WAGO I/O System 750 Table of Contents 3

750-600/000-001 End Module with Potential Group

Manual

Version 1.0.1

Table of Contents

1Notes about this Documentation .............................................................4

1.1 Validity of this Documentation.................................................................4

1.2 Copyright................................................................................................4

1.3 Symbols .................................................................................................5

1.4 Number Notation ....................................................................................7

1.5 Font Conventions ...................................................................................7

2Important Notes ........................................................................................8

2.1 Legal Bases............................................................................................8

2.1.1 Subject to Changes............................................................................8

2.1.2 Personnel Qualifications ....................................................................8

2.1.3 Use of the 750 Series in Compliance with Underlying Provisions.......8

2.1.4 Technical Condition of Specified Devices...........................................9

2.1.4.1 Disposal ........................................................................................9

2.1.4.1.1 Electrical and Electronic Equipment ..........................................9

2.1.4.1.2 Packaging ...............................................................................10

2.2 Safety Advice (Precautions) .................................................................11

3Device Description..................................................................................14

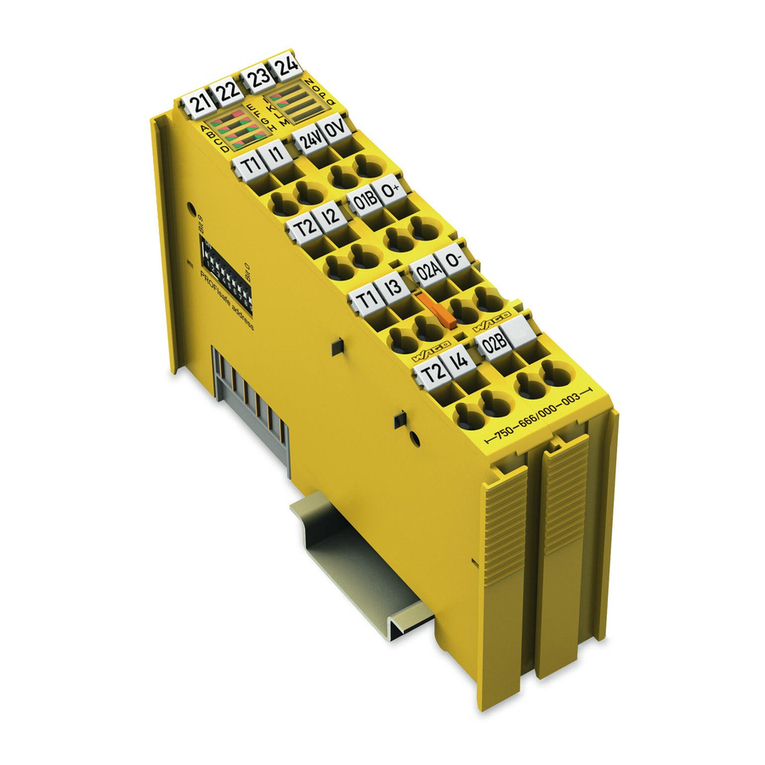

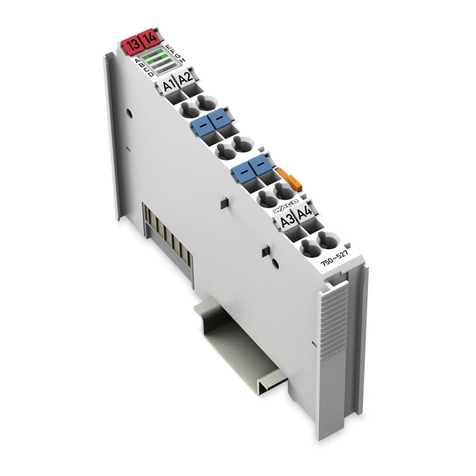

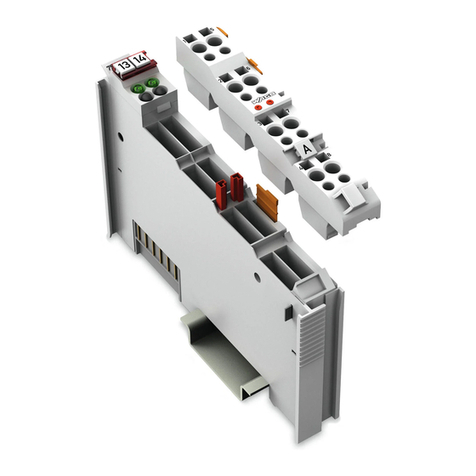

3.1 View .....................................................................................................15

3.2 Connectors ...........................................................................................16

3.2.1 Data Contacts/Local Bus..................................................................16

3.2.2 Power Jumper Contacts/Field Supply ..............................................16

3.2.3 CAGE CLAMP®Connectors.............................................................17

3.3 Display Elements..................................................................................17

3.4 Operating Elements..............................................................................17

3.5 Schematic Diagram ..............................................................................18

3.6 Technical Data .....................................................................................19

3.6.1 Device..............................................................................................19

3.6.2 Rated Voltages ................................................................................19

3.6.3 Connection Type..............................................................................19

3.6.4 Climatic Environmental Conditions...................................................20

3.7 Approvals .............................................................................................21

3.8 Standards and Guidelines ....................................................................22

4Mounting..................................................................................................23

4.1 Mounting Sequence..............................................................................23

4.2 Inserting and Removing Devices ..........................................................24

4.2.1 Inserting the End Module .................................................................24

4.2.2 Removing the End Module...............................................................25

5Connect Devices .....................................................................................26

5.1 Connecting a Conductor to the CAGE CLAMP®...................................26

5.2 Connection Examples...........................................................................27

List of Figures ..................................................................................................28

List of Tables....................................................................................................29