3 Contents

5

Pos: 17 /TD/Übersc hriften/MUF/Inhal t @ 3\mod_1234794019831_ 79.doc @ 26261 @ 1

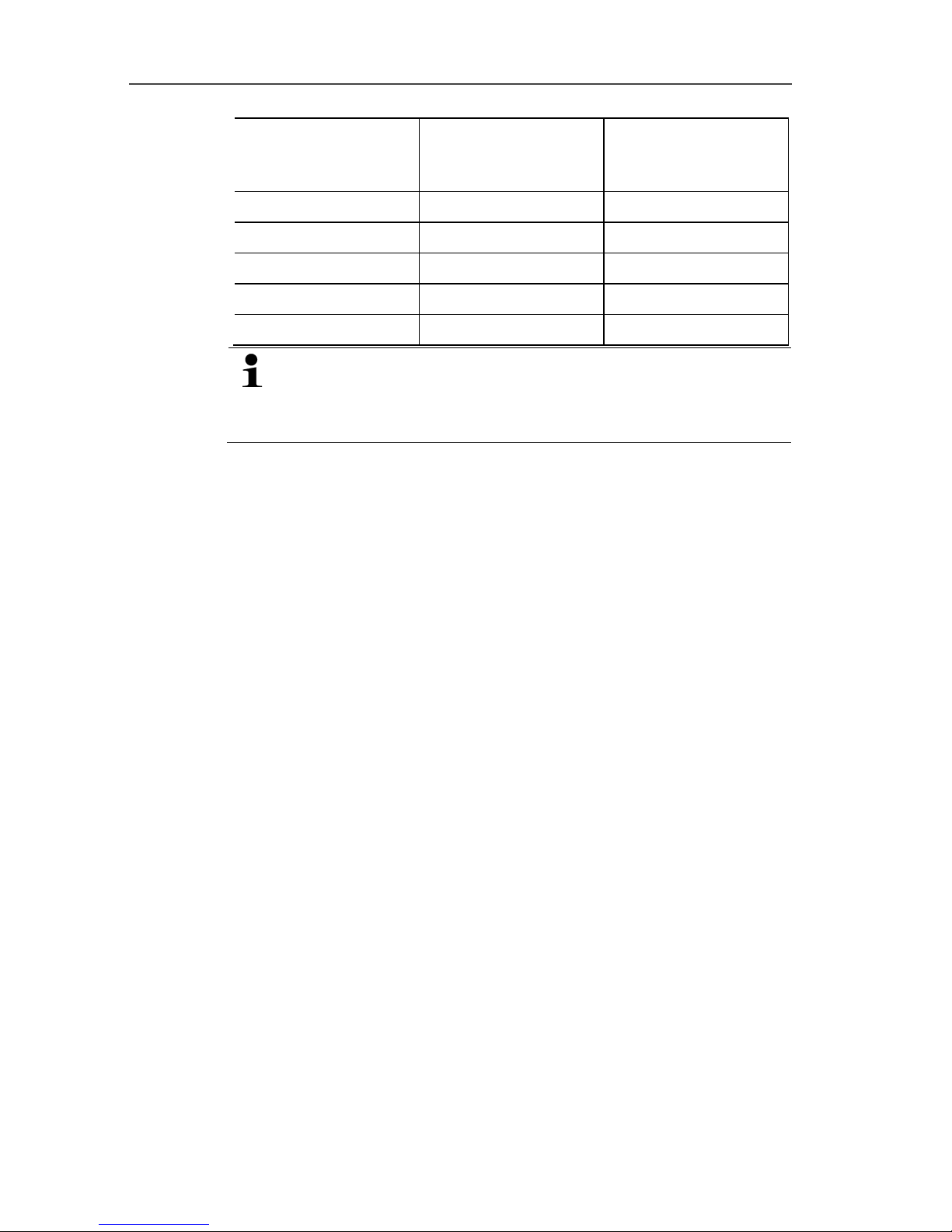

3Contents

1Safety and the environment....................................................................3

2About this document...............................................................................4

3Contents ...................................................................................................5

4Transmitter...............................................................................................7

4.1. Specifications ..................................................................................7

4.1.1. Functions and use ...........................................................................................7

4.1.2. Scope of delivery .............................................................................................7

4.1.3. Dimensions......................................................................................................7

4.1.4. Technical data .................................................................................................7

4.2. Product description........................................................................11

4.2.1. At a glance.....................................................................................................11

4.2.2. Scaling .........................................................................................................12

4.3. Commissioning ..............................................................................13

4.3.1. Assembling the instrument.............................................................................13

4.3.1.1. Wall mounting ...................................................................................13

4.3.2. Wiring the instrument.....................................................................................14

4.3.2.1. 4-wire system....................................................................................16

4.3.2.2. 3-wire system....................................................................................16

4.4. Maintenance and cleaning.............................................................17

4.4.1. Cleaning housing ...........................................................................................17

4.4.2. Namur fault conditions ...................................................................................17

5Parameterizing, adjusting and analyzing software (P2A software)...18

5.1. Specifications ................................................................................18

5.1.1. Functions and use .........................................................................................18

5.1.2. System requirements.....................................................................................19

5.1.3. Scope of delivery ...........................................................................................19

5.2. First steps......................................................................................20

5.2.1. Installing the software/driver ..........................................................................20

5.2.1.1. Installing P2A software......................................................................20

5.2.1.2. Installing USB driver .........................................................................20

5.2.1.3. P2A software upgrade ......................................................................20

5.2.2. Starting the software......................................................................................20

5.2.2.1. Starting the program .........................................................................20

5.2.2.2. Establishing a connection with the instrument...................................21

5.2.2.3. Activating the connection with the instrument....................................21