Operator’s Gu de

Volume Range Catalog No. Color Increment

10 to 50µL 1136 Green 0.5µL

50 to 200µL 1137 Red 1.0µL

200 to 1000µL 1138 Gray 5.0µL

D g tal P pette

Volume Volume Change Volume Accepta le Accuracy

per 1/2 revolution Setting Range (µL)

10 to 50µL 2.5µL Low 10µL 9.5 - 10.5 ±5%

id 30µL 29.1 - 30.9 ±3%

High 50µL 49.0 - 51.0 ±2%

50 to 200µL 5.0µL Low 50µL 49.0 - 51.0 ±2%

id 125µL 123.75 - 126.25 ±1%

High 200µL 198.0 - 202.0 ±1%

200 to 1000µL 25µL Low 200µL 198.0 - 202.0 ±1%

id 600µL 594.0 - 606.0 ±1%

High 1000µL 990.0 - 1010.0 ±1%

Spec f cat ons Table

2 Geneva Road

Brewster NY 10509 USA

(888) 652-6520 or (914) 244-6226

05/26/10

326720 Rev.H

See www.vistalab.com for

the most current listing of

tips and accessories.

T

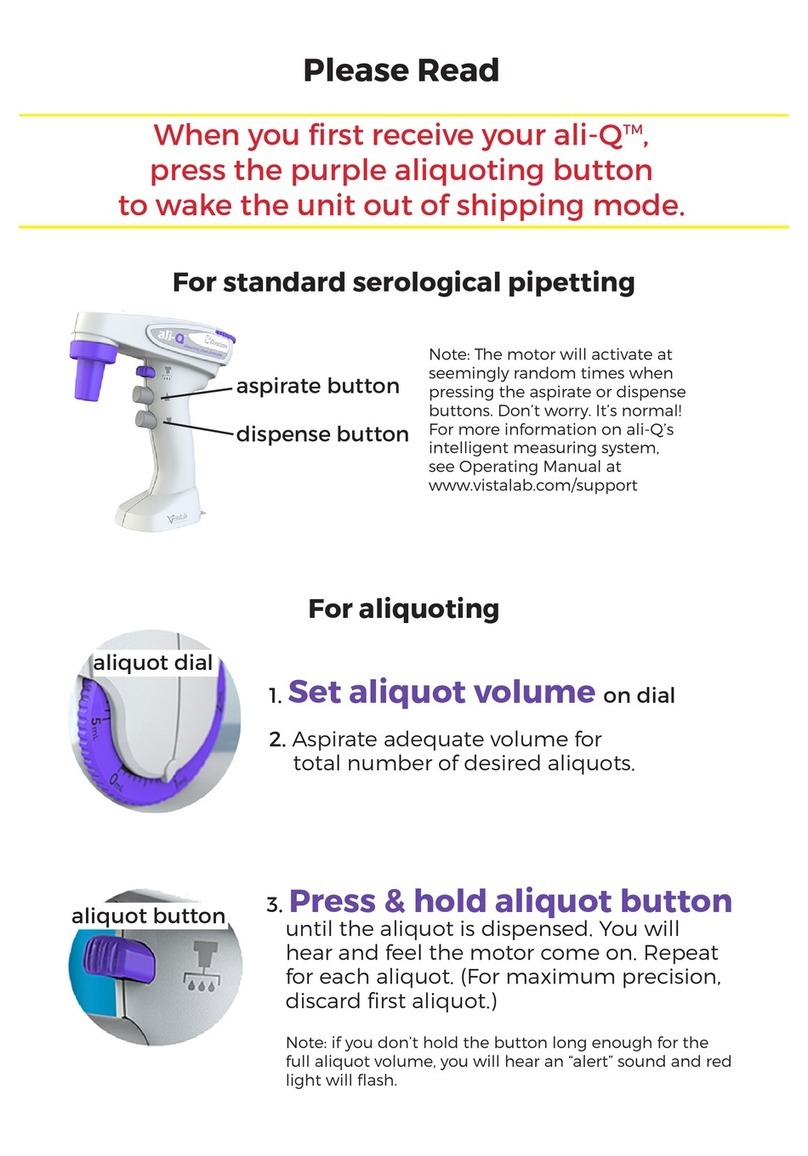

Introduct on

LA Digital Pipettes are “to deliver” air displacement adjustable volume instruments. Three

models are available covering a volume range of 10 to 1000µL. Volume is adjusted by

rotating the plunger. The plunger clicks in place for any desired setting. The volume display

is located in the bonnet of the pipette.

P pette T ps

It is recommended that LA Pipettes be used with VistaLab Pipette Tips. The use of tips from

other sources may degrade the pipette performance. For information on VistaLab Pipette Tips,

refer to the Tip Table.

P pett ng Procedure

a. Rotate the plunger to display desired volume (clockwise to decrease, counterclockwise to increase).

Note: Do not rotate beyond the p pette’s volume l m ts!

Th s w ll damage the p pette and vo d the warranty.

b. Using VistaLab Pipette Tips, press the pipette nozzle firmly into a fresh tip.

c. Fully depress the pipette plunger and then immerse the tip into the solution a maximum of

1/8 inch or 3mm.

d. Smoothly release the plunger and allow the solution to enter the pipette tip.

e. Remove the tip from the solution and touch the tip against the side of the vessel to remove

any solution that may have adhered to the outside of the tip.

f. Place the tip against the side of the receiving vessel as close to the bottom as possible or,

if the vessel contains liquid, as close to the liquid as possible. Smoothly depress the plunger.

g. While holding the plunger depressed, slowly withdraw the tip, keeping it against the wall of

the container.

Note: Performance may be improved by pre-wetting pipette tips. See Hint A on next page.

h. Release the plunger and remove the tip by applying a slight upward pressure to the bonnet.

(See figure below)

NON-STERILESTERILE

T I P S I Z E : S M A L L L A R G E

10 to 50µL

Digital M

odel

:50 to 200µL 201–1000µL

Vist R k™

192 tips/r ck, 5 r cks 4060-2004 4060-3004

Vist St k™, 192 tips/l yer, 5 l yers (sm ll size)

or 3 l yers (l rge size) 4060-9025 4060-9026

St cked R ck, 200 tips/l yer,

5 l yers (sm ll size) or 3 l yers (l rge size) 9025 9026

St cked R ck, Tr ce Met l Certified, 200 tips/l yer,

5 l yers (sm ll size) or 3 l yers (l rge size) 9022 9023

Vist Bulk™, 1000 tips/b g 4058-2000 4058-3000

Protect iner™Bulk P ck,

1000 tips (sm ll) or 750 tips (l rge) 4025 4026

Econo-P k™Bulk P ck,

1000 tips 4225 4226

Vist R k, Sterile,

Pyrogen-free,

RN se/DN se certified,

192 tips/r ck, 5 r cks 4060-2132 4060-3132

Vist Tip™Individu lly Wr pped

Sterile,

200 tips

2025 2026

Vist Tip Individu lly Wr pped, Sterile,

Pyrogen-free, 200 tips

2027 2028

Vist R k, Filtered, Sterile,

Pyrogen-free,

RN se/DN se certified,

192 tips/r ck, 5 r cks 4060-2332 4060-3332

T p Table

9025

Catalog

Number

Accessor es

Cat # Description

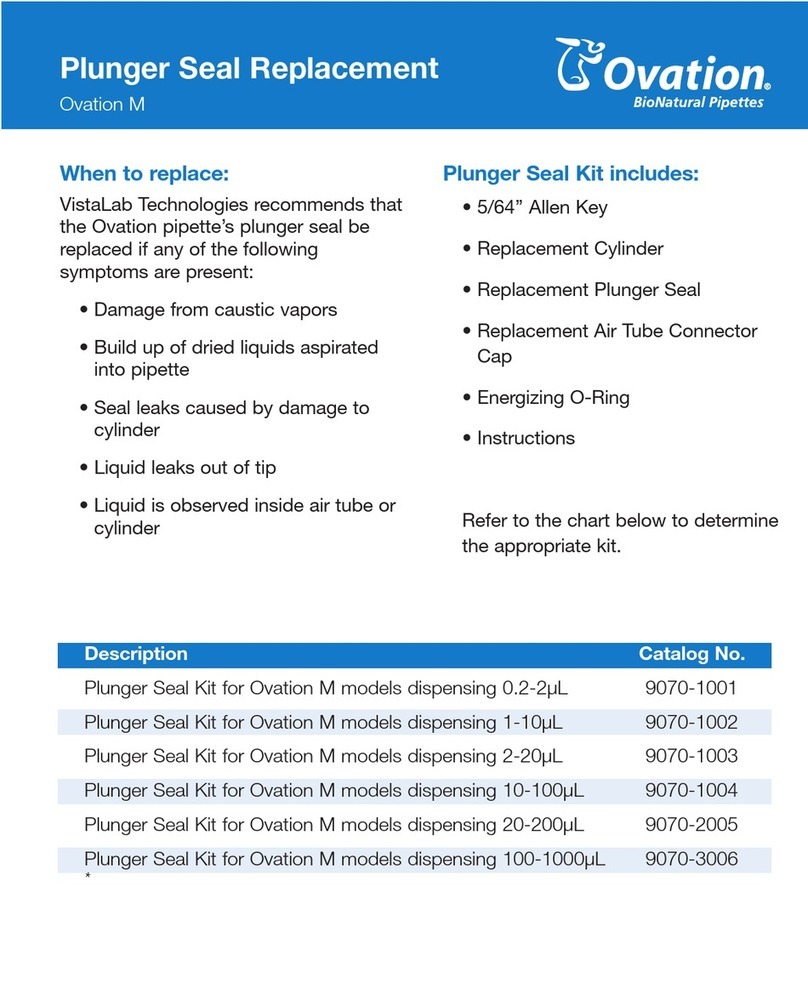

9091 Seal Kit, 10 to 50µL

9092 Seal Kit, 50 to 200µL

9094 Seal Kit, 200 to 1000µL

Cat # Description

8066 Nozzle Inserts

1700 Pipette Stand

Note: Filtered tips contain a unique hydrophobic filter which acts as a barrier to aqueous liquids and aerosols,

protecting the pipette and sample from trace amounts of carryover.