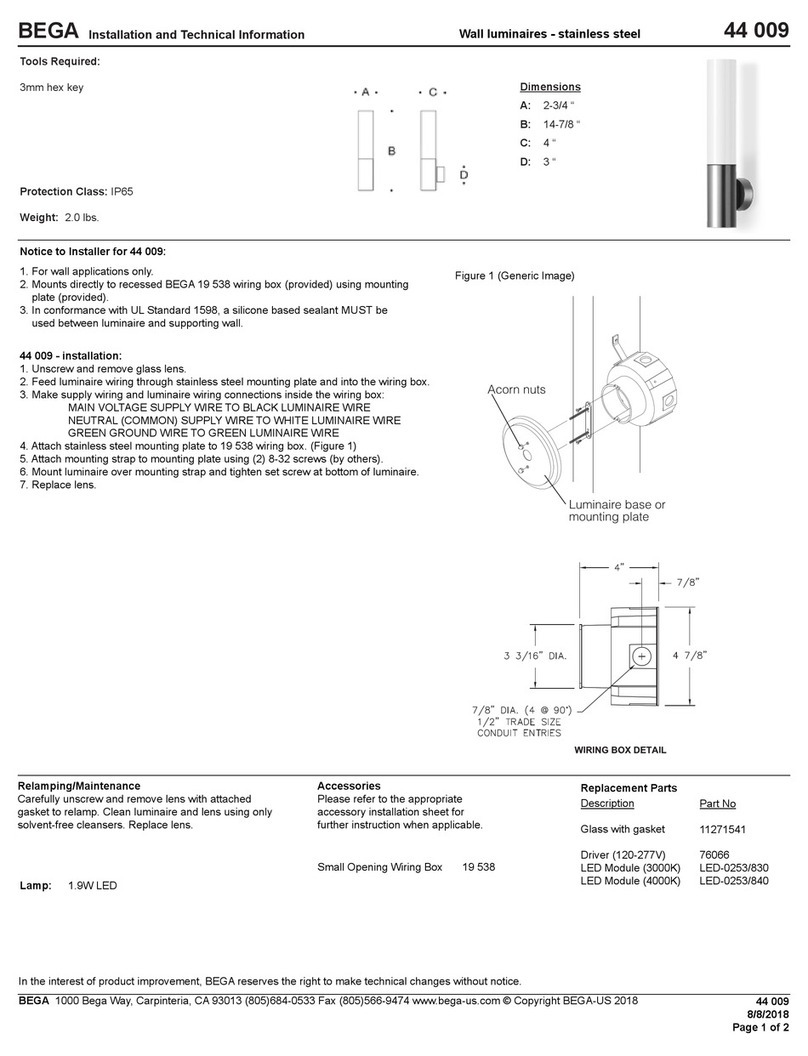

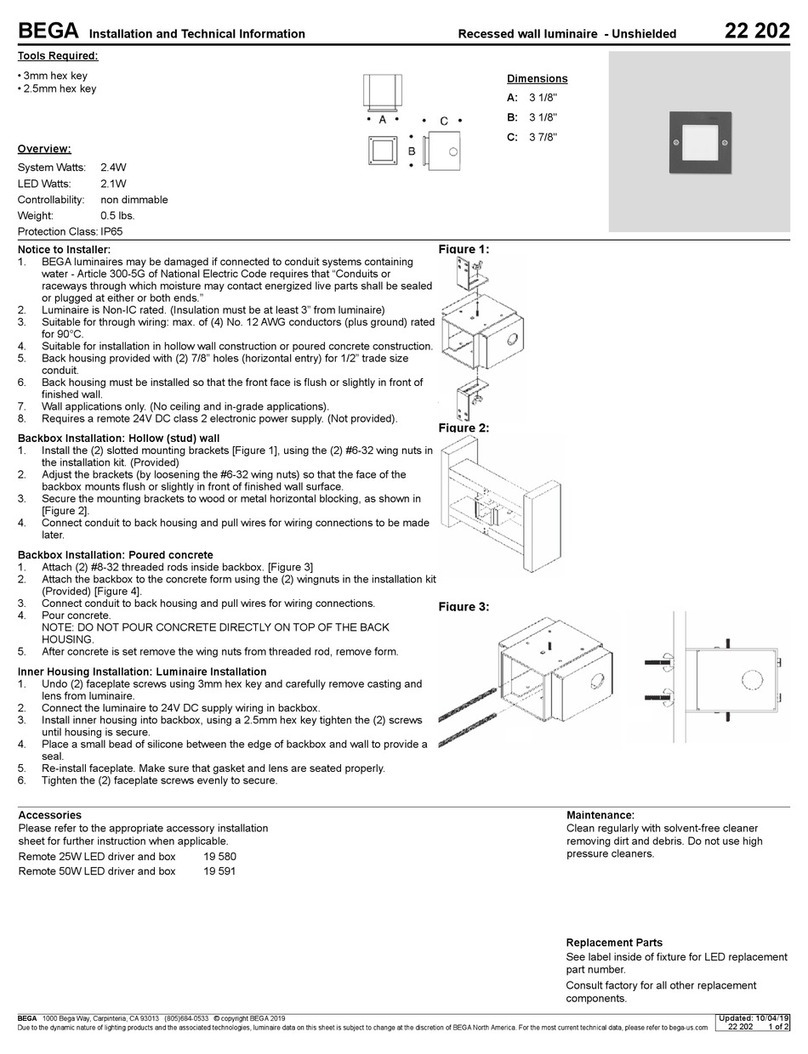

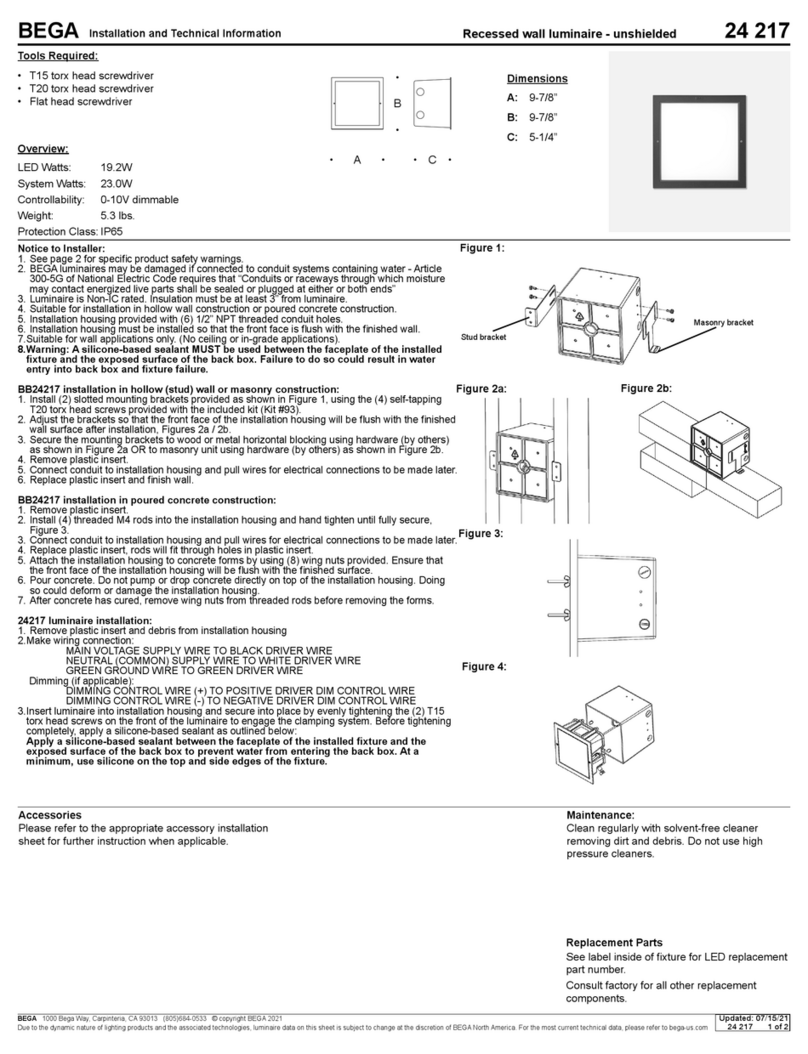

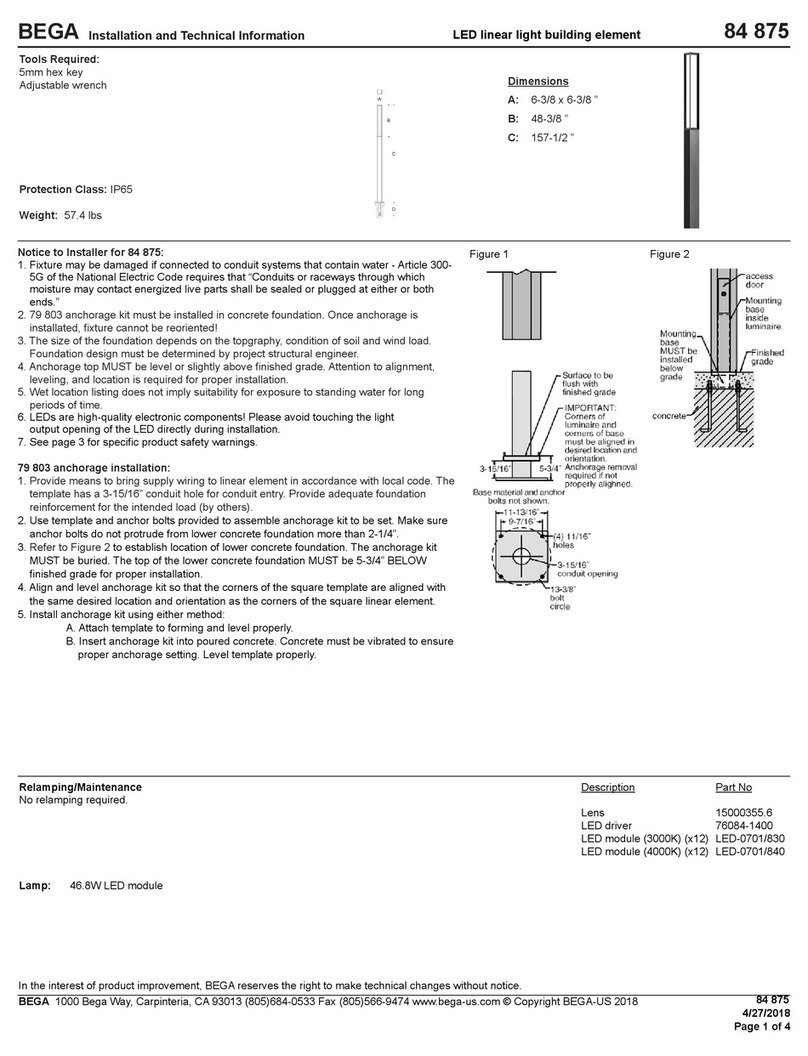

Installation and Technical Information

BEGA

Due to the dynamic nature of lighting products and the associated technologies, luminaire data on this sheet is subject to change at the discretion of BEGA North America. For the most current technical data, please refer to bega-us.com

BEGA 1000 Bega Way, Carpinteria, CA 93013 (805)684-0533 © copyright BEGA 2021

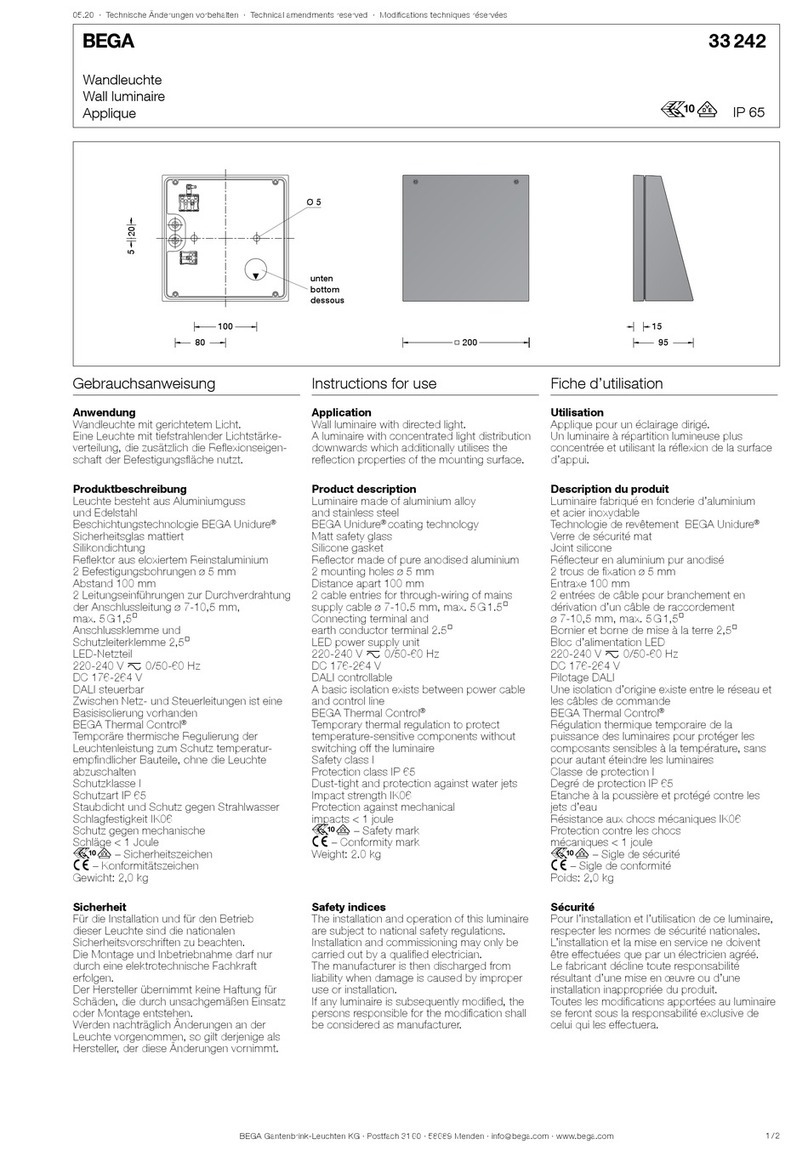

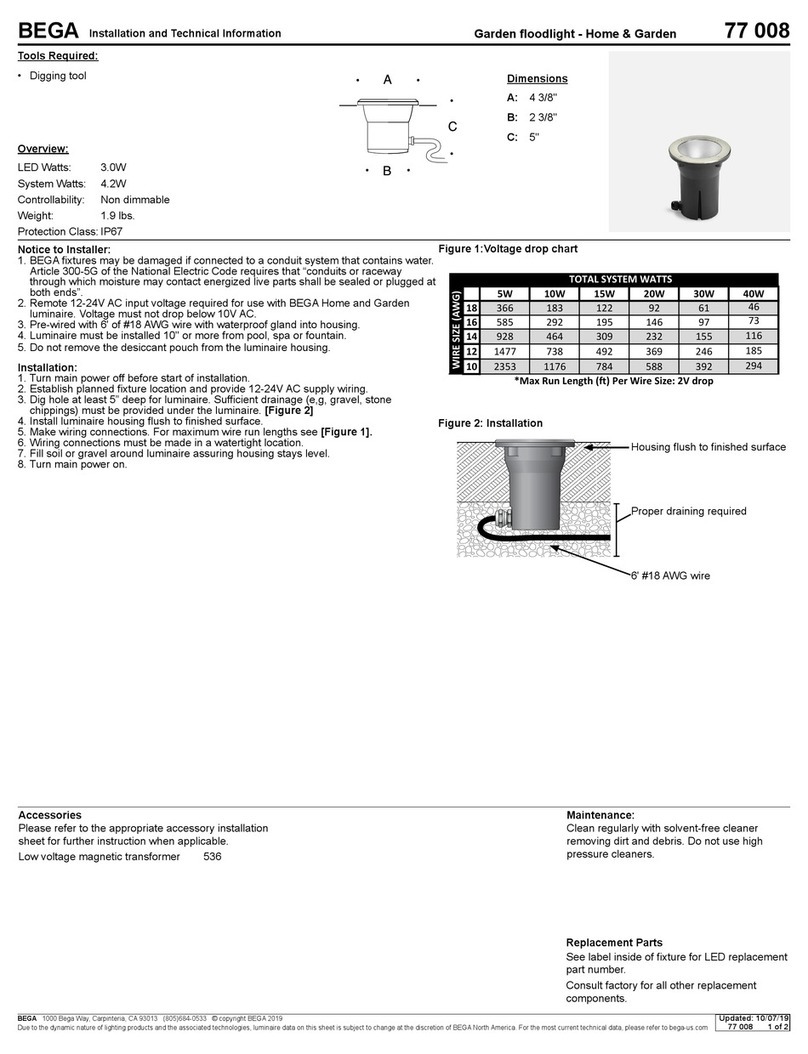

Figure 1:

Overview:

LED Watts: 11.5W

System Watts: 18.0W

Controllability: 0-10V, TRIAC, and ELV dimmable

Weight: 13.9 lbs.

Protection Class: IP65

Tools Required:

• 5mm hex head screwdriver

• Adjustable wrench

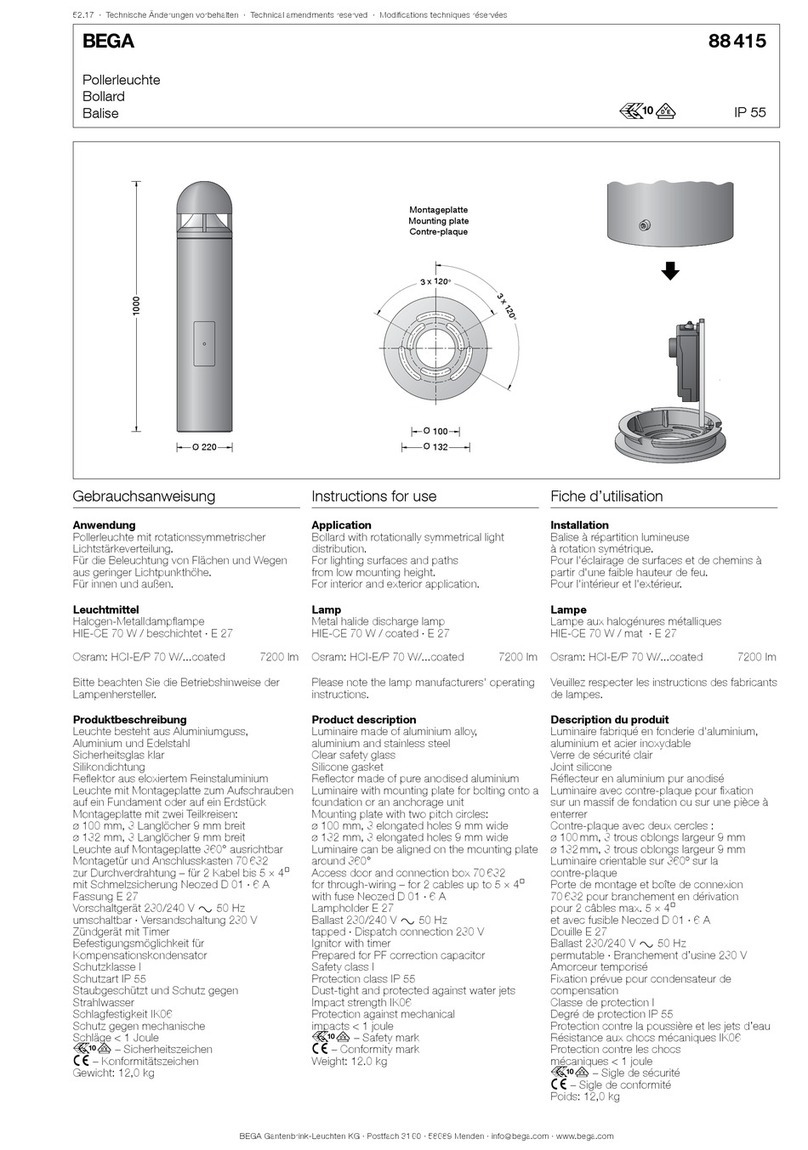

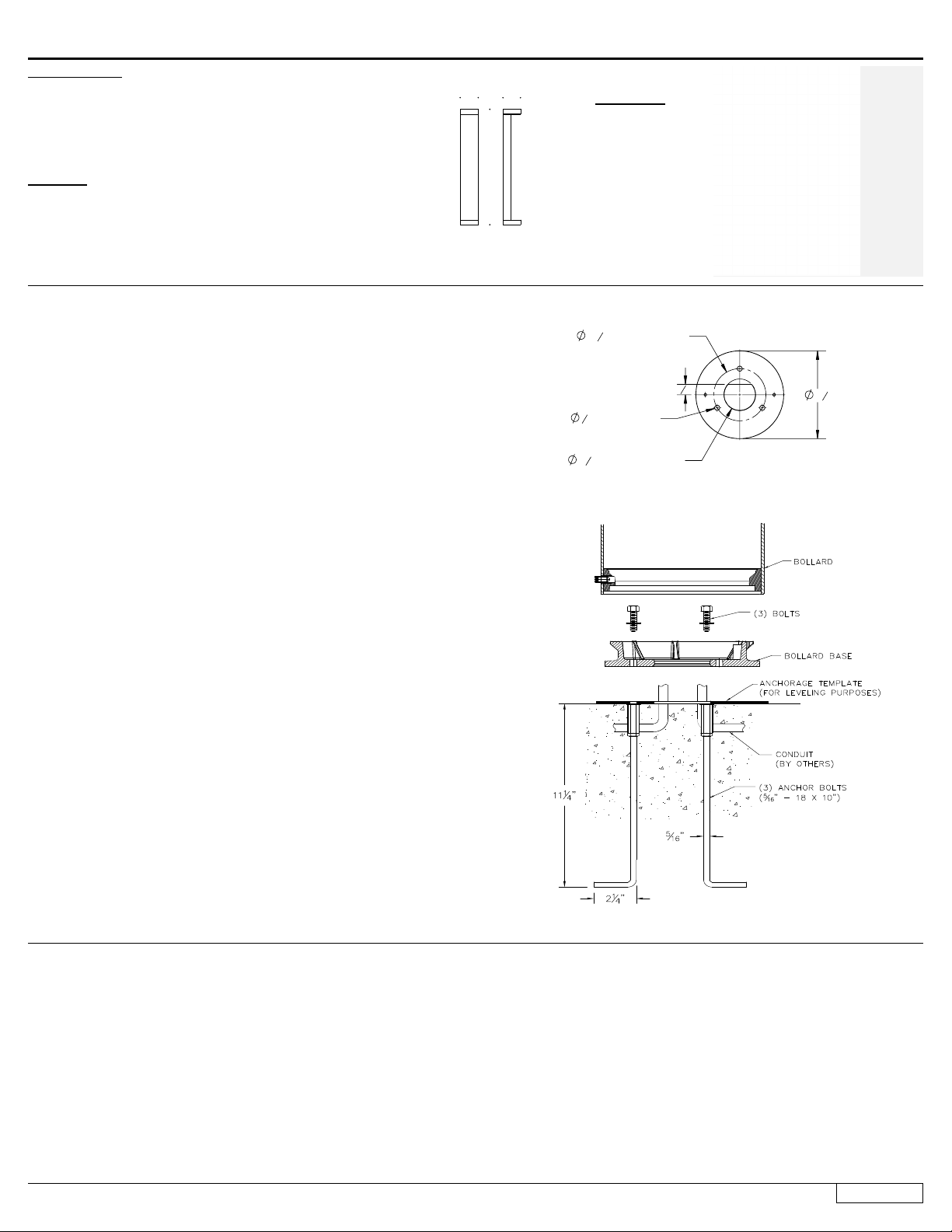

Figure 2:

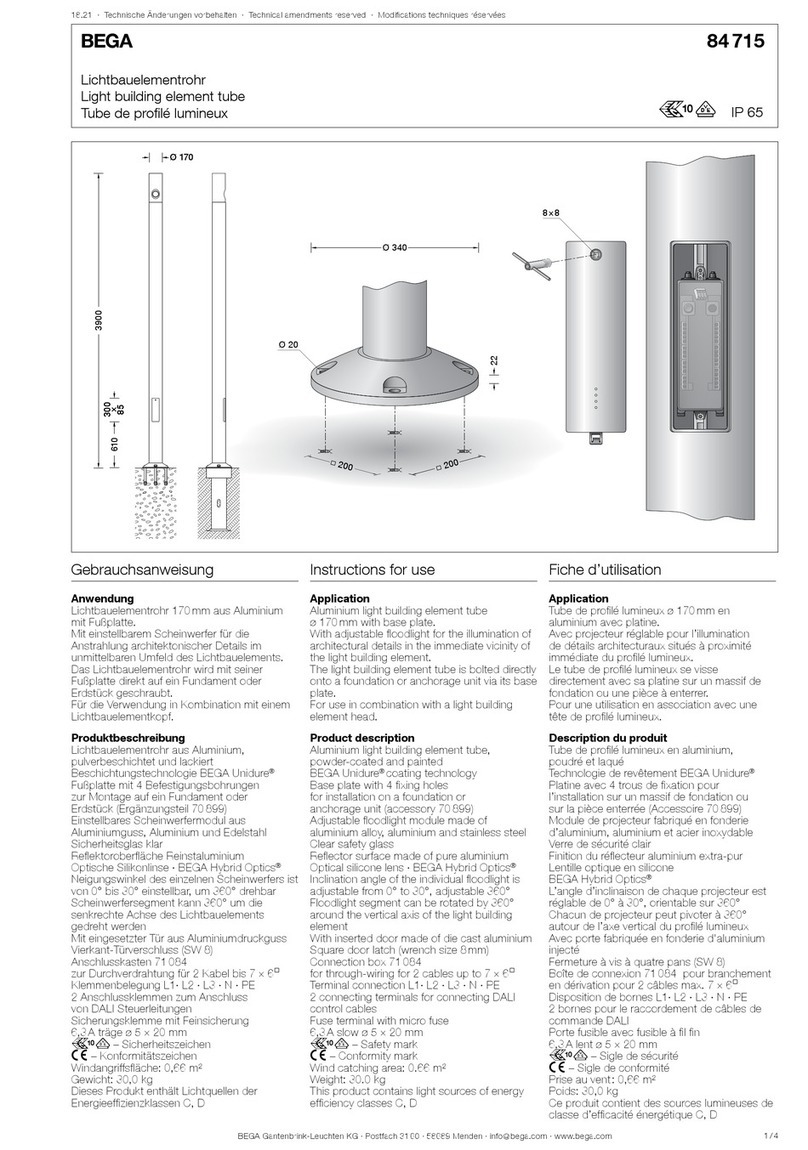

Shielded Bollard - Asymmetric 84 239

Dimensions

A: 7-1/2”

B: 39-3/8”

Maintenance:

Clean regularly with solvent-free cleaner

removing dirt and debris. Do not use high

pressure cleaners.

Replacement Parts

See label inside of xture for LED replacement

part number.

Consult factory for all other replacement

components.

Accessories

Please refer to the appropriate accessory installation

sheet for further instruction when applicable.

Updated: 03/02/21

84 239 2 of 3

B

FIXTURE OPTIONAL INSTALLATION METHODS

Notice to Installer:

1. See page 3 for specic product safety warnings.

2. Fixture may be damaged if connected to conduit systems that contain water - Article

300-5G of the National Electric Code requires that “Conduits or raceways through which

moisture may contact energized live parts shall be sealed or plugged at either or both

ends.”

3. It is recommended that when installing in planting areas the bollard base be slightly

elevated to avoid prolonged submerging during heavy rains.

4. Wet location listing does not imply suitability for exposure to standing water for long

periods of time.

5. LEDs are high-quality electronic components! Please avoid touching the light

output opening of the LED directly during installation.

70895 Direct Burial Anchor Kit Installation:

1. Provide means to bring supply wiring to the conduit entry location in accordance with

local code.

2. Prepare soil for anchorage or cast the post in concrete.

3. Make sure anchorage is installed rmly into the ground and mounted level to the surface.

NOTE: ENSURE THAT THE FLANGE PLATE IS ENTIRELY LEVEL AND FLUSH WITH

THE TOP EDGE OF THE SURFACE

4. Remove (3) mounting bolts and washers from the anchorage unit.

5. Align mounting base of the bollard tube, place onto top of anchorage post.

6. Secure by replacing (3) bolts through bollard base, into threaded holes of anchorage

ange. Tighten bolts rmly.

7. Skip to step 6 on 84238 luminaire installation (below)

84239 Luminaire Installation:

1. Remove (3) hex bolts and washers, once anchorage is set.

2. Leave template in place to provide a smooth, at surface to mount the base.

3. Turn the base plate and remove from bollard, after loosening the 5mm set screw.

4. Align base plate holes with anchorage holes.

5. Bolt the base plate to the anchorage kit using the (3) hex bolts and washers

6. Make supply wiring connections to wire leads from driver inside the xture

MAIN VOLTAGE SUPPLY WIRE TO BLACK LUMINAIRE WIRE;

NEUTRAL (COMMON) SUPPLY WIRE TO WHITE LUMINAIRE WIRE;

GREEN GROUND WIRE TO GREEN LUMINAIRE WIRE.

Dimming (if applicable):

DIMMING CONTROL WIRE (+) TO POSITIVE DRIVER DIM CONTROL WIRE

DIMMING CONTROL WIRE (-) TO NEGATIVE DRIVER DIM CONTROL WIRE

7. Place the bollard over the base plate so that the (3) notches in the base plate align with

the top.

8. Secure the bollard by tightening the 5mm set screw at the base.

84239-EMPK Option Luminaire Installation:

1. Follow steps 1-6 above for 84239 luminaire installation.

2. After installation is complete, supply AC power to the emergency driver and join the

converter connection (Figure 2).

3. At this point, power should be connected to both the LED driver and the emergency

driver, and the charging indicator light should illuminate indicating the battery is charging.

4. A short-term test may be conducted after the emergency driver has been charged for one

hour. Charge for 24 hours before conducting a long-term discharge test.

5. Place the bollard over the base plate so that the (3) notches in the base plate align with

the top.

6. Secure the bollard by tightening the 5mm set screw at the base.

Wire Entry

Flange Plate