WIKA UPT-20 User manual

Operating instructions

Betriebsanleitung

GB

D

Prozesstransmitter, Typ UPT-2x

Process transmitter, model UPT-20

Process transmitter, model UPT-2x

2

14068347.01 06/2014 GB/D

WIKA operating instructions process transmitter, model UPT-2x

GB

D

© 2014 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA®is a registered trademark in various countries.

WIKA®ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Operating instructions model UPT-2x Page 3 - 62

Betriebsanleitung Typ UPT-2x Seite 63 - 122

3

WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

Contents

Contents

1. General information 8

2. Safety 9

3. Specications 12

4. Design and function 20

5. Transport, packaging and storage 22

6. Commissioning, operation 23

7. Display and operating unit, model DI-PT-U 27

7.1 Design and description 27

7.2 Accessing/exiting the operating menu 27

7.3 Installation/Removal 28

7.4 Setting the main display 29

7.5 Setting the additional display 30

8. Congurationwithoutdisplayandoperatingunit 31

8.1 Performing a mounting correction (oset) 31

8.2 Conguring over HARTinterface 32

9. Congurationviadisplayandoperatingunit 33

9.1 Conguring the measuring task 33

9.1.1 Conguring pressure measurement 33

9.1.2 Conguring level measurement 34

9.2 Setting the units 35

9.2.1 Setting the pressure unit 35

9.2.2 Set length unit (for level measurement) 35

9.2.3 Setting the density unit 36

4WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

Contents

9.2.4 Setting the temperature unit 36

9.3 Scaling the measuring range 37

9.3.1 Performing a wet adjustment 37

9.3.2 Performing a dry adjustment 38

9.4 Setting the mode 39

9.5 Mounting correction (oset) 40

9.5.1 Performing a wet adjustment 40

9.5.2 Performing a dry adjustment 40

9.6 Setting the damping 41

9.7 Write protection 42

9.7.1 Activating/deactivating the write protection 42

9.7.2 Changing PIN 42

10. Diagnostic functions 43

10.1 Simulations 43

10.1.1 Performing a pressure simulation 43

10.1.2 Performing a current simulation 43

10.2 Indicating/ressetting drag pointer 44

10.2.1 Drag pointer Pmin / Pmax 44

10.2.2 Drag pointer PVmin / PVmax 45

10.2.3 Drag pointer Tmin / Tmax 45

10.3 Indicating/resetting operating time 45

11. Detail setup 46

11.1 Setting the language 46

11.2 Marking the measuring point (TAG) 46

11.2.1 Setting the TAG short 46

5

WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

Contents

11.2.2 Setting the TAG long 46

11.3 Setting the alarm signal 47

11.4 Setting the signal limits 47

11.5 Setting the contrast of the LC display 48

11.6 Restoring factory setting 48

11.7 Setting the HARTcommunication 49

11.7.1 Setting the short address (multidrop mode) 49

11.7.2 Activating/deactivating constant current 49

12. Instrument information 50

12.1 Indicating measuring range 50

12.2 Indicating date of manufacture 50

12.3 Indicating rmware version 50

12.4 Indicating serial number 51

13. Maintenance and cleaning 51

14. Faults 52

15. Dismounting, return and disposal 53

16. Accessories 54

Appendix 2: Menu tree, basic setting 56

Appendix 3: Menu tree, display 58

Appendix 4: Menu tree, diagnostic 59

Appendix 5: Menu tree, detail setup 60

Appendix 6: Menu tree, info 62

Declartations of conformity can be found online at www.wika.com

6WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

1. General information

1. General information

■

The process transmitter described in the operating instructions has been designed

and manufactured using state-of-the-art technology. All components are subject

to stringent quality and environmental criteria during production. Our management

systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instru-

ment. Working safely requires that all safety instructions and work instructions are

observed.

■

Observe the relevant local accident prevention regulations and general safety regula-

tions for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage caused by using the

product contrary to its intended use, non-compliance with these operating instruc-

tions, assignment of insuciently qualied skilled personnel or unauthorised modi-

cations to the instrument.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: PE 86.05

- Application consultant: Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.com

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious injury

or death, if not avoided.

7

WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

1. General information / 2. Safety

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries

or damage to equipment or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for ecient and

trouble-free operation.

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the appro-

priate instrument has been selected in terms of measuring range, design

and specic measuring conditions.

Non-observance can result in serious injury and/or damage to the equip-

ment.

Further important safety instructions can be found in the individual

chapters of these operating instructions.

2.1 Intended use

The process transmitter measures gauge pressure, absolute pressure and vacuum. The

physical quantity pressure is converted into an electrical signal.

The process transmitter has been designed exclusively for industrial applications in

internal and external locations. Its scope of application is dened by its technical perfor-

mance limits and its materials. Improper use is dened as any application that exceeds

the technical performance limits or is not compatible with the materials. Checking

against improper use is the responsibility of the operator.

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

The technical specications contained in these operating instructions must be

observed. Improper handling or operation of the instrument outside of its technical

specications requires the instrument to be taken out of service immediately and

inspected by an authorised WIKA service engineer.

The manufacturer shall not be liable for claims of any type based on operation contrary

to the intended use.

8WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

2. Safety

2.2 Personnelqualication

WARNING!

Riskofinjuryshouldqualicationbeinsucient!

Improper handling can result in considerable injury and damage to equipment.

The activities described in these operating instructions may only be carried

out by skilled personnel who have the qualications described below.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowl-

edge of country-specic regulations, current standards and directives, are capable of

carrying out the work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media, compatibility of materials.

2.3 Personalprotectiveequipment

The personal protective equipment is designed to protect the skilled personnel from

hazards that could impair their safety or health during work. When carrying out dierent

work on and with the instrument, personal protective equipment must be worn.

Followtheinstructionsdisplayedintheworkarearegardingpersonalprotective

equipment!

The requisite personal protective equipment must be provided by the operating

company.

2.4 Specialhazards

WARNING!

For hazardous media such as oxygen, acetylene, ammable or toxic gases

or liquids, and refrigeration plants, compressors, etc., in addition to all

standard regulations, the appropriate existing codes or regulations must also

be followed.

WARNING!

Residual media in the dismounted process transmitter can result in a risk to

personnel, the environment and equipment.

Take sucient precautionary measures.

9

WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

2. Safety

2.5 Labelling, safety marks

Product label

Pin assignment Model code

Power supply S# Serial no.

Output signal P# Product no.

Measuring range Date of manufactureYYYY-MM

Explanation of symbols

Before mounting and commissioning the instrument, ensure you read the

operating instructions!

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European directives.

Output signal

Powersupply

Ground (GND)

10 WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

3.Specications

3. Specications

3.1 Measuring range (see product label)

Gauge pressure

bar 0 ... 0.4 0 ... 1.6 0 ... 6 0 ... 16 0 ... 40

0 ... 100 0 ... 250 0 ... 600 0 ... 1,000

psi 0 ... 10 0 ... 15 0 ... 30 0 ... 100 0 ... 300

0 ... 500 0 ... 1,500 0 ... 5,000 0 ... 10,000

Absolute pressure

bar 0 ... 0.4 0 ... 1.6 0 ... 6 0 ... 16 0 ... 40

psi 0 ... 30 0 ... 100 0 ... 300 0 ... 500

Vacuum and +/- measuring ranges

bar -0.4 ... 0 -0.2 ... +0.2 -1 ... +0.6 -1 ... +5 -1 ... +15

-1 ... +40

psi -14.5 ... 0 -14.5 ... +15 -14.5 ... +100 -14.5 ... +300 -14.5 ... +600

Vacuumtightness

Vacuum resistance is provided, except for instruments for oxygen applications.

Overpressurelimit

Measuring range Overpressurelimit

≤ 16 bar/300 psi 3 times

> 16 bar/300 psi 2 times

11

WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

3.Specications

3.2 Accuracy data

Accuracy at reference conditions

Including non-linearity, hysteresis, zero oset and end value deviation (corresponds to

measured error per IEC 61298-2).

Accuracy

Standard 0.15 % of span

Option 1 0.10 % of span

Option 2 0.20 % of span

Mounting correction

-20 ... +20 %

Non-repeatability

≤ 0.15 % of span

Behaviourwithturndown(withaccuracy0.15%)

Turndown = basic measuring range : scaled measuring range

■

1:1 ... 5:1 No change in accuracy

■

> 5:1 < 0.03 % x turndown

Long-term stability

≤ (0.1 % x turndown)/year

Thermalchangezeropoint/span(referencetemperature20°C)

In compensated range 10 ... 70 °C:

< 0.05 % / 10 K x turndown

Outside compensated range:

Typical < 0.1 % / 10 K x turndown

Thermalchangeofthecurrentoutput(referencetemperature20°C)

< 0.05 % / 10 K, max. 0.15 %

12 WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

3.Specications

3.3 Operating conditions

The process pressure transmitter is suitable for internal and external operation.

Direct exposure to sunlight is permitted.

Humidity

≤ 93 % r. h.

Ambient temperature

Instrument with display: -20 ... +60 °C

Instrument without display: -40 ... +80 °C 1)

1) Instrument with angular connector or circular connector: -30 ... +80 °C

Storage temperature

-40 ... +80 °C

Medium temperature

Oxygen application: -20 ... +60 °C

Model UPT-20: -40 ... +85 °C

-40 ... +105 °C at max. 40 °C ambient temperature

-40 ... +120 °C at max. 30 °C ambient temperature

Model UPT-21: Depending on sealing, cooling element and ambient temperature

UPT-21 without cooling element:

85 °C at max. 80 °C ambient temperature

105 °C at max. 40 °C ambient temperature

120 °C at max. 30 °C ambient temperature

UPT-21 with cooling element:

85 °C at max. 80 °C ambient temperature

120 °C at max. 50 °C ambient temperature

150 °C at max. 40 °C ambient temperature

Sealing

Material Medium temperature

NBR -20 ... +105 °C

FKM -20 ... +105 °C

FKM -20 ... +150 °C 2)

EPDM 1) -40 ... +105 °C

EPDM 1) -40 ... +150 °C 2)

1) EPDM only with hygienic process connection

2) Process connection with cooling element

13

WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

3.Specications

Vibration resistance

4 g (5 ... 100 Hz) per GL characteristic curve 2

Shockresistance

150 g (3.2 ms) per IEC 60068-2-27

Ingress protection

IP 66/67

IP 65 for versions with circular connector, angular connector or overvoltage protection

Ingress protection only applies with closed case head and closed cable glands.

3.4 Materials

Wetted parts

■

Model UPT-20, measuring range ≤ 40 bar: Stainless steel 1.4404

■

Model UPT-20, measuring range > 40 bar: Stainless steel 1.4404 and

stainless steel 2.4711

■

Model UPT-21: Stainless steel 1.4435

Sealing material

See table “medium temperature” under chapter 3.3 “Operating conditions”

Casehead

Plastic (PBT) with conductive surface per EN 60079-0:2012

Colour: night blue RAL5022

Pressure transmission medium

Model Medium

Model UPT-20 Measuring range ≤ 40 bar:

Synthetic oil, halocarbon oil

Measuring range > 40 bar:

Dry measuring cell

Model UPT-21 Synthetic oil, halocarbon oil

14 WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

3.Specications

3.5 Display and operating unit (option)

Refreshrate

200 ms

Main display

4 ½-digit

Additional display

Selectable via menu, three-line scale range

Bargraphdisplay

20 segments, radial, pressure gauge simulation

Colours

Background: light grey, digits: black

Operating state

Display via symbols

3.6 Output signal (see product label)

Signal

4 ... 20 mA

4 ... 20 mA with HART®signal

LoadinΩ

(UB- UBmin) / 0.023 A

UB = applied power supply (see “Power supply”)

UBmin = minimum permissible power supply (see “Power supply”)

Damping

0 ... 99.9 s, adjustable

After the set damping time the instrument outputs 63 % of the applied pressure as

output signal.

Settling time t90

60 ms without HART®

80 ms with HART®

Refreshrate

20 ms without HART®

50 ms with HART®

15

WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

3.Specications

3.7 Voltage supply

PowersupplyUB

DC 12 ... 36 V

3.8 Electrical connections

Availableconnections Ingress pro-

tection

Wire cross-section

Cable gland M20 x 1.5 and spring-loaded terminals IP 66/67 max. 2.5 mm2 (AWG 14)

Angular connector DIN 175301-803A with mating

connector IP 65 max. 1.5 mm2

Circular connector M12 x 1 (4-pin) without mating

connector IP 65 -

The stated ingress protection only applies when plugged in using mating connectors

that have the appropriate ingress protection.

3.9 Reference conditions (per IEC 61298-1)

Temperature

23 °C ± 2 °C

Powersupply

DC 23...25 V

Atmosphericpressure

860 ... 1,060 mbar (86 ... 106 kPa, 12.5 ... 15.4 psig)

Humidity

35 ... 93 % r. h.

Characteristiccurvedetermination

Terminal method per IEC 61298-2

Curvecharacteristics

Linear

Reference mounting position

Vertical, diaphragm points downward

16 WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

3.Specications

3.10 CE conformity

Pressureequipmentdirective

97/23/EC

EMCdirective

2004/108/EG interference emission (group 1, class B) and immunity per

EN 61326-1:2013 (industrial application), EN 61326-2-3:2013 and per

NAMUR NE 21:2011

During interference, increased measuring deviations of up to 0.15 % can

occur.

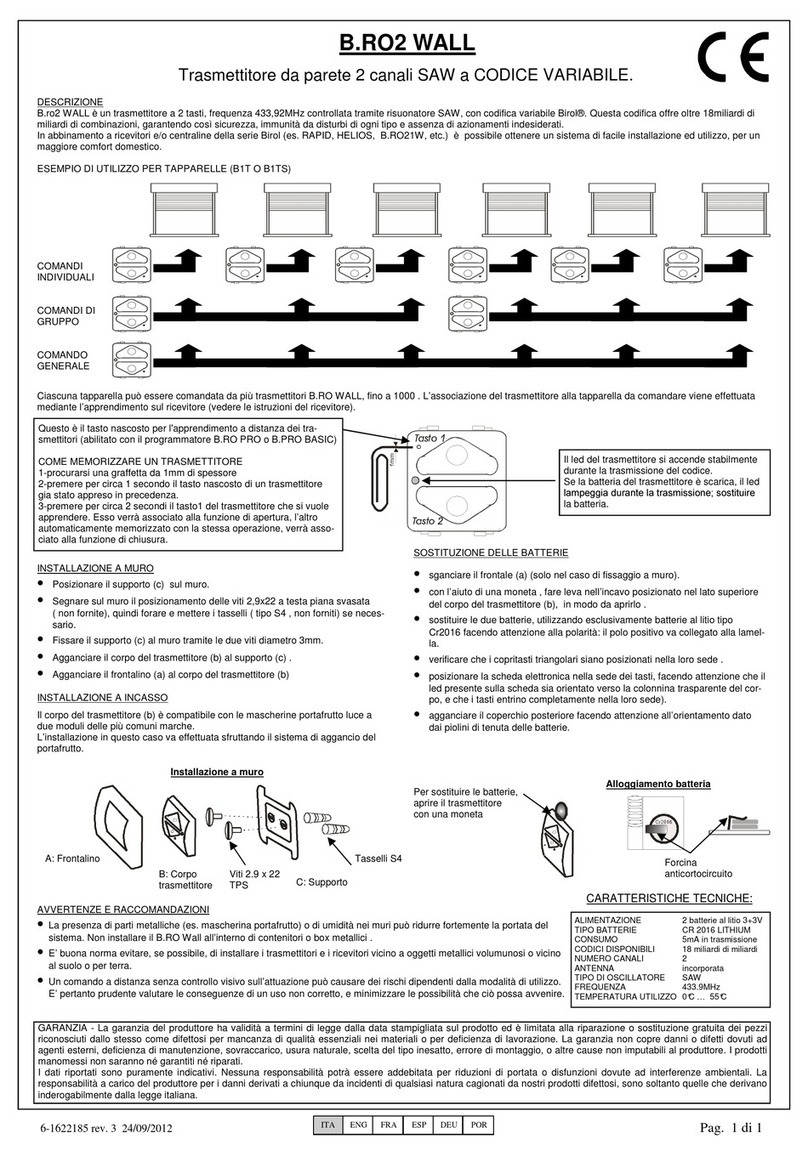

3.11 Dimensions in mm

Process transmitter, models UPT-20 and UPT-21

17

WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

3.Specications

Hygienic Hygienic

Process connections for model UPT-20

G L1

G ⅜ B 16

G ½ B 20

M20 x 1.5 20

Hexagon dimension: 12 mm

G L1

¼ NPT 13

½ NPT 19

Hexagon dimension: 12 mm

G L1 L2 D1

½ NPT, female 20 19 26.5

Hexagon dimension: 12 mm

Process connections for model UPT-21

G L1 L2 L3 D1

G ½ B 23 20.5 10 18

Hexagon dimension: 12 mm

G L1 L2 L3 D1

G 1 B 23 20.5 10 30

Hexagon dimension: 13 mm

G L1 L2 D1

G 1 ½ B 25 22 55

Hexagon dimension: 14 mm

G L1 L2 L3 D1

G 1 B 28 25 9 29.5

Hexagon dimension: 13 mm

G L1 L2 L3 L4 D1

G 1 B 28 25 9 15.5 29.5

Hexagon dimension: 13 mm

18 WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

4. Design and function

4. Design and function

4.1 Design

4.2 Description

The process transmitter processes the prevailing pressure and converts it into a current

signal. This current signal can be used for the evaluation, control and monitoring of the

process.

HART(option)

The instrument version with HART can communicate with a controller (master).

Measuringrangescaling(turndown)

The start and end of the measuring range can be set within dened ranges.

Process connection, thread Push-on cap

Process connection, spanner ats Product label

Sensor housing Ground screw, outside

Ex-relevant data Electrical connection, cable gland

Case head Second bore for cable gland (delivered sealed

with blind plug)

19

WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

4. Design and function

Display and operating unit (accessory)

The display and operating unit model DI-PT-U has a main and an additional display.

The main display and the additional display are able to be set in almost any way. In the

factory setting, the main display shows the pressure value of the output signal.

The process transmitter is congured via the display and operating unit.

Adaptable to mounting position

The process transmitter is tted with a case head which can be turned through 330°.

The display and operating unit can be attached in 90° steps. Thus the measured value

can be read irrespective of the mounting position.

4.3 Scopeofdelivery

■

Pre-assembled process transmitter

■

Ordered accessories

■

Operating instructions

■

Measured value protocol

Cross-check scope of delivery with delivery note.

Displaceable display and operating unit

Rotatablecasehead

330°

20 WIKA operating instructions process transmitter, model UPT-2x

14068347.01 06/2014 GB/D

GB

5. Transport, packaging and storage

5. Transport, packaging and storage

5.1 Transport

Check the process transmitter for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change

in installation site, return for calibration).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: -40 ... +80 °C

■

Humidity: 35 ... 93 % relative humidity (no condensation)

Avoidexposuretothefollowingfactors:

■

Proximity to hot objects, when permissible storage temperature is exceeded by

radiation

■

Mechanical vibration, mechanical shock (putting it down hard), when the permissible

values are exceeded, see chapter 3 “specications”

■

Soot, vapour, dust and corrosive gases

■

Hazardous areas and ammable atmospheres where the instruments are not suitable

for installation in or mounting to equipment in explosive atmospheres.

Store the process transmitter in its original packaging in a location that fulls the condi-

tions listed above. If the original packaging is not available, then store the instrument

in a container that is similar to the original packaging, so that the instrument can't be

scratched and is protected against damage if dropped.

WARNING!

Before storing the instrument (following operation), remove any residual

media. This is of particular importance if the medium is hazardous to health,

e.g. caustic, toxic, carcinogenic, radioactive, etc.

Other manuals for UPT-20

2

Table of contents

Languages:

Other WIKA Transmitter manuals