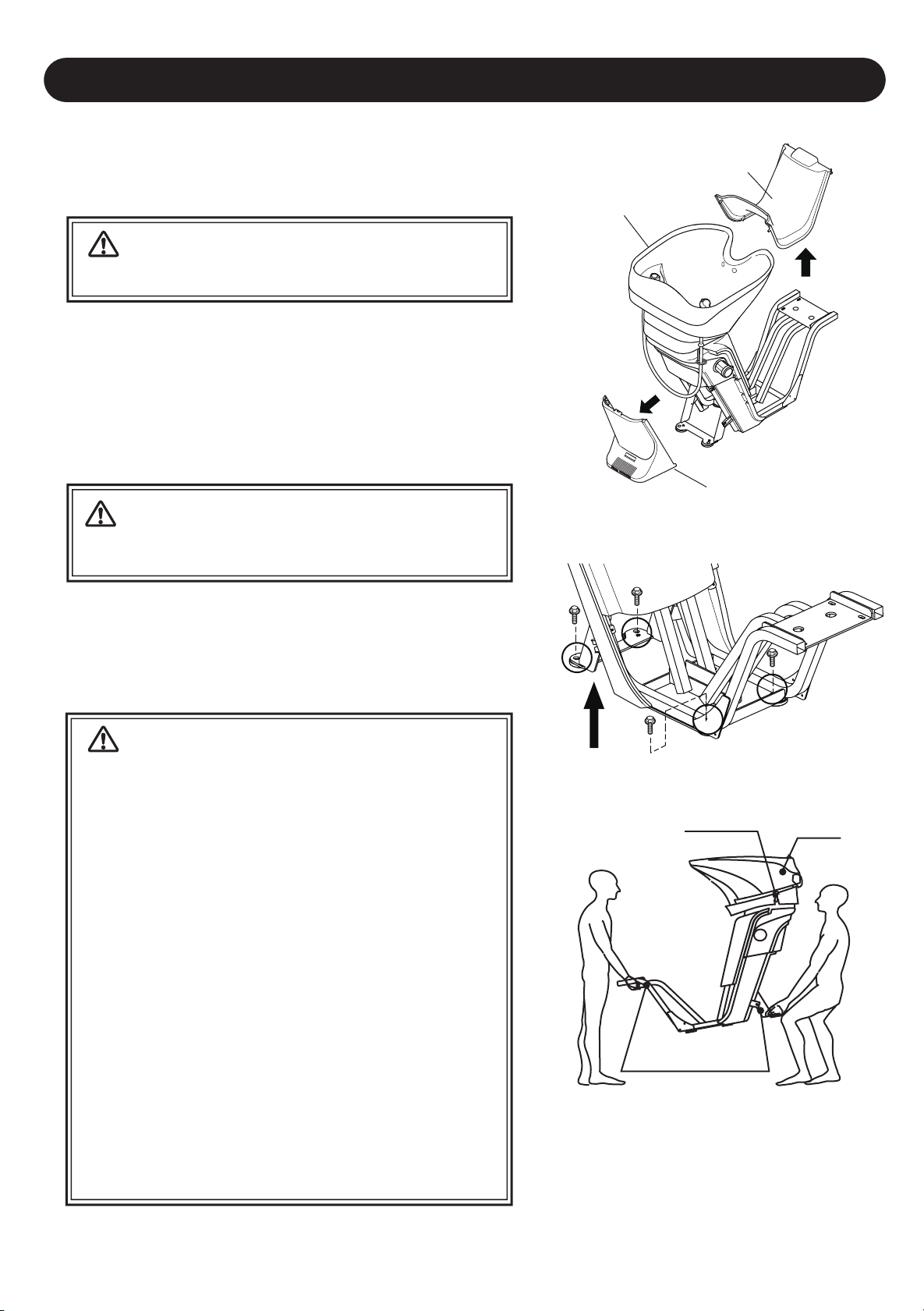

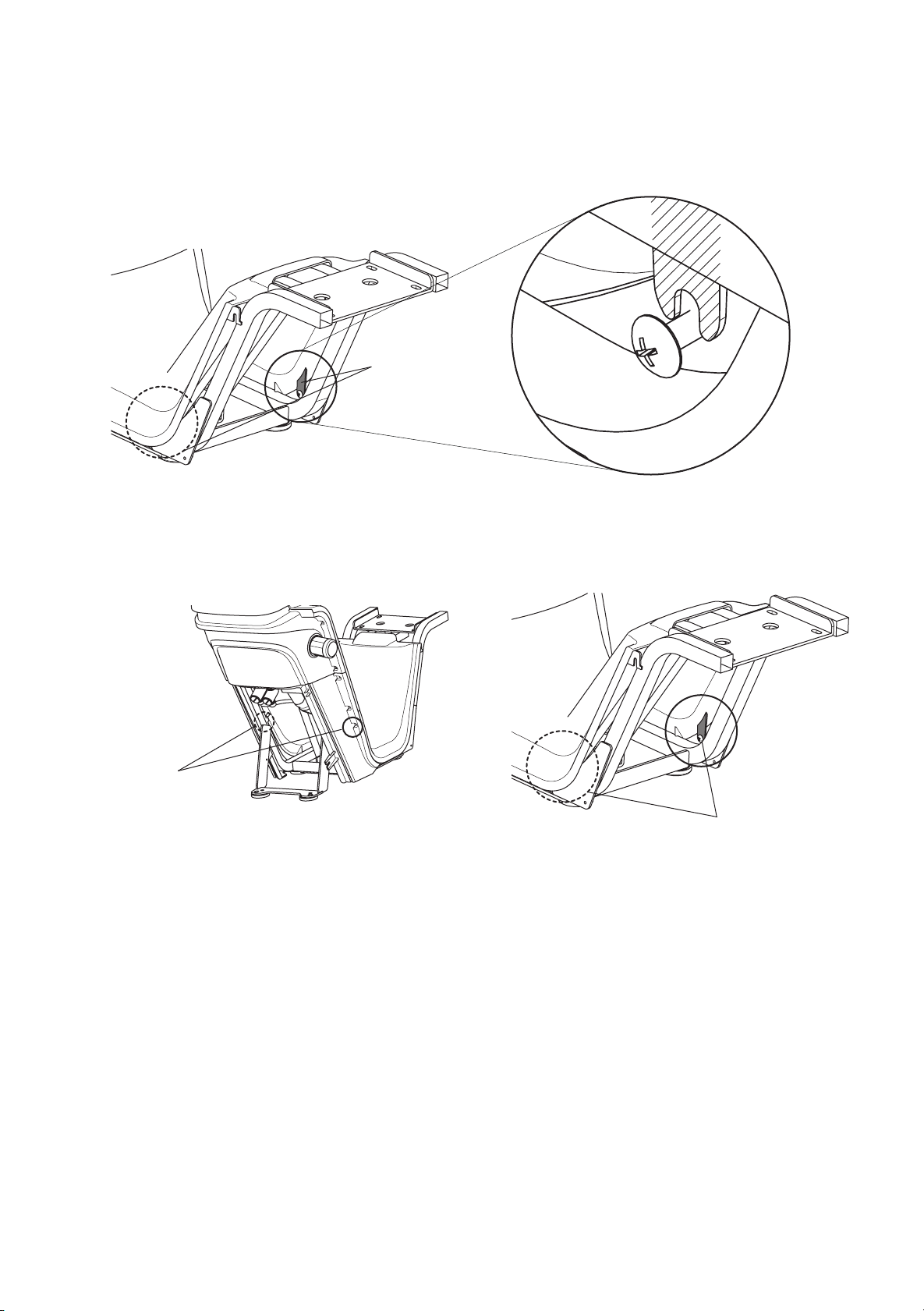

Takara Belmont RS III PRIME User manual

Other Takara Belmont Indoor Furnishing manuals

Takara Belmont

Takara Belmont CLIPPER AY-CLIP User manual

Takara Belmont

Takara Belmont Salon Console User manual

Takara Belmont

Takara Belmont Arcadia Series User manual

Takara Belmont

Takara Belmont EX-ESYMZ User manual

Takara Belmont

Takara Belmont DIVAN-Z AB-DVZF User manual

Takara Belmont

Takara Belmont Yume DX User guide

Takara Belmont

Takara Belmont AUBREY with MAJOLICA PORTO User manual

Takara Belmont

Takara Belmont Compact Hilox SP-PBN User manual

Takara Belmont

Takara Belmont LUAR User manual

Takara Belmont

Takara Belmont Square EPIPHANY User manual

Takara Belmont

Takara Belmont AK-S23S User manual

Takara Belmont

Takara Belmont LUAR AB-MF User manual

Takara Belmont

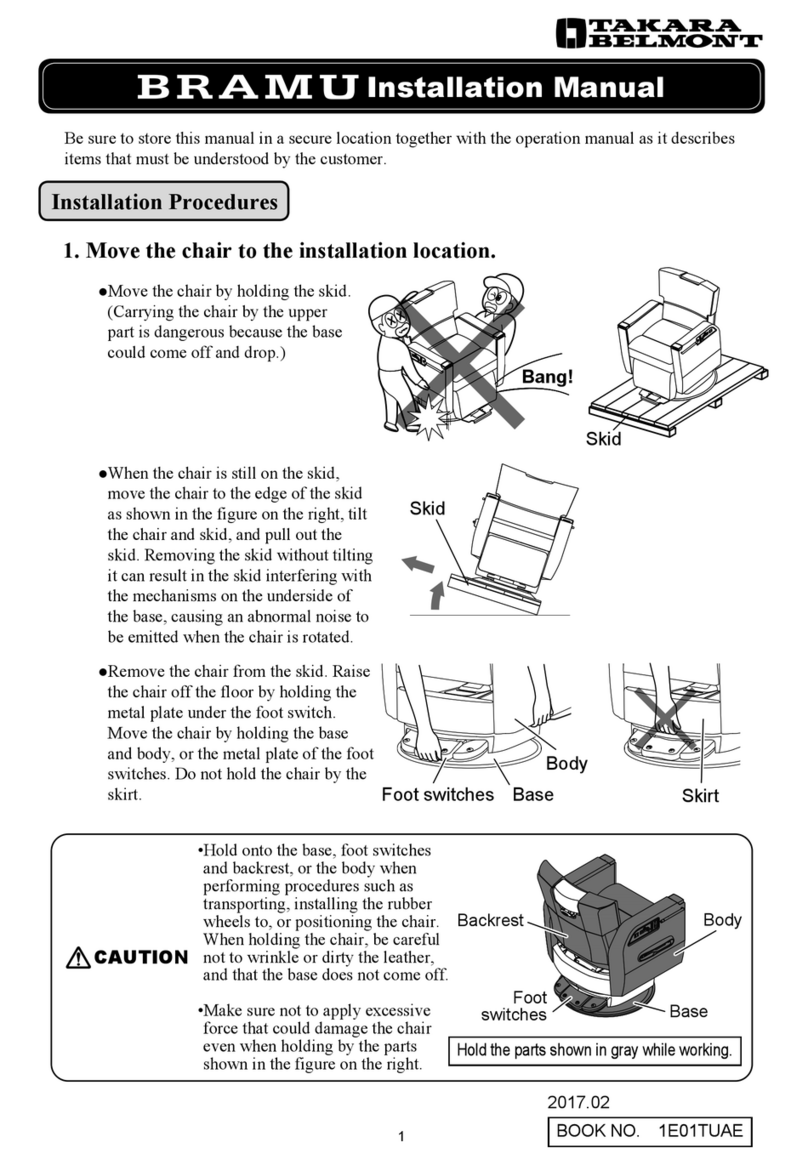

Takara Belmont BRAMU User manual

Takara Belmont

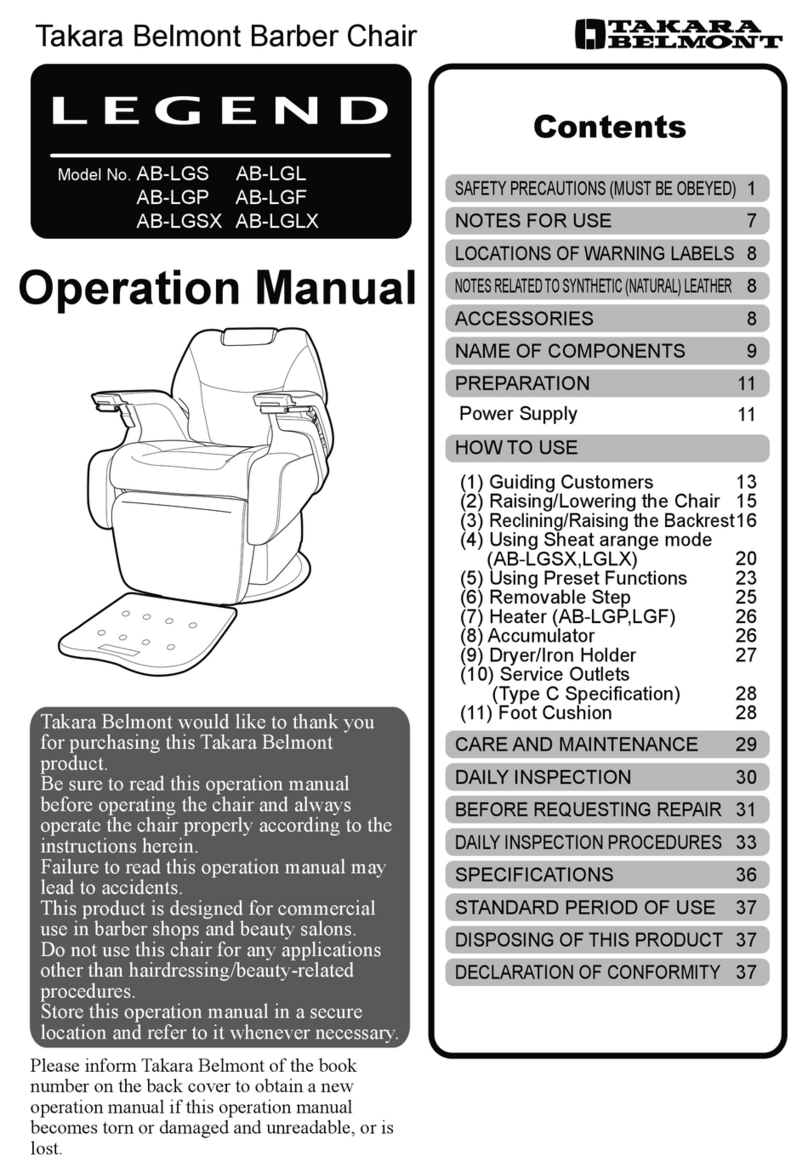

Takara Belmont LEGEND User manual

Takara Belmont

Takara Belmont ALVIS TETRA User manual

Takara Belmont

Takara Belmont BRAMU User manual

Takara Belmont

Takara Belmont Square EPIPHANY User manual

Takara Belmont

Takara Belmont Yume DX User manual

Takara Belmont

Takara Belmont apollo 2 User manual

Takara Belmont

Takara Belmont LEGEND AB-LGF User manual

Popular Indoor Furnishing manuals by other brands

Coaster

Coaster 4799N Assembly instructions

Stor-It-All

Stor-It-All WS39MP Assembly/installation instructions

Lexicon

Lexicon 194840161868 Assembly instruction

Next

Next AMELIA NEW 462947 Assembly instructions

impekk

impekk Manual II Assembly And Instructions

Elements

Elements Ember Nightstand CEB700NSE Assembly instructions