CONTENT

I. Introduction......................................................................................................................1

1. Package content.........................................................................................................2

2. Disclaimer...................................................................................................................2

. Characteristics of the meter........................................................................................

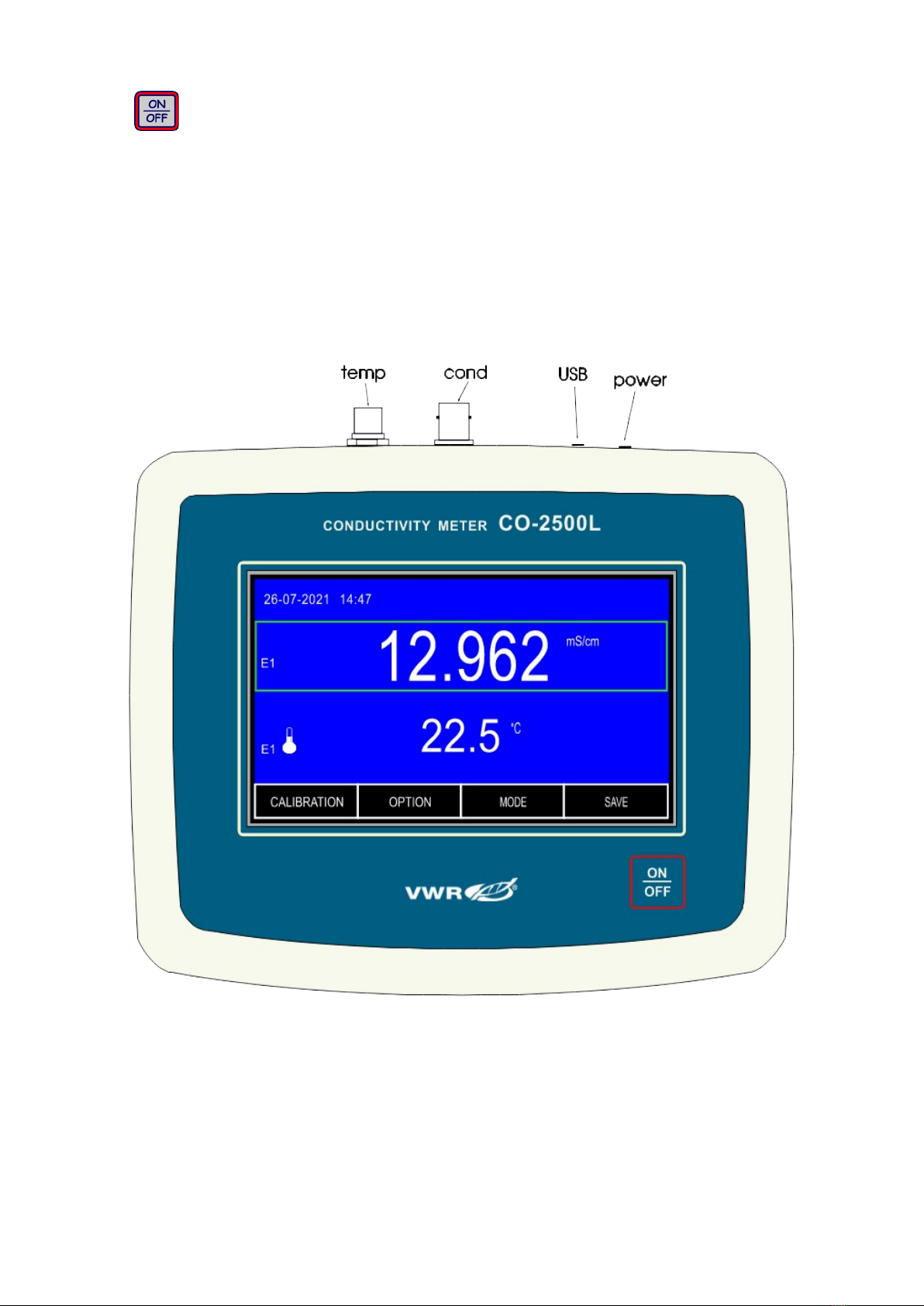

4. The outside view.........................................................................................................4

5. The meter‘s maintenance...........................................................................................6

6. Switching the meter on and off...................................................................................7

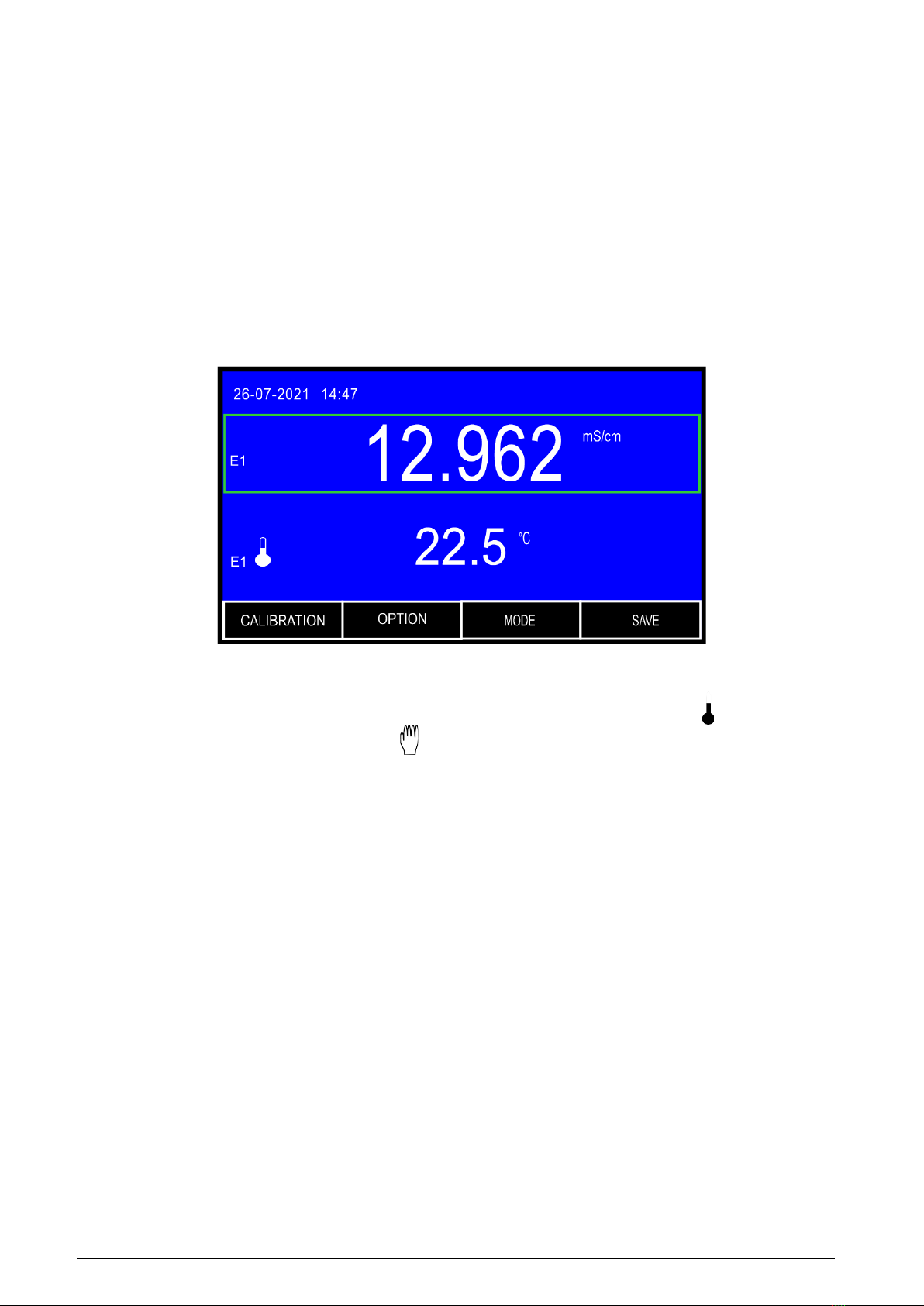

6.1. Stabilised reading.............................................................................................8

7. Preparation to work....................................................................................................9

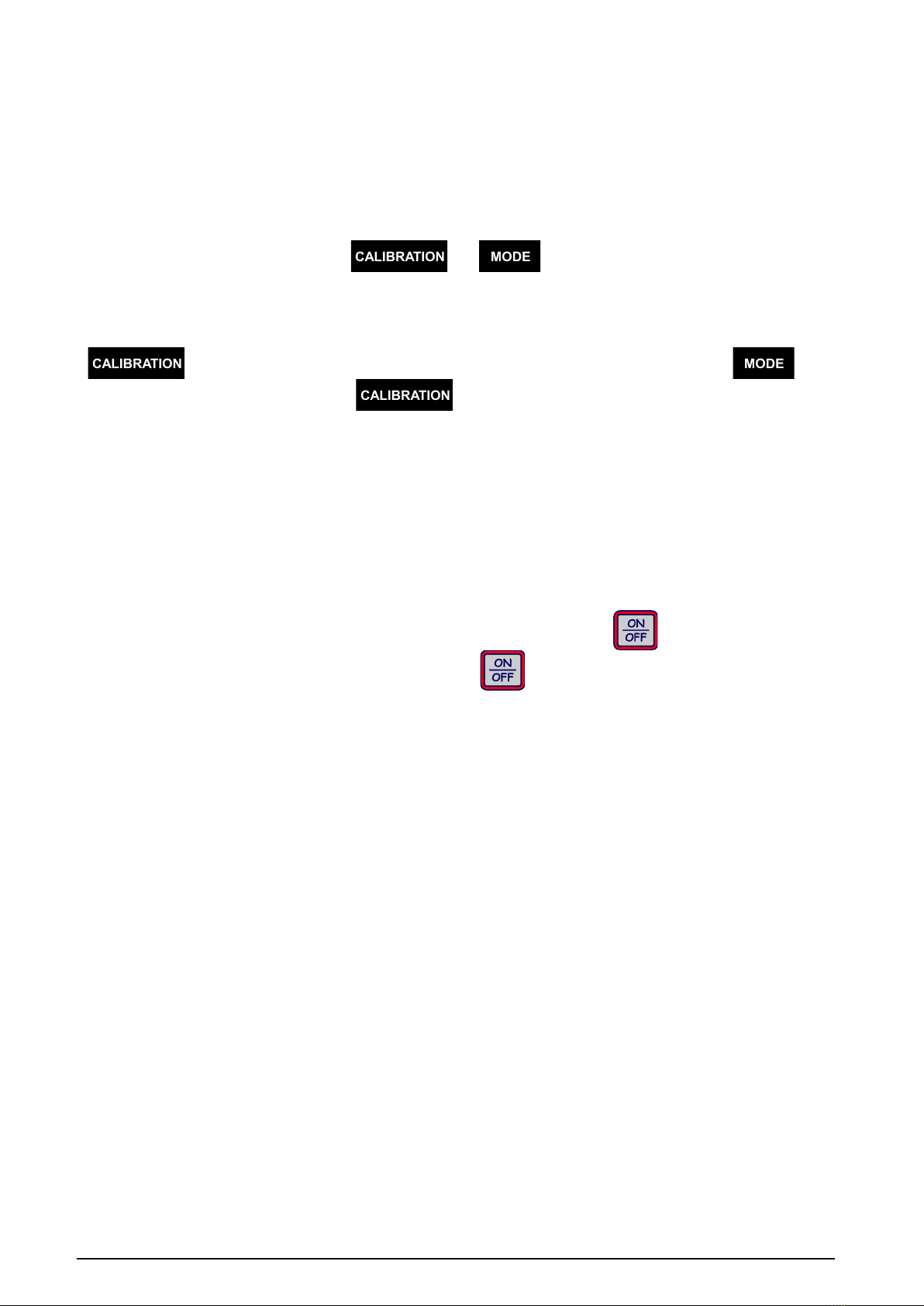

7.1. Choosing the kind of the temperature compensation......................................9

II. Conductivity and salinity measurement.....................................................................10

8. Entering the conductivity parameters.......................................................................11

8.1. Resolution.......................................................................................................12

8.2. Cell number....................................................................................................12

8. . Choosing the unit............................................................................................12

8.4. Calibration points and date.............................................................................14

8.5. Calibration validity time...................................................................................14

8.6. Choosing the type of temperature compensation..........................................14

8.7. Entering the a coefficient................................................................................15

8.8. Entering the reference temperature...............................................................15

8.9. Entering the WTDS coefficient...........................................................................15

9. Maintenance of the conductivity cell.........................................................................16

10. Calibration...............................................................................................................17

10.1. Calibration without standard solution...........................................................18

10.2. Calibration with use of standard solution.....................................................19

10.2.1. Entering the standard solution value..........................................................20

10.2.2. Calibration with automatic temperature compensation..............................21

10.2. . Calibration with manual temperature compensation..................................2

11. Conductivity measurement.....................................................................................25

11.1. Measurement without temperature compensation.......................................25

11.2. Measurement with automatic temperature compensation...........................26

11. . Measurement with manual temperature compensation...............................27

12. Salinity and total dissolved solids measurement....................................................28

12.1. Salinity measurement with conversion to NaCl or KCl.................................29

1 . Notices about temperature compensation............................................................. 0

1 .1. Natural water................................................................................................ 0

1 .2. Ultra pure water............................................................................................ 0

III. Temperature measurement.........................................................................................32

14. Setting the temperature measurement parameters...............................................

14.1. Resolution.....................................................................................................

14.2. Probe number............................................................................................... 4

14. . Sensor group................................................................................................ 4

14.4. Unit............................................................................................................... 4

14.5. Temperature of the manual compensation.................................................. 4

15. Temperature measurement.................................................................................... 5

I . Options.........................................................................................................................36

16. Option screen......................................................................................................... 7

16.1. Function........................................................................................................ 7

16.2. Series............................................................................................................ 8

16. . Miscellaneous............................................................................................... 8

16.4. Info................................................................................................................40