Contents Page

1

2

2.1

2.2

3

3.1

3.2

3.3

3.4

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.4.6

3.5

3.6

3.6.1

3.6.2

3.7

3.8

3.9

3.10

4

5

6

7

7.1

7.2

On receipt of the machine .......................................................................... 4

Technical safety precautions .................................................................... 5

Declined use of the machine ........................................................................ 5

General safety and accident prevention advice ............................................ 5

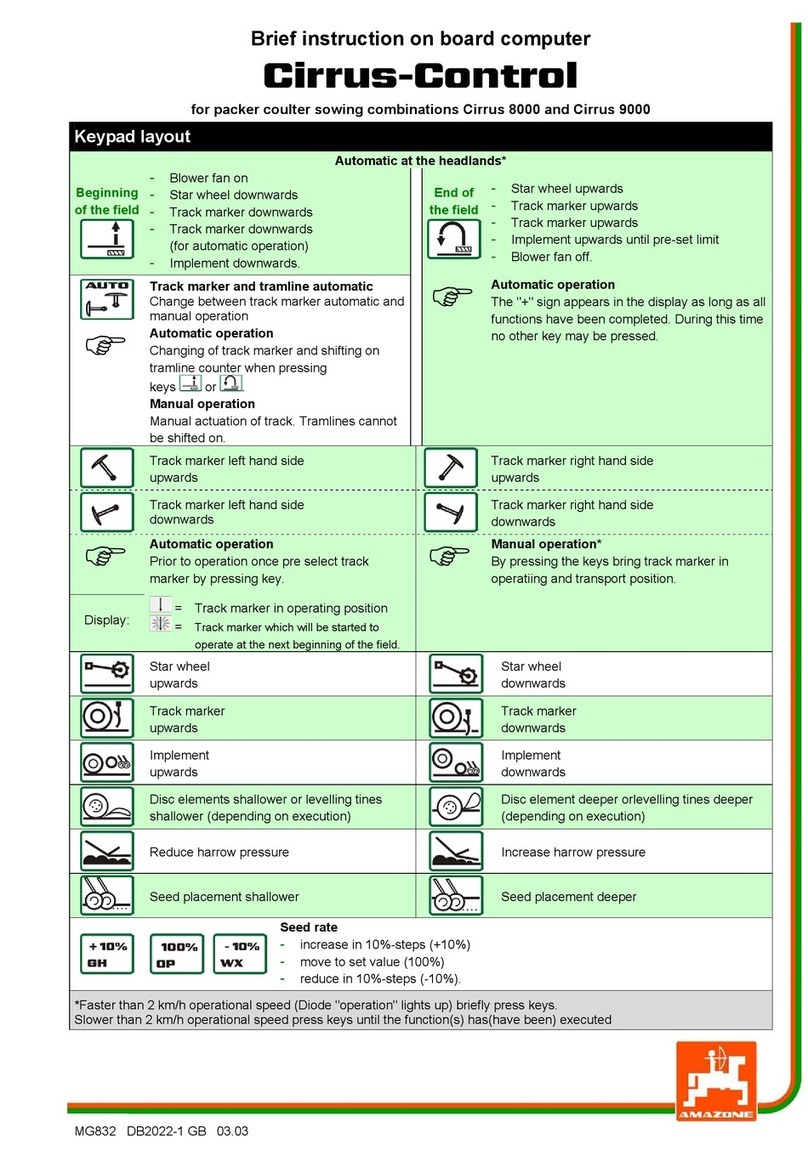

Putting into Operation .............................................................................. 11

Mounting to the threepoint linkage .............................................................. 11

Matthing of the PTO-shaft to the tractor .................................................... 11

Setting of the tractor’s hydraulic .................................................................. 11

Setting up the broadcaster .......................................................................... 11

Setting of the mounting height .................................................................... 11

Opening or shutting of the outlet openings .................................................. 13

Setting of the spread rate ............................................................................ 13

Checking the spread rate (caiibration test) .................................................. 15

Setting of the working width ........................................................................ 17

Checking the working width ........................................................................ 21

Trimmer ...................................................................................................... 21

Boundary spreading .................................................................................... 21

Broadcasting to one side only (centre 1st tramline

being 1.5 . 2 m from field side) .................................................................... 21

Broadcasting towards the boundary with ‘Tele Set’

boundary spread discs ................................................................................ 21

Broadcasting on headlands ........................................................................ 25

Late top dressing ........................................................................................ 27

Agitating spiral ............................................................................................ 27

Advice for spreading snail-pesticides (e.g. Mesurol) .................................. 27

Special hints for Operation ...................................................................... 29

Maintenance .............................................................................................. 29

Special executions and Options .............................................................. 31

Hints for adjustments ................................................................................ 33

Checking the basic setting of the shutter slides ............................................ 33

Amount of pressure in the tractor’s hydraulics ............................................ 33