Z Corporation Z810 System User Manual

www.zcorp-users.com 2

TABLE OF CONTENTS

1INTRODUCTION.......................................................................................................................7

1.1 OVERVIEW .......................................................................................................................... 7

1.2 HOW IT WORKS .................................................................................................................... 8

2SYSTEM COMPONENTS.......................................................................................................11

2.1 Z810 PRINTER COMPONENTS............................................................................................ 11

2.1.1 Z810 3D Printer........................................................................................................ 11

2.1.1.1 Z810 Carriage Assembly...................................................................................... 14

2.1.1.2 Z810 Service Station............................................................................................ 15

2.1.1.3 Z810 Rear Connector Panel ................................................................................ 16

2.1.1.4 Z810 Printer Control Panel................................................................................... 17

2.1.2 ZF8 Powder Feeder................................................................................................. 18

2.1.2.1 ZF8 Rear Connector Panel .................................................................................. 19

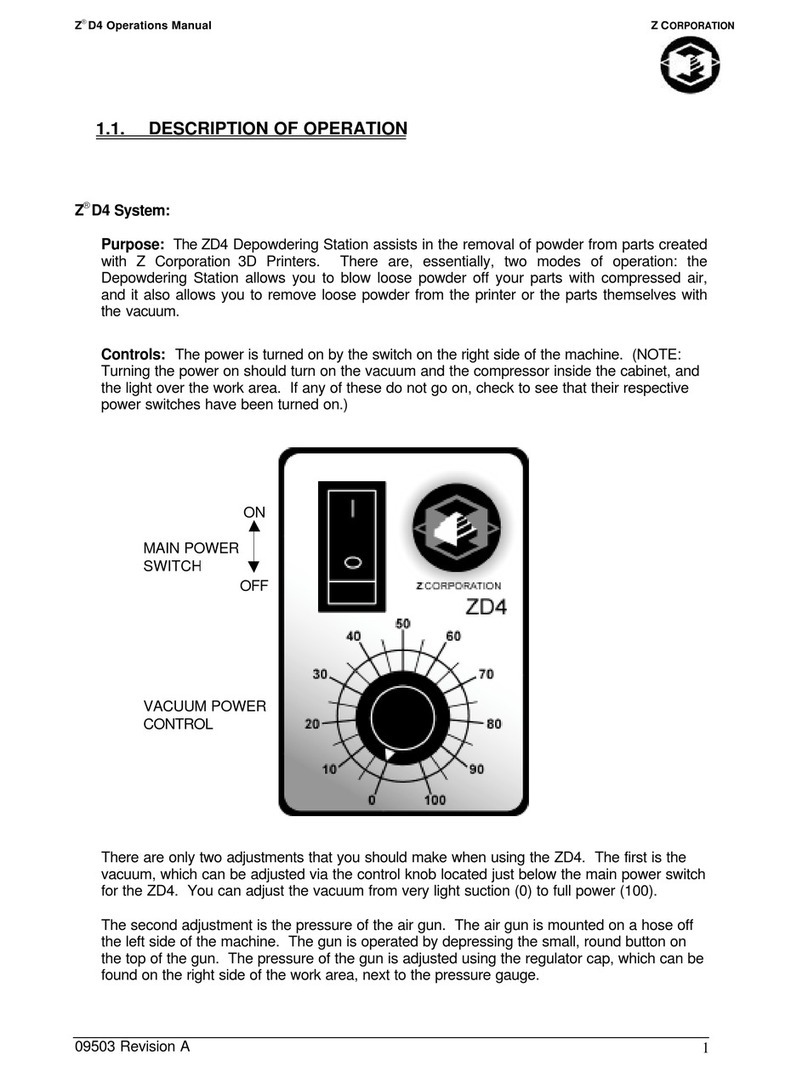

2.2 ZD8 DEPOWDERING UNIT.................................................................................................. 20

2.2.1 Air Curtain................................................................................................................ 22

2.2.2 ZD8 Control Panel ................................................................................................... 23

2.2.3 Powder Collection Drawer ....................................................................................... 24

2.2.4 ZD8 Cart .................................................................................................................. 24

2.3 DESPATCH LBB FORCED CONVECTION OVEN (OPTION)...................................................... 25

3QUICK START GUIDE ...........................................................................................................26

3.1 PRINTER PREPARATION ..................................................................................................... 26

3.2 SETTING UP THE BUILD ...................................................................................................... 28

3.3 TRANSFERRING THE PART TO THE DEPOWDERING UNIT ...................................................... 29

3.4 DEPOWDERING THE PART.................................................................................................. 30

3.5 TRANSFER TO OVEN.......................................................................................................... 31

3.6 FINISH PART ..................................................................................................................... 31

3.7 USER TIPS ........................................................................................................................ 31

3.7.1 Set-up and Post-processing .................................................................................... 31

3.7.1.1 Part Setup, Orientation, and Print Settings.......................................................... 31

3.7.1.2 Gross and Fine Depowdering .............................................................................. 32

3.7.1.3 Oven Dry the Part................................................................................................. 32

3.7.2 Part Infiltration.......................................................................................................... 32

3.7.2.1 When Using Z-Bond Resin................................................................................... 32

3.7.2.2 When Using a Z-Snap or Z-Max Epoxy ............................................................... 32

4PREPARING THE Z810 3D PRINTER...................................................................................33

4.1 REPLACING THE BUILD PALLET........................................................................................... 33

4.2 CLEANING THE SERVICE STATION ...................................................................................... 33

4.3 GREASING THE FAST AXIS ................................................................................................. 34

4.4 OIL SLOW AXIS ................................................................................................................. 35

4.4.1 Snowplows............................................................................................................... 35

4.4.2 Slow Axis Path......................................................................................................... 35

4.5 FILL BED........................................................................................................................... 36

4.6 REMOVE POWDER FROM OVERFLOW CHUTE ...................................................................... 36

4.7 CHECKING POWDER LEVELS.............................................................................................. 37

4.8 CHECK FLUID LEVELS........................................................................................................ 38

4.8.1 Binder Containers.................................................................................................... 38

4.8.2 Check Waste Container........................................................................................... 39

4.8.3 zc3 Wash Fluid Container........................................................................................ 40

5USING ZPRINT SOFTWARE .................................................................................................41

5.1 OPEN OR IMPORT THE FILE................................................................................................ 41

5.2 ORIENTING THE PART ........................................................................................................ 41