6

Read manual instructions and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check Lists are completed

before releasing equipment to the owner.

The dealer must complete the Warranty Registration found on the Dealer Portal website located at dealer.jm-inc.com. and return

it to J. & M. Mfg. Co., Inc. at the address indicated on the form. Warranty claims will be denied if the Warranty Registration has not

been submitted.

EXPRESS WARRANTY:

J. & M. Mfg. Co. Inc. warrants against defects in construction or materials for a period of ONE year. We reserve the right to inspect

and decide whether material or construction was faulty or whether abuse or accident voids our guarantee.

Warranty service must be performed by a dealer or service center authorized by J. & M. Mfg. Co., Inc. to sell and/or service the type

of product involved, which will use only new or remanufactured parts or components furnished by J. & M. Mfg. Co., Inc. Warranty

service will be performed without charge to the purchaser for parts or labor based on the Warranty Labor Times schedule. Under no

circumstance will allowable labor times extend beyond the maximum hours indicated in the Warranty Labor Times schedule for each

warranty procedure. The purchaser will be responsible, however, for any service call and/or transportation of the product to and

from the dealer or service center’s place of business, for any premium charged for overtime labor requested by the purchaser, and

for any service and/or maintenance not directly related to any defect covered under the warranty. Costs associated with equipment

rental, product down time, or product disposal are not warrantable and will not be accepted under any circumstance.

Each warranty term begins on the date of product delivery to the purchaser. Under no circumstance will warranty be approved

unless (i) the product warranty registration card has been properly completed and submitted to the equipment manufacturer, and

(ii) a warranty authorization number has been issued by the equipment manufacturer. This Warranty is eective only if the warranty

registration card is returned within 30 days of purchase.

This warranty does not cover a component which fails, malfunctions or is damaged as a result of (i) improper modication or

repair, (ii) accident, abuse or improper use, (iii) improper or insucient maintenance, or (iv) normal wear or tear. This warranty

does not cover products that are previously owned and extends solely to the original purchaser of the product. Should the original

purchaser sell or otherwise transfer this product to a third party, this implied, with respect to tires or other parts or accessories not

manufactured by J. & M. Mfg. Co., Inc. Warranties for these items, if any, are provided separately by their respective manufacturers.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES OR CONDITIONS, EXPRESS, IMPLIED OR STATUTORY, INCLUDING

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE.

In no event shall J. & M. Mfg. Co., Inc. be liable for special, direct, incidental or consequential damages of any kind. The exclusive

remedy under this Warranty shall be repair or replacement of the defective component at J. & M. Mfg. Co., Inc’s. option. This is the

entire agreement between J. & M. Mfg. Co., Inc. and the Owner about warranty and no J. & M. Mfg. Co., Inc. employee or dealer is

authorized to make any additional warranty on behalf of J. & M. Mfg. Co., Inc.

The manufacturer reserves the right to make product design and material changes at any time without notice. They shall not incur

any obligation or liability to incorporate such changes and improvements in products previously sold to any customer, nor shall

they be obligated or liable for the replacement of previously sold products with products or parts incorporating such changes.

SERVICE:

The equipment you have purchased has been carefully manufactured to provide dependable and satisfactory use. Like all

mechanical products, it will require cleaning and maintenance. Lubricate the unit as specied. Observe all safety information in

this manual and safety signs on the equipment.

For service, your authorized J. & M. dealer has trained mechanics, genuine J. & M. service parts, and the necessary tools and

equipment to handle all your needs.

Use only genuine J. & M. service parts. Substitute parts may void warranty and may not meet standards required for safety and

satisfactory operation. Record the model number and serial number of your equipment in the spaces provided:

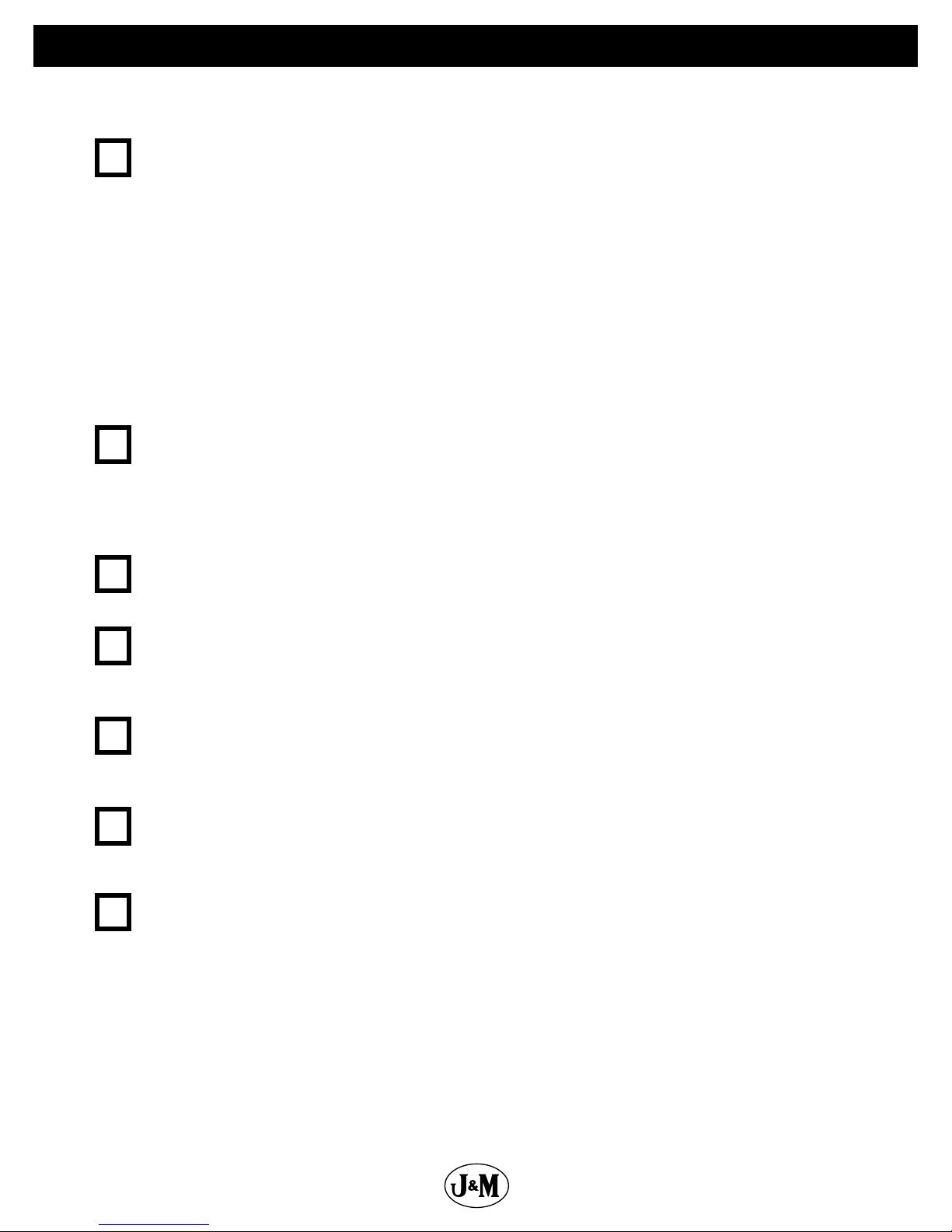

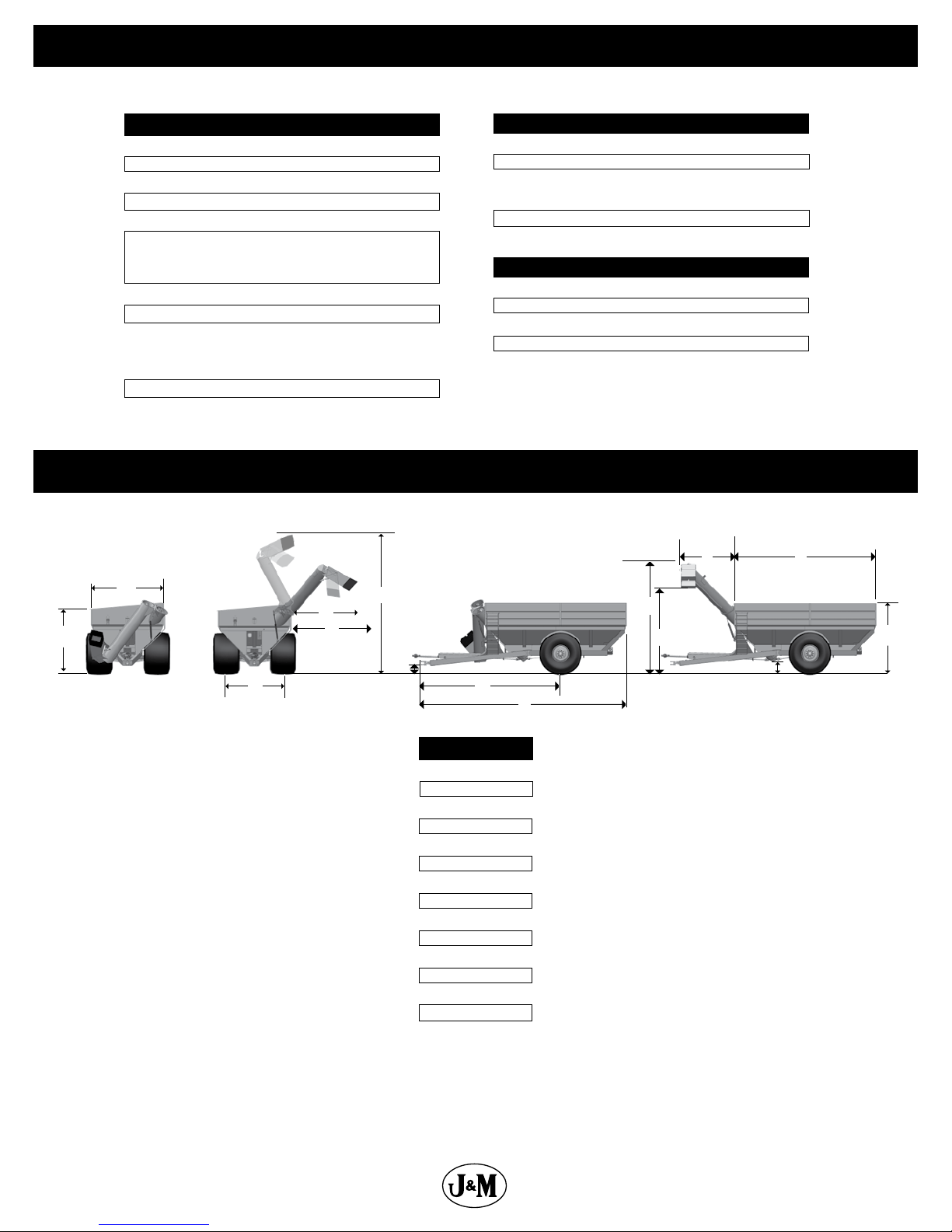

Model No:1132 Serial No: ________________________ Date of Purchase: ___________________

Purchased From: ________________________________________________________________________________

Provide this information to your dealer to obtain correct repair parts.

To The Dealer