1. 2 Application

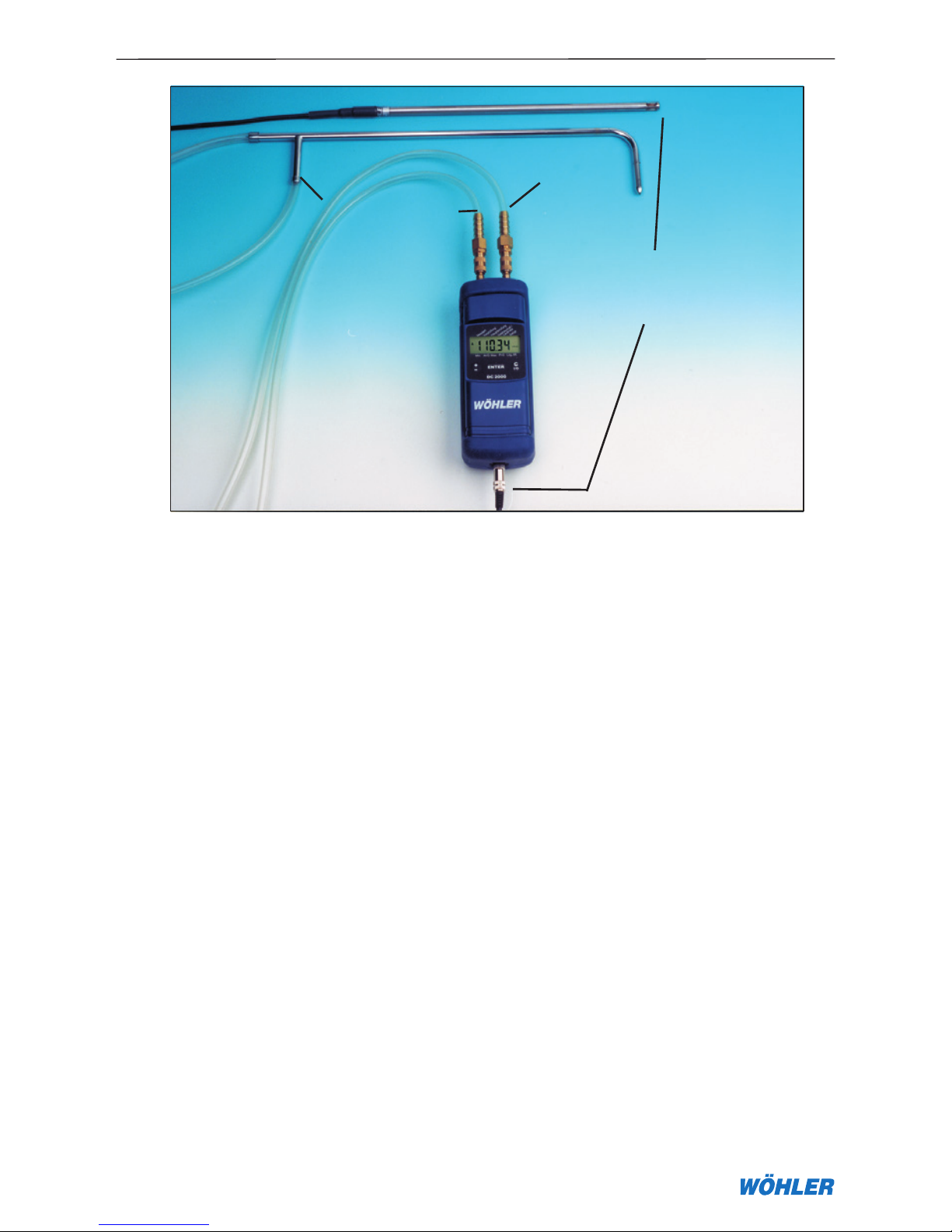

The Pressure Computer DC 2000PRO is a high-precision multifunctional meter

for registering differential pressures, flow rates, temperatures, and humidities

(optional). From the basic version on, this device exhibits an extremely wide

dynamic range that not only takes highly sensitive measurements of mini-

mum draughts and gas pressures in the pascal range, but also lets the user

measure leakage rates and examine sealing properties for main assessments

as per DVGW-TRGI and conduct measurements for load tests during pre-

assessments. A maximum measuring range of 2 bar and a rupture pressure

of 3 bar also provide for adequate safety at higher pressure ranges. During all

measurements the user is guided by plaintext instructions on the display.

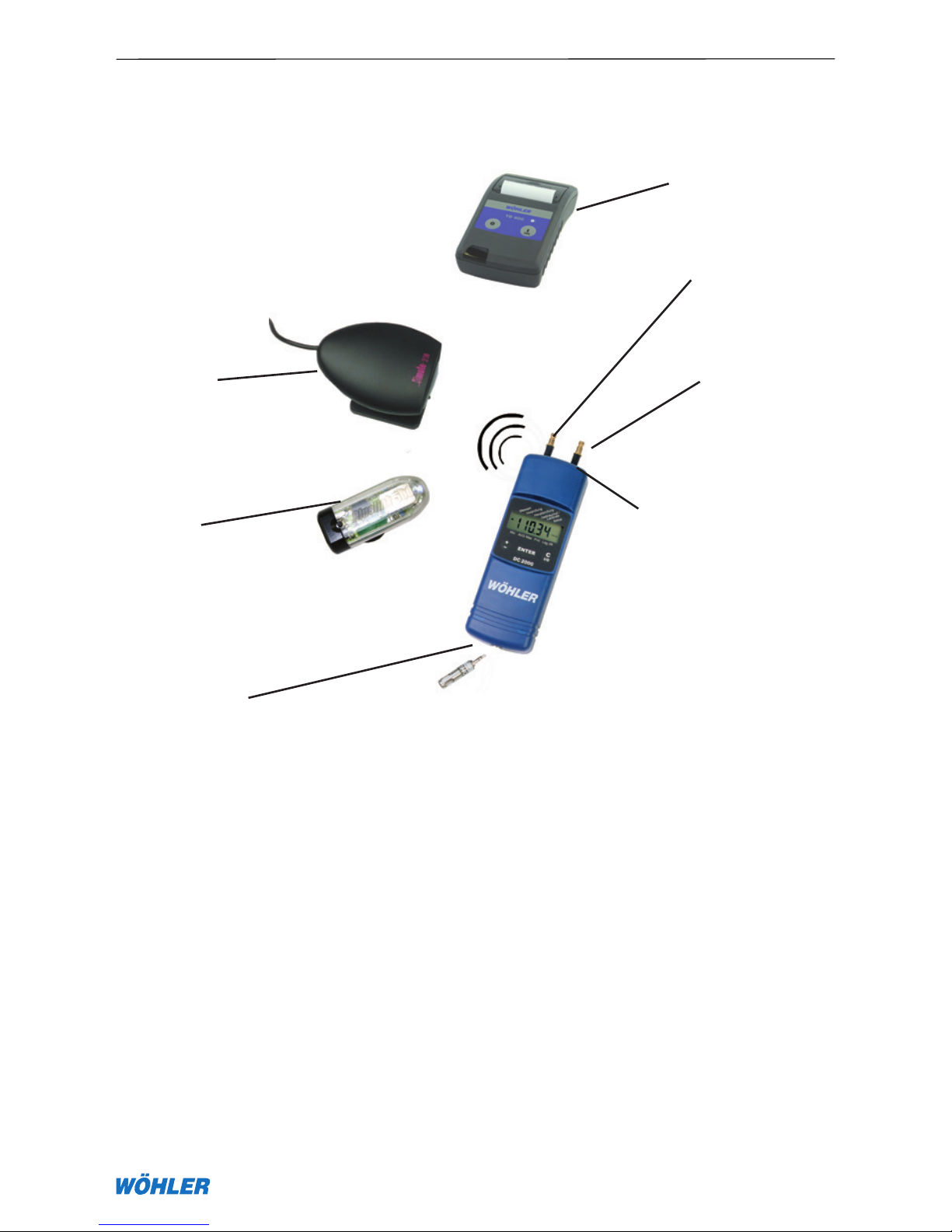

This device, which can store all measured values in a logger, can also be

used for measurements of (ambient) climates. This is made possible by a

temperature sensor also integrated as standard in addition to the pressure

sensor. Optionally, the range of applications can be expanded with an exter-

nal temperature sensor. Depending on the selected scan rate, all measured

values can be logged for several years and transferred to a PC via the inte-

grated IrDA interface. Measurement records can be sent to a thermal printer

for printouts with the company logo. If needed, continuous IrDA transfer can

be activated in the Setup menu so that during measurements all four mea-

sured values (pressure, external and internal temperature, and humidity) and

their respective channel numbers are transferred to a PC every second.

The extremely low current consumption is made possible by an all-new pro-

cessor technology that automatically and dynamically adapts the power draw

to the measuring task. Also the mode with the maximum current consumption

(6 mA) runs continuously for over 300 hours on two standard AA batteries (2

Ah). In logger mode the device can run on the same batteries and without

memory overflow for several years when the scan rate between two measure-

ments is 4 h (4680 measurements x 4 h). The pressure meter can be used on

both gaseous media (air or inert gas) and liquids, e.g. water or fuel oil. In this

case, it is important to observe that remains of liquid at the pressure connec-

tions can falsify the result of the following gas measurement. Therefore, the

device should no longer be used on gaseous media, after it has been used to

measure liquids.

The processor’s arithmetic and logic unit (ALU) can perform simple operations

on the measured values so that, for example, the leakage rate is automatically

displayed in l/h or the flow rate measured with a Prandtl’s tube in m/s.

The German association for safety inspections on gas leak meters, TÜV SÜD

Industrie Service zur Gasleckmengenmessung has certified and approved the

DC 2000PRO in accordance with the new DVGW requirements under VP 952

for low-pressure gas lines complying with DVGW worksheets G 600 and G

624. (DVGW-Certificate DG-4805BQ0012)

1. Specifications