43

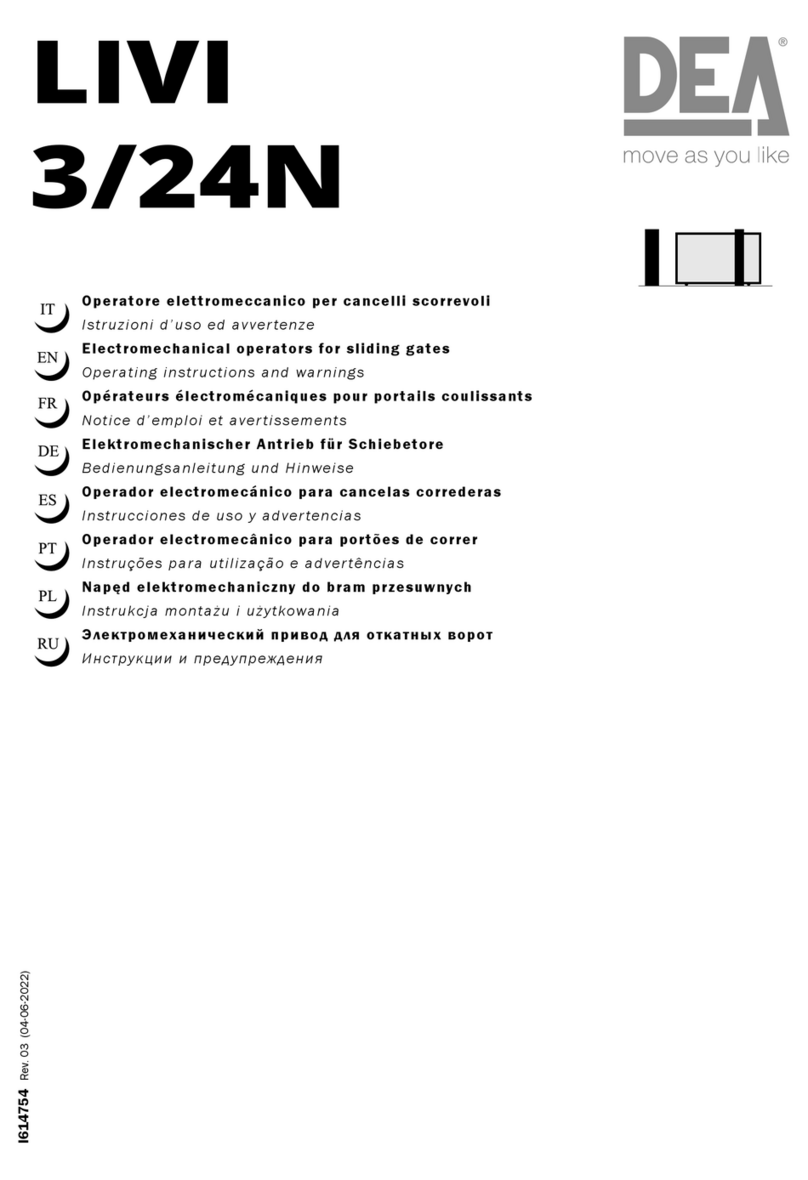

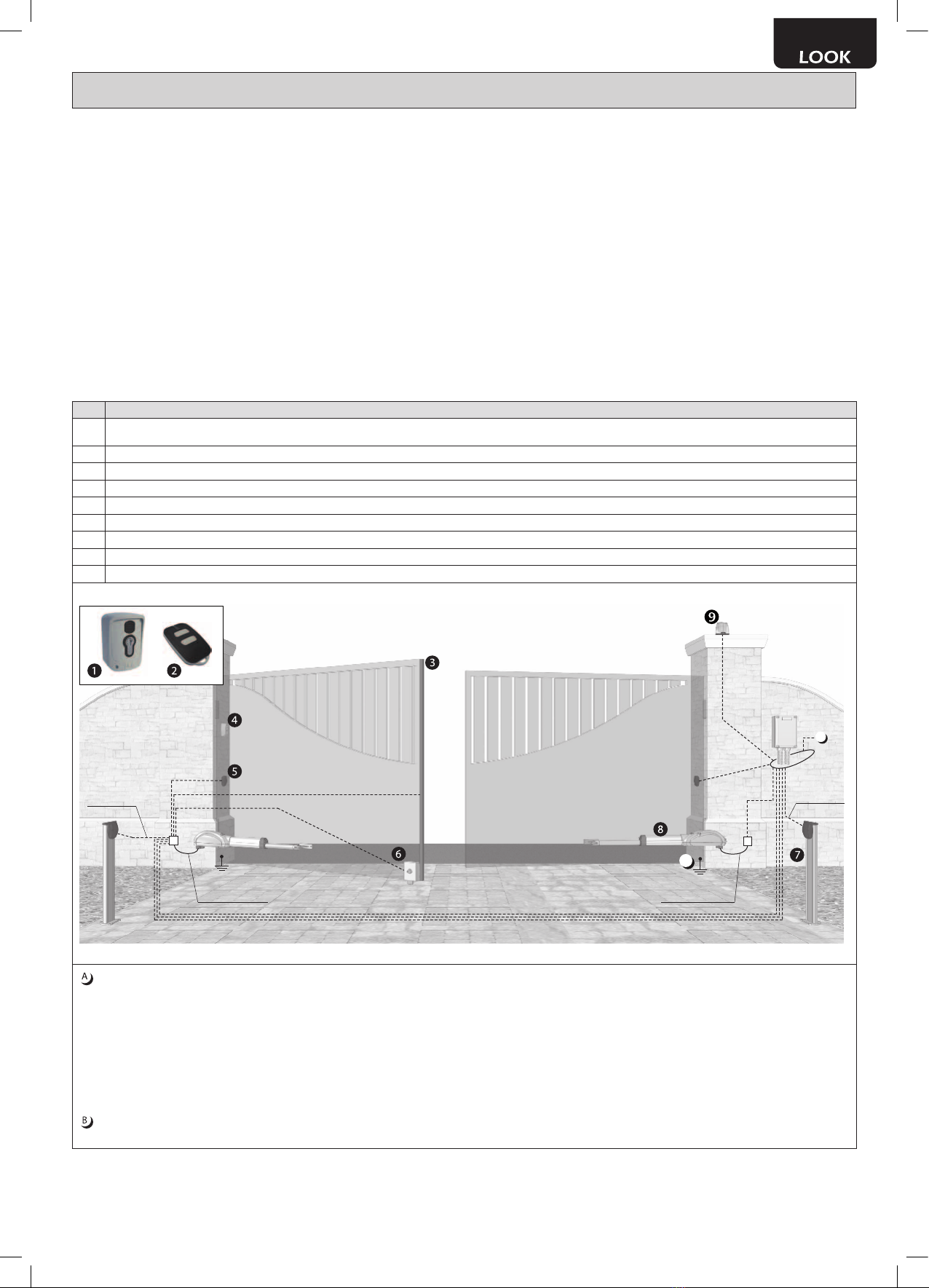

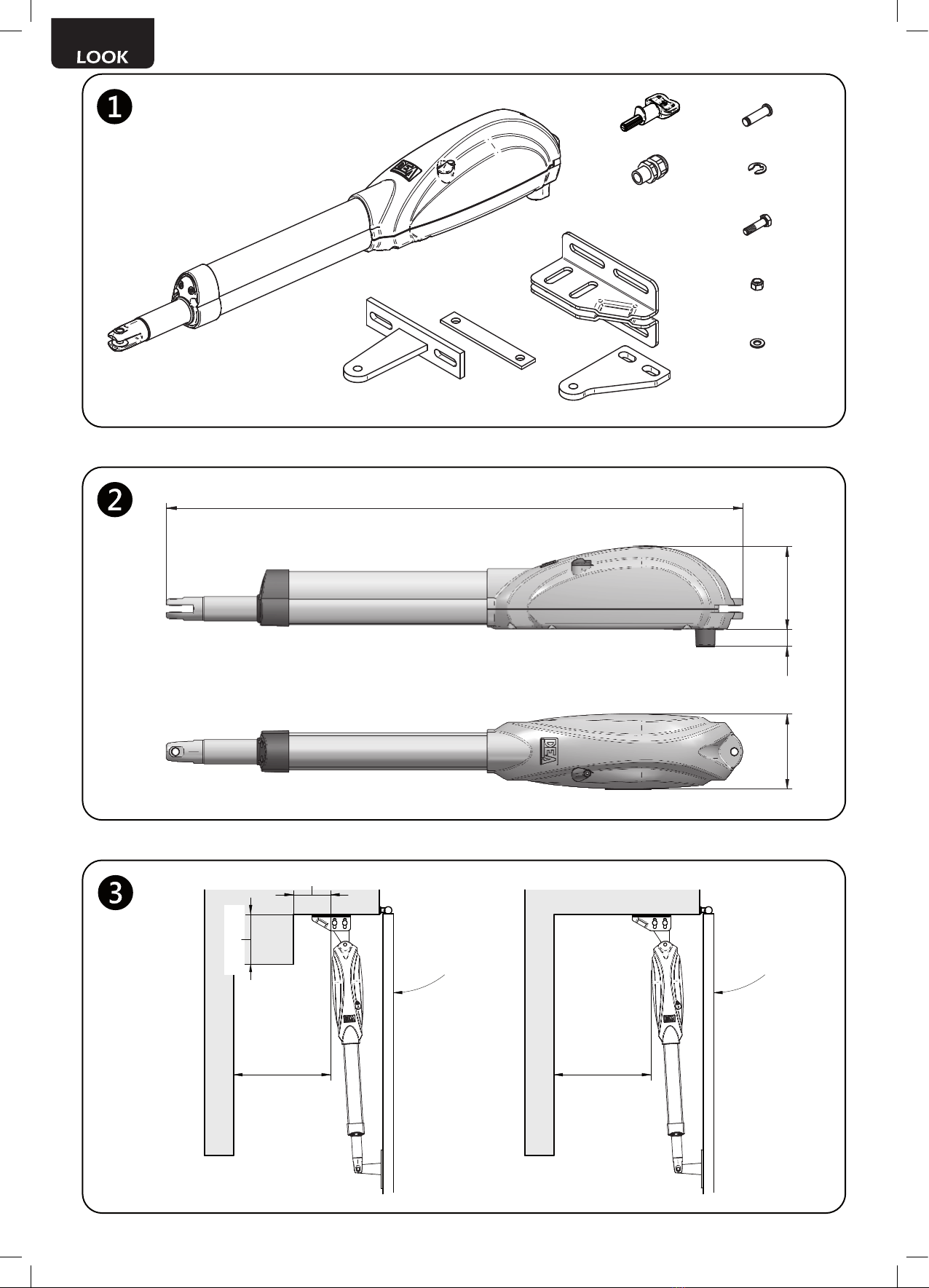

Esempio di installazion tipica - Example of typical installation - Exemple d’installation typique - Installationsbeispiel - Ejemplo de insta-

lación típica - Exemplo de instalação típica - Przyład standardowego systemu automatyzacji

Pos. Descrizione - Description - Description - Beschreibung - Descripción - Descrição - Opis

1Selettore a chiave antiscasso - Anti lock-picking key switch - Sélecteur à clé anti-intrusion - Einbruchfester Schlüsselschalter - Selector a llave antisabotaje - Interruptor de chave

burglar - Przełącznik kluczowy wandaloodporny

2Radiocomando - Remote-control - Radiocommande - Funksteuerung - Radiocomando - Comando via rádio - Nadajnik

3Safety edge - Bord sensible - Berührungssensible Schaltleiste - Borde sensible - Dispositivo sensível de protecção - Listwa bezpieczeństwa

4Selettore digitale - Radio keypad - Digicode radio - Digitalwahlschalter - Teclado digital radio - Teclado via radio - Bezprzewodowa klawiatura

5Fotocellule - Photocells - Photocellules - Fotozellen - Fotocélulas - Fotocélulas - Fotokomórki

6Elettroserratura - Electric lock - Électroserrure - Elektroschloss - Electrocerradura - Fechadura eléctrica - Elektozamek

7Colonnina Pilly 60 - Pilly 60 column - Colonnette Pilly 60 - Kleine Säule Pilly 60 - Columna Pilly 60 - Coluna Pilly 60 - Kolumienka Pilly 60

8LOOK

9Lampeggiante - Flashing light - Clignotant - Blinker - Lámpara - Intermitente - Lampa Ostrzegawcza

B

A

4 x 0,5 mm²

2 x 0,5 mm²

4x1,5 mm² (230V) o 3x1,5 mm² (24V) - 6 x 0,5 mm²

2 x 0,5 mm² - RG58

4 x 0,5 mm²

2 x 0,5 mm²

2 x 1,5 mm² 2 x 0,5 mm²

4 x 1 mm² (230V)

3 x 1 mm² (24V)

4 x 1 mm² (230V)

3 x 1 mm² (24V)

Collegarsi alla rete 230 V ± 10% 50-60 Hz tramite un interruttore onnipolare o altro dispositivo che assicuri la onnipolare disinserzione della rete, con

una distanza di apertura dei contatti ≥ 3 mm - Make the 230V ± 10% 50-60 Hz mains connection using an omnipolar switch or any other device that

guarantees the omnipolar disconnection of the mains network with a contact opening distance of 3 mm - Connectez-vous au réseau 230 V ± 10% 50-60

Hz au moyen d’un interrupteur omnipolaire ou d’un autre dispositif qui assure le débranchement omnipolaire du réseau, avec un écartement des contacts

égal à 3 mm. - Den Anschluss an das 230 V ~ ± 10% 50-60 Hz Netz mit einem Allpolschalter oder einer anderen Vorrichtung vornehmen, durch die eine

allpolige Netzunterbrechung bei einem Öffnungsabstand der Kontakte von ≥ 3 mm gewährleistet wird. - Efectuar la conexión a una línea eléctrica 230

V ± 10% 50-60 Hz a través de un interruptor omnipolar u otro dispositivo que asegure la omnipolar desconexión de la línea, con 3 mm de distancia de

abertura de los contactos. - Ligue na rede de 230 V. ± 10% 50-60 Hz mediante um interruptor omnipolar ou outro dispositivo que assegure que se desliga

de maneira omnipolar da rede, com abertura dos contactos de pelo menos 3 mm. de distância - Podłączyć się do sieci 230 V ± 10% 50-60 Hz poprzez

przełącznik jednobiegunowy lub inne urządzenie które zapewni brak zakłóceń w sieci, przy odległości między stykami ≥ 3 mm.

Collegare a terra tutte le masse metalliche - All metal parts must be grounded - Connectez toutes les masses métalliques à la terre - Alle Metallteile erden

- Conectar con la tierra todas las masas metálicas - Realize ligação à terra de todas as massas metálicas - Uziemić wszystkie elementy metalowe.

DEA System fornisce queste indicazioni che si possono ritenere valide per un

impianto tipo ma che non possono essere complete. Per ogni automatismo, in-

fatti, l’installatore deve valutare attentamente le reali condizioni del posto ed i

requisiti dell’installazione in termini di prestazioni e di sicurezza; sarà in base

a queste considerazioni che redigerà l’analisi dei rischi e progetterà nel detta-

glio l’automatismo. - DEA System provides the following instructions which are

valid for a typical system but obviously not complete for every system. For each

automatism the installer must carefully evaluate the real conditions existing

at the site. The installation requisites in terms of both performance and safety

must be based upon such considerations, which will also form the basis for

the risk analysis and the detailed design of the automatism. - DEA System

fournit ces indications que vous pouvez considérer comme valables pour une

installation-type, même si elles ne peuvent pas être complètes. En effet, pour

chaque automatisation, l’installateur doit évaluer attentivement les conditions

réelles du site et les pré-requis de l’installation au point de vue performances

et sécurité ; c’est sur la base de ces considérations qu’il rédigera l’analyse des

risques et qu’il concevra l’automatisation d’une manière détaillée. - Diese An-

gaben von DEA System können als gültig für eine Standardanlage angesehen

werden, können aber nicht erschöpfend sein. So muss der Installationsfach-

mann für jedes Automatiksystem sorgfältig die Voraussetzungen des Installa-

tionsortes sowie die Leistungs- und Sicherheitsanforderungen an die Instal-

lation abwägen; aufgrund dieser Überlegungen muss er die Risikobewertung

erstellen und genau das Automatiksystem entwickeln. - DEA System facilita

estas indicaciones que pueden considerarse válidas para una instalación tipo

pero que no pueden considerarse completas. El instalador, en efecto, tiene

que evaluar atentamente para cada automatismo las reales condiciones del

sitio y los requisitos de la instalación por lo que se reere a prestaciones y se-

guridad; en función de estas consideraciones redactará el análisis de riesgos

y efectuará el proyecto detallado del automatismo. - DEA System fornece estas

indicações que podem ser consideradas válidas para o equipamento padrão,

mas que podem não ser completas. Para cada automatismo praticamente

o técnico de instalação deverá avaliar com atenção as condições reais do

sítio e os requisitos da instalação em termos de performance e de segurança;

será em função destas considerações que realizará uma análise dos riscos e

projectará. - DEA System dostarcza wskazówek, do wykorzystania w typowej

instalacji ale nie będą one nigdy kompletne. Dla każdego typu automatyki,

instalator musi sam oszacować realne warunki miejsca montażu i wymogi in-

stalacyjne mając na uwadze przepisy dotyczące bezpieczeństwa. Na podsta-

wie zebranych informacji będzie w stanie przeanalizować zagrożenia mogące

wystąpić i zaprojektować w szczegółach automatyzację.