Weller WX1 User manual

Other Weller Soldering Gun manuals

Weller

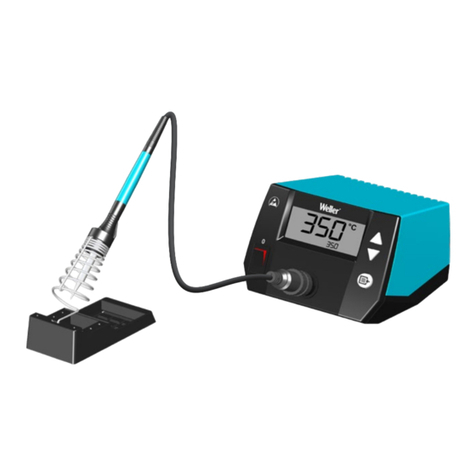

Weller WE 1 User manual

Weller

Weller wsd 81 User manual

Weller

Weller wtt 1 User manual

Weller

Weller WAS 101 User manual

Weller

Weller T0052919299N User manual

Weller

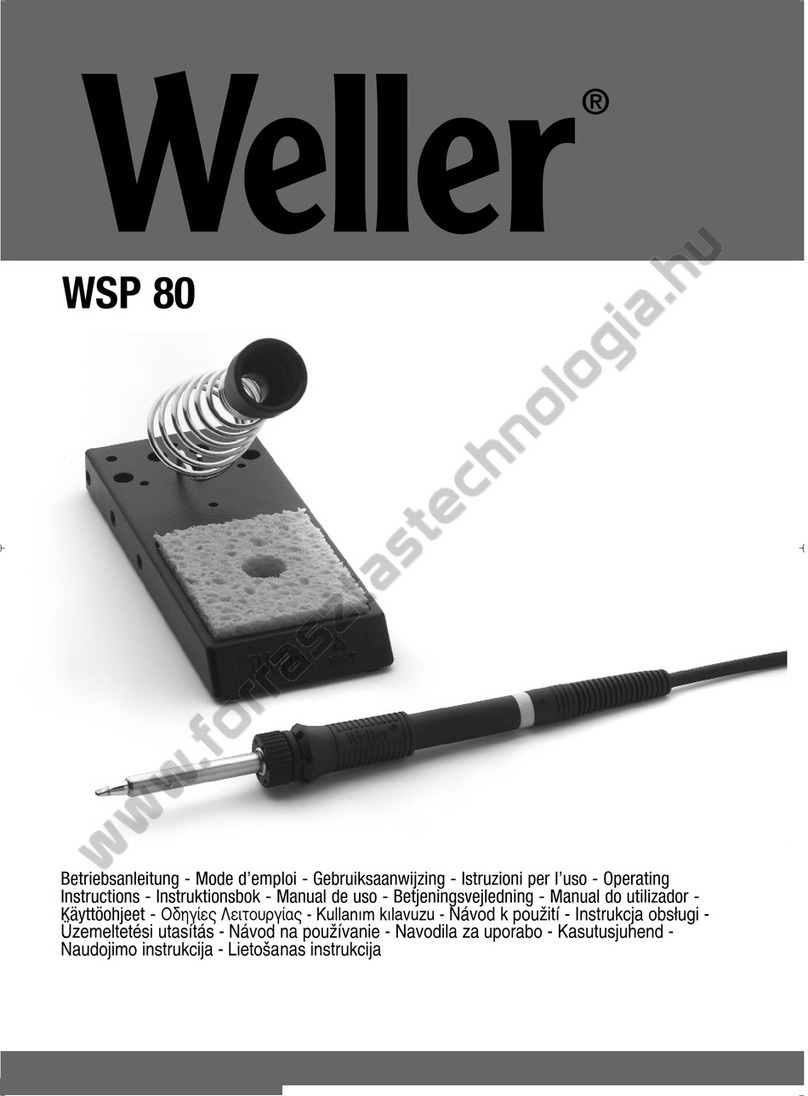

Weller WSP 80 User manual

Weller

Weller WMD 3 User manual

Weller

Weller WSP 80 User manual

Weller

Weller WXP?65 User manual

Weller

Weller WAD 101 User manual

Weller

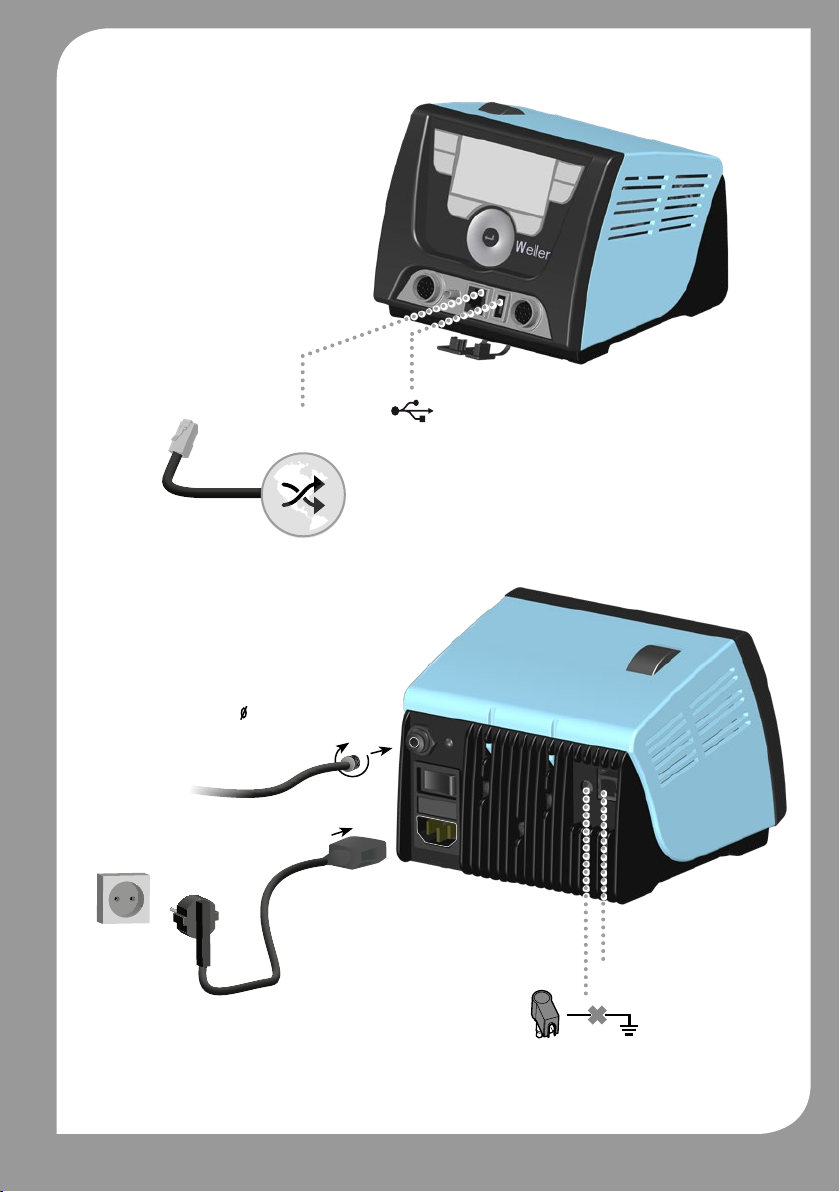

Weller WXsmart User manual

Weller

Weller WSP 80 User manual

Weller

Weller WS 51 User manual

Weller

Weller WSD 151 User manual

Weller

Weller WXD 2 User manual

Weller

Weller WD 1000T User manual

Weller

Weller D550 Series User manual

Weller

Weller WR 2 User manual

Weller

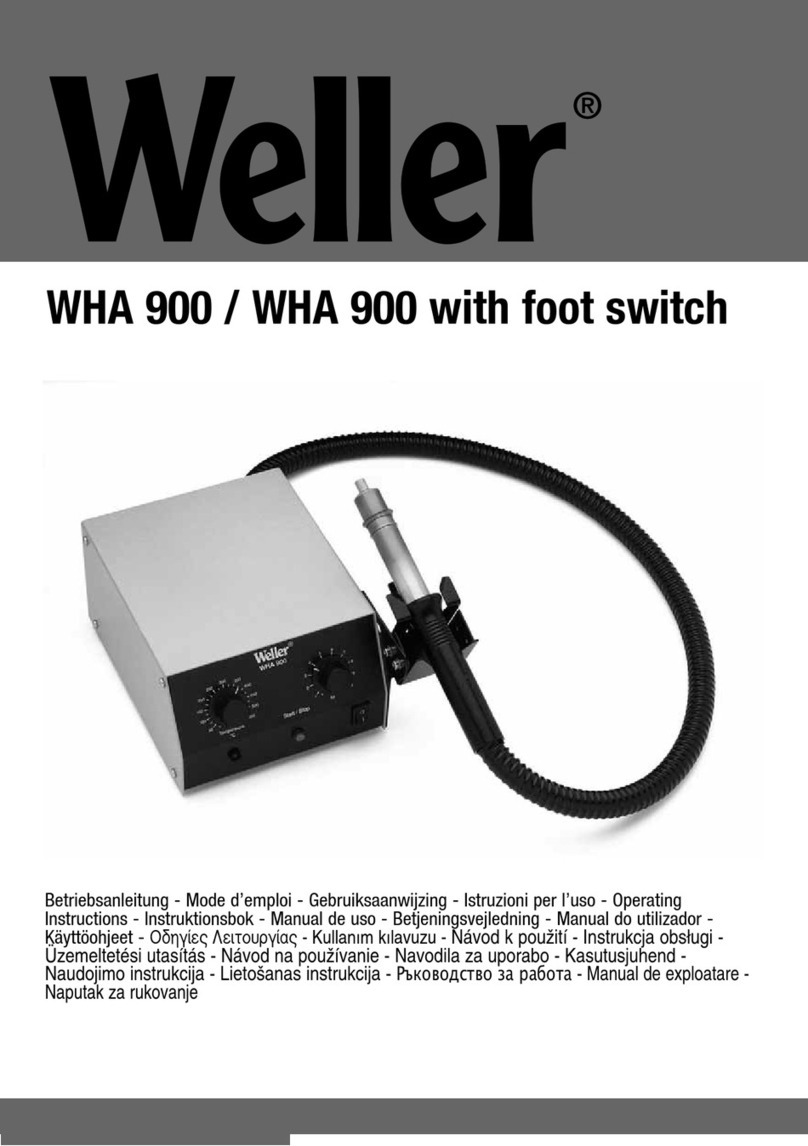

Weller WHA900 User manual

Weller

Weller W 101H User manual