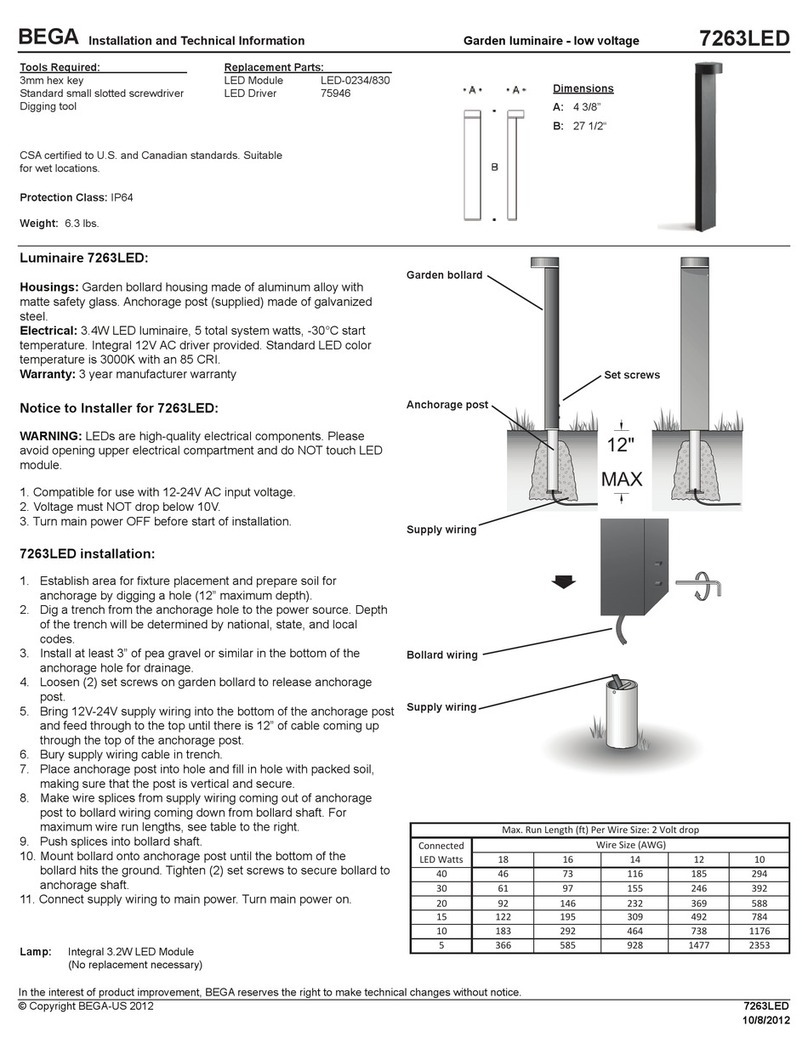

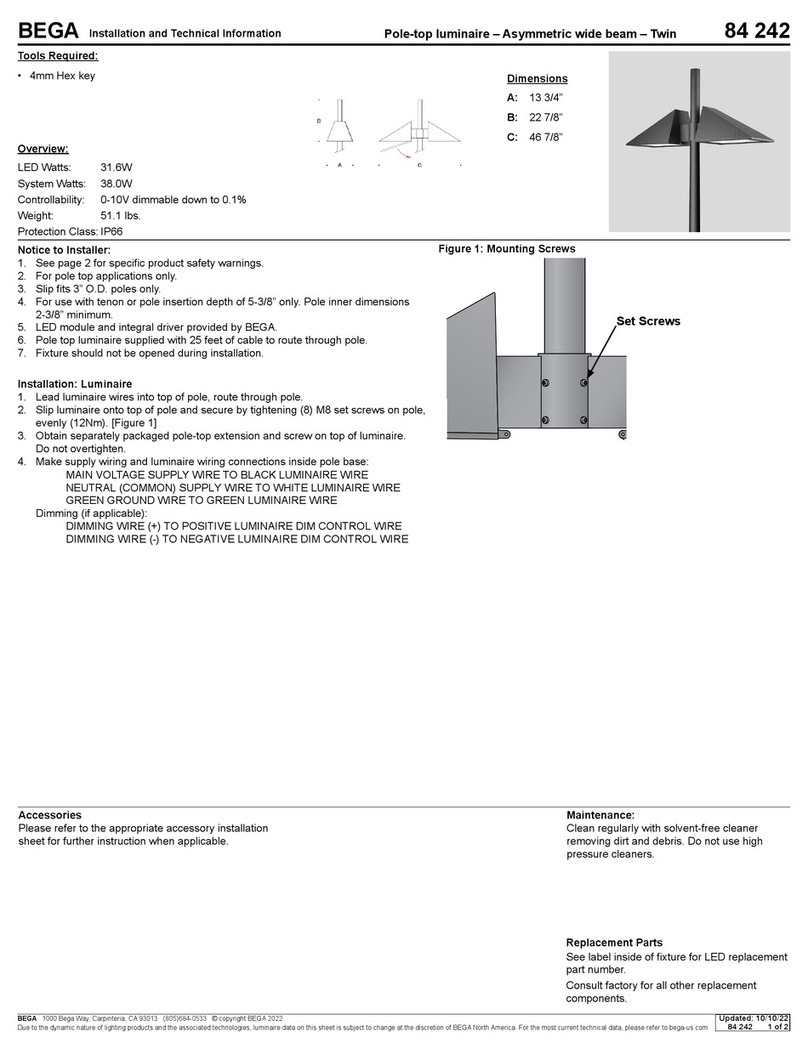

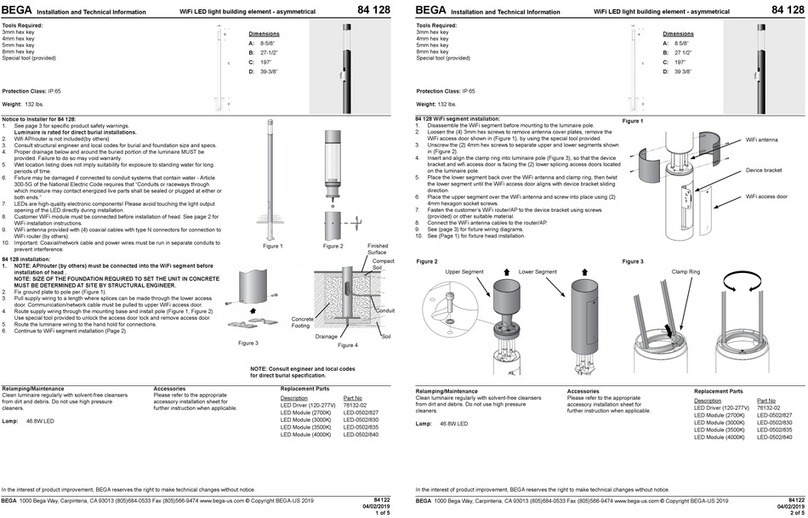

Installation and Technical Information

BEGA

Replacement Parts

In the interest of product improvement, BEGA reserves the right to make technical changes without notice.

Accessories

Please refer to the appropriate

accessory installation sheet for

further instruction when applicable.

BEGA 1000 Bega Way, Carpinteria, CA 93013 (805)684-0533 Fax (805)566-9474 www.bega-us.com © Copyright BEGA-US 2018

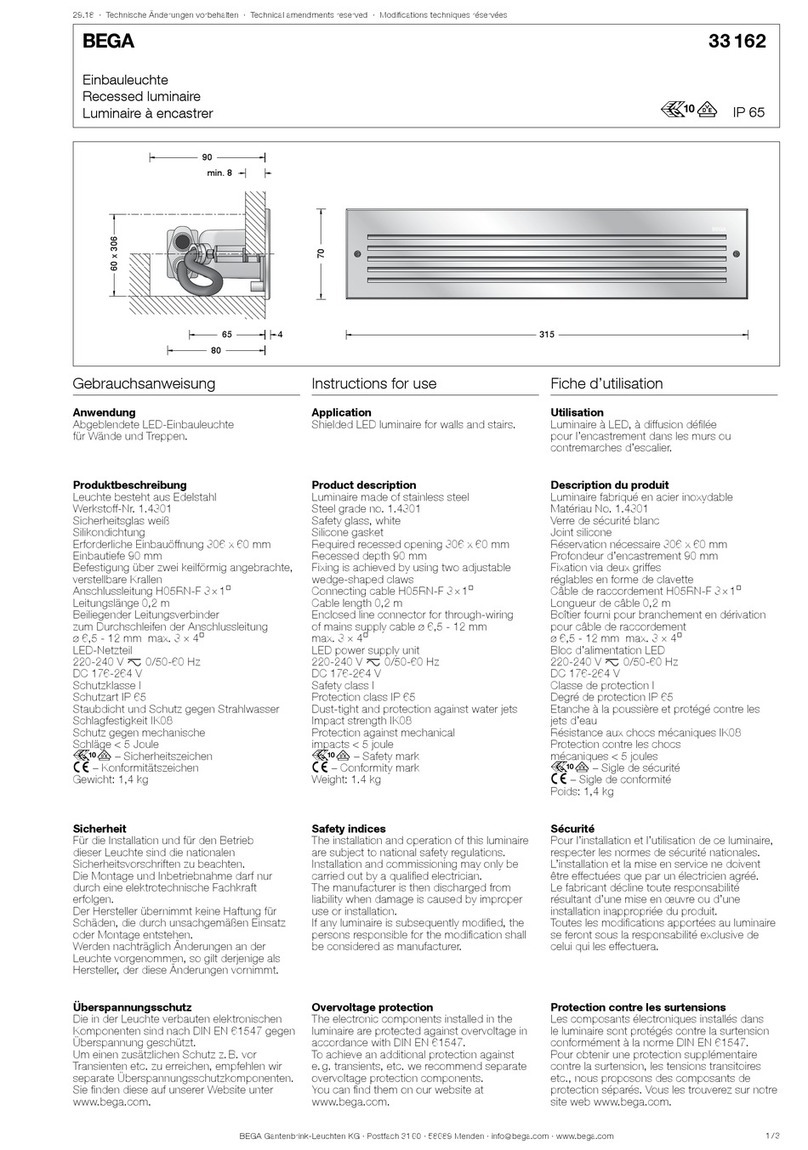

LED recessed wall luminaires made of stainless steel 33 200

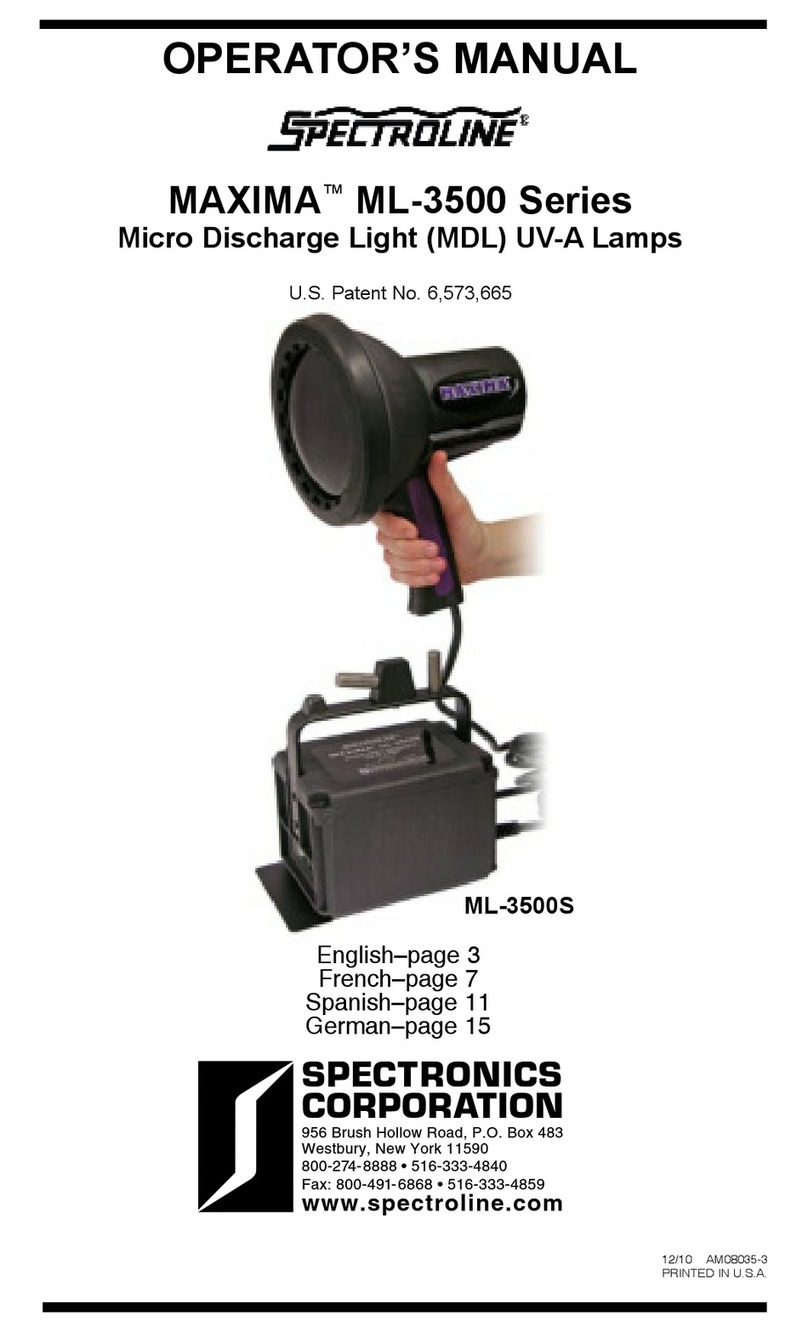

Tools Required:

Phillips medium screw driver

3 mm hex key

Standard medium slotted screwdriver

Protection Class: IP65

Weight: 0.4 lbs.

Dimensions

A: 3⅛

B: 4 ”

Relamping/Maintenance

No relamping required.

Lamp: 2.1W LED - 24V DC

33 200

06/2018

Page 1 of 2

Description

Faceplate

Glass

Gasket

LED (3000K)

Part No

710813B

140515

830887.1

74020

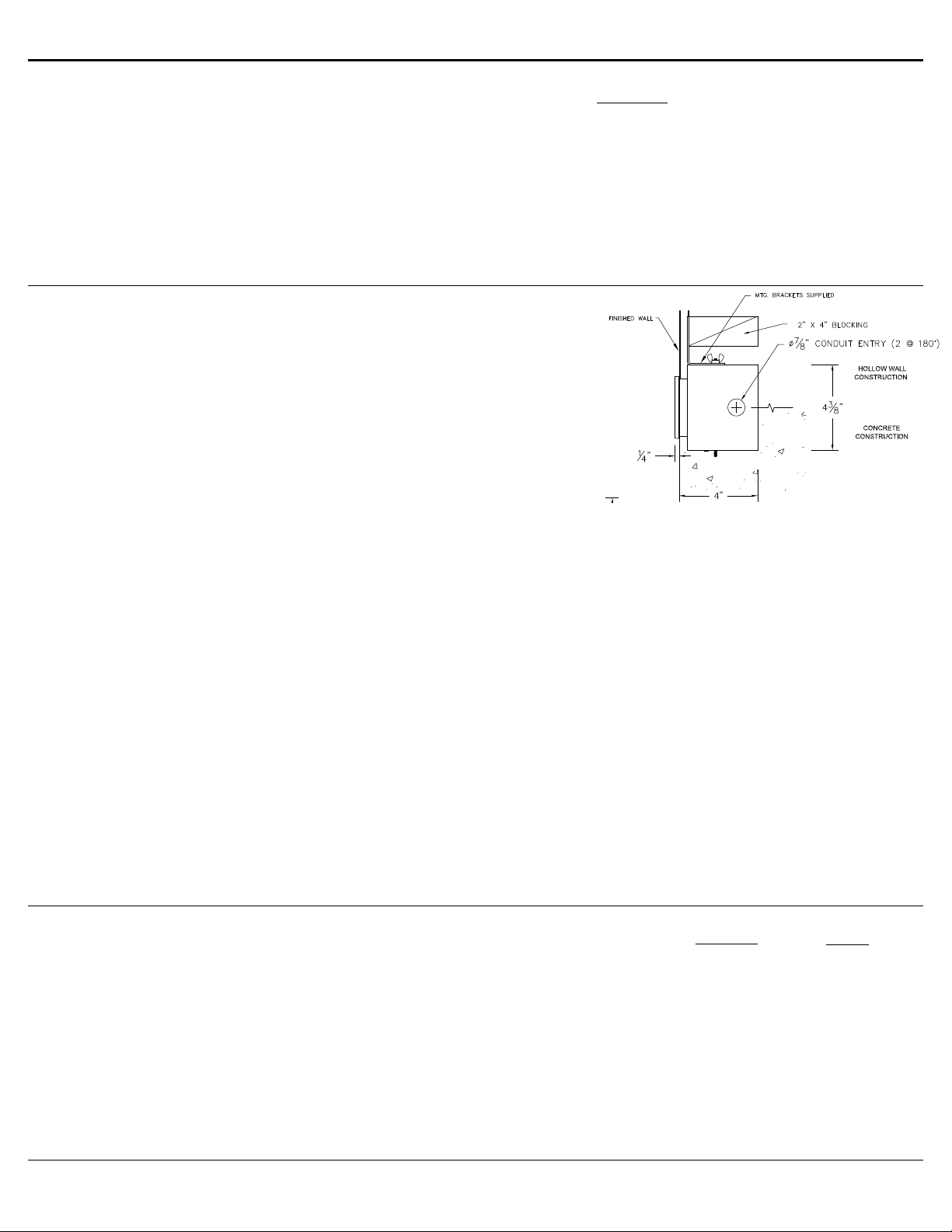

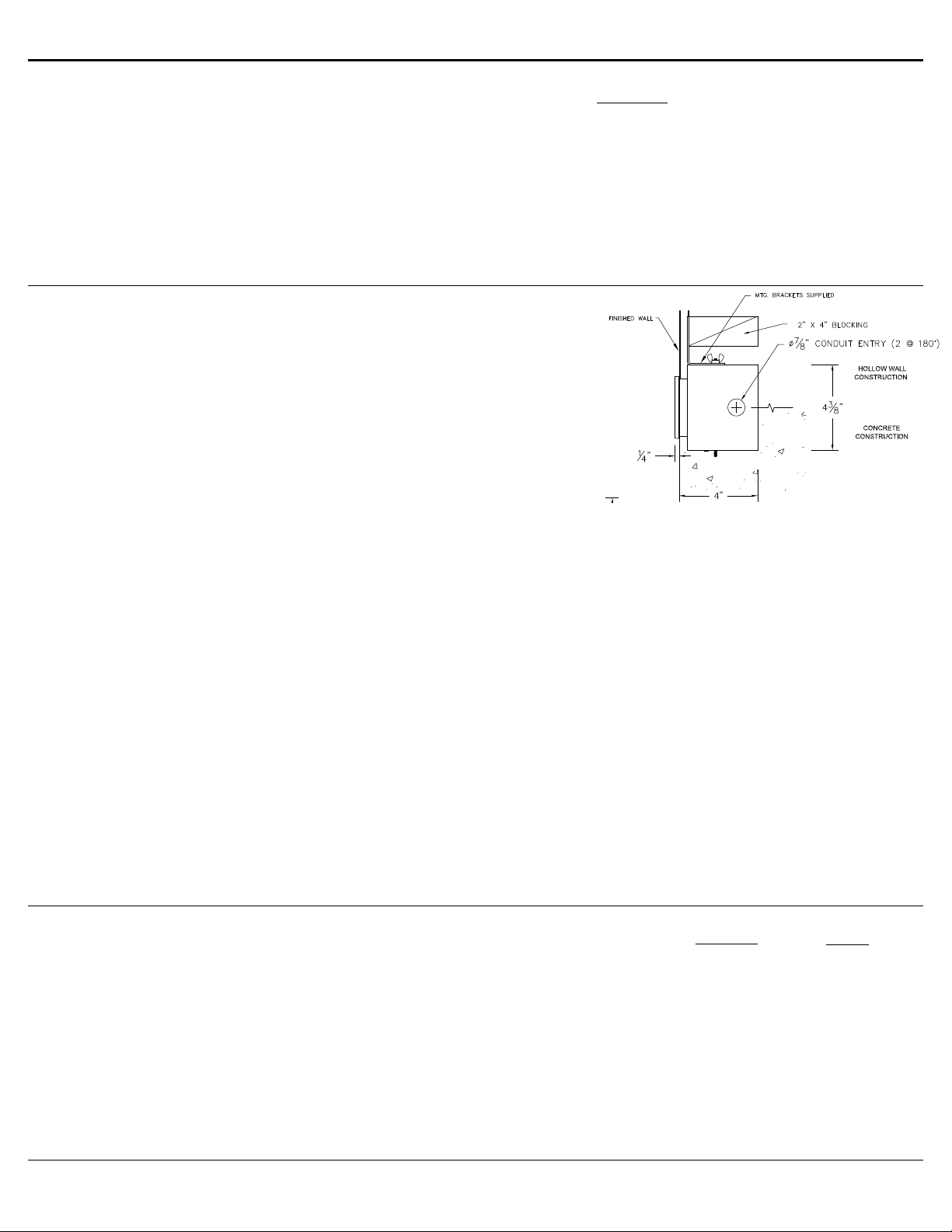

Notice to Installer for 33 200:

1. BEGA luminaires may be damaged if connected to conduit systems containing water - Article

300-5G of National Electric Code requires that “Conduits or raceways through which moisture

may contact energized live parts shall be sealed or plugged at either or both ends”.

2. Luminaire is Non-IC rated. Insulation must be at least 3” from luminaire.

3. Suitable for installation in hollow wall construction or poured concrete construction.

4. Back housing (BB2100LED) provided with (2) 7/8” holes (horizontal entry) for 1/2” trade size conduit.

NOTE: Internal components will not fit if conduit enters vertically.

5. Back housing must be installed so that the front face is ush with the finished wall.

6. Suitable for through wiring: max. of (4) No. 12 AWG conductors (plus ground) rated for 90°C.

7. Suitable for wall applications only. (No ceiling and in-grade applications).

8. LEDs are high-quality electronic components! Please avoid touching the light output opening of the

LED directly during installation.

NOTE: Requires a 24V DC class 2 electronic power supply to operate intended LED

wattage. (not included). DO NOT USE LINE VOLTAGE

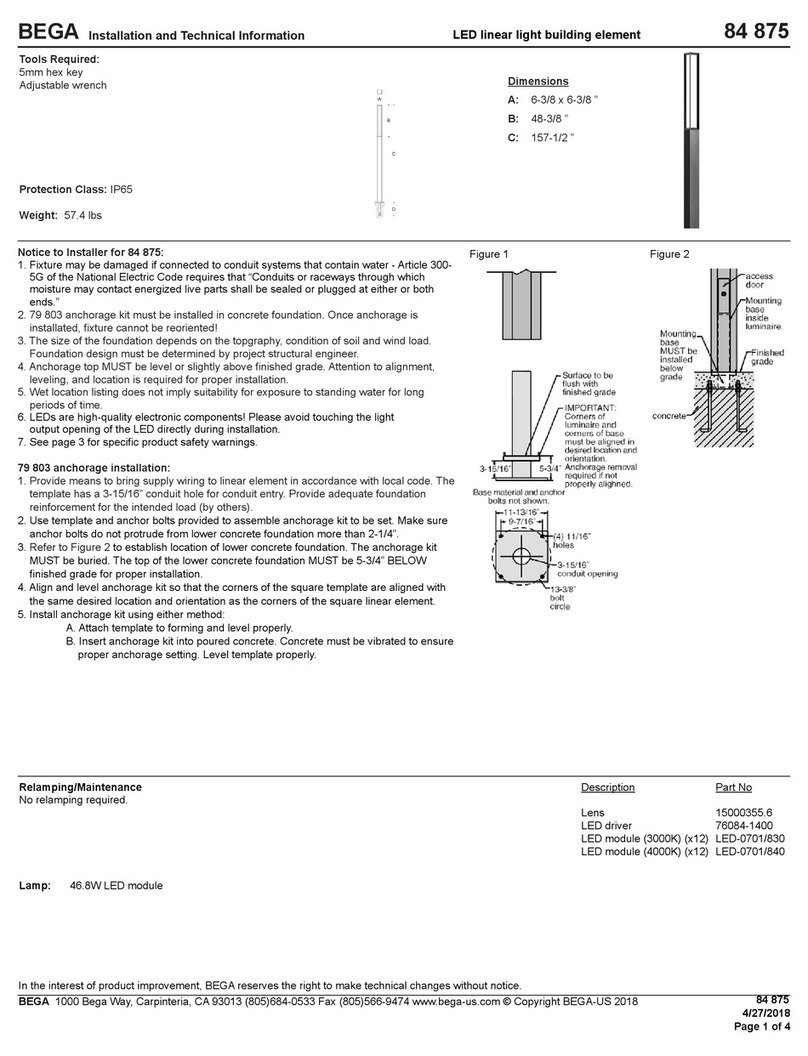

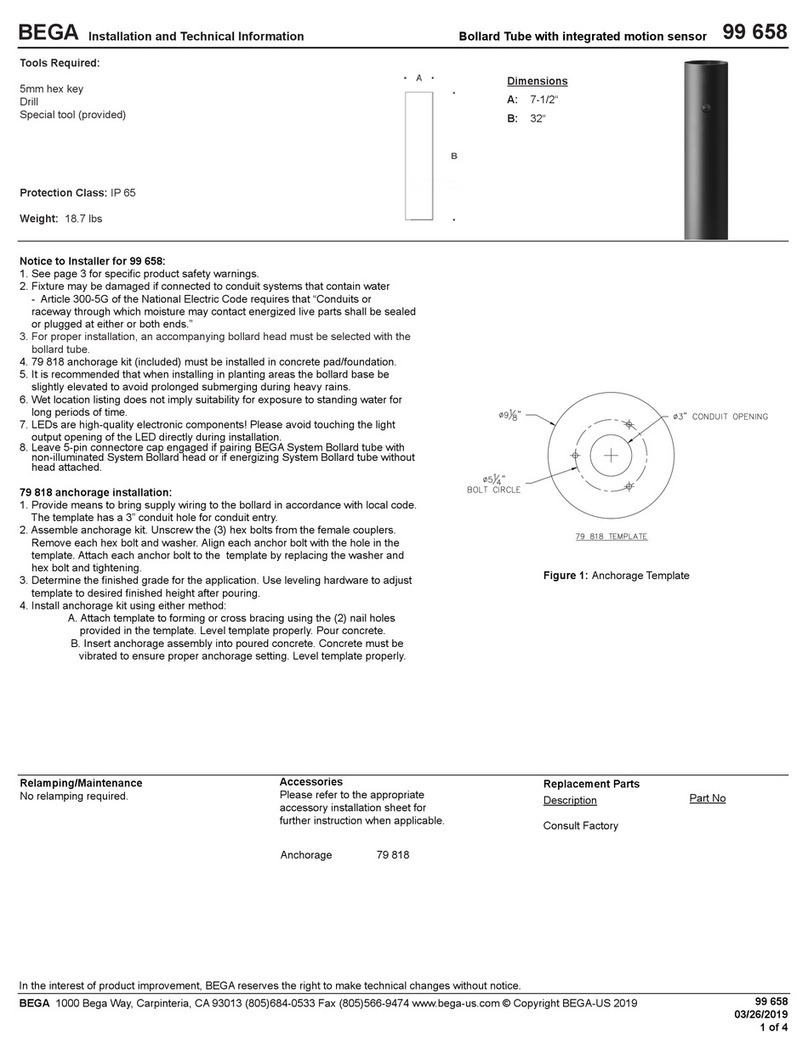

BB2100LED - back housing installation in hollow (stud) wall construction:

1. Install the (2) slotted mounting brackets provided as shown in Figure #1, using the (2) #6-32

wing nuts provided in the installation kit.

2. Adjust the brackets (by loosening the #6-32 wing nuts) so that the face of the back box will be

ush to the finished wall surface after installation.

3. Secure the mounting brackets to wood or metal horizontal blocking as shown in Figure #2.

4. Connect conduit to back housing and pull wires for electrical connections to be made later.

BB2100LED - back housing installation in poured concrete construction:

1. Attach (2) #8-32 threaded rods into the pressed nuts located in the bottom of the fixture back box (Fig

#3).

2. Attach the fixture back box to the concrete form using the wing nuts and washers provided in the

installation kit (Fig #4).

3. Connect conduit to back housing and pull wires for electrical connections to be made later. Pour

concrete. IMPORTANT NOTE!!! DO NOT PUMP OR DROP CONCRETE DIRECTLY ON TOP OF

THE BACK HOUSING.

4. After concrete is poured, remove the #8-32 wing nuts from the threaded rod before removing the form.

33 200 - inner housing wiring and installation:

1. Undo faceplate screws and carefully remove trim ring and lens.

2. Connect the corresponding positive and negative wires from the inner housing to the remote driver.

3. Place a small bead of silicone between edge of housing and wall to provide a seal.

4. Install inner housing into back housing, and tighten the (2) M3 screws until secure.

5. Install faceplate casting and lens. Make sure that gasket and lens are seated properly.

6. Tighten the (4) M4 athead screws evenly to secure.

Remote 25W LED Driver 19 580

Remote 50W LED Driver 19 591