16 – VWR EHP PIPETTORS Instruction Manual – 17

Aspirating High-density Liquids

When pipetting liquids of higher viscosity or lower sur-

face tension than water (e.g., sera or organic solvents),

a film of liquid may be formed on the inside of the

pipet tip which may produce erroneous results. As the

film remains relatively constant in successive pipetting

operations with the same tip, this error can be elimi-

nated by pre-rinsing the tip and allowing a film to form

before transferring the first sample. This is achieved by

aspirating asample and dispensing it back into the

same vessel. Allowing a film to form prior to sampling

ensures optimal accuracy and repeatability.

This pre-rinsing operation should be repeated when

thevolume to be aspirated is changed or when a new

pipet tip is used.

NOTE: Normally the degree of error resulting from

viscous liquids is negligible if pipetting is performed

slowly and carefully, however can be minimized further

by holding the pipet tip in position for at least 2 seconds

after aspiration to allow the liquid time to react to the

change in pressure before it is dispensed.

If the above method does not result in accurate values,

recalibrate the pipettor in accordance with Section 9.

It is recommended to record recalibration and correc-

tion values, in order to facilitate reverse calibration to

astandard liquid.

Filters

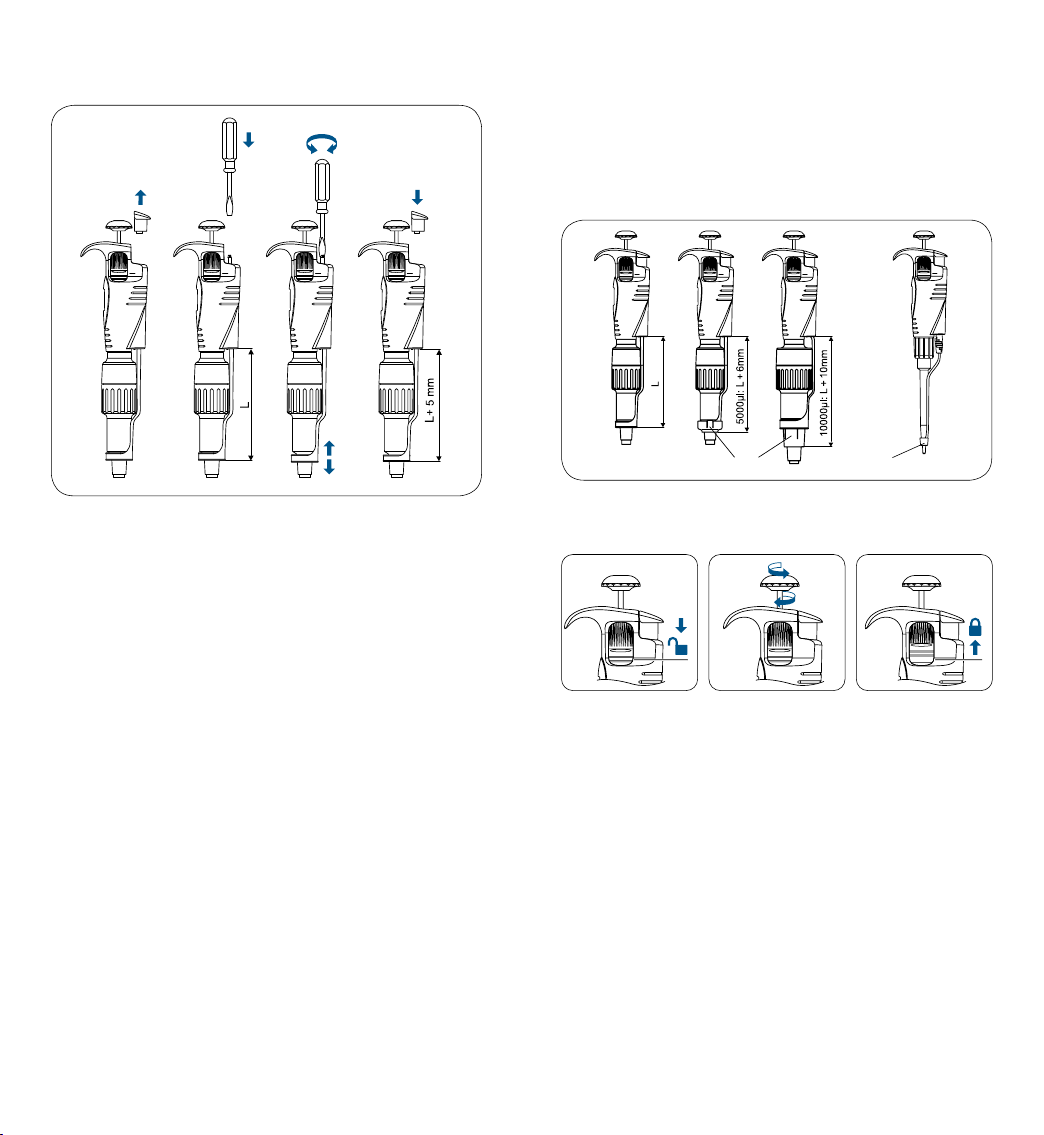

The 5,000 μL and 10,000 μL pipettors include a replace-

able filter (L), fitted at the bottom of the shaft which

prevents aspirated liquid from entering the shaft and

contaminating the inner surface and plunger. Use of

the filter is particularly important when aspirating and

dispensing large volumes of liquid. The filter should be

replaced if it becomes wet.

9. Checking Pipetting Accuracy Parameters

and Pipettor Recalibration

The pipettors have been factory-calibrated using

gravimetric methods with manufacturer pipet tips and

distilled water, in accordance with ISO 8655 guidelines

for the maximum (nominal) liquid volume drawn by the

pipettor and for 10% of the maximum or minimum liquid

volume according to the values given (Section 5).

The pipettors are designed to enable recalibration and

adaptation to different pipetting techniques and liquid

properties (e.g., temperature, density, and viscosity).

8. Aspiration and Dispensing Instructions

Aspirating Liquid

1. Press the pushbutton to the first stop point.

Holdingthe pipettor vertically, immerse the pipet tip

into the sample liquid to the recommended depth

(for recommended values see Section 7). Ifthepipet

tip is not immersed to the recommended depth or if

the pipetting pushbutton is rapidly released, air may

enter the pipet tip.

2. Release the pipetting pushbutton slowly and

smoothly to aspirate the sample. Wait one second

and then withdraw the pipet tip from the liquid.

CAUTION: Do not touch the used tip.

Dispensing Liquid

3. Place the end of the pipet tip against the inside wall

of the vessel at an angle of 10° to 40°. Press the push-

button smoothly to the first stop. Wait one second.

4. Press the pushbutton to the second stop to expel

any remaining liquid. While keeping the pushbutton

depressed, remove the pipettor from the vessel by

drawing the pipet tip against the inside surface of

thevessel.

5. Release the pushbutton to its starting position.

6. Eject the pipet tip by pressing the tip ejector

pushbutton.

Remember to change the pipet tip whenever

a different type of liquid is to be sampled.