Assa Abloy 3090 User manual

Other Assa Abloy Lock manuals

Assa Abloy

Assa Abloy Sargent 6500 Instruction Manual

Assa Abloy

Assa Abloy IKON eCLIQ N111 BA3 User manual

Assa Abloy

Assa Abloy ELECTRIC LOCK User manual

Assa Abloy

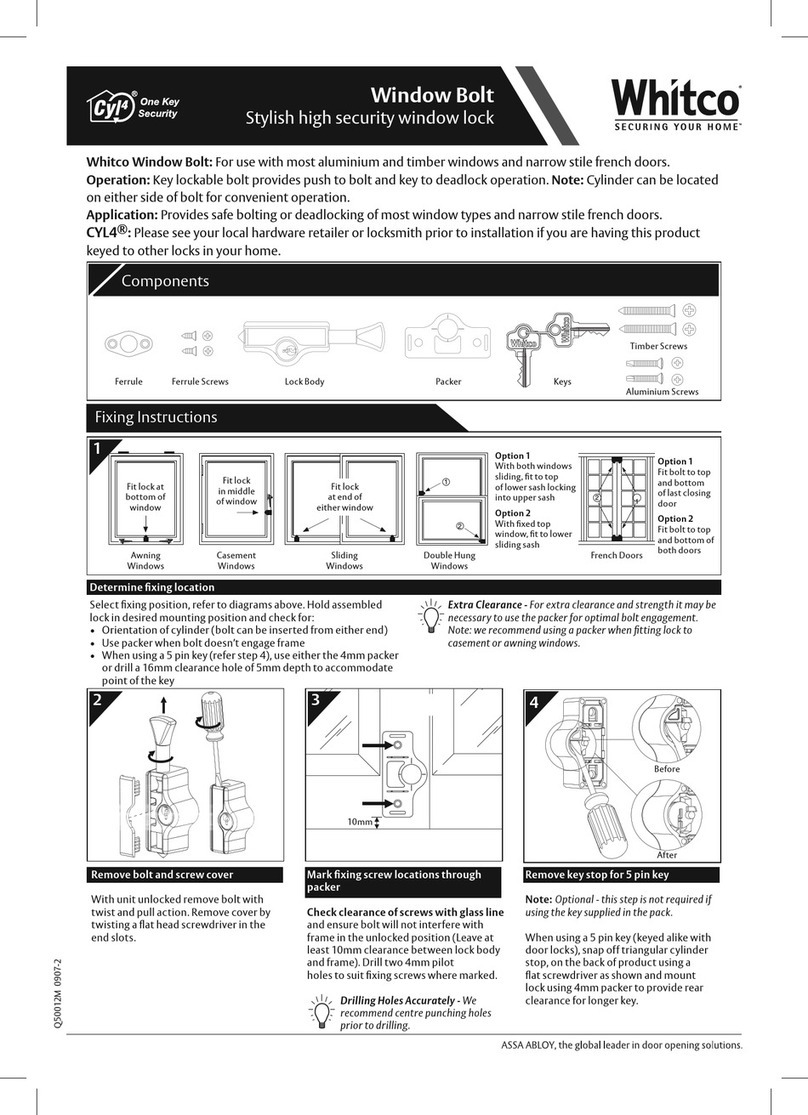

Assa Abloy Whitco Cyl4 Window Bolt User manual

Assa Abloy

Assa Abloy Yale Real Living Assure Lever YRL256 Technical specifications

Assa Abloy

Assa Abloy KESO eCLIQ N0.001 BA3 User manual

Assa Abloy

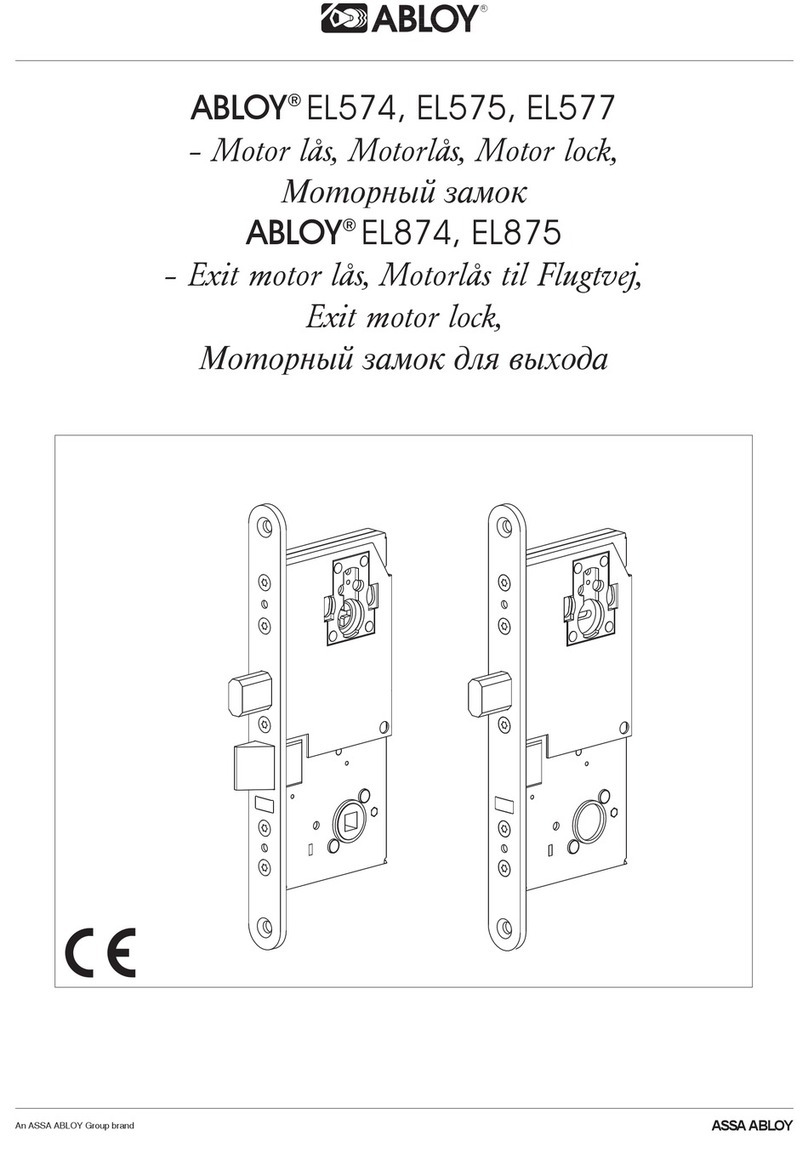

Assa Abloy ABLOY EL574 User manual

Assa Abloy

Assa Abloy SARGENT FM7300 Series User manual

Assa Abloy

Assa Abloy Yale YDD424A User manual

Assa Abloy

Assa Abloy Corbin Russwin BLSS ML2000 Series User manual

Assa Abloy

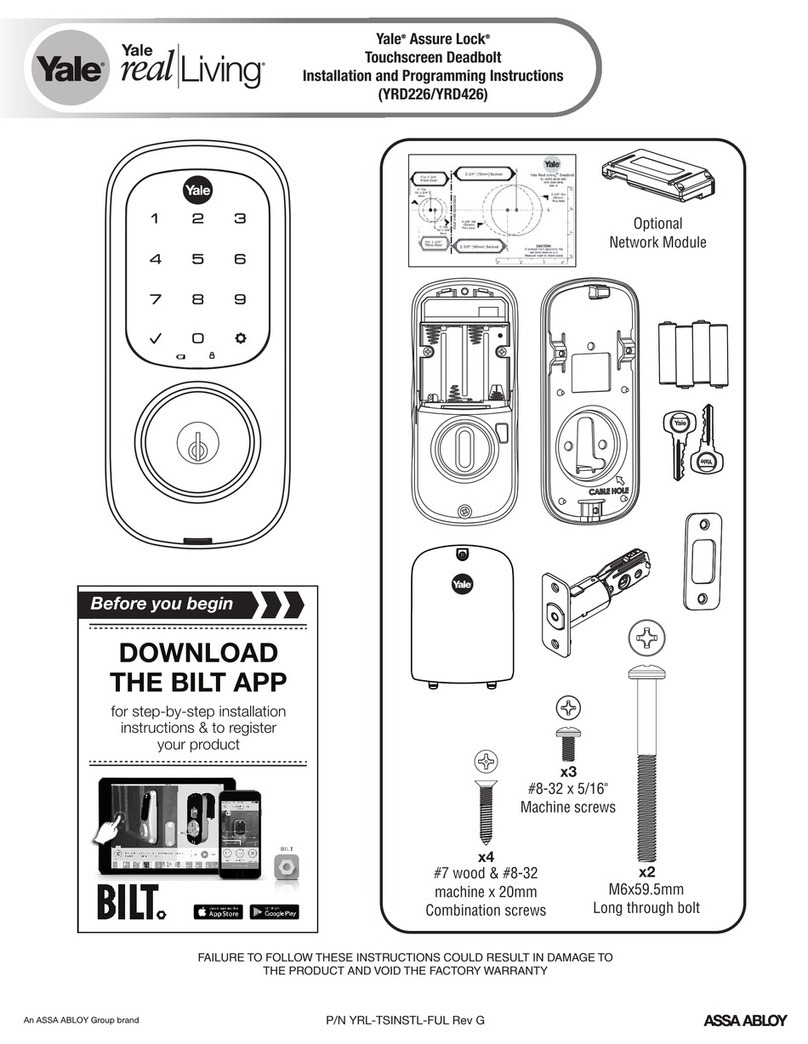

Assa Abloy Yale Real Living Assure Lock YRD426 User manual

Assa Abloy

Assa Abloy HES Aperio K100 Manual

Assa Abloy

Assa Abloy 421-30-10 User manual

Assa Abloy

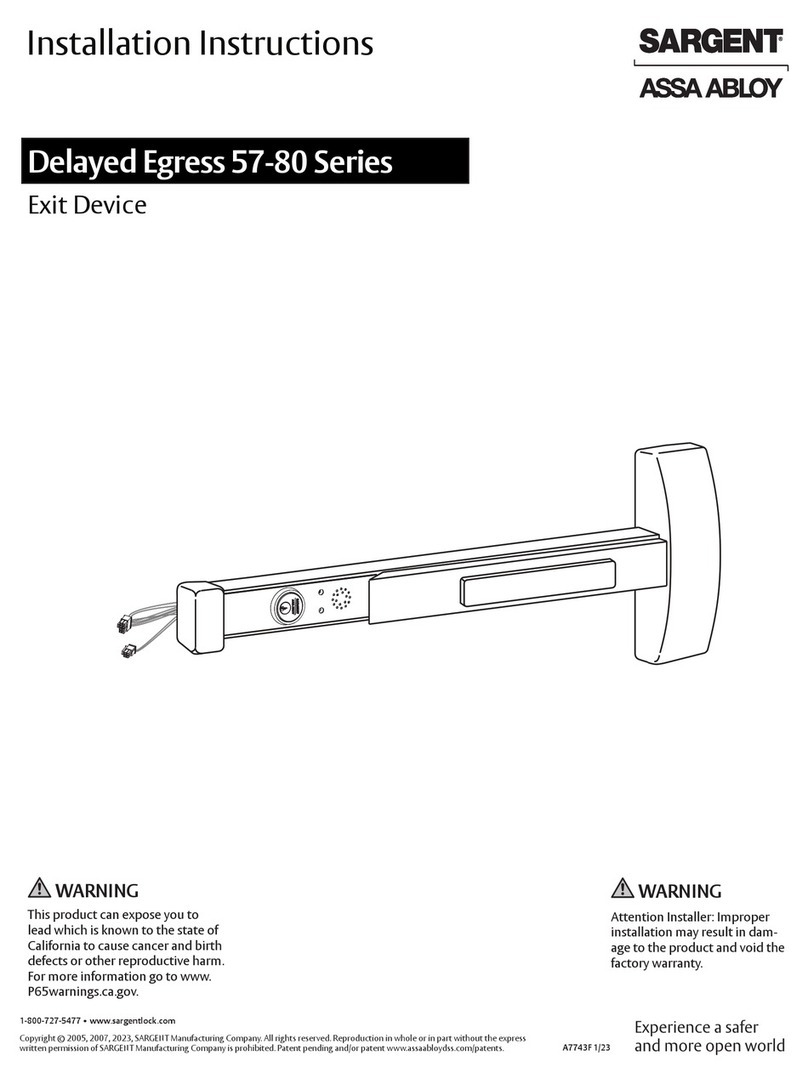

Assa Abloy SARGENT Delayed Egress 57-80 Series User manual

Assa Abloy

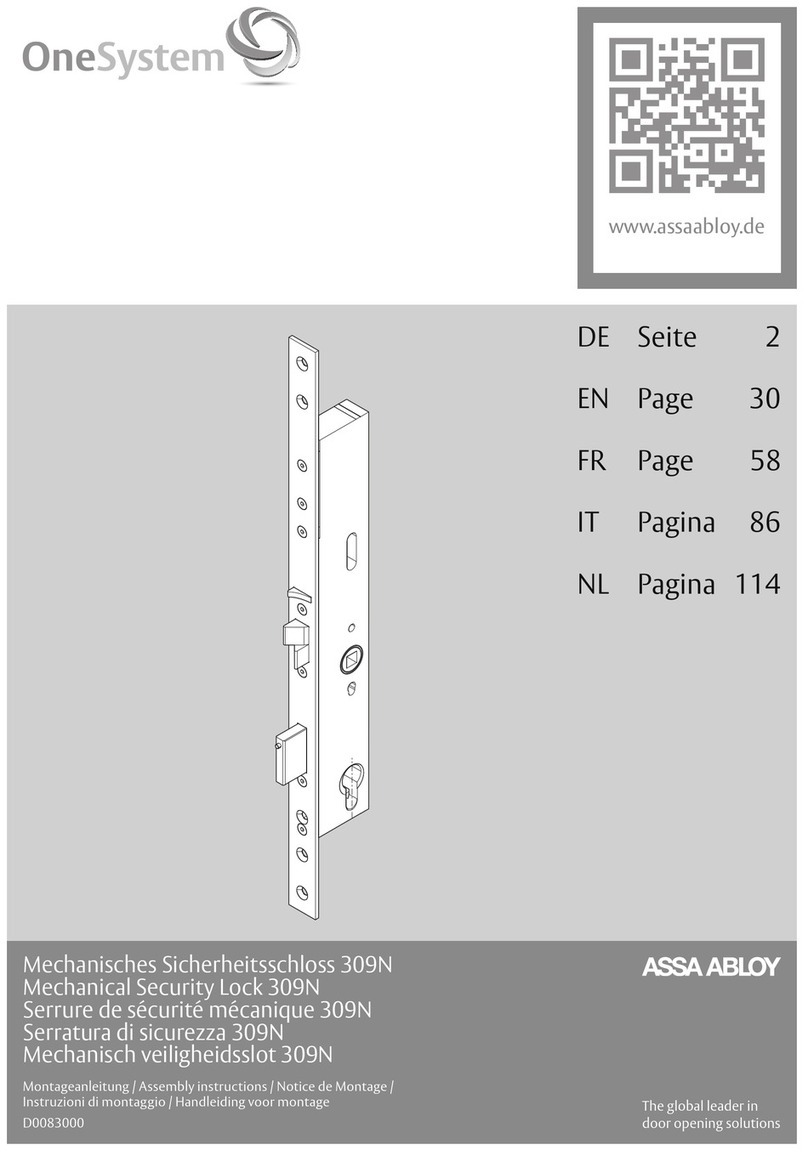

Assa Abloy OneSystem 309N User manual

Assa Abloy

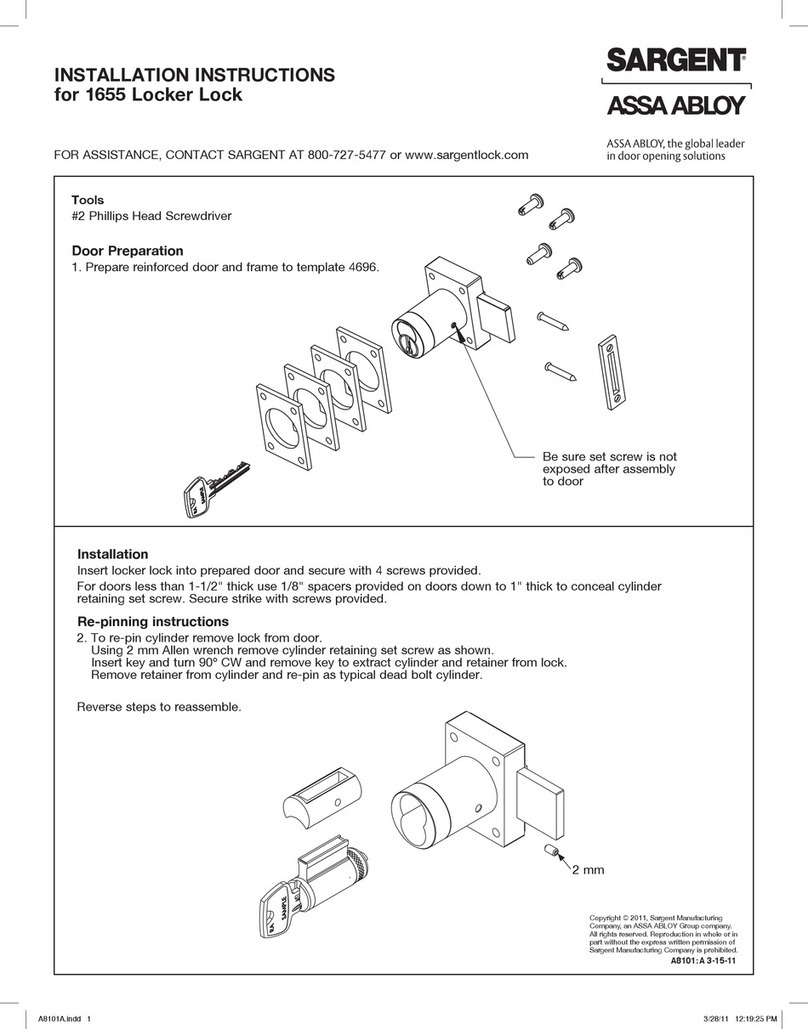

Assa Abloy SARGENT 1655 User manual

Assa Abloy

Assa Abloy Corbin Russwin BLSS ML2000 Series User manual

Assa Abloy

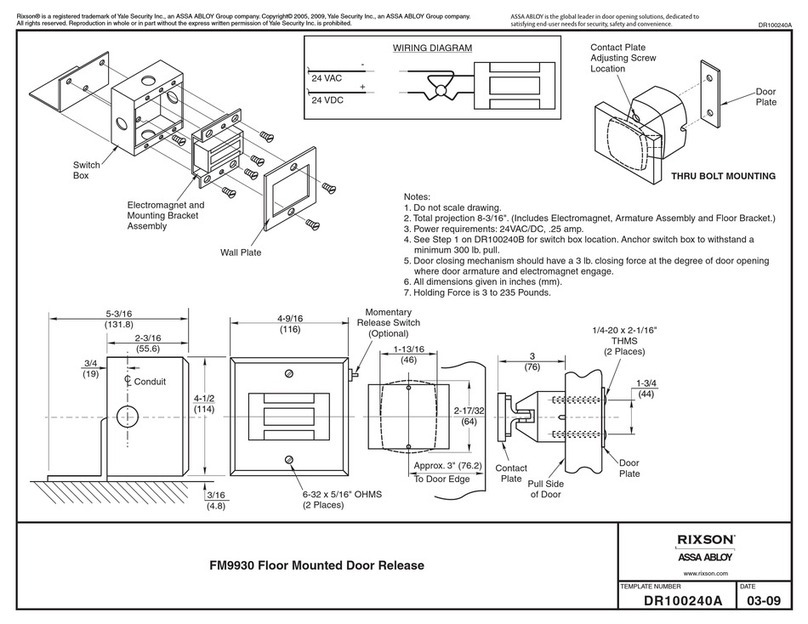

Assa Abloy RIXSON FM9930 User manual

Assa Abloy

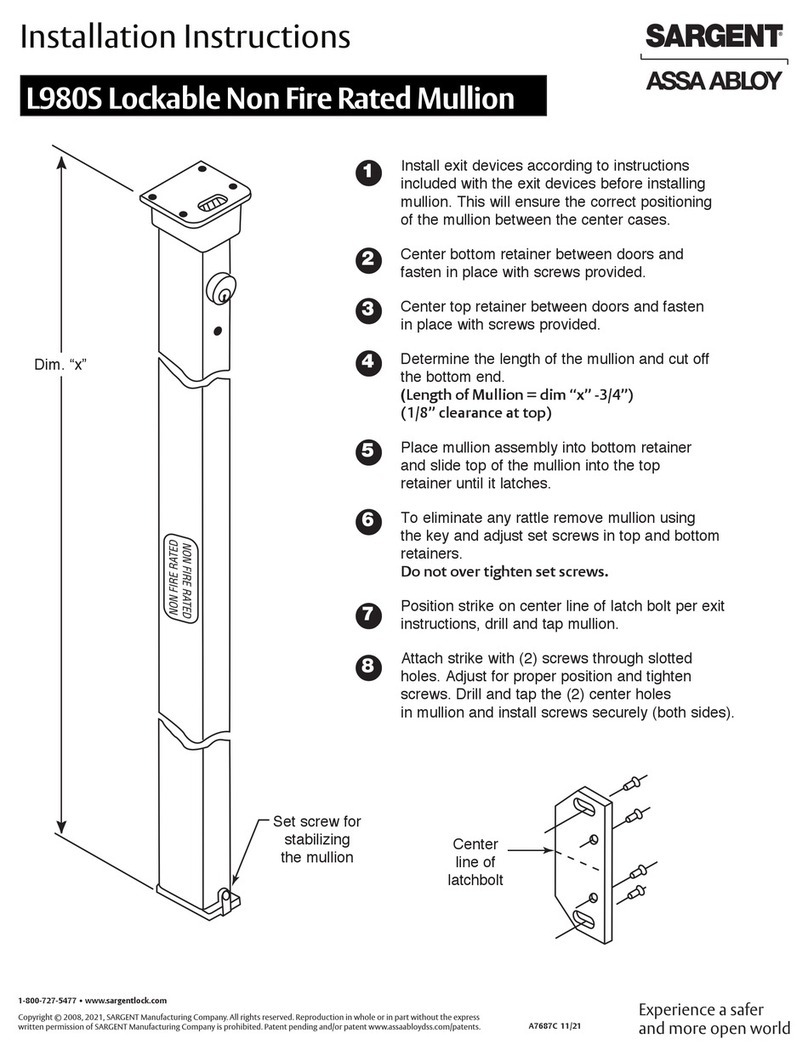

Assa Abloy Sargent L980S User manual

Assa Abloy

Assa Abloy Sargent 8200 Series User manual