10/2/07 All Rights Reserved

Use Of Equipment

Z Corporation's Equipment, and use of the Equipment, may be subject to limitations imposed under pat-

ents licensed to or owned by Z Corp., and is to be used solely for the fabrication of appearance models

and prototypes using new Z Corporation-supplied consumables from Z Corporation or its authorized dis-

tributors in the original packaging. Other uses may be restricted; contact Z Corporation for further informa-

tion. Consult the User's Manual before operation of any Z Corporation Equipment. The Equipment may be

covered by the following U.S. Patents and/or U.S. Patent Applications:

5,204,055 5,340,656 5,387,380 6,007,318 6,375,874 5,902,441

60/558,940 08/771,009 60/612,068 60/789,758 10/999,847 11/000100

60/741,573 60/808,721 09/706,350 09/835,292 11/453,695 60/472,221

10/848,831 6,416,850 6,610,429 6,403,002 6,989,115 7,037,382

7,087,109 11/335,282 10/817,159 10/650,086

The Equipment is designed to be used by design engineers and other professionals in the production of

early-stage 3D appearance models and prototypes. The Equipment is not to be used to produce, either

directly or indirectly, medical or other products that may require precise dimensions or tolerances to ensure

the safe and effective operation of such products. You agree to indemnify, defend and hold Z Corporation

and its officers, directors and employees harmless from and against any and all claims, losses, damages,

costs and expenses resulting from any use of the Equipment other than for the production of early-stage

appearance models and prototypes.

Overview Of The ZPrinter®450 Hardware Manual Chapters

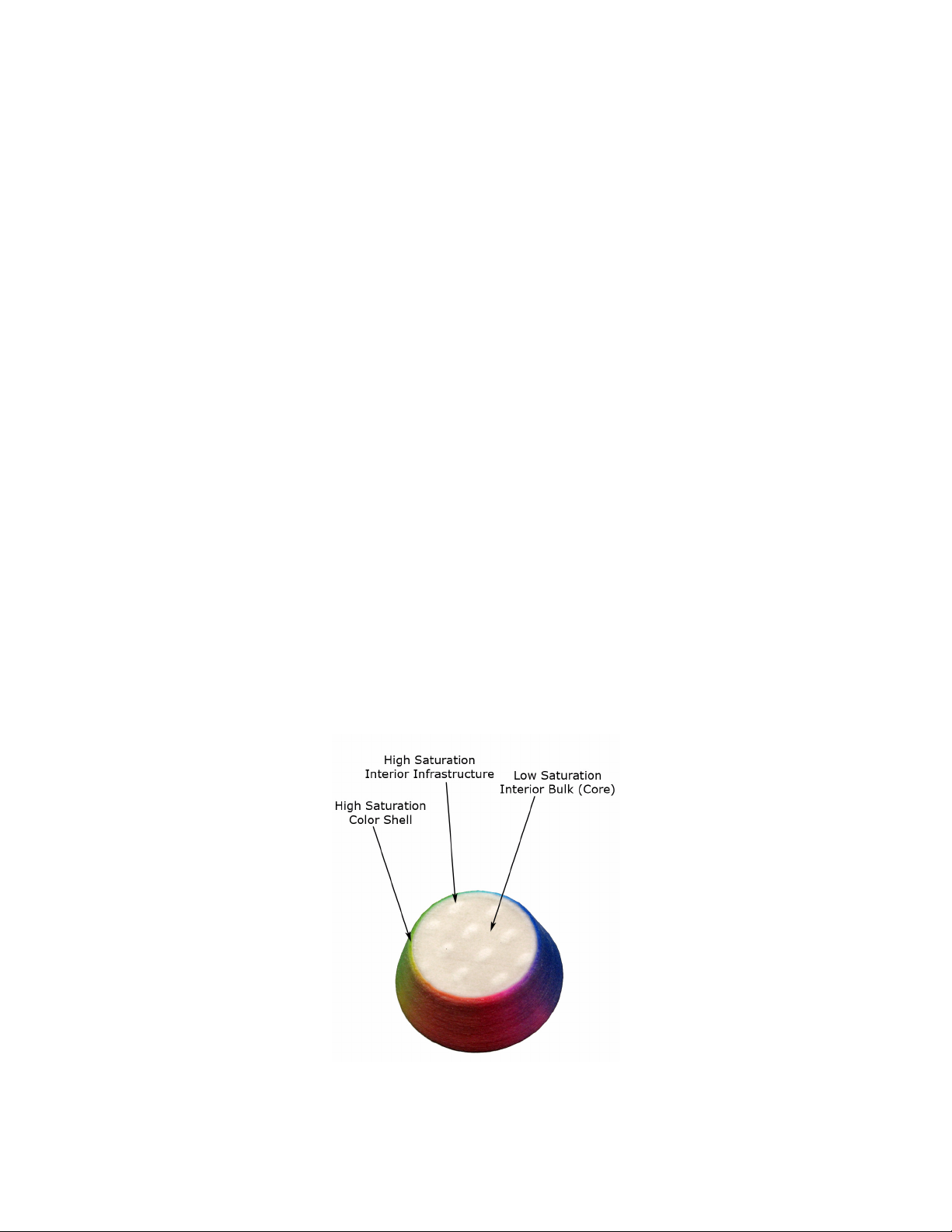

1 - ZPrinter 450 Overview. Details the ZPrinter 450 specifications and computer requirements; pro-

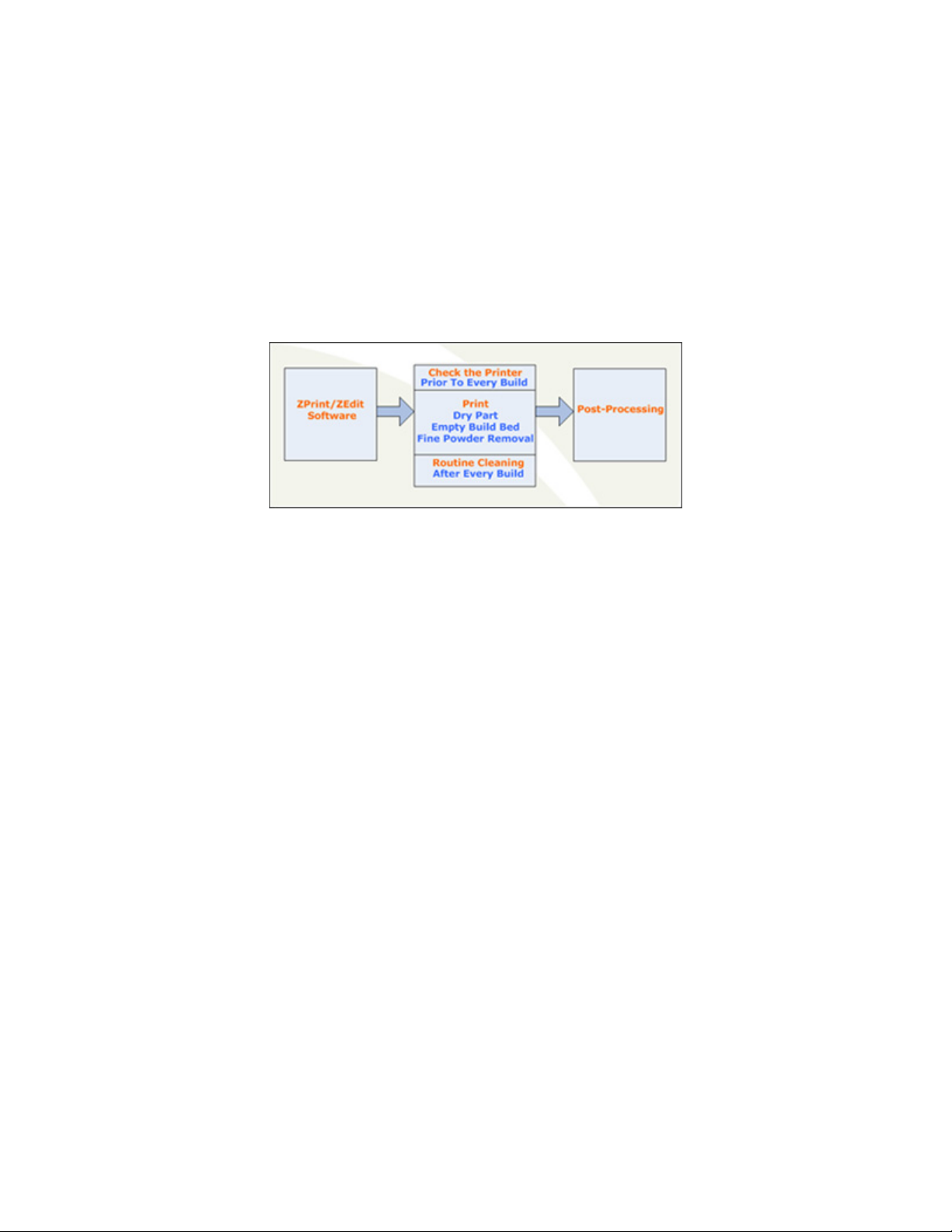

vides a brief overview of the principles behind 3D printing; a process diagram; a list of important terms;

labelled diagrams of the ZPrinter 450 components and the Control Panel; a description of the printer

Accessories Kit; and where to go for more information.

2 - Setup And Print The Build. Describes the necessary steps for printing a part with step-by-step

instructions; a description of the options available for transforming a part; how to create a part fixture

and why you may need to use one; a description of the ZPrint™ Printer Status and Printing dialogs;

automatic and manual powder removal options; and how to use the fine powder removal chamber.

3 - Routine Cleaning. Guides you through simple routine cleaning the operator performs after every

build including vacuuming up excess powder, cleaning the Service Station, cleaning the Parking Caps,

and emptying the Debris Filter.

4 - Post-Processing. An overview of post-processing and how to use Z-Bond™, Z-Max™, and infil-

tration systems for part strength and finish. Provides links to information regarding different infiltration

systems, and ZShop, where you can order online the consumables you need.

5 - Additional Operations. Covers how to add powder to the printer feeder, raise the build bed plat-

form, add binder, and change a print head.

6 - Printer Maintenance. Details the periodic maintenance required for keeping your printer running

smoothly and problem-free. Includes steps for lubricating the Fast Axis bearing, the Slow Axis bearing,

and the Piston Screw; changing the Binder Waste Tray; cleaning the Alignment Sensor Window;

checking the Cleaning Fluid; and printer storage preparations.

7 - Troubleshooting. References the online Help Troubleshooting Guide for common errors.