WELLS BLOOMFIELD, LLC• www.wellsbloom ield.com

265 Hobson St •Smithville, Tennessee 37166

Telephone 888 356 5362 •Fax 314 781 5445

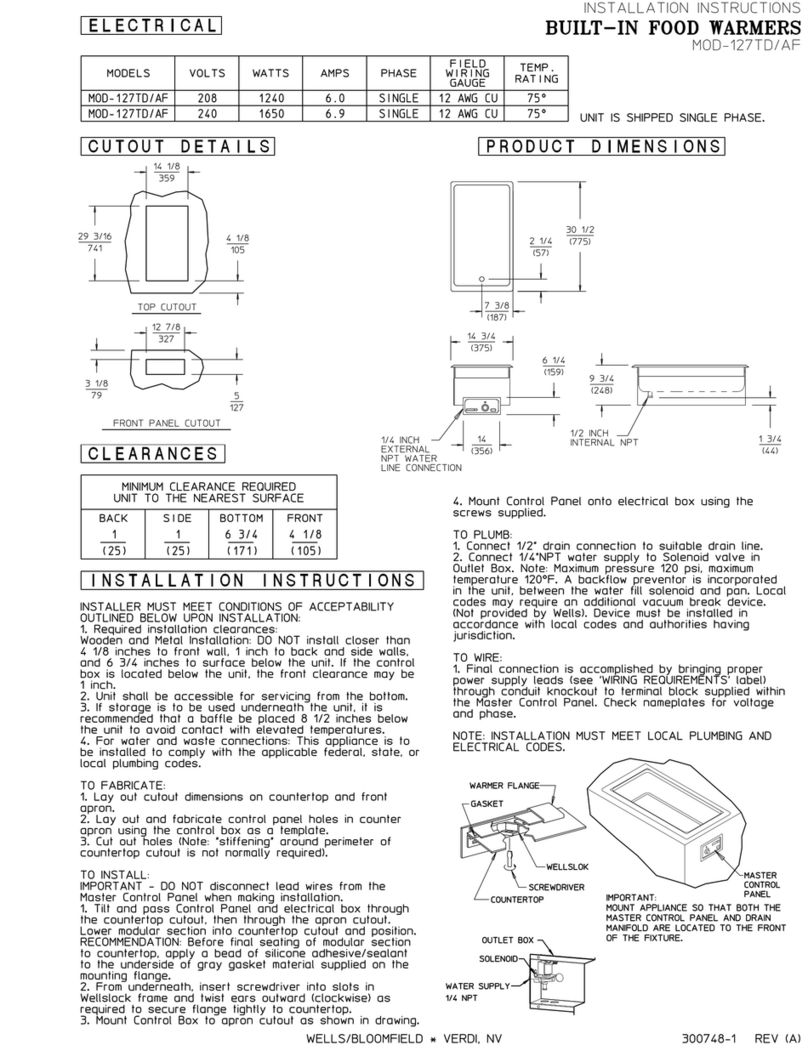

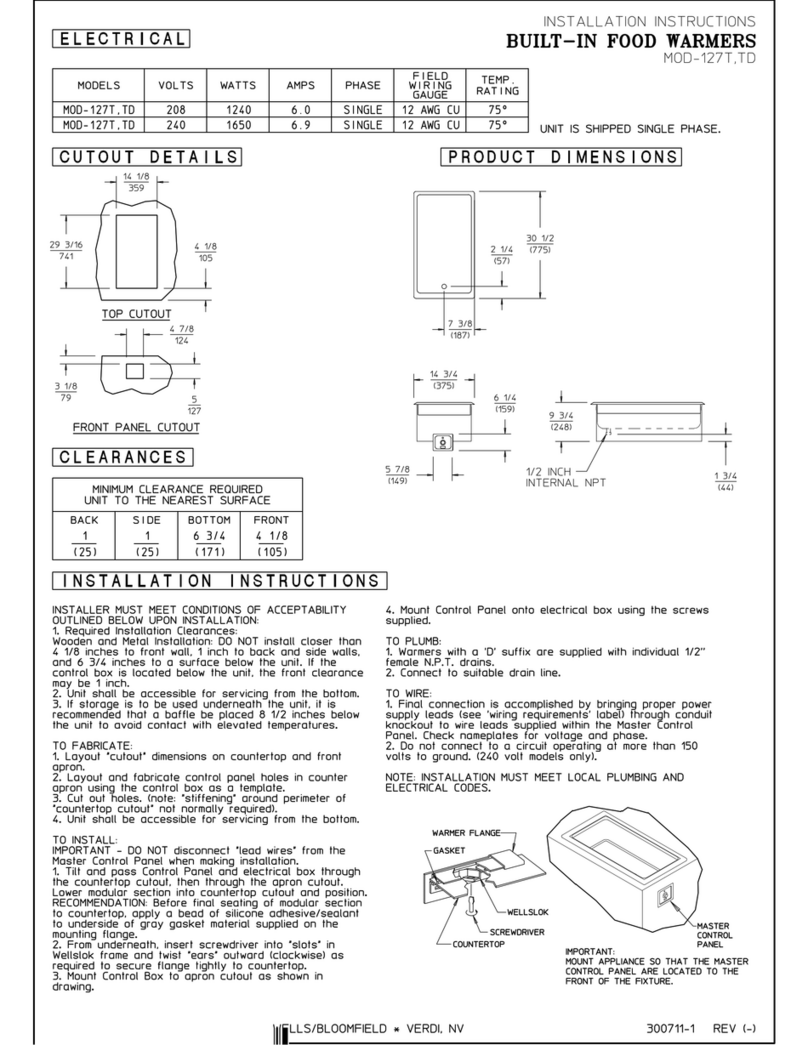

The supply wire will need to be the correct gauge as described by

the National Electrical Code and be rated to at least 167°F (75°C).

1Wellslok adapter kit will use hex screws to tighten and allow

installation on countertops up to 1.5 inches (38 mm) thick.

The unit’s overall depth is 12.125 inches (308 mm) will sit

approximately 11.75 inches (298 mm) below the counter

surface depending on counter thickness.

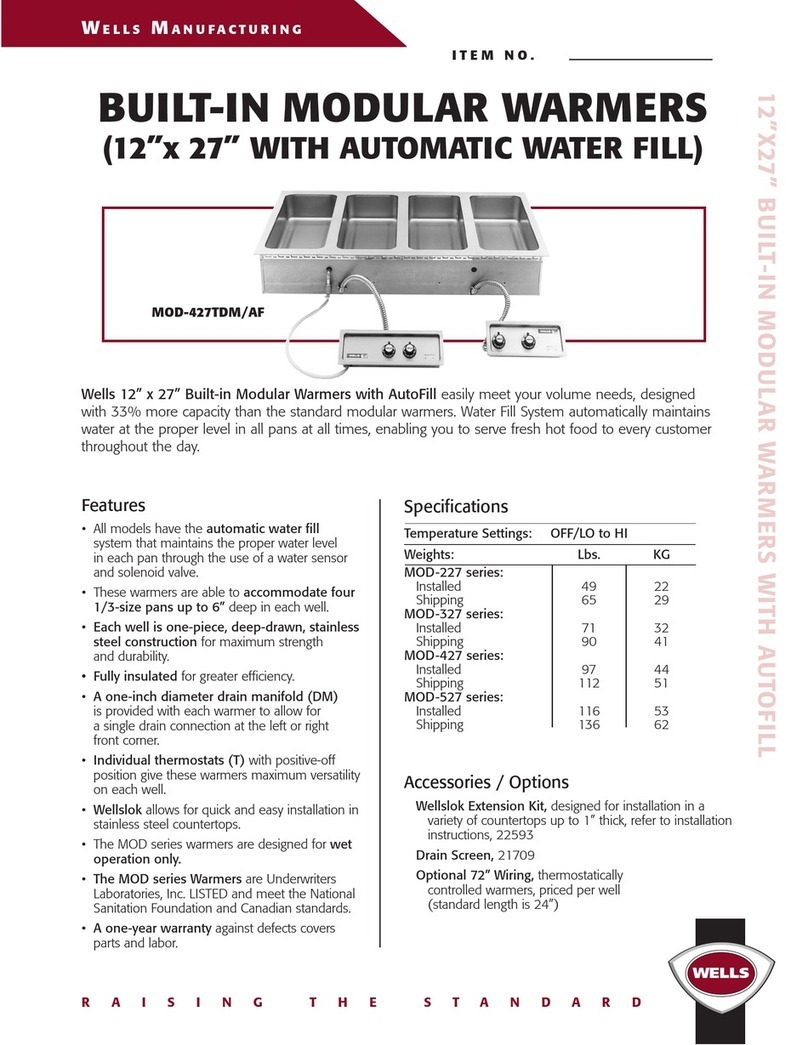

When installing multiple units, each unit will need a space

of at least 2.125 inches (54 mm) between the cutouts on

the long dimension sides [A] and at least 3.625 inches

(92 mm) between cutouts on the short dimension side [B].

MDW100 Modular Dry Well

Installation Instructions

Printed in the U.S.A. • 2M-Z20755 • Rev B• 05.2018

The owner is responsible for proper installation as

described above. Please refer tothe owner’s manual

for information regarding installation or use.

Do not disconnect the control box from the modular unit.

i. Remove the knobs and faceplate from the control box. Pass the

control box through the countertop cutout, and then through

the apron cutout. This will require the box to be rotated so the

mounting tabs clear the hole. Next, lower and position the

modular section into countertop cutout.

ii. Before final seating of modular section to countertop, apply

a bead of silicone sealant to the underside of the grey gasket

material supplied on the mounting flange. From underneath,

insert screwdriver into the slots in the Wellslok frame and twist

clockwise to move the ears outward as required to secure the

flange tightly to countertop.1

iii. Mount the control box to apron cutout using #10 sheet metal [or

wood] screws to the facing side where the holes were drilled.

iv. Run wiring through the conduit knockout to the terminal block,

making connection as shown in the unit’s wiring diagram to the

correct power source.

v. Mount the front panel onto the control box using the provided

hardware and place the knob on. At this point, you should be

able to power on the unit and check for proper operation.

Do not install closer than 4.125 inches (105 mm) to front wall,

one [1] inch (25 mm) to back and side walls, and 6.75 inches

(171 mm) to a surface below the unit. If storage is to be used

underneath, it is recommended that a bae be placed 8.5

inches (216 mm) below the unit to avoid contact with elevated

temperatures. The unit will need to be accessible from the

bottom after installation is complete.

A proper electrical connection based on the units electrical

specifications will be necessary for installation. This must

be wired and connected by a licensed electrician. Electrical

installation will need to pass local electrical codes.

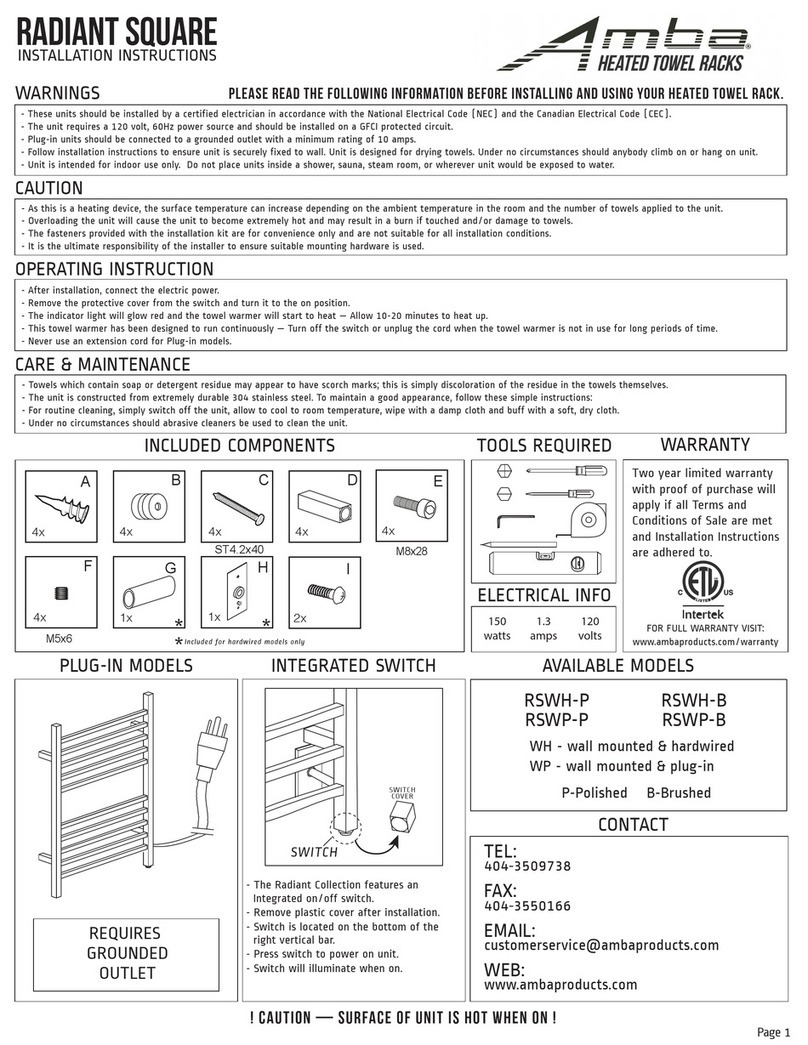

i. Lay out cutout dimensions on countertop and front apron.

ii. Lay out control panel mounting holes in counter apron using

the provided dimensions. The mounting holes should be

0.144 inch (3.7 mm) in diameter [drill size 27].

iii. Cut out the holes. On many countertops, reinforcement may

beneeded to stiffen the countertop.

INSTALLATION INSTRUCTIONS

INSTALLATION REQUIREMENTS

FABRICATION

MODEL TOTAL kW VOLTS, PHASE AMPS

MDW100 0.61

0.8

208, 1Φ

240, 1Φ

2.9

3.3

3 in.

(76 mm)

7/8 in.

(22 mm)

1/4 in.

(6 mm)

0.144 inch ø

(3.7 mm ø)

[#27 drill]

4.125 in. (105 mm)

minimum clearance

on control side

2.25 in. (57 mm)

minimum clearance

on non-control side

dry well cutout

13.5 in.

(343 mm)

[B]

22.5 in.

(572 mm)

[A] countertop

3.125 in.

(79 mm)

5 in.

(127 mm)

control cutout

see detail A

4.875 in.

(124 mm)