Turnstone Crank User manual

Other Turnstone Indoor Furnishing manuals

Turnstone

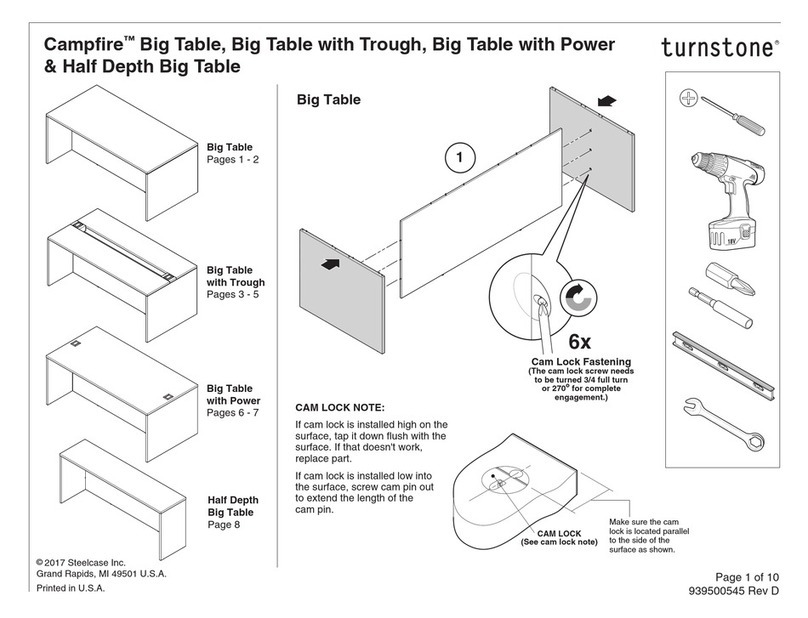

Turnstone Campfire User manual

Turnstone

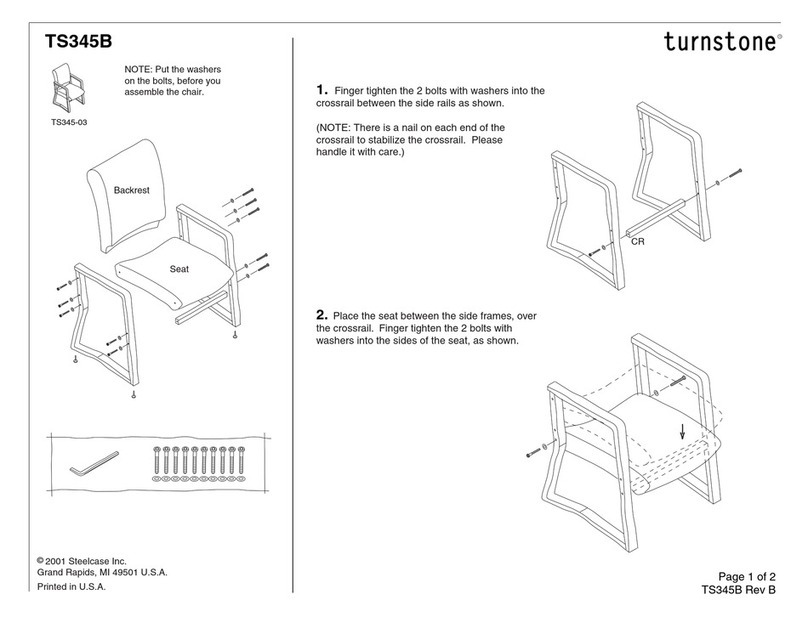

Turnstone TS345B User manual

Turnstone

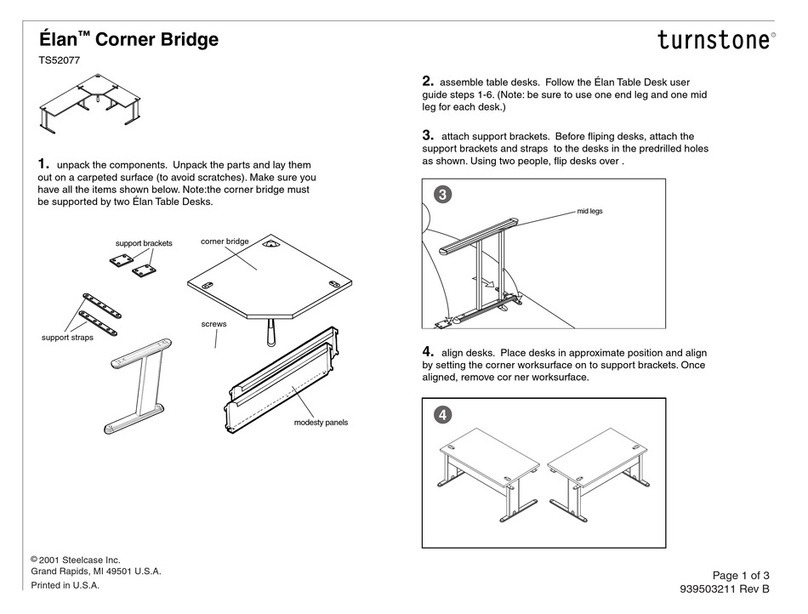

Turnstone Elan TS52077 User manual

Turnstone

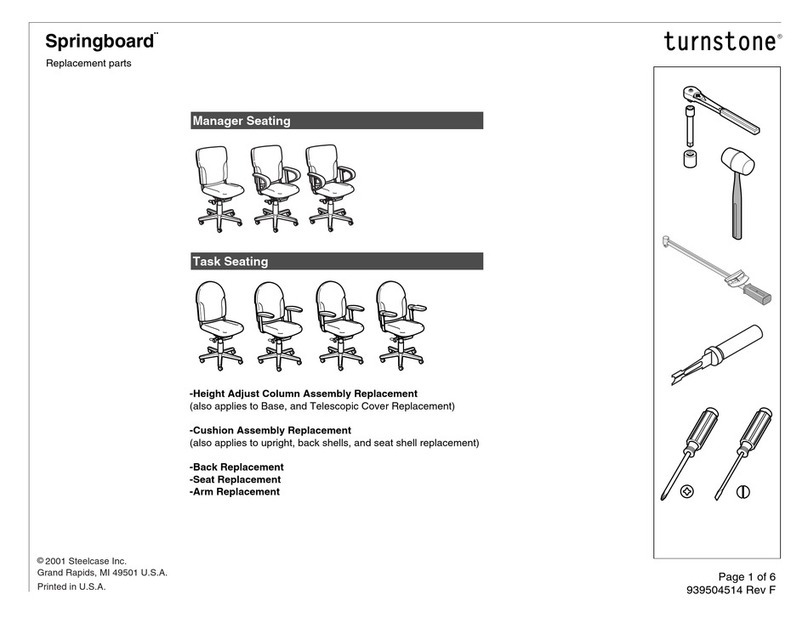

Turnstone Springboard User manual

Turnstone

Turnstone Tour Counter User manual

Turnstone

Turnstone Bivi User manual

Turnstone

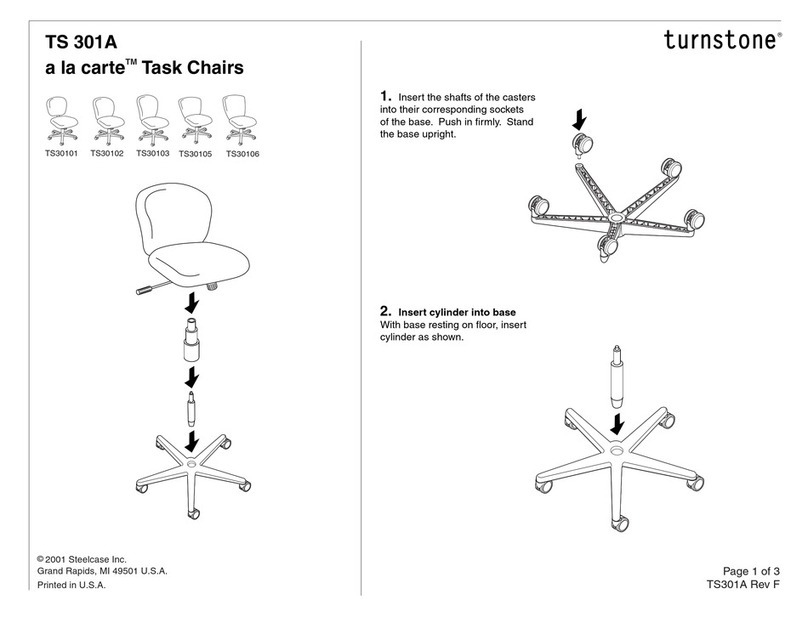

Turnstone A la carte TS 301A Series User manual

Turnstone

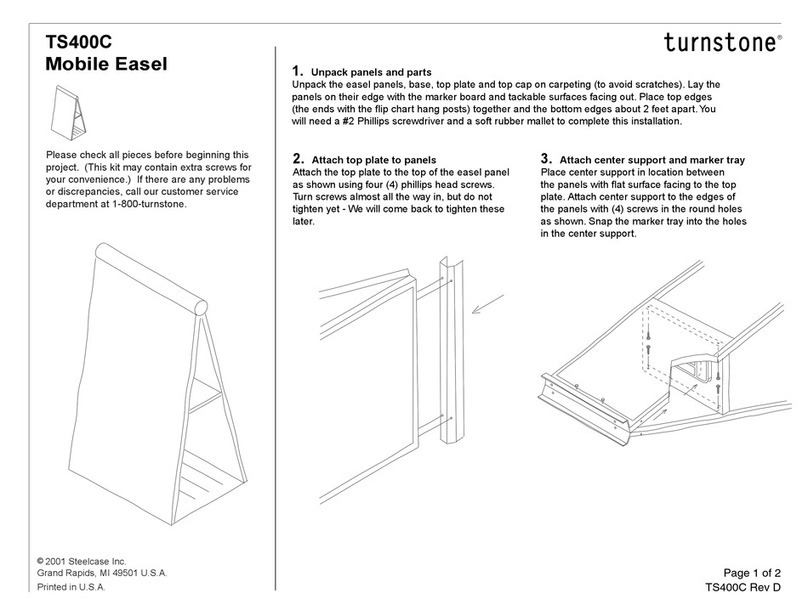

Turnstone TS400C User manual

Turnstone

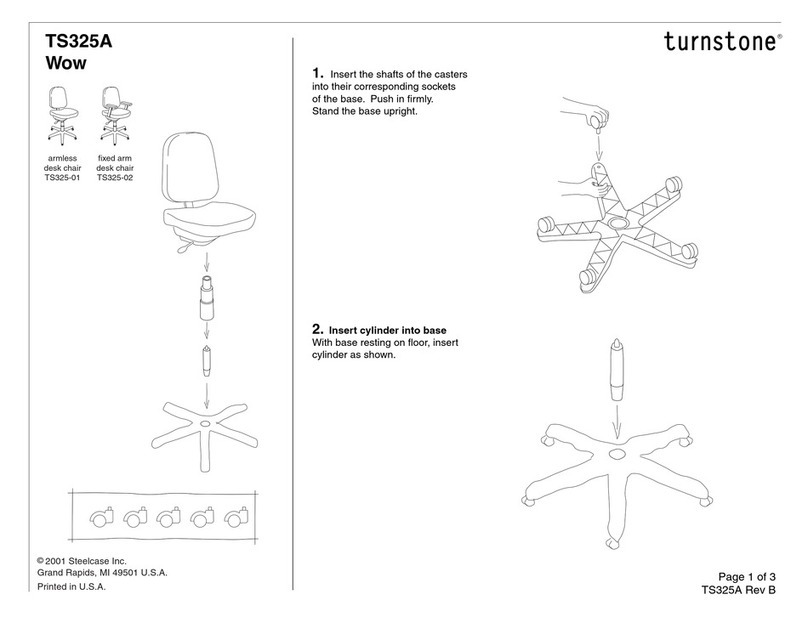

Turnstone Wow TS325 Series User manual

Turnstone

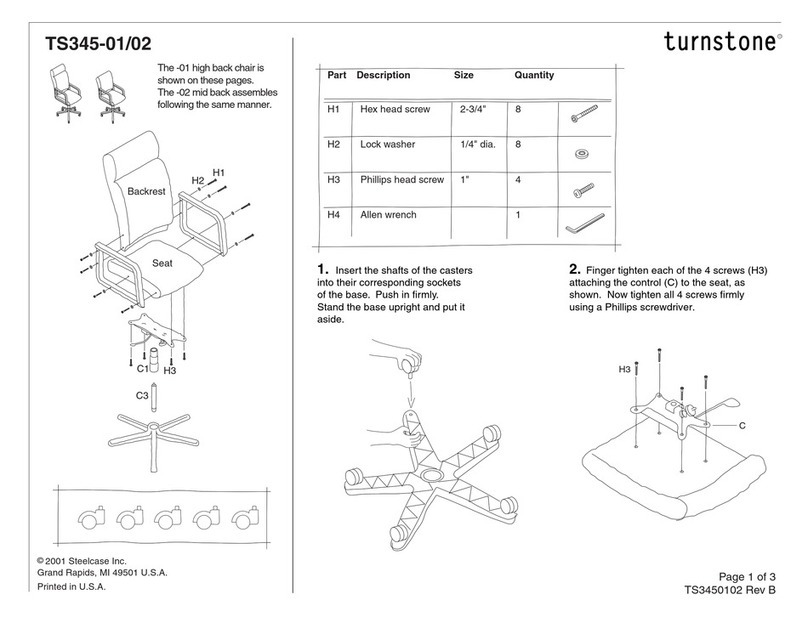

Turnstone TS345-01 User manual

Turnstone

Turnstone Bivi Straight Screen User manual

Turnstone

Turnstone Surprise TS305 User manual

Turnstone

Turnstone Bassline OTTOMAN User manual

Turnstone

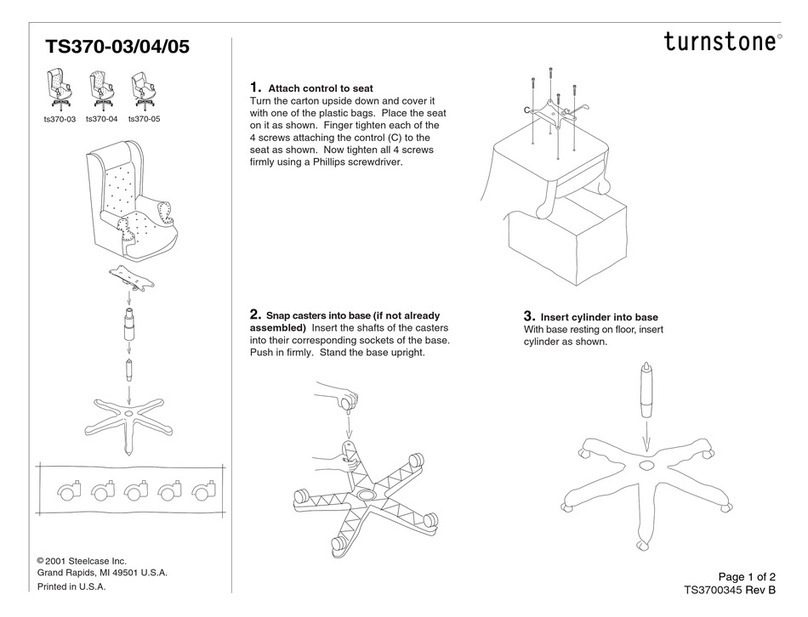

Turnstone TS370-03 User manual

Turnstone

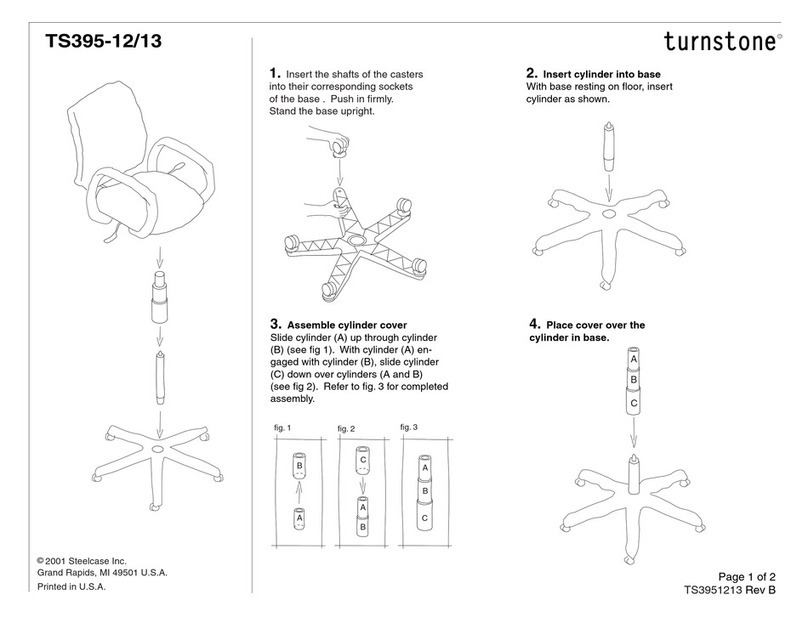

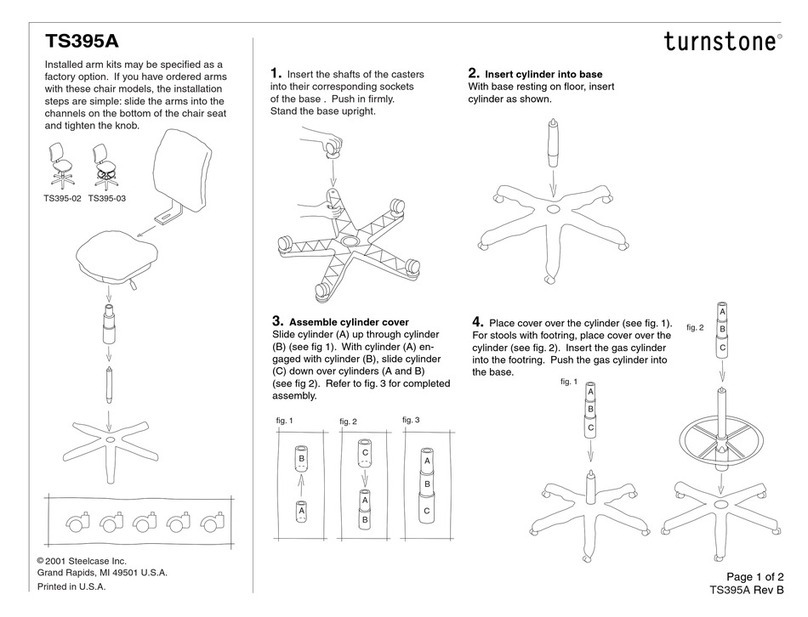

Turnstone TS395-02 User manual

Turnstone

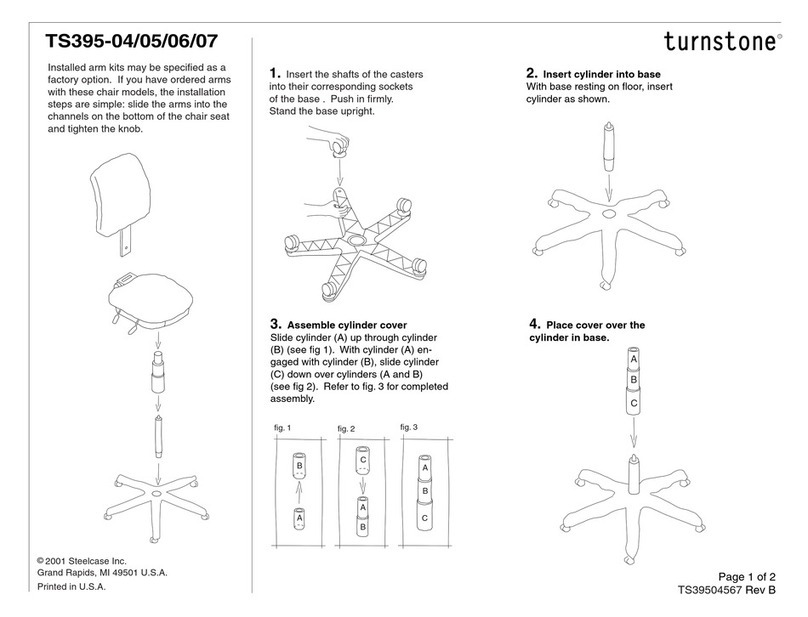

Turnstone TS395-04 User manual

Turnstone

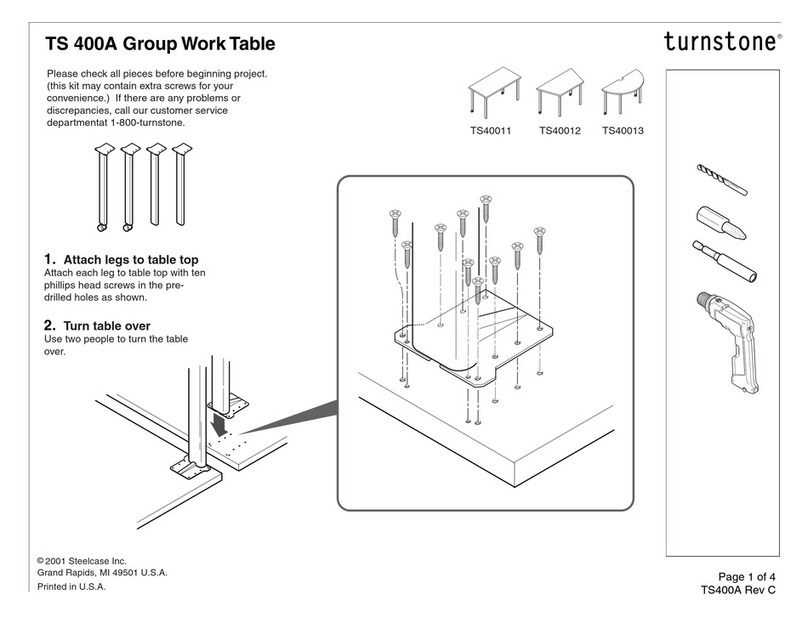

Turnstone TS 400A User manual

Turnstone

Turnstone Jenny Lounge Chair User manual

Turnstone

Turnstone Crew Task Chair User manual

Turnstone

Turnstone Campfire User manual

Popular Indoor Furnishing manuals by other brands

Coaster

Coaster 4799N Assembly instructions

Stor-It-All

Stor-It-All WS39MP Assembly/installation instructions

Lexicon

Lexicon 194840161868 Assembly instruction

Next

Next AMELIA NEW 462947 Assembly instructions

impekk

impekk Manual II Assembly And Instructions

Elements

Elements Ember Nightstand CEB700NSE Assembly instructions