Contents

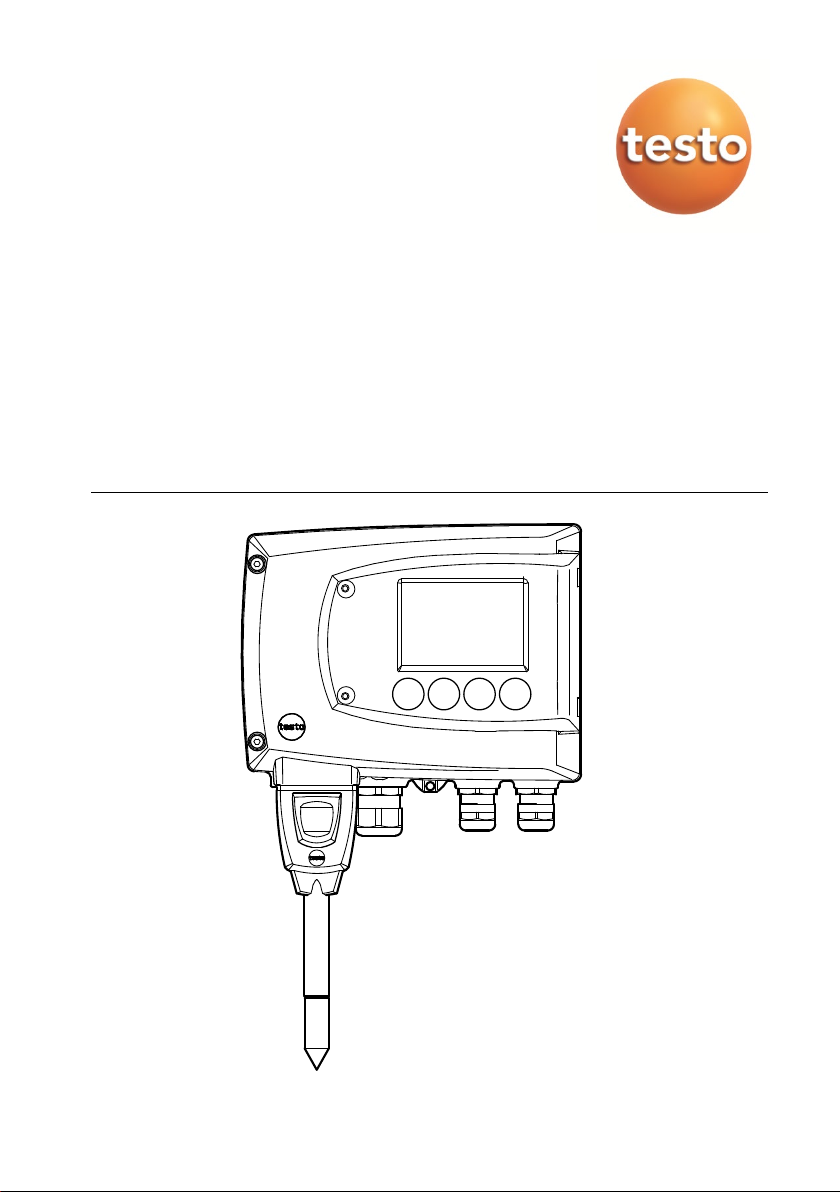

2TESTO 6610 PROBES ............................................................................... 73

2.1 Specifications......................................................................................... 73

2.1.1 Functions and use.....................................................................73

2.1.2 Design of the probe ...................................................................75

2.1.3 Accessories...............................................................................76

2.2 Product description ................................................................................76

2.2.1 Overview of probe and filter types ............................................76

2.2.2 testo 6611 wall probe ................................................................ 81

2.2.3 testo 6612 duct probe ...............................................................84

2.2.4 testo 6613 cable probe..............................................................88

2.2.5 testo 6614 heated cable probe .................................................92

2.2.6 testo 6615 trace humidity cable probe (self-adjustment) ..........95

2.2.7 testo 6617 cable probe (self-monitoring) ..................................99

2.3 Commissioning ....................................................................................103

2.3.1 Installing the probe..................................................................103

2.3.2 Connecting/removing the probe to/from the transmitter .........107

2.4 Maintenance and cleaning................................................................... 107

2.4.1 Replacing filters/protection caps .............................................107

2.4.2 Cleaning the instrument and filter/protection cap ...................110

2.4.3 Replacing the sensor ..............................................................110

3PARAMETERIZING,ADJUSTING AND ANALYZING SOFTWARE (P2A SOFTWARE)

............................................................................................................. 111

3.1 Specifications....................................................................................... 111

3.1.1 Functions and use...................................................................111

3.1.2 System requirements ..............................................................112

3.1.3 Scope of delivery.....................................................................113

3.2 First steps ............................................................................................ 113

3.2.1 Installing the software/driver ...................................................113

3.2.2 Starting the software ...............................................................114

3.3 Using the software ...............................................................................115

3.3.1 User interface.......................................................................... 115

3.3.2 Editing instrument/parameter file ............................................117

3.3.3 Analyzing/testing the transmitter .............................................127

3.3.4 Adjusting the transmitter .........................................................133

3.3.5 Transmitter history ..................................................................138