Assa Abloy RIXSON W0700 Series User manual

Other Assa Abloy Door Lock manuals

Assa Abloy

Assa Abloy Sargent PR100 User manual

Assa Abloy

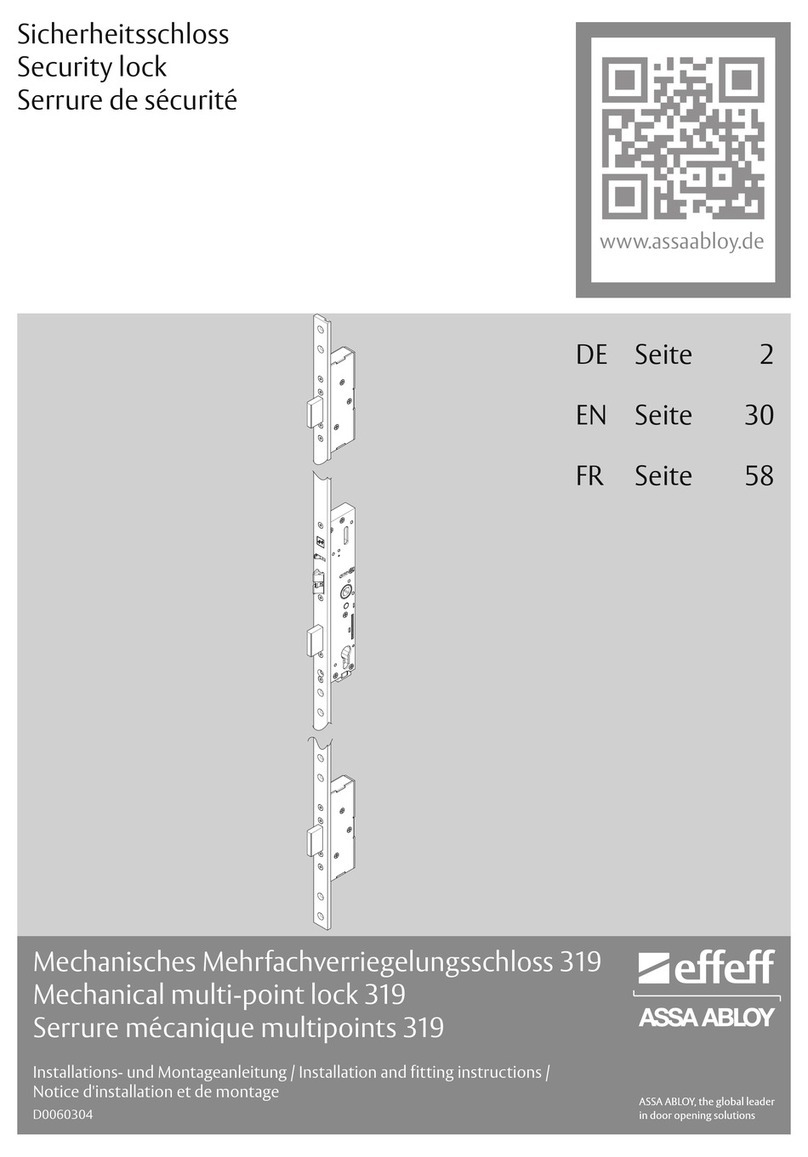

Assa Abloy Effeff 319 Series User manual

Assa Abloy

Assa Abloy Connect 310 User manual

Assa Abloy

Assa Abloy Yale YDM3109A User manual

Assa Abloy

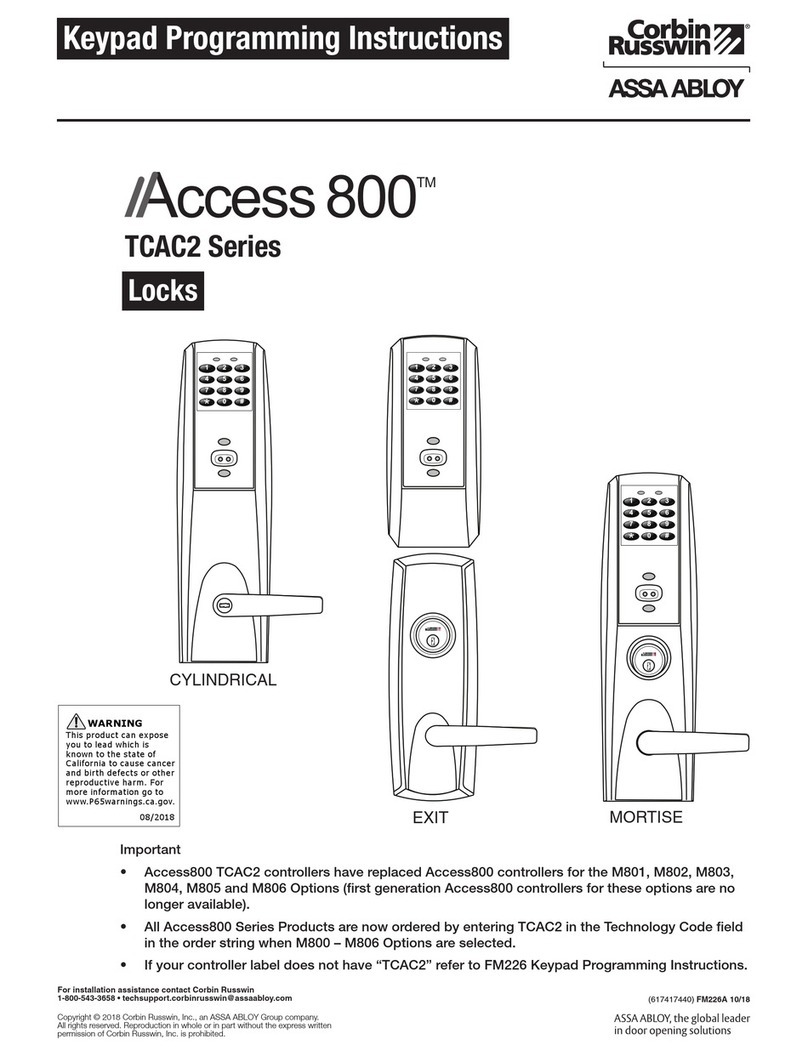

Assa Abloy Corbin Russwin Access 800 TCAC2 Series Installation manual

Assa Abloy

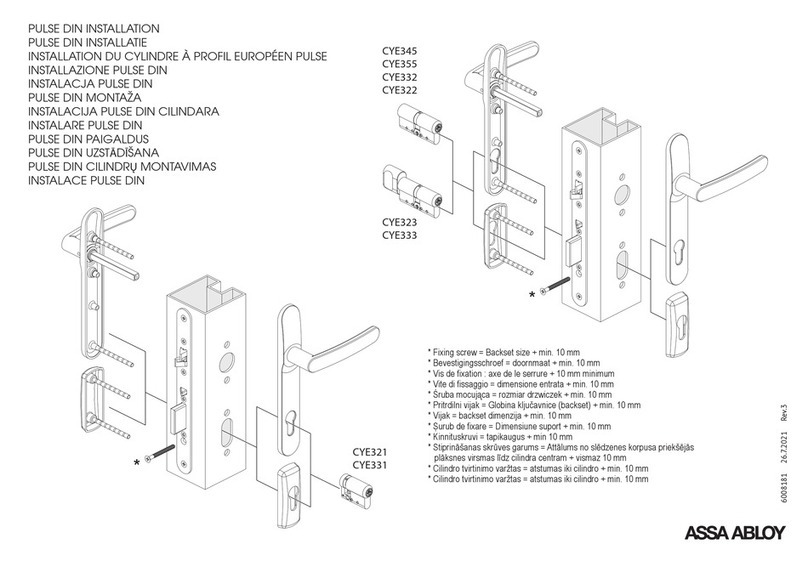

Assa Abloy CYE321 User manual

Assa Abloy

Assa Abloy SARGENT Profile Series User manual

Assa Abloy

Assa Abloy Yale Assure Lock with Wi-Fi User manual

Assa Abloy

Assa Abloy E100 User manual

Assa Abloy

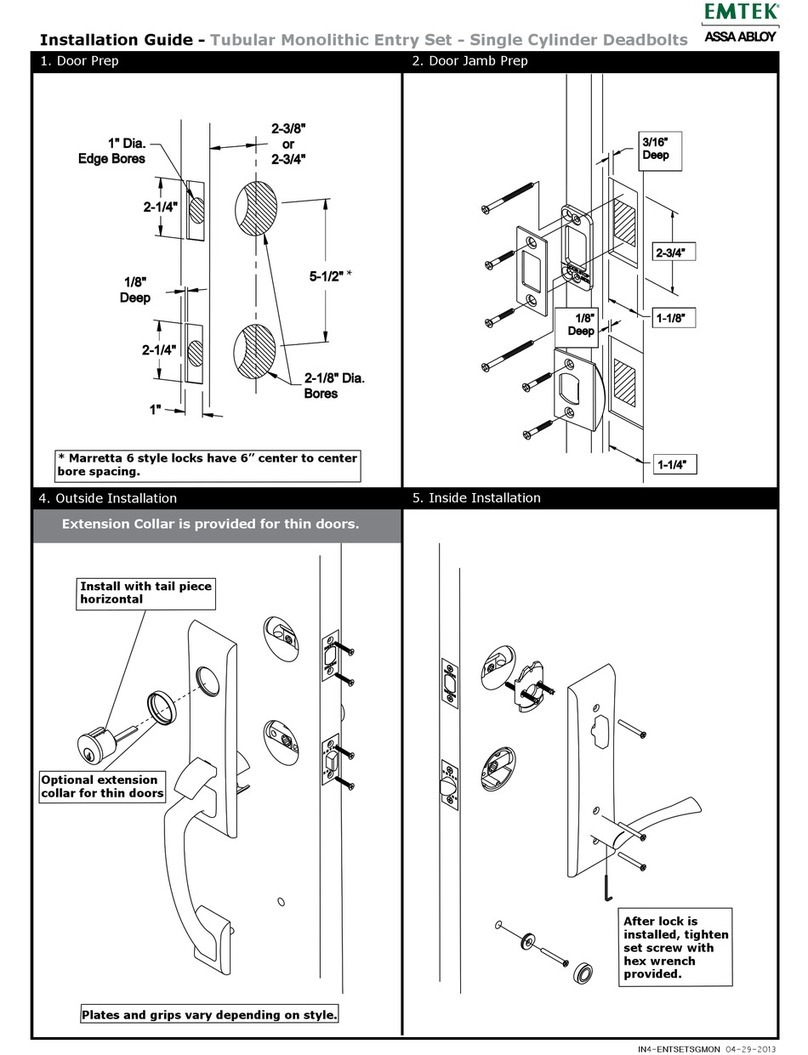

Assa Abloy EMTEK Tubular Monolithic Entry Set User manual

Assa Abloy

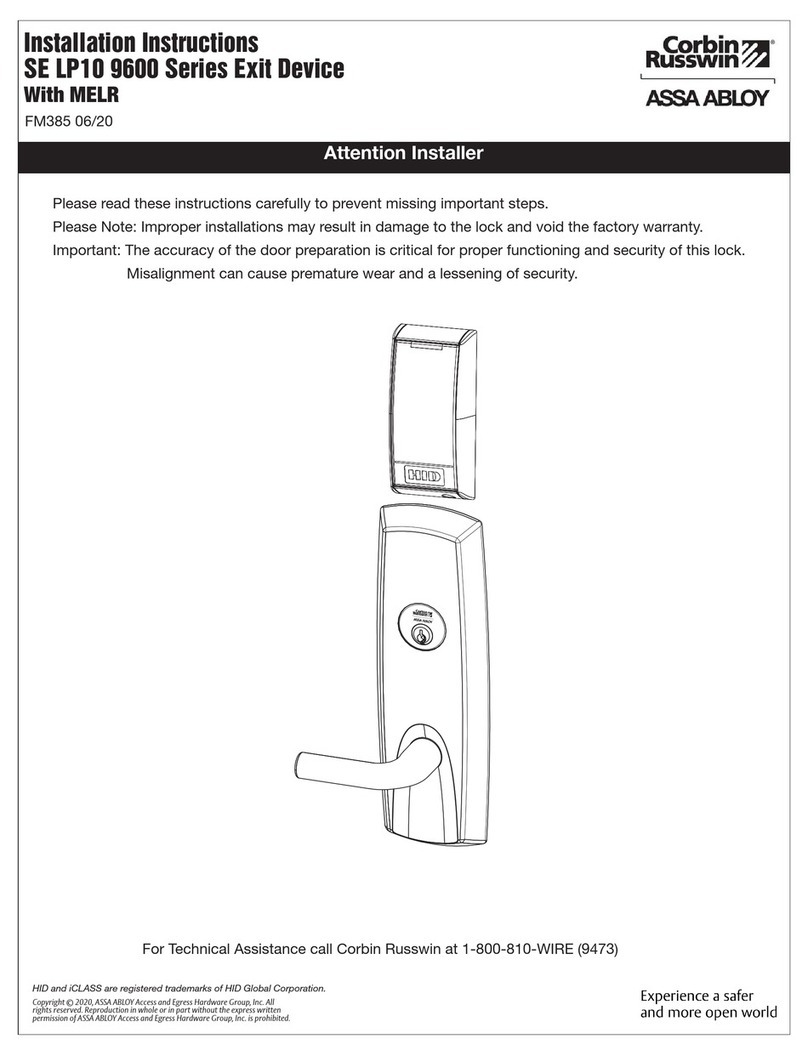

Assa Abloy Corbin Russwin SE LP10 9600 Series User manual

Assa Abloy

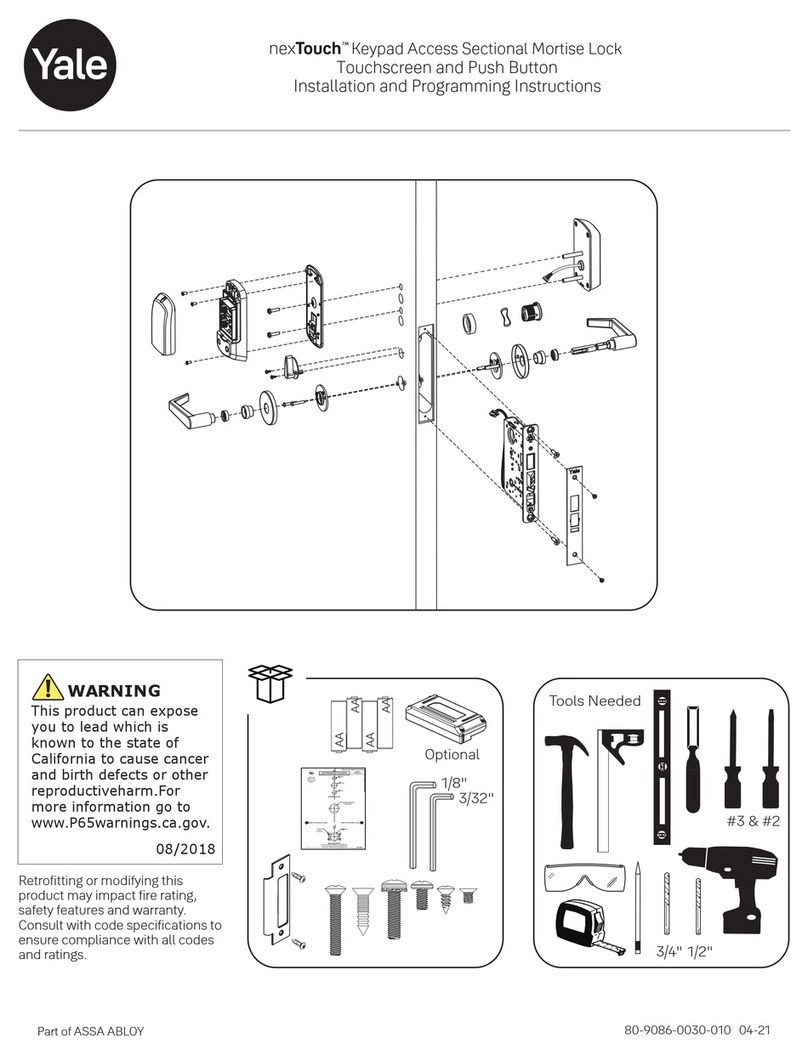

Assa Abloy Yale nexTouch Technical specifications

Assa Abloy

Assa Abloy Yale YD-01-CON-NOMOD-PB User manual

Assa Abloy

Assa Abloy Sargent Signature Series User manual

Assa Abloy

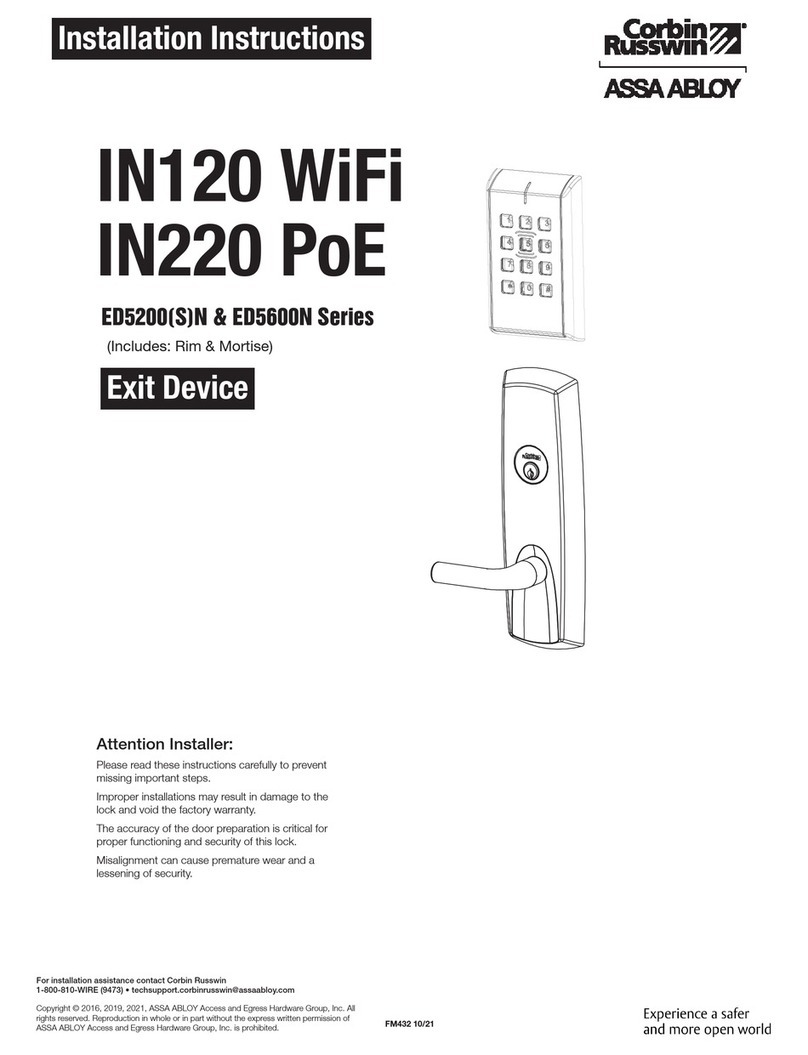

Assa Abloy Corbin Russwin ED5200N Series User manual

Assa Abloy

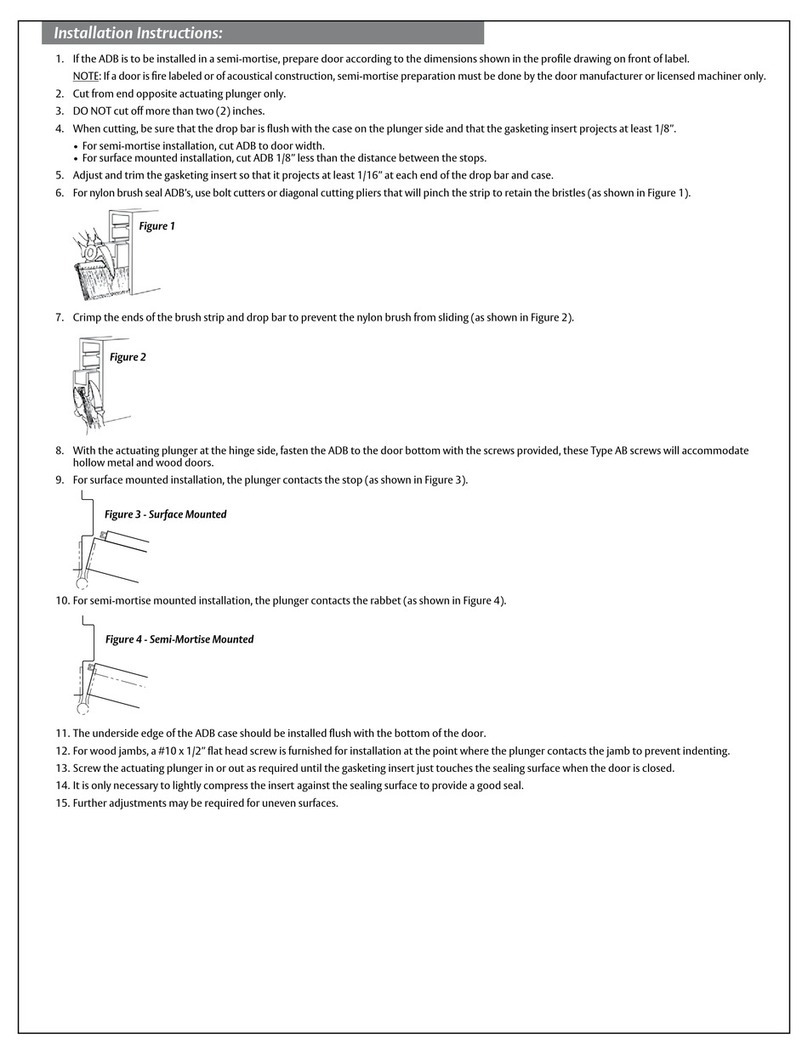

Assa Abloy Pemko 4131RL User manual

Assa Abloy

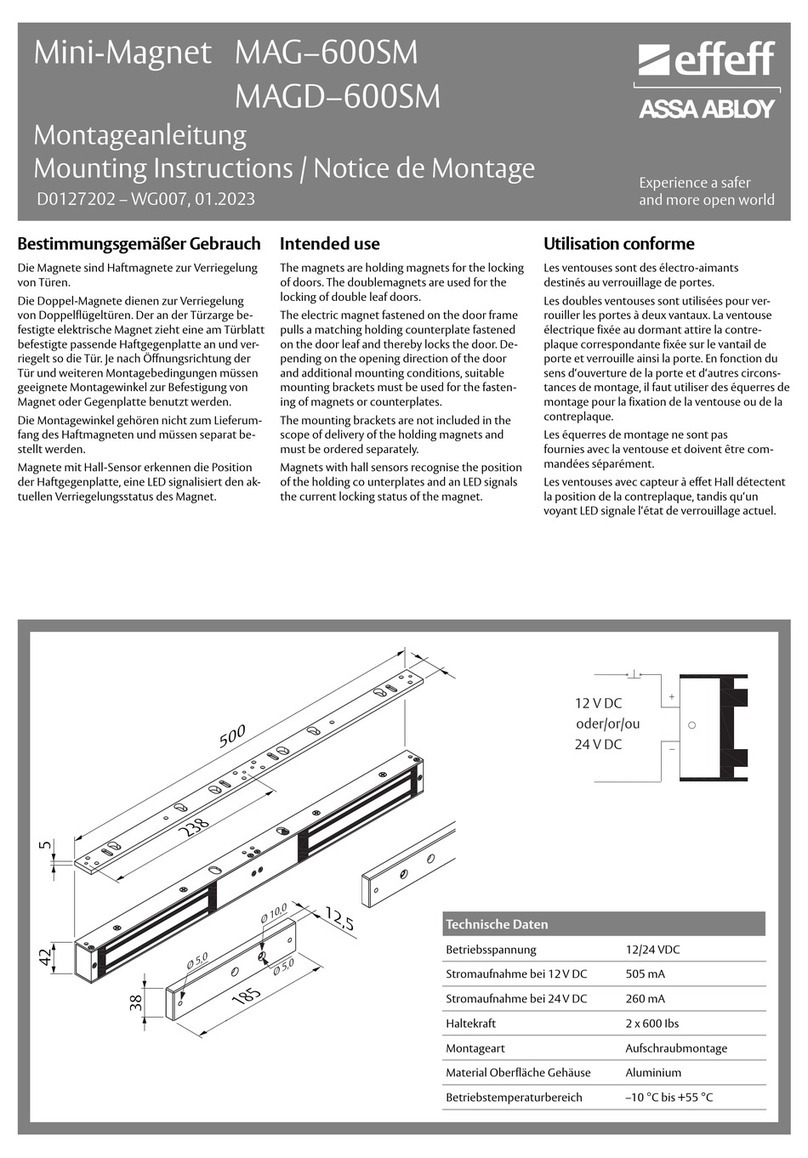

Assa Abloy effeff MAG-600SM User manual

Assa Abloy

Assa Abloy TD0192 User manual

Assa Abloy

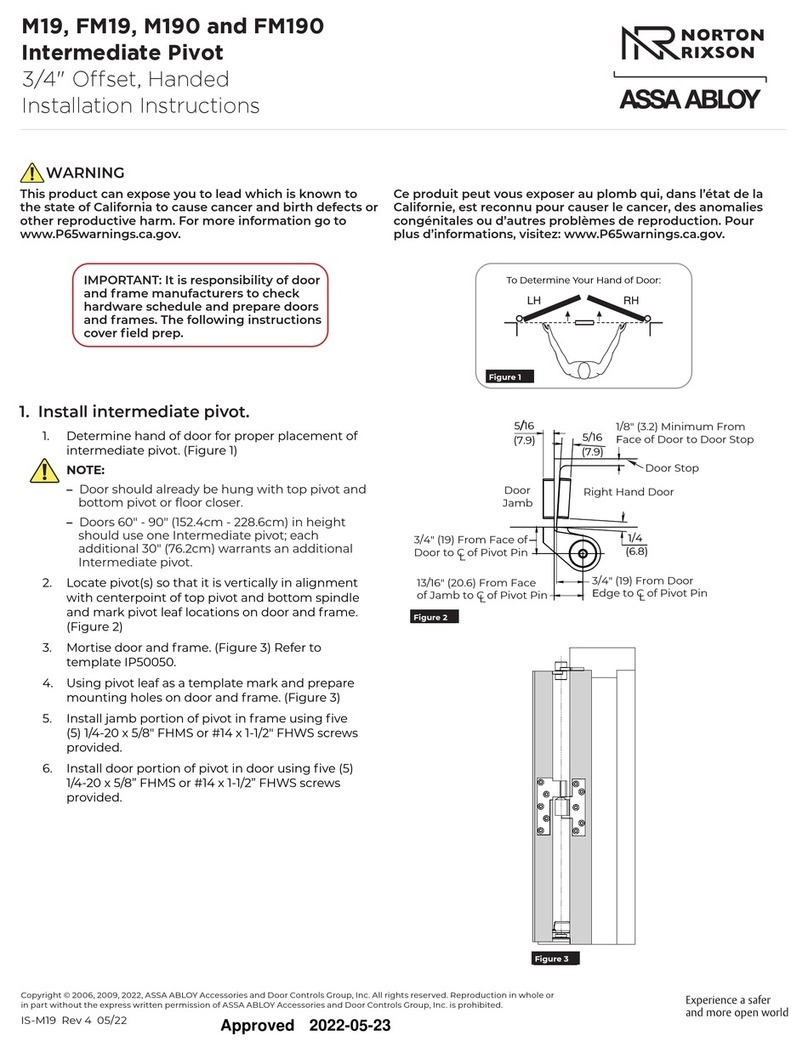

Assa Abloy NORTON RIXSON M19 User manual

Assa Abloy

Assa Abloy 8654 User manual

Popular Door Lock manuals by other brands

SCOOP

SCOOP Pullbloc 4.1 FS Panik Assembly instruction

Yale

Yale MORTISE 8800 SERIES installation instructions

Siegenia

Siegenia KFV AS3500 Assembly instructions

Saflok

Saflok Quantum ädesē RFID installation instructions

ArrowVision

ArrowVision Shepherd 210 installation manual

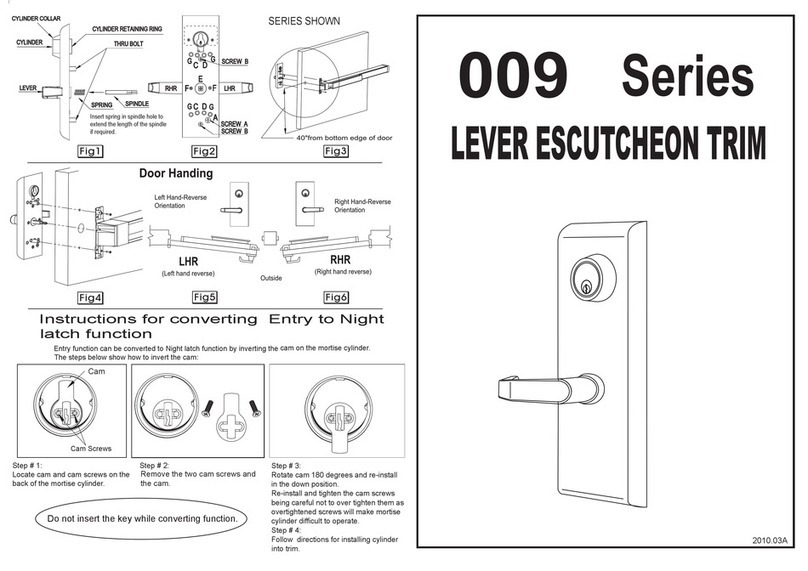

Baldwin

Baldwin 009 Series quick start guide