VM1-T - VACUUM CIRCUIT BREAKER8

—

3. Function

3.3 Quenching principle of the

vacuum interrupter

Due to the extremely low static interrupter chamber

pressure of 10-4 to 10-8 hPa, only a relatively small

contact gap is required to achieve a high dielectric

strength. The vacuum arc is extinguished on one of

the first natural current zeros.

Due to the small contact gap and the high

conductivity of the metal vapour plasma, the arc

drop voltage, and additionally, due to the short

arcing time, the associated arc energy, are

extremely low, which has advantageous effects on

the life of the contacts and thus on that of the

vacuum interrupters.

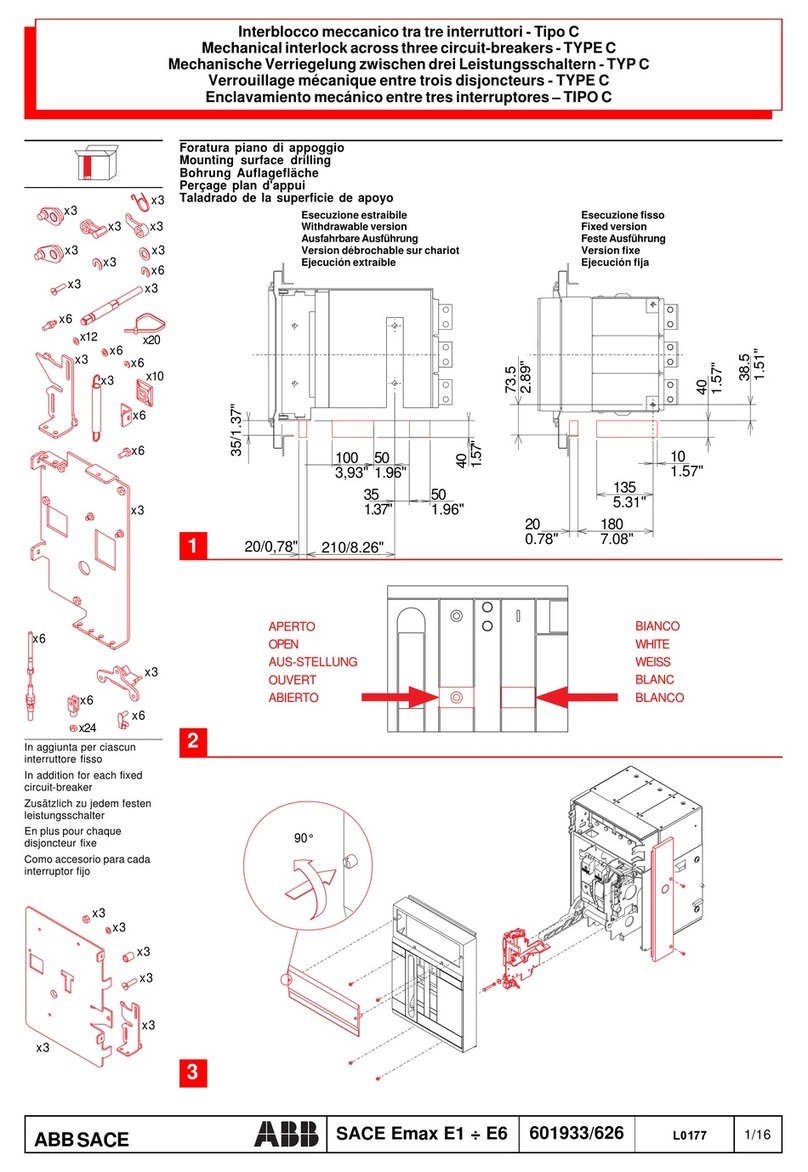

3.4 Interlocks

3.4.1 Interlocks/protection against

maloperation (for C.B. on withdrawable

parts)

(Figure 9/8)

A series of interlocks are provided to prevent

dangerous situations and any maloperation. The

interlocks of the panel system ZS and/or the

Powerbloc/mounting frame, which are normally

effective, are as follows (concerning the circuit

breaker):

The withdrawable part can only be moved from

the test/disconnected position into the service

position (and back) with the circuit breaker open

and the blocking magnet supplied.

The circuit breaker can only be closed if the

withdrawable part is precisely in the defined test

position or service position (electrical interlock).

The circuit breaker can only be opened manually in

the service or test position when no control

voltage is applied, and it can not be closed.

The panel is equipped with devices which allow

the connection and disconnection of the control

wiring plug 36.1 only in the test/disconnected

position.

Details of any additional interlocks, e.g. in

connection with a blocking magnet on the

earthing switch operating mechanism, can be

found in the order documents for each individual

case.

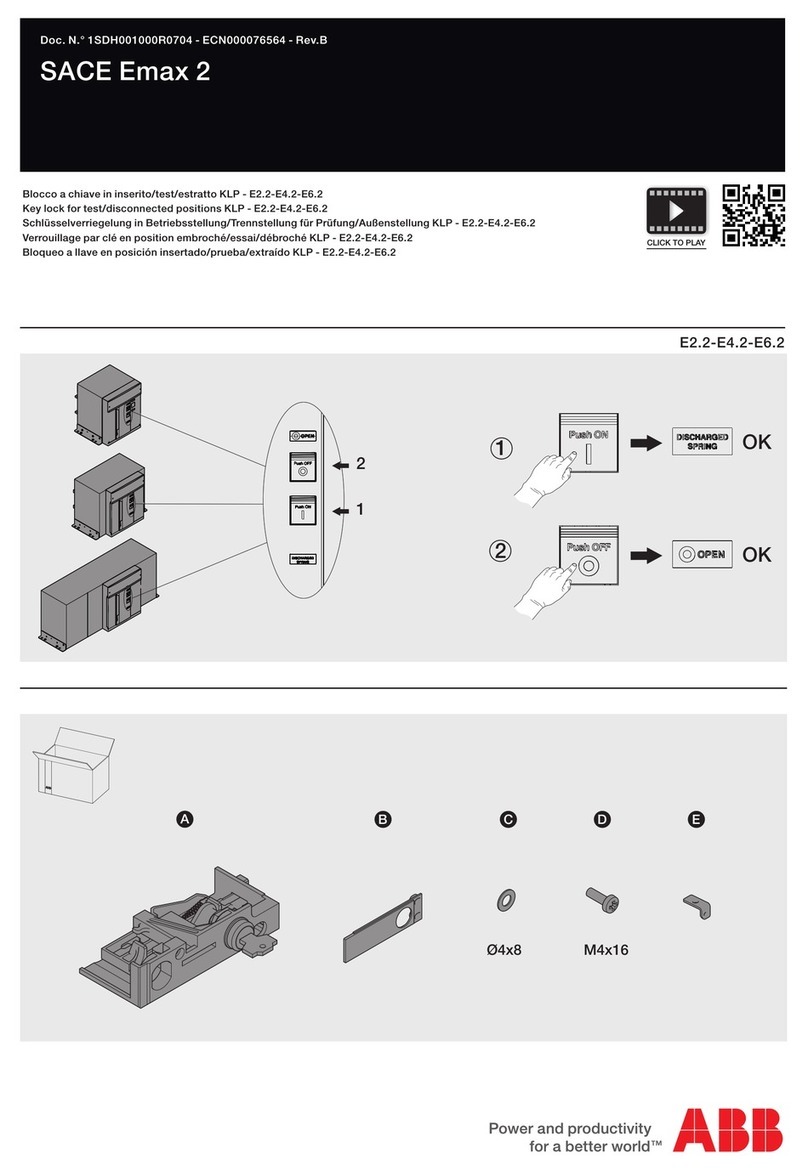

3.4.2 Interlocks for VM1-T withdrawable parts

3.4.2.1 Interlocks when ABB withdrawable

assemblies are used

(Figures 9/9 and 9/26)

1. The VM1-T can only be closed via input -MC when

a voltage of 24 V to 240 V AC/DC is applied to

input -RL1 (electrical closing lock-out).

2. The VM1-T can only be closed when the

withdrawable assembly is in service or test

position. In the intermediate positions, the

voltage for the closing lock-out is interrupted by

auxiliary switches -BT2 / -BT1.

3. A mechanical interlock 35.5 and 41.2 prevents a

closed breaker that is not in the OFF position

being moved.

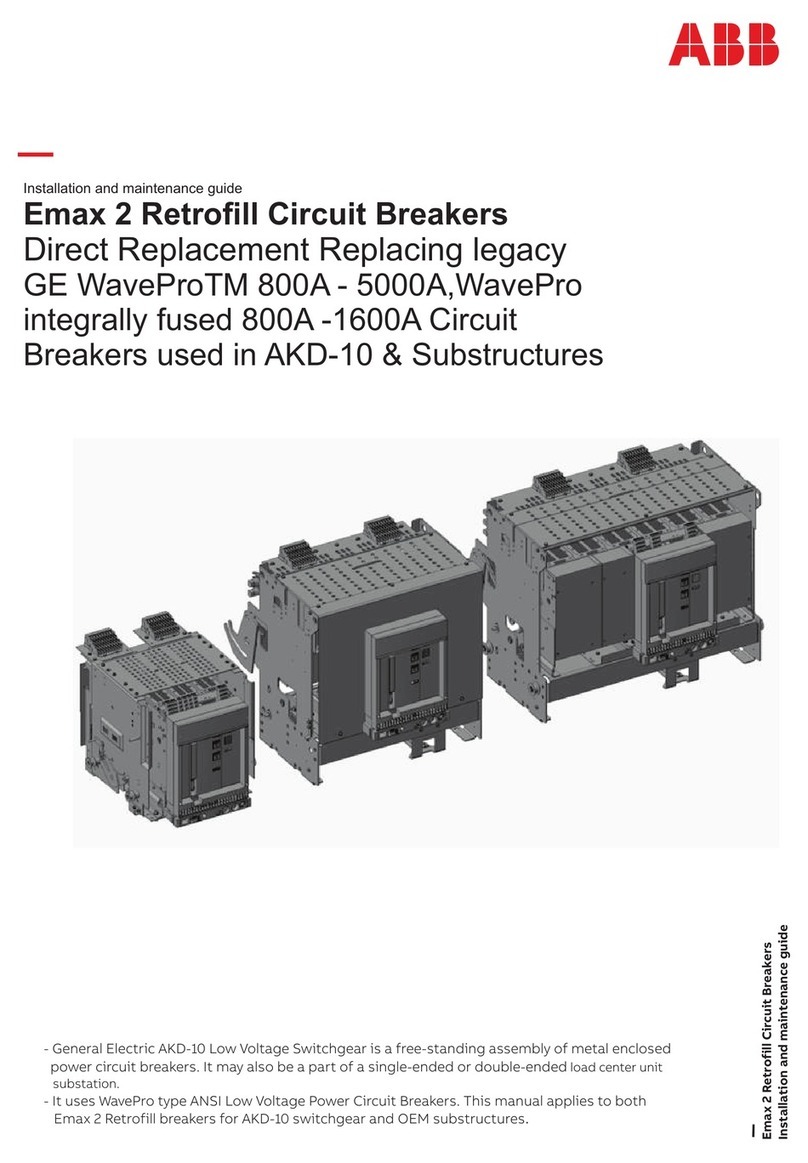

3.4.3 Interlocks when non-original withdrawable

assemblies are used

(Figure 9/26)

VM1-T circuit breakers which are not mounted on

ABB withdrawable part must be electrically

interlocked with one or two additional auxiliary

switches. These must interrupt the input voltage to

the electrical closing lock-out (input -RL1).

In a similar manner to auxiliary switches -BT2 and

-BT1 on the ABB withdrawable part, no further

electrical pulse may be received by -RL1 after the

first half revolution of spindle system 35.1, and it

may only be re-applied after the last half revolution.

This ensures that the circuit breaker cannot be

closed when the withdrawable part is in an

intermediate position.

A mechanical interlock as described in 3.4.2.1 part 3.)

is to be implemented to prevent a circuit breaker

which is not in the OFF position being moved. The

slide blocker 41.2 on the VM1-T (optional accessory

for stationary mounted breakers) can be used for

this purpose: the slide blocker is outside base plate

41.4. Figure 9/9 shows pawl 35.5 on the ABB

withdrawable part. With the circuit breaker not in

the OFF position, pawl 35.5 cannot be moved

upwards. This prevents movement of the

withdrawable assembly and therefore movement of

the circuit breaker.

Note:

Additionally fitted interlocks must not exert any

force on the operating mechanism of the circuit

breaker.

If the interlock mechanism projects beyond the base

of the circuit breaker casing, measures must be

taken to prevent the the circuit breaker from

weighing down on the interlock, for instance during

transport.