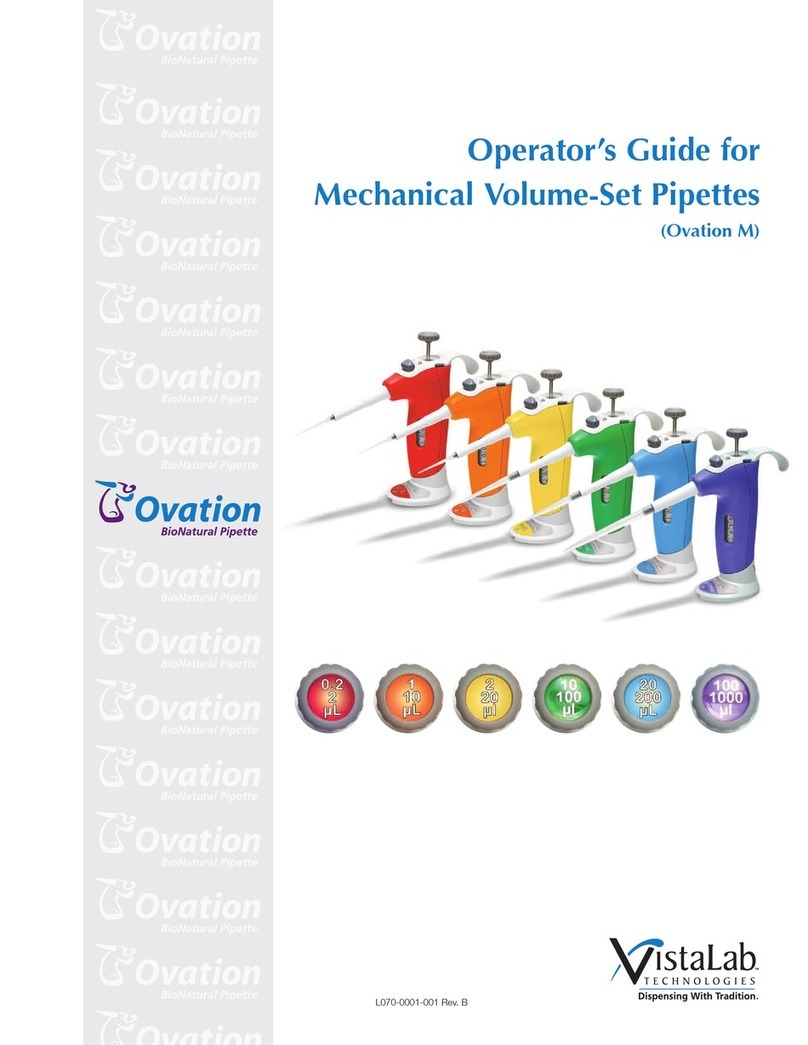

VistaLab Ovation M Operating and safety instructions

Other VistaLab Laboratory Equipment manuals

VistaLab

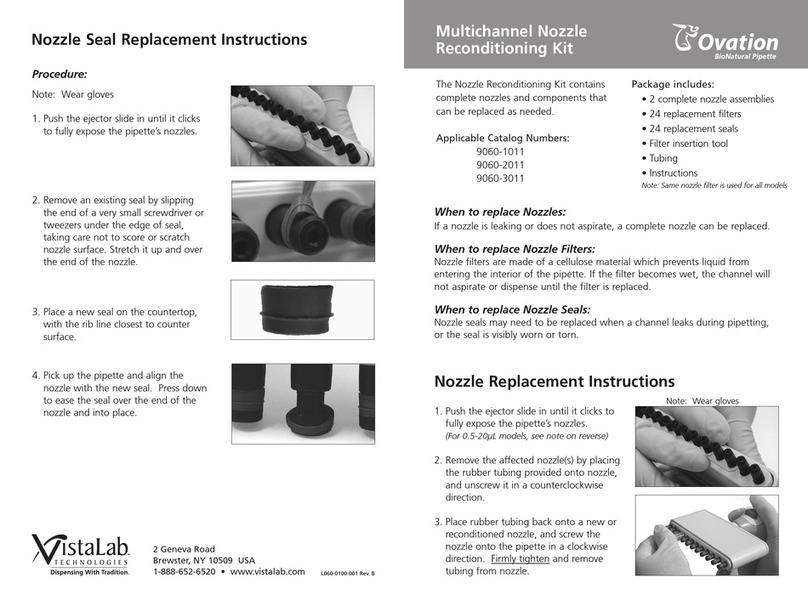

VistaLab Ovation 9060-1011 Guide

VistaLab

VistaLab 1070-0002 User manual

VistaLab

VistaLab MLA Series User manual

VistaLab

VistaLab Ovation QS Manual

VistaLab

VistaLab ali-Q 2 Installation instructions

VistaLab

VistaLab Ovation Manual

VistaLab

VistaLab Ovation ESC User manual

VistaLab

VistaLab MLA pipette MLA 1061 Manual

VistaLab

VistaLab Ovation 9057-2009 Use and care manual

VistaLab

VistaLab Ovation 9060-4005 Guide

Popular Laboratory Equipment manuals by other brands

Sony

Sony UP-D71XR Instructions for use

Lilly

Lilly Entuzity KwikPen Instructions for use

Shimadzu

Shimadzu Shim-pack GIST Series instruction manual

Thermo Scientific

Thermo Scientific SlideMate AS Operator's guide

Beckman Coulter

Beckman Coulter Optima LE-80K instruction manual

Kubota

Kubota 2420 Nstruction and service manual

Antec Leyden

Antec Leyden DECADE II installation manual

Azure Biosystems

Azure Biosystems Azure 200 user manual

Data Translation

Data Translation DT2802 user manual

Velp Scientifica

Velp Scientifica ECO 6 instruction manual

D-Link

D-Link DPE-101GI Quick installation guide

Labconco

Labconco FreeZone 7750000 user manual