Contents

Legal Notice ..........................................................................4

Introduction to this Manual ................................................... 5

About the safety notices in this document .................. 6

Disclaimer ................................................................. 7

Introduction .......................................................................... 8

Intended Use ............................................................. 9

Intended User .......................................................... 10

Training ................................................................... 11

Features ...................................................................12

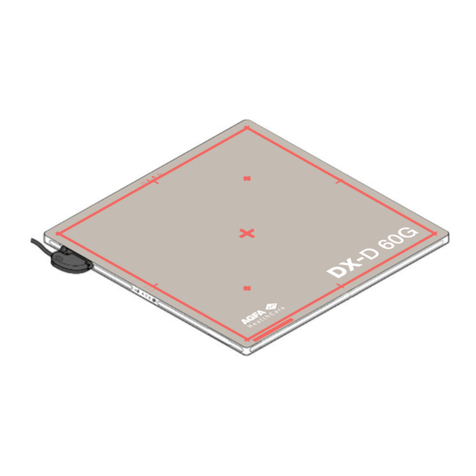

Compatibility ...........................................................13

Compliance ..............................................................16

Connectivity ............................................................ 17

Installation .............................................................. 18

Product Complaints ................................................. 19

Messages ................................................................. 20

Related Documentation ........................................... 21

Safety Directions ..................................................................22

Auto QC² Hardware Components .........................................23

Filter Module and Filters ..........................................24

Positioning Template ............................................... 27

Test Phantom ........................................................... 31

Light Field Indicator Target ......................................35

Metal Pins ................................................................37

Dosimeter ................................................................38

Operating Auto QC² Software .............................................. 39

Starting Auto QC² Software ..................................... 40

Stopping Auto QC² Software .................................... 41

Switching to Windows without Stopping Auto QC²

Software ..................................................................42

Auto QC² Software Windows ................................... 43

Worklist Window ......................................... 44

History Window ...........................................46

Search Window ............................................47

Main Menu Window .................................... 48

General Workflow ............................................................... 49

Test Group Selection ................................................50

Preparing the Modality and Acquiring an Exposure ....

51

Identifying the Cassette and Sending the Examinations to

the Auto QC² Software Station using NX .................. 53

Managing the Worklist .............................................54

Removing images .........................................57

Editing Image Information ...........................58

Performing the Visual Check ........................60

ii | Auto QC² | Contents

2370C EN 20180330 1524