TABLE OF CONTENTS

CHAPTER 1 - OVERVIEW ..................................................................................................................................... 4

MANUAL OVERVIEW ............................................................................................................................... 5

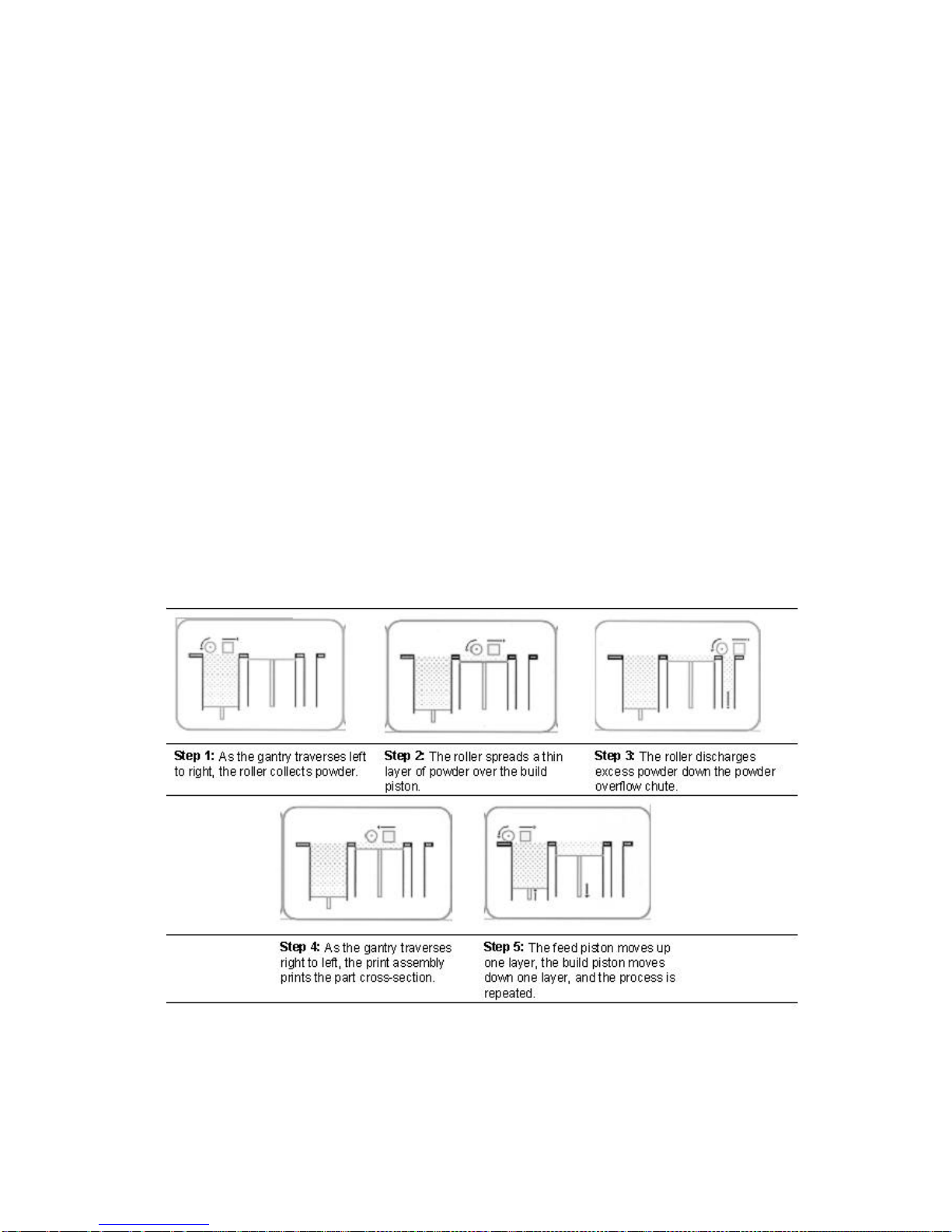

HOW IT WORKS.................................................................................................................................... 6

SYSTEM COMPONENTS ........................................................................................................................... 9

ZPRINTER 310 SUBCOMPONENTS........................................................................................................... 10

CHAPTER 2 - QUICK STARTGUIDE ..................................................................................................................... 14

PRINTER PREPARATION......................................................................................................................... 15

PARTPRINTING .................................................................................................................................. 17

POST PROCESSING.............................................................................................................................. 19

USEFUL TIPS ..................................................................................................................................... 20

PARTSETUP AND POST-PROCESSING ......................................................................................... 20

OVEN DRYTHE PART.............................................................................................................. 21

PARTINFILTRATION .................................................................................................................. 21

CHAPTER 3 - MATERIAL SYSTEMS ...................................................................................................................... 22

USING ZCASTTM POWDER .................................................................................................................... 23

GENERAL INFORMATION ............................................................................................................ 23

USING ZCAST ONYOUR ZPRINTER 310 PRINTER ........................................................................ 23

LOADING ZCAST POWDER ........................................................................................................ 28

SETTING UPZCAST BUILDS ..................................................................................................... 28

POST PROCESSING ................................................................................................................. 28

MATERIAL ORDERING............................................................................................................... 29

RECYCLING ........................................................................................................................... 29

STORAGE.............................................................................................................................. 29

DISPOSAL ............................................................................................................................. 29

USING ZP®250 POWDER ...................................................................................................................... 30

MACHINE SETUP .................................................................................................................... 30

SOFTWARE SETUP .................................................................................................................. 30

PARTREMOVAL AND POST PROCESSING...................................................................................... 32

INFILTRATION ADDENDUM .......................................................................................................... 33

CHAPTER 4 - PREPARING THE 3D PRINTER .......................................................................................................... 34

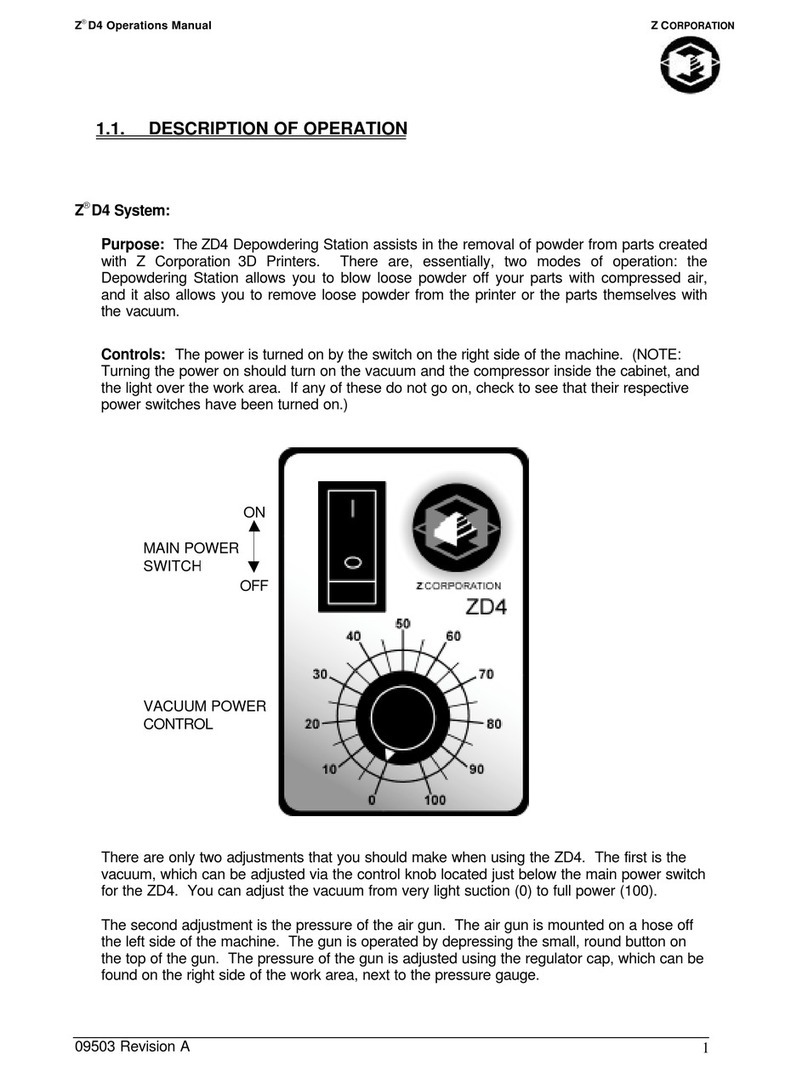

TURNING THE PRINTER ON................................................................................................................... 35

PREPARING THE BUILD ......................................................................................................................... 36

FILLING THE FEED BOX............................................................................................................ 36

REMOVING AIR FROM POWDER AND PACKING THE FEED BOX ........................................................... 37

PREPARING THE BUILD AREA..................................................................................................... 38

CLEANING UP.................................................................................................................................... 39

CLEANING THE SERVICE STATION ............................................................................................................ 40

CLEANING THE SQUEEGEES AND PARKING CAPS ........................................................................... 40

REFILLING THE BINDER BOTTLE .............................................................................................................. 43

CHANGING THE PRINT HEAD .................................................................................................................. 43

EMPTYING THE WASTE BOTTLE .............................................................................................................. 44

PUTTING THE PRINTER ONLINE............................................................................................................... 44

CHAPTER 5 - USING ZPRINT SOFTWARE .............................................................................................................. 45

OPENING OR IMPORTING AFILE .............................................................................................................. 46

ORIENTING THE PART........................................................................................................................... 46

PARTCONTAINING AN OPENING OR HOLLOW AREA ........................................................................ 46

PARTCONTAINING OVERHANGS ................................................................................................. 47