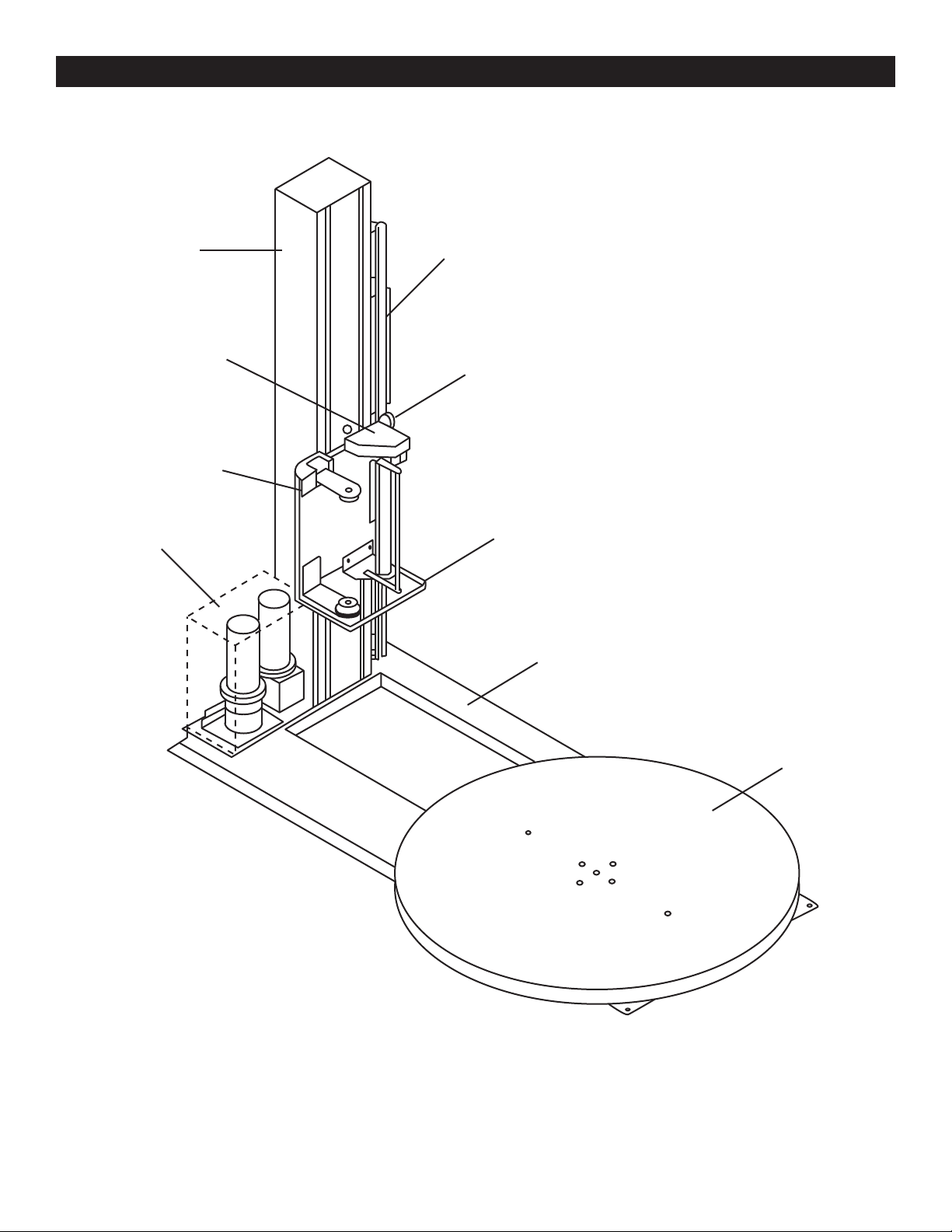

U-Line H-1675 User manual

Other U-Line Dispenser manuals

U-Line

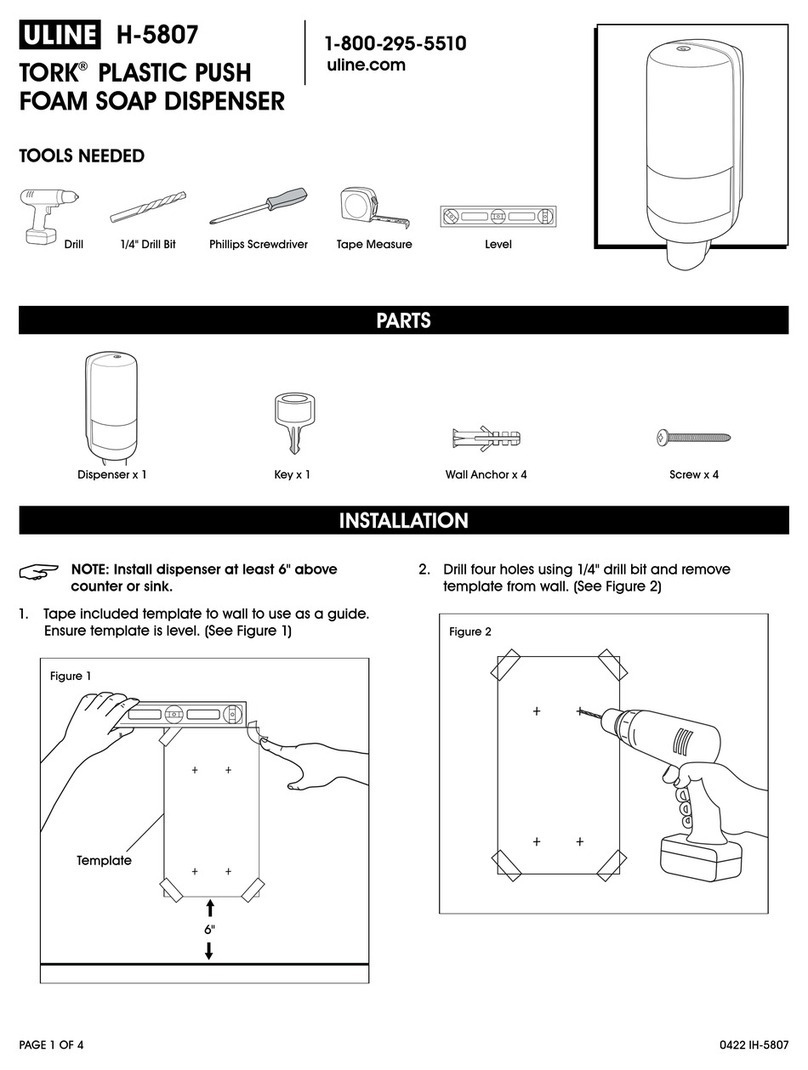

U-Line TORK H-5807 User manual

U-Line

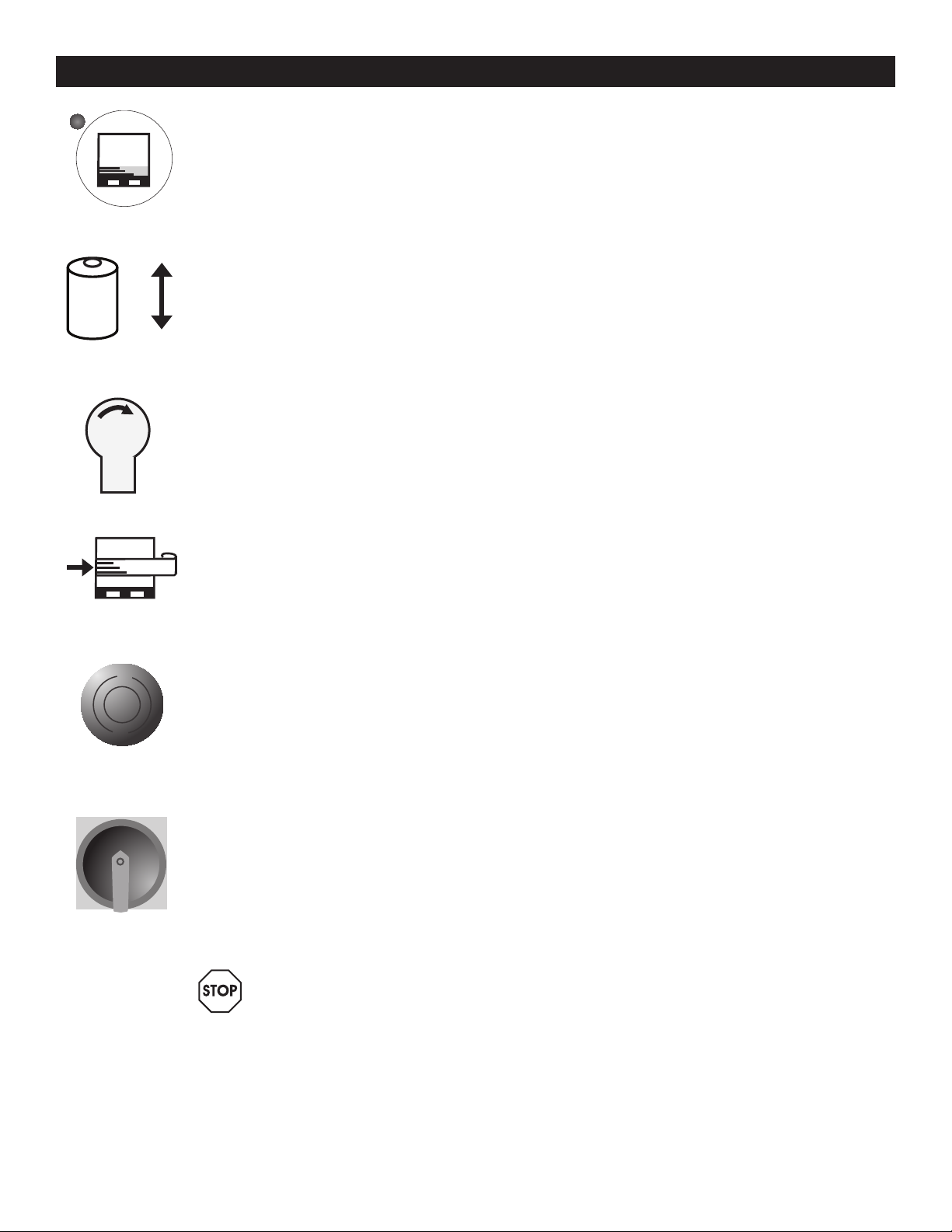

U-Line Better Pack 555eS User manual

U-Line

U-Line H-4017 User manual

U-Line

U-Line H-878 User manual

U-Line

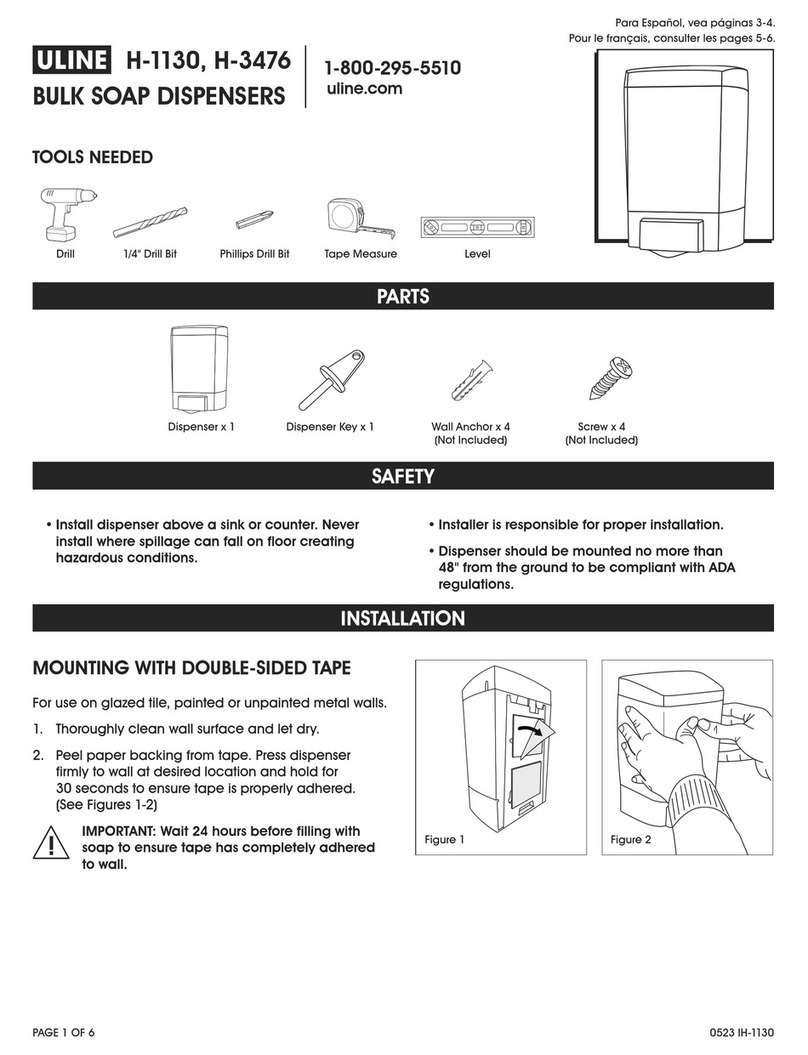

U-Line I-I-1130 User manual

U-Line

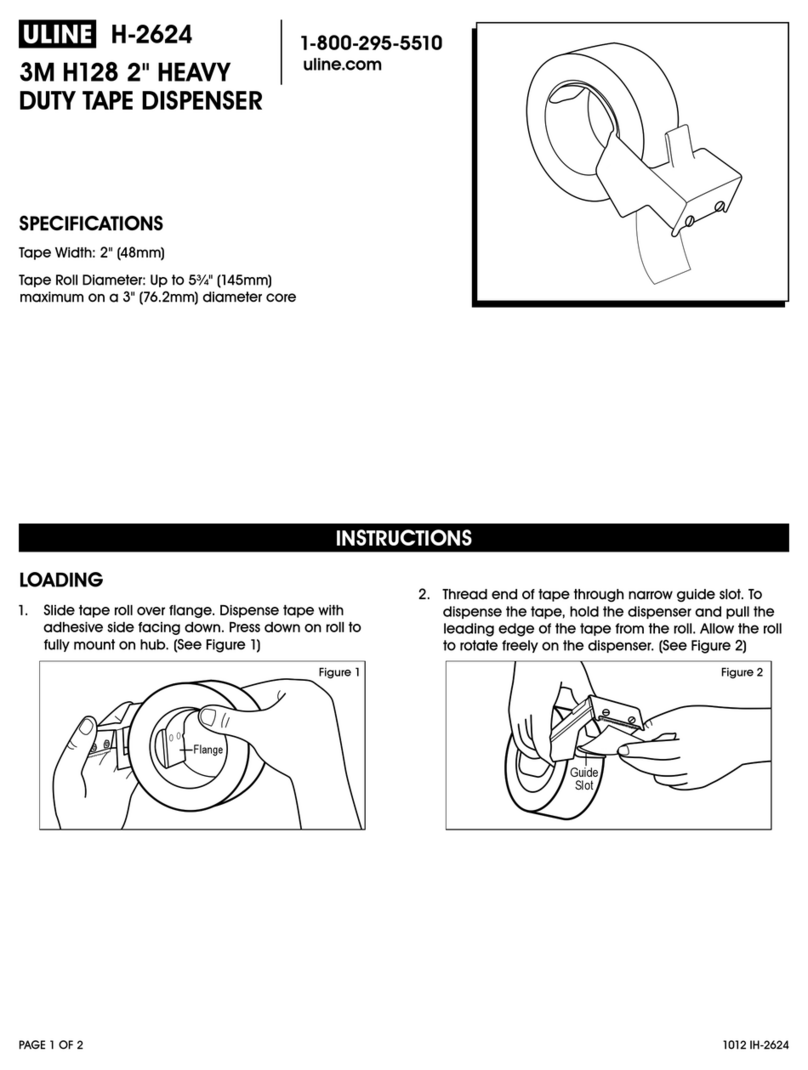

U-Line H-2624 User manual

U-Line

U-Line H-9504 User manual

U-Line

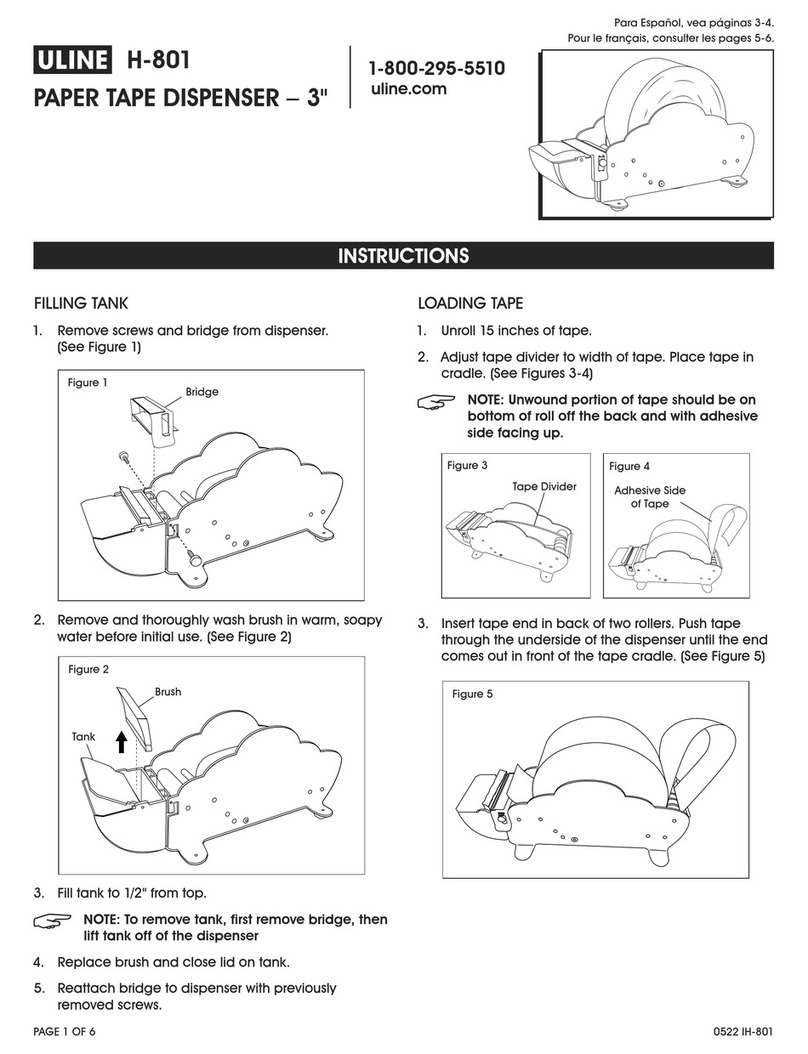

U-Line H-801 User manual

U-Line

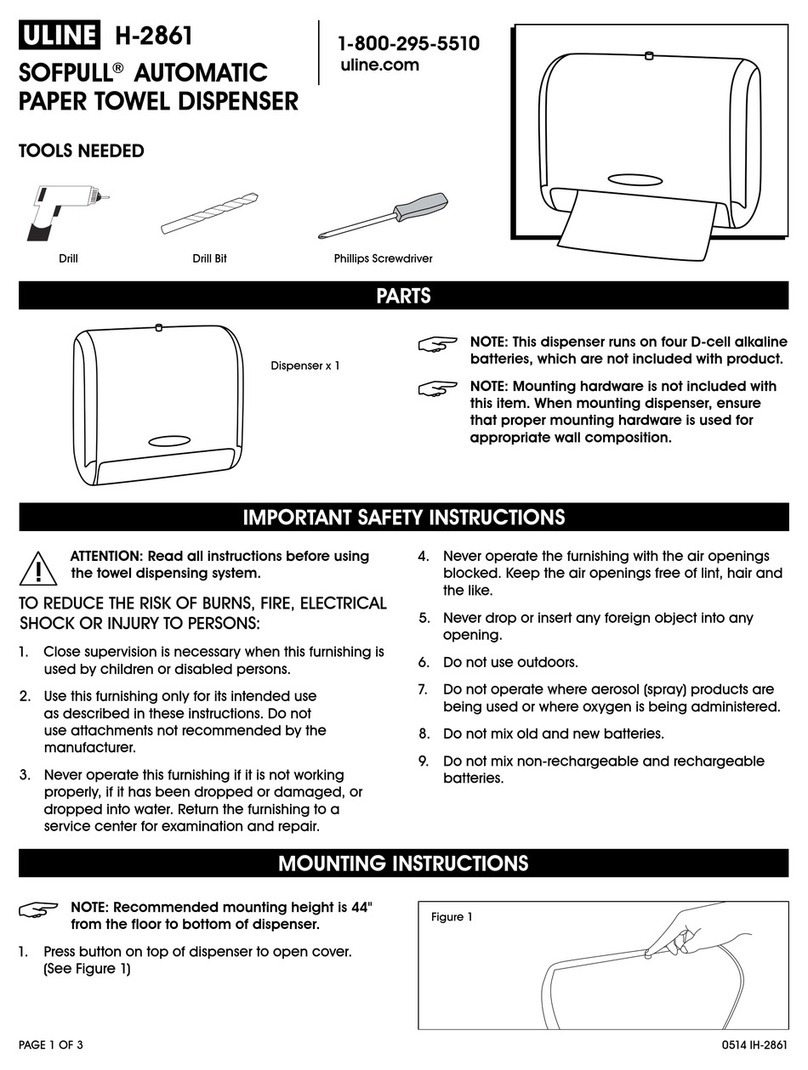

U-Line SOFPULL H-2861 User manual

U-Line

U-Line TORK H-7177 User manual

U-Line

U-Line H-725 User manual

U-Line

U-Line H-1036 User manual

U-Line

U-Line H-2557 User manual

U-Line

U-Line H-3415 User manual

U-Line

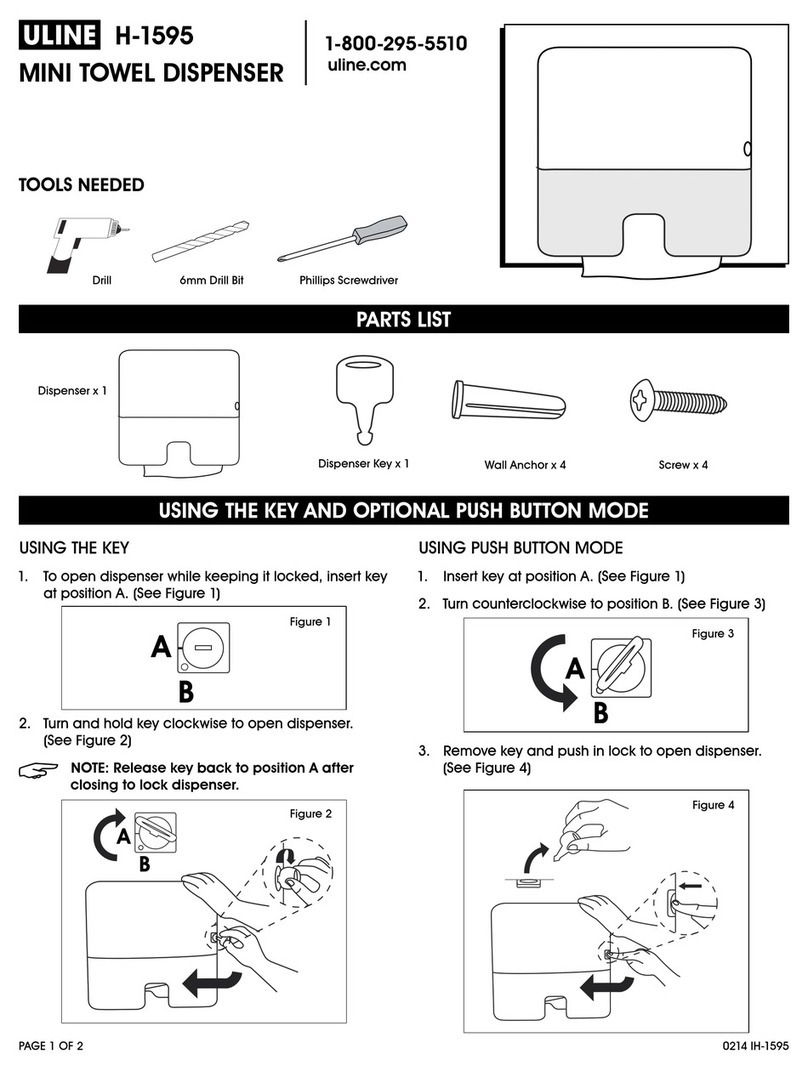

U-Line TORK XPRESS H-1595 Service manual

U-Line

U-Line HDE215 User manual

U-Line

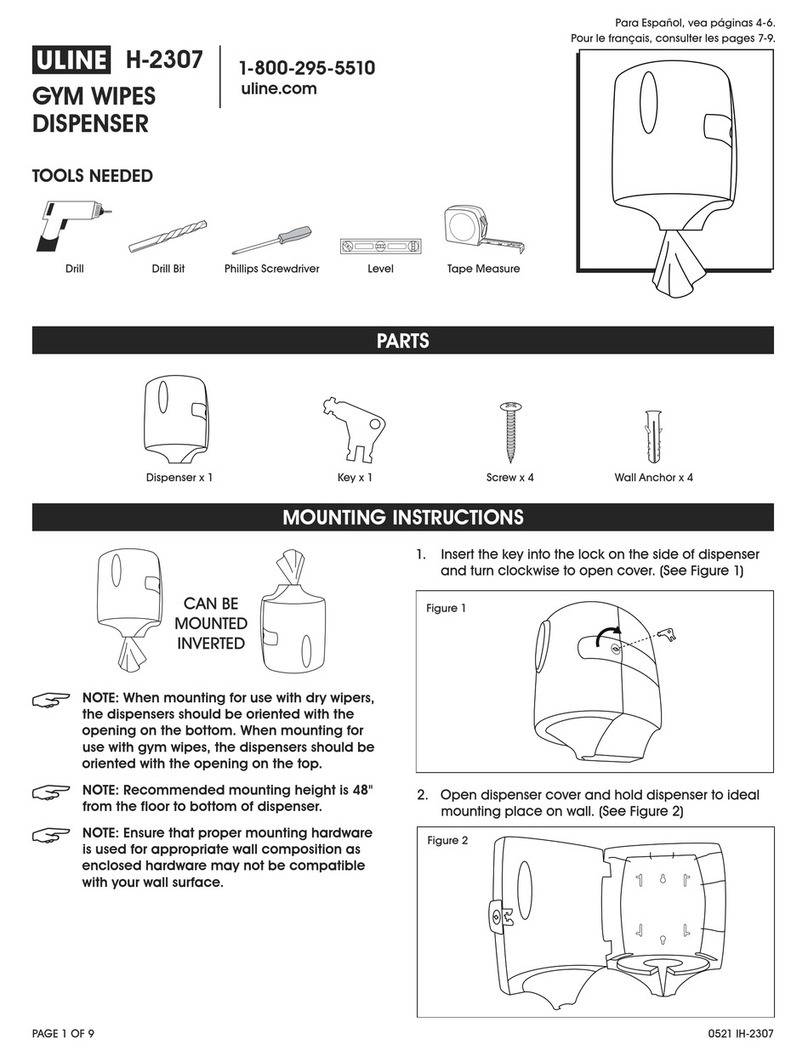

U-Line H-2307 User manual

U-Line

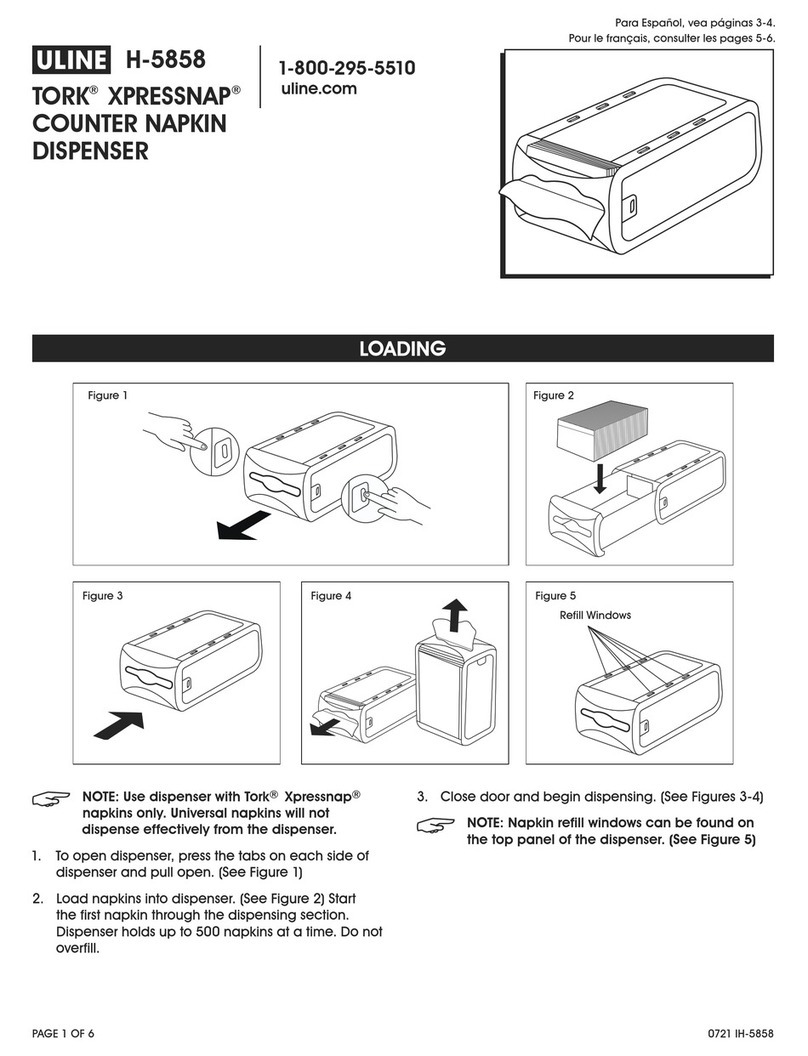

U-Line Tork Xpressnap H-5858 User manual

U-Line

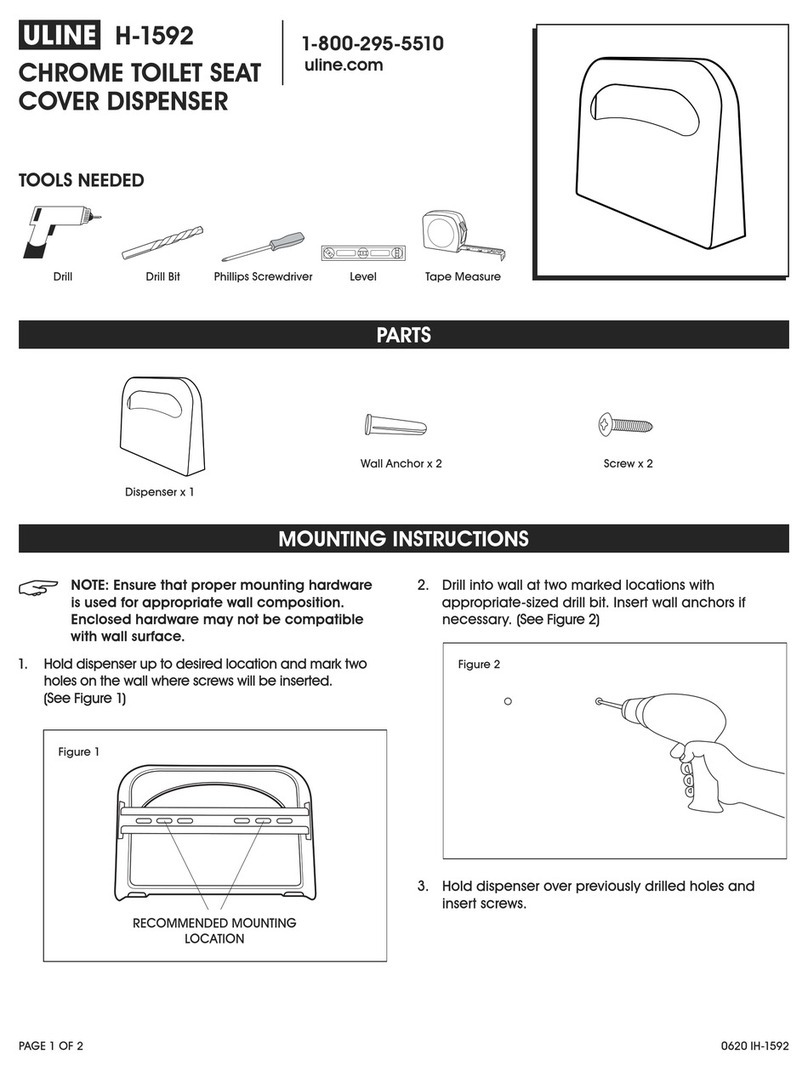

U-Line H-1592 User manual

U-Line

U-Line Boraxo H-3884 User manual

Popular Dispenser manuals by other brands

Silver King

Silver King Majestic SK12MAJ Technical manual and replacement parts list

Franke

Franke F3Dn Twin Service manual

STIEBEL ELTRON

STIEBEL ELTRON UltraHot Plus Operation and installation instructions

DAN DRYER

DAN DRYER 282 installation guide

Essity

Essity Tork 473208 manual

CBS

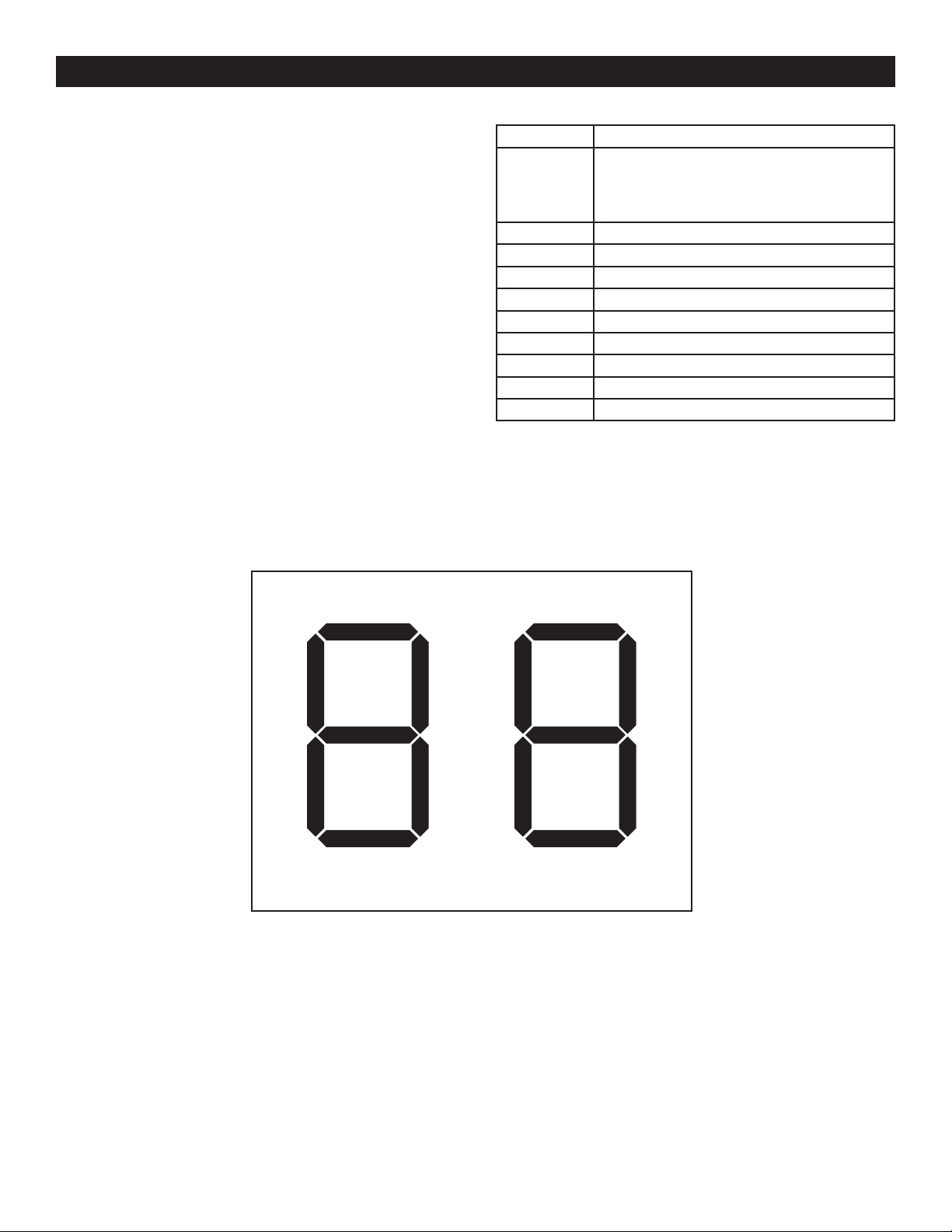

CBS SD300BU-88 COMPONENT MAINTENANCE MANUAL WITH ILLUSTRATED PARTS LIST