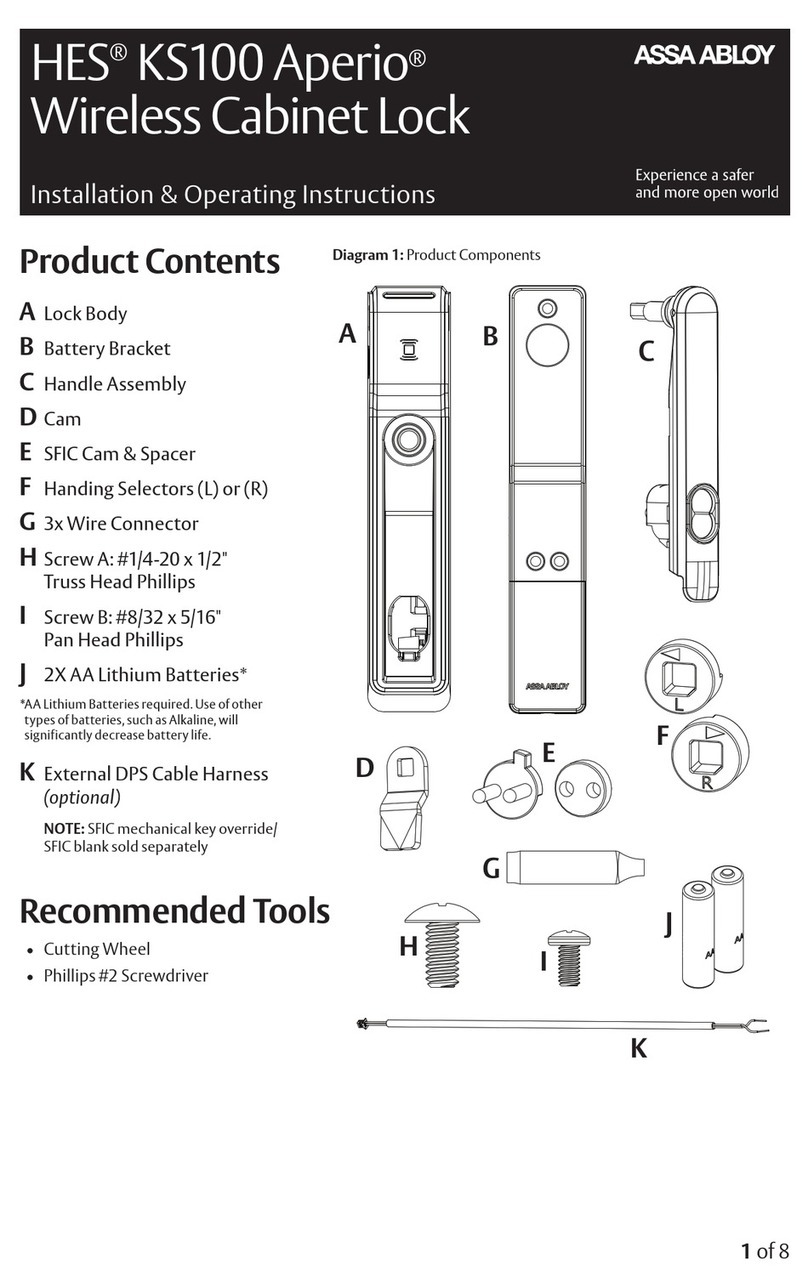

2

Installation

3

Installation (continued)

LBM Wiring

White

Orange Normally Open

Green Normally Closed

Common

Normally Open

Yellow Normally Closed

DIAGRAM 5: CYLINDRICAL LOCKSETS

LBSM Wiring

Brown

Blue Normally Open

Yellow Normally Closed

Common

Note 1: The 5200 series Electric Strikes are

pre-set for FAIL SECURE OPERATION.

Note 2: There are two #2-56 screws located

on the back of the strike for coverting

the operation mode.

10. To convert from FAIL SECURE OPERATION

to FAIL SAFE OPERATION, LOOSEN the two

#2-56 screws located on the back of the

strike, but DO NOT REMOVE them.

11. MOVE the Selector Stop Pins to the FAIL

SAFE OPERATION position as pictured in

Diagram 5.

12. TIGHTEN the two #2-56 screws to secure

the strike in FAIL SAFE OPERATION.

13. VERIFY the 5200 is now in FAIL SAFE

OPERATION.

14. IF the 5200 still operates as FAIL SECURE,

THEN ENSURE the #2-56 screws are fully

seated and tightened.

Diagram 5: FAIL SAFE OPERATION Mode Setting

Brown

Blue

Yellow

White

Orange

Green

Converting the Operation Mode

Diagram 3: Latchbolt Monitor Diagram 4: Latchbolt Strike Monitor

Verifying the Operation Mode

15. TURN the horizontal adjustment screws slowly to

adjust the strike in-frame, as shown in Diagram 6.

16. DO NOT REMOVE the screws or ROTATE them more

than 3 full turns.

17. TIGHTEN the screws securely once the strike has

been adjusted to allow the K-Nut teeth to dig into

the strike housing and prevent slippage during use.

Adjusting the Horizontal

Diagram 6: Horizontal Adjustment

K-NUT

b

Horizontal

Adjustment

Screws

Note: For 12 VDC, the Plug In Connector (pigtail)

marked “12 VDC” should be used; for 24 VDC,

the pigtail marked “24 VDC should be used.

1. SELECT the appropriate pigtail that matches system

power and electrically CONNECT as illustrated in

Diagram 2.

2. If no connector is present, CONFIGURE the wires as

illustrated in Diagram 2.

3. If using the Latchbolt Monitor (LBM) or Latchbolt

Strike Monitor (LBSM), REFER to Diagrams 3 and 4

on Page 3 to complete wiring.

Note: The 5200 ships in FAIL SECURE OPERATION

mode.

4. USE Diagrams 5 and 6 on Page 3 as a guide to

convert 5200 to FAIL SAFE OPERATION, if needed.

5. ATTACH the appropriate faceplate.

CAUTION!

Before connecting any device at the installation site, verify input voltage using a multimeter.

Many power supplies and low voltage transformers operate at higher levels than listed. Any input voltage exceeding

10% of the solenoid rating may cause severe damage to the unit and will void the warranty.

6. PREPARE the frame using the appropriate template

for the faceplate (see Page 4).

RED

RED/GREEN

BLACK

VIOLET

RED

BLACK

VIOLET

RED/GREEN

IF CONNECTOR IS MISSING

(+ 12 VDC)

(-NEG)

(+ 24 VDC)

(-NEG)

or

Electric

Strike

Electric

Strike

CONNECT

TOGETHER

CONNECT

TOGETHER

CONNECT

TOGETHER

7. Electrically CONNECT the wires from the power

source to the 5200.

8. INSTALL the 5200 in the jamb cutout.

9. IF horizontal adjustment is needed,

THEN GO TO the “Adjusting the Horizontal”

section (see Page 3).

Preparing the Strike

Finishing the Installation

Preparing the Frame

Diagram 2: 12V to 24V Conversion