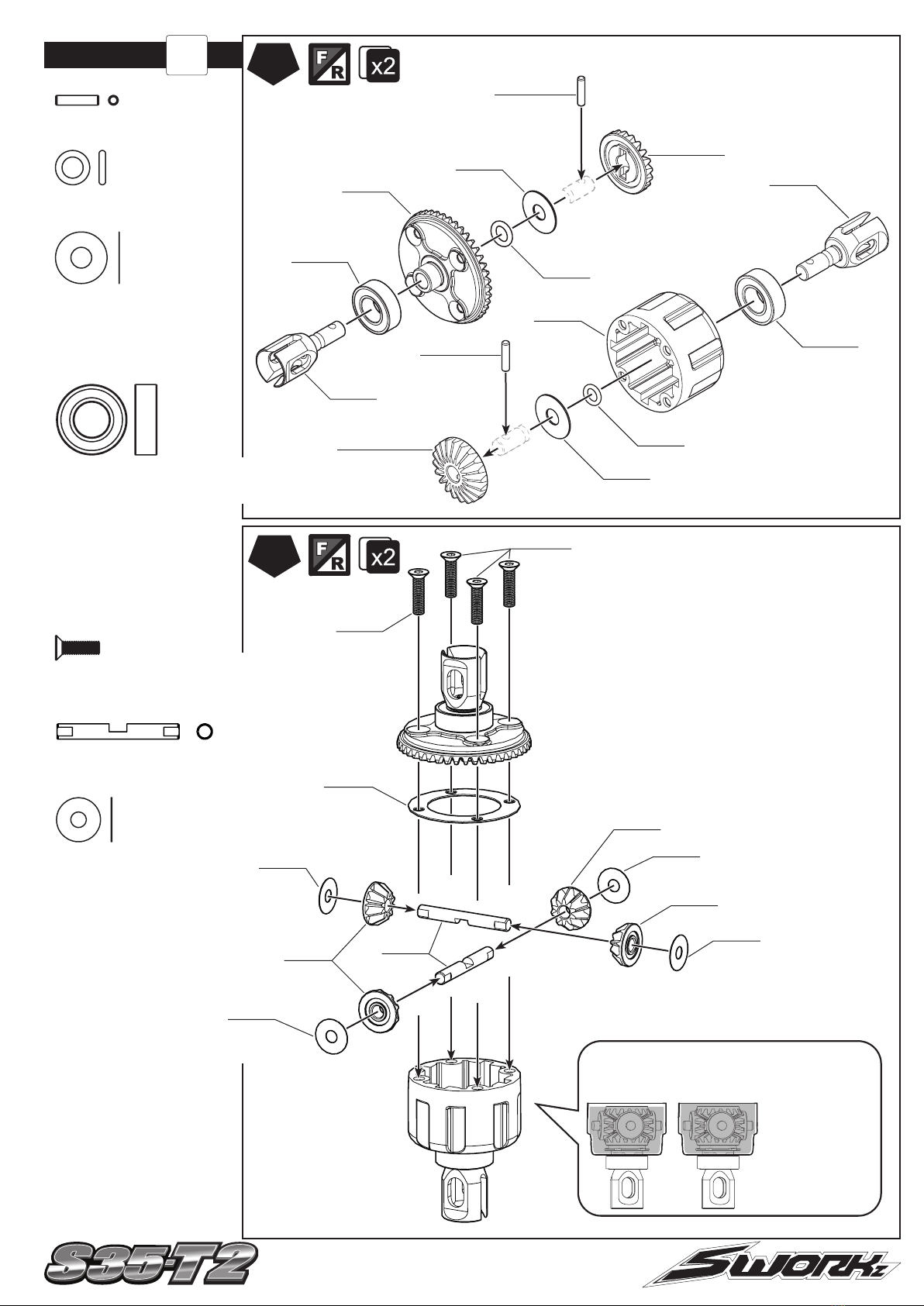

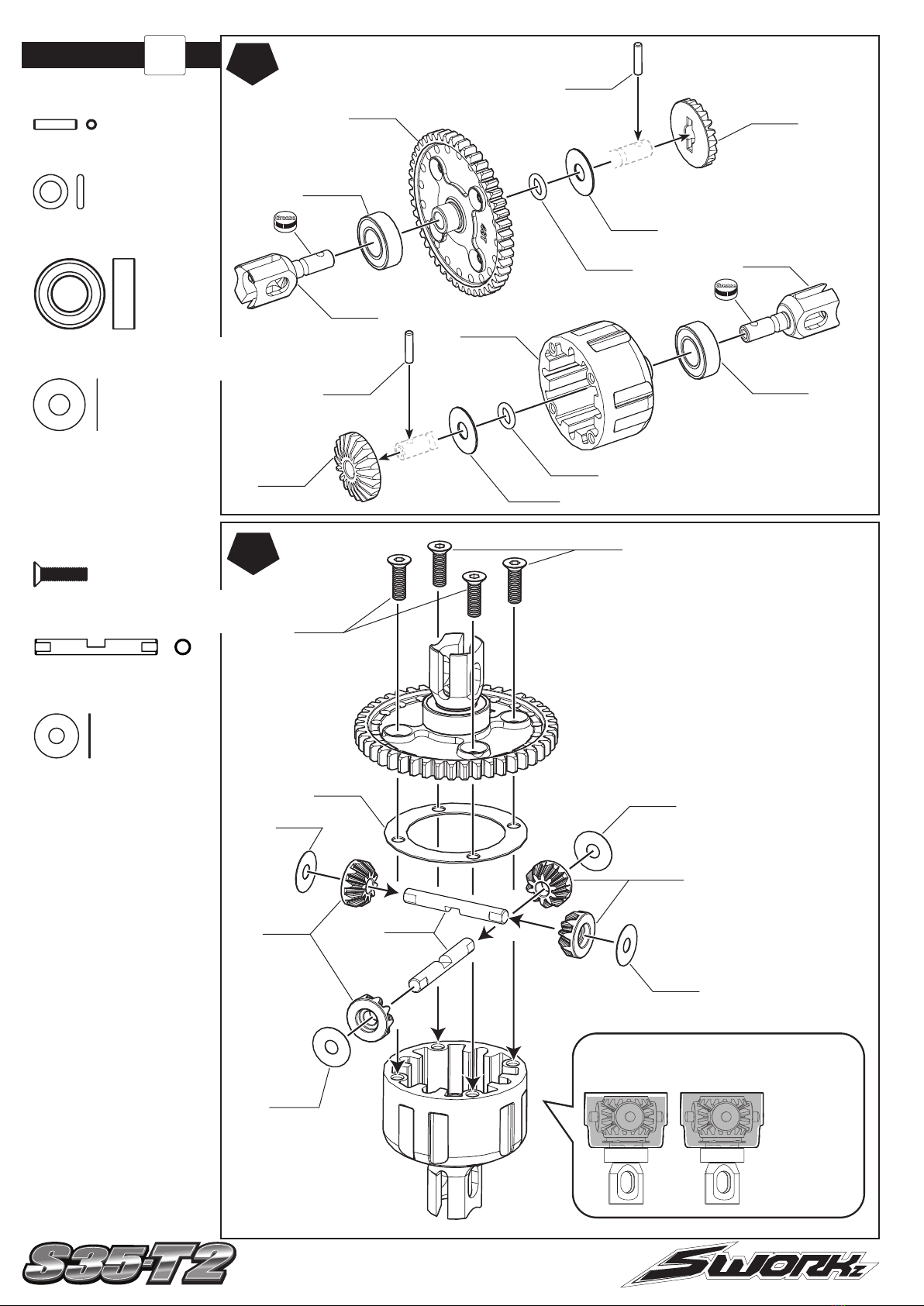

• 3 HET Dierentials Included

• New Front and Rear Universal Cross Drive Shafts

• 2 Front Chassis Braces Included

• Black Competition Shock Springs Included

• Adjustable Wing Position

• Adjustable Wing Angle