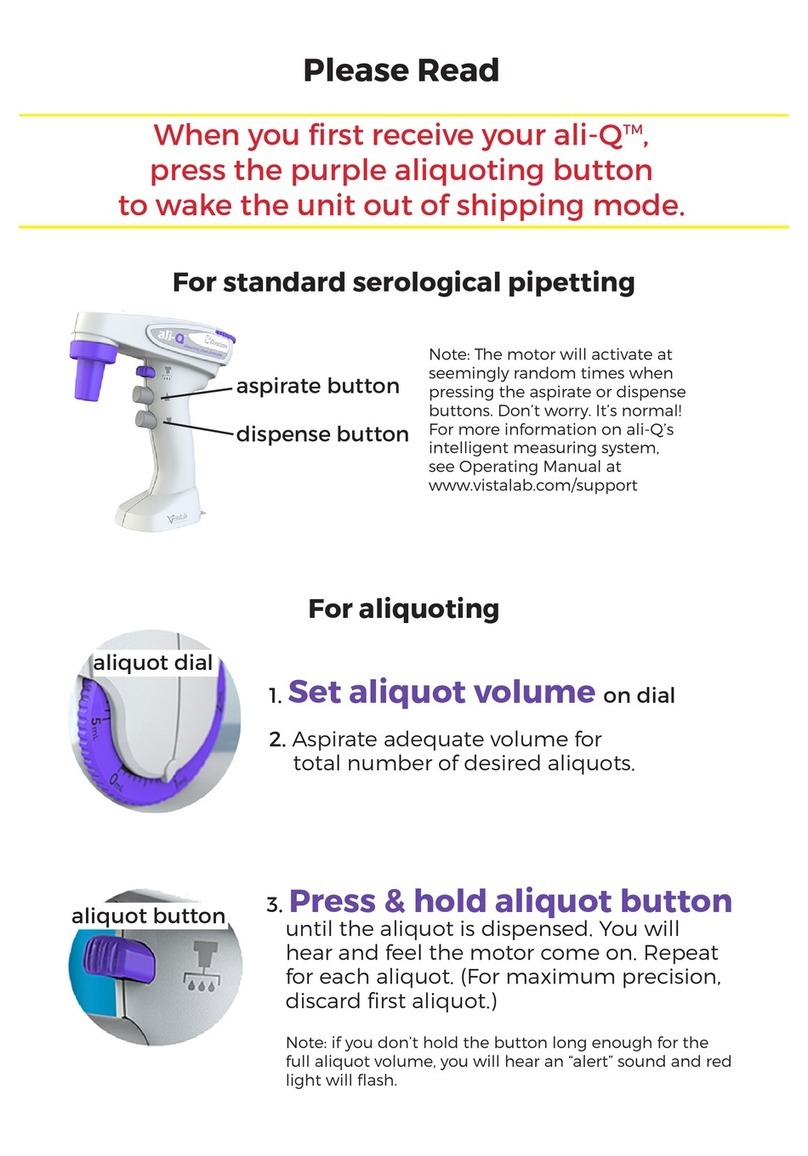

PIPETTE OPERATION

PIPETTE TIP

The pipette is a precision instrument.System performance depends on the pipette

and tip system used.Using tips which were not used to calibrate the pipette

may effect accuracy and precision.For best results,use the manufacturer

recommended tips.

ASPIRATING/FILLING

1. Securely attach the appropriate,unused pipette tip.

2. Press plunger button down to the first stop.

3. Hold pipette vertically and immerse the tip approximately 3 mm into the

sample solution.

4. Gently and slowly return the plunger button to up position.Do not let it snap back.

5. Withdraw the tip from the liquid so that no drops remain attached on the

outside of the tip.Should any liquid remain,wipe the outside of the tip with a

lint-free tissue,taking special care not to touch the tip opening.

DISPENSING/EMPTYING

6. Place the tip against the side wall of the receiving vessel.

7. Depress the plunger slowly to the first stop.Pause.

8. Depress the plunger further to the second stop (blow out) or bottom of stroke,

dispensing all liquid from tip.

9. With the plunger still fully depressed,slowly withdraw the tip while sliding

along the wall of the vessel.Release plunger to up position.

10. Eject tip by lifting the tip ejector bonnet.

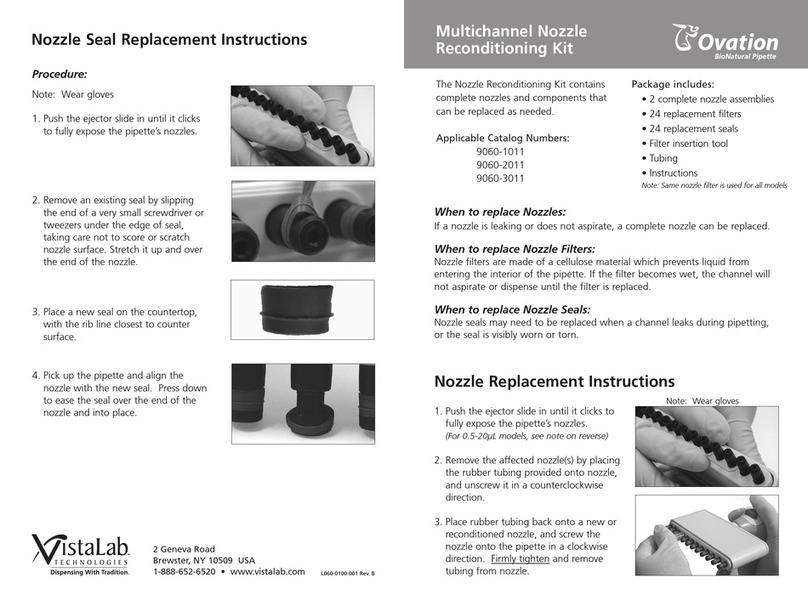

Figure 2: Nozzle Insert Removal and Replacement

SPECIAL NOTES

• Do Not pre-wet tips.

• Use a new tip for each aspirate/dispense.

• Dispensing must be performed along the vessel wall or directly into liquid.

Perform blow-out stroke,hold plunger down,and withdraw pipette from vessel.

• With small sample volumes,results can be optimized by rinsing the tip after

dispensing.After the first dispense is performed,keep the tip in the receiving

vessel and aspirate and dispense several times.Perform blow-out and slide tip

out along the vessel wall.

OPERATIONAL LIMITATIONS AND PRECAUTIONS

•Consistent technique and smooth,steady movements are key to precision.

•Keep the pipette in a vertical position at all times when in use.

•Always depress the plunger to the proper stop before putting the tip into liquid

to avoid air and incorrect volume intake.

•Differences in the temperature of the pipette and solution can result in inaccurate

dispensing.

RECOMMENDED MLA PIPETTE TIPS

Cat. No. Description U/M

9025 Stacked Dense Pack,5 trays;200 tips per tray 1000 tips

4025 Protectainer Bulk Pack 1000 tips

4225 Econo-Pak 1000 tips

2025 Sterile,Individually wrapped 200 tips

2027 Pyrogen-free Sterile,Individually wrapped 200 tips

9022 Trace Metal Certified,Stacked Dense Pack 1000 tips

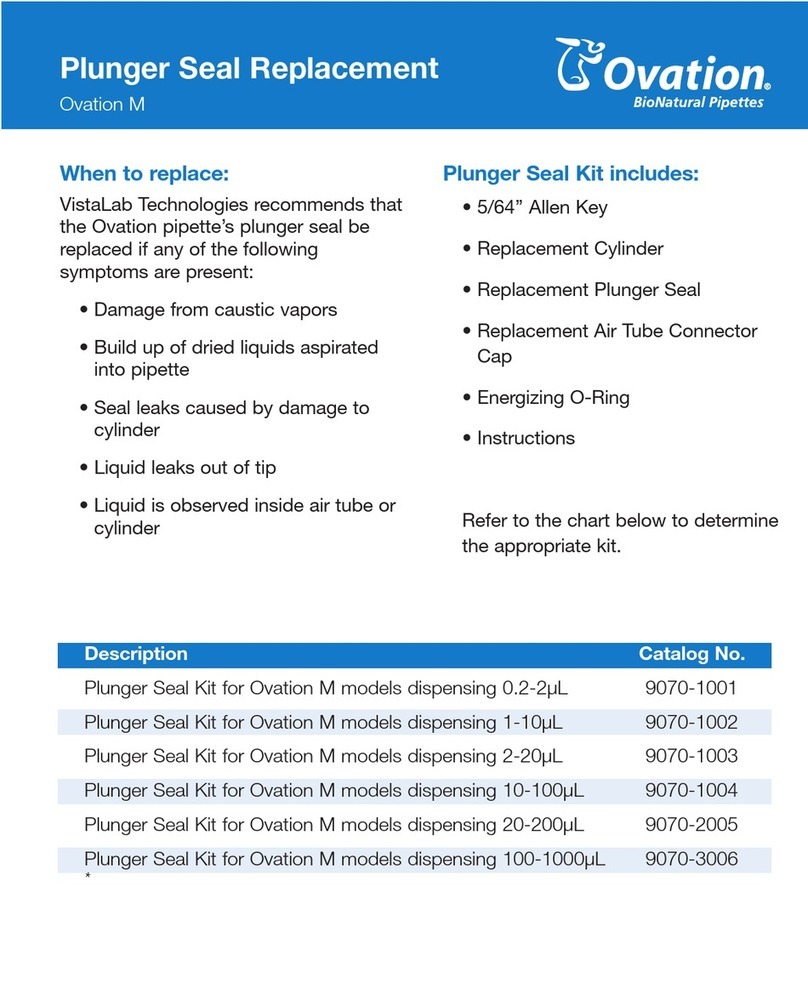

SERVICE AND MAINTENANCE INFORMATION

During factory assembly,the internal parts of the pipette (plunger,seals,etc.) are

lubricated with a silicone grease.Normally,cleaning,replacement of seals and nozzle

inserts,and lubrication should be necessary only every 6 months.If the pipette is

used with corrosive chemicals or solvents,or roughness in the plunger movement is

observed,cleaning and lubrication may be necessary more often.

Cleaning

The pipette should be checked each day of use for dirt and dried liquids on the

outside surfaces of the pipette.Wipe clean with soapy water and lint-free cloth.

If stronger cleaning agents are used,rinse well with water and wipe dry.

Inspect the nozzle insert for cleanliness.Remove and rinse clean if debris is seen.Dry

with jet of air.

Maintenance

Every six months,or as required,replace seals and lubricate.Refer to Maintenance

and Repair Kits for proper replacement parts to have on hand.

1. Hold the pipette around the sleeve and pull the nozzle away from the sleeve to

expose the spring cap assembly.

2. Grasp the spring cap with your thumb and forefinger and unscrew the nozzle.

Remove the nozzle and sleeve.

3. Unscrew and remove the spring cap assembly.

4. Remove and discard old seals. Note: The 2 µL,3 µL and 4 µL pipette models

includes a separate part,a metering seal housing,with two small“O”rings. This

housing should stay on the plunger when the nozzle assembly is removed. If

metering seal housing remains in the spring cap assembly,remove it,the two“O”

rings and the quad ring from the spring cap assembly,using a small straight pin.

Remove the two“O”rings from the seal housing and discard seals.

5. Depress and hold the button plunger to advance the plunger mechanism.Wipe

exposed surface with soft clean cloth.Lubricate with a thin film of grease from kit.

6. Apply grease to the new seals and carefully place on plunger.Use only the silicone

grease supplied in the Seal Maintenance Kit. Note: When replacing the“O”rings

for 2 µL,3 µL and 4 µL pipette models assemble both“O”rings,then the metering

seal housing and then the quad ring onto plunger.

7. Reassemble pipette being careful while inserting plunger and seals into seals in

nozzle assembly.

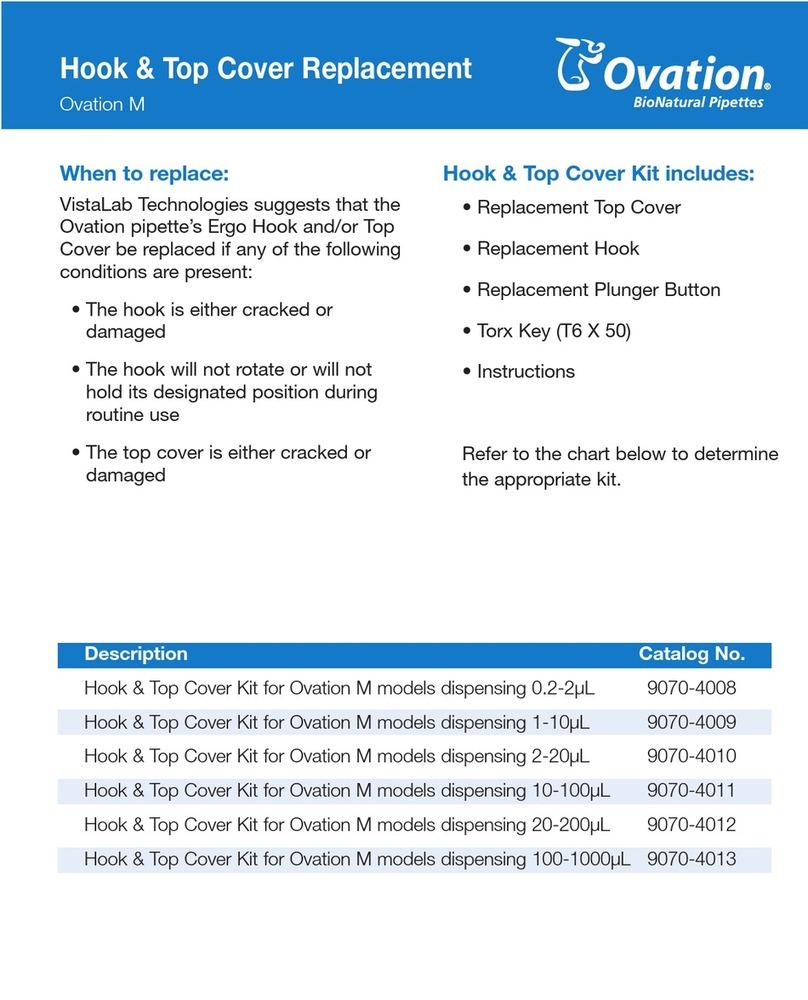

MAINTENANCE AND REPAIR KITS

For Micro D-Tipper Seal Kits Nozzle Insert

Volume Cat. No. Cat. No.

2 µL 9075 8066

3 - 4 µL 9076 8066

5 - 10 µL 9077 8066

CALIBRATION

The pipettes have been calibrated at the factory to perform within the specifications

in table.Ordinarily the pipettes do not need to be calibrated but they are designed

to permit easy in-lab calibration.(Warning: Experienced and proper training is

required to accurately perform calibration using gravimetric method.All procedures

are to be performed under controlled environment conditions.)

Calibration Verification

Verification of pipette calibration is recommended every six months.This should be

performed after the routine maintenance is completed.

Some laboratories may not have access to facilities capable of performing the

gravimetric method.In these instances,you may consider using the MLA Pipette

Verification Calibration Kit or returning the pipettes to MLA Systems for calibration

and/or repair.

5-10 µL. Sizes

Tubing

2, 3 & 4 µL. Sizes

Sleeve

Button

Bonnet

TUBING

PLUNGER

ASSEMBLY

NOZZLE TIP

ASSEMBLY

Plunger

Metering Seal

Housing

Nozzle

Body

“O” Rings

Quad Ring

Quad Rings

Spring Cap

Nozzle Insert

Figure 3: Pipette Disassembly and Seal Replacement

Insert pipette tip in hole,

and

PULL to remove.

Nozzle insert

Nozzle