101073 Rev. B, 3/99

CAUTION: Use a separate circuit breaker for

each pump motor. Make sure the pump motor

is never on the same circuit breaker as any

other power circuit for the dispenser.

CAUTION: Install RC Networks correctly for

proper dispenser operation.

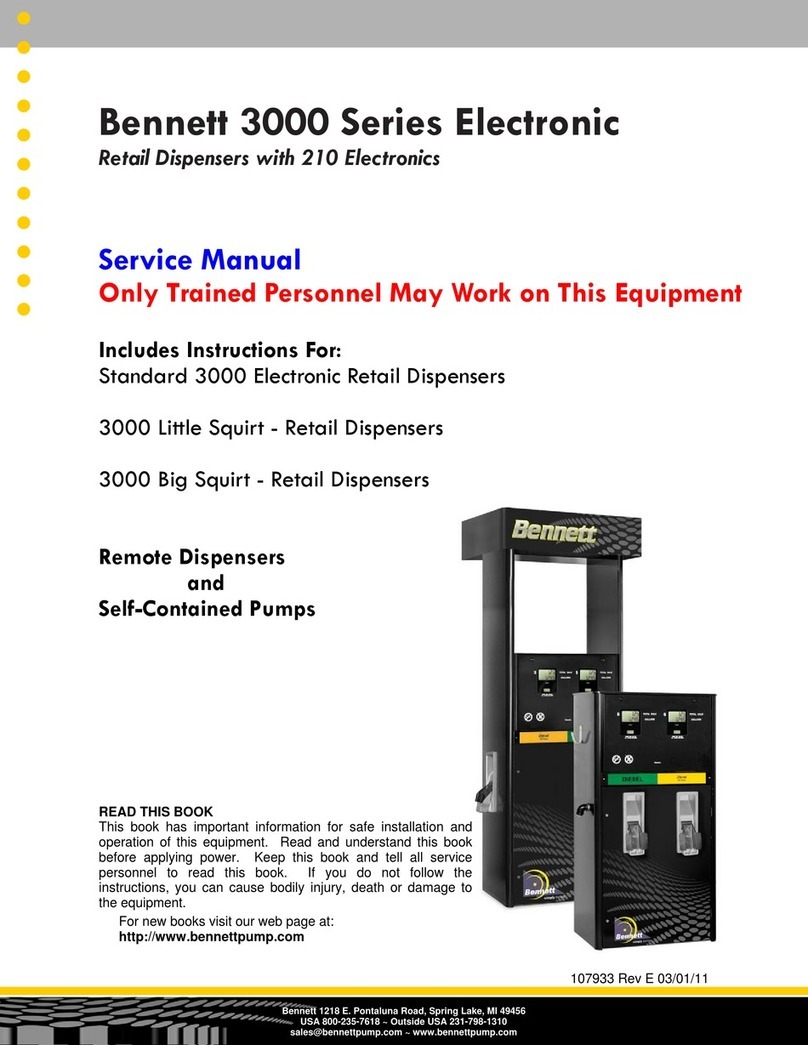

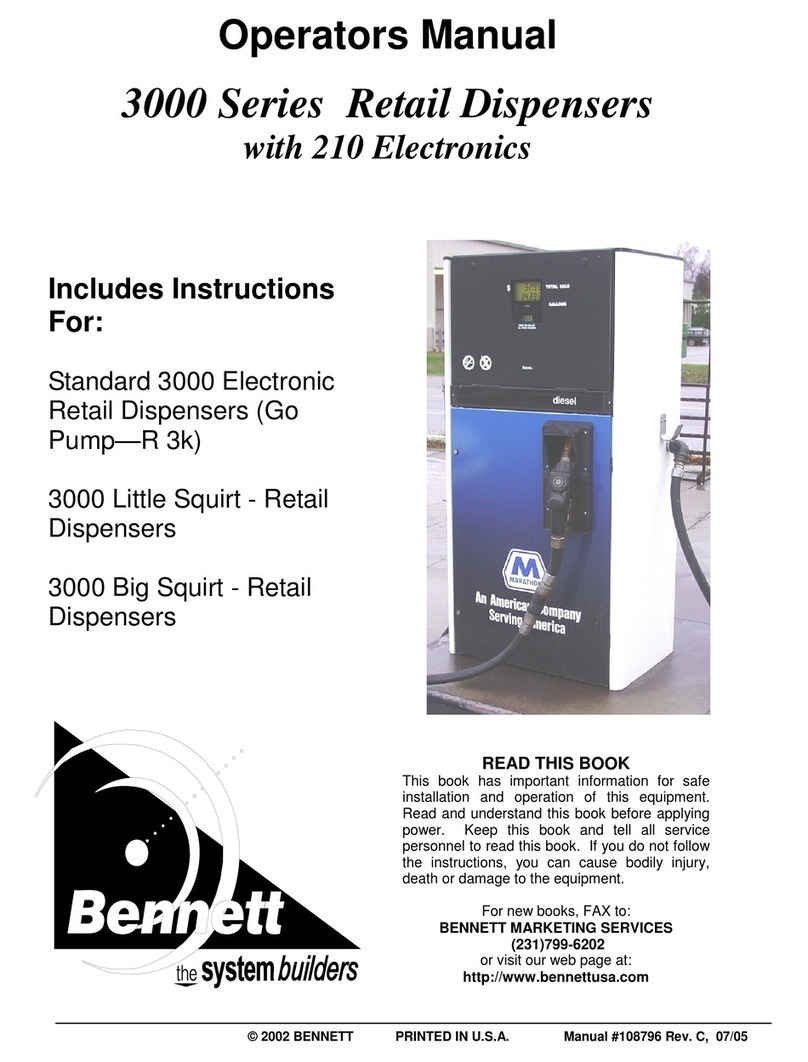

Self-Contained Dispensers

Self-contained dispensers have the pump motor

mounted in the lower hydraulic area. The power is

passed to the pump motor using the pump motor relay

located in the electronic enclosure. The pump motor

is contained in the dispenser on a self-contained unit.

Connect the 120 or 240 VAC motor circuit to the

dispenser power board. Use 14-gauge (or larger)

stranded THHN wire.

Termination of Field Wiring for Pump Motor Power

of Self-Contained Dispensers.

Product A: L1 - 120 or 240 VAC (HOT) in to COM

Terminal Red 14-gauge wire. Neutral/L2 to motor A

wire nut

Product B: L1 - 120 or 240 VAC (HOT) in to COM

Terminal Blue 14-gauge wire. Neutral/L2 to motor B

wire nut

The motors are shipped from the factory set for 120

volt operation. If 240 volt operation is needed, change

the Voltage Selector Switch on the motor from the low

setting (120 Volt) to the high setting (240 Volt).

CAUTION: Use a separate circuit breaker for

each pump motor. Make sure the pump motor

is never on the same circuit breaker as any

other power circuit for the dispenser.

CAUTION: Install RC Networks correctly for

proper dispenser operation.

RC NETWORKS

An RC Network is an electrical noise suppression

device. It is used on AC power devices such as coils

and across relay contacts. When AC voltage is

applied to coils they are converted to electromagnets.

Coils are used to operate AC devices, such as

solenoid dispensing valves and AC power relays or

contactors. When the AC power is removed from a

coil, the electromagnetic field collapses. This causes

an AC voltage spike as high as 1500 VAC which can

affect electronic systems.

RC Networks must also be used on motor relay

contacts to suppress the noise from the arc and noise

spikes that are caused by the relays opening and

closing.

The submerged pump motors are controlled by an

auxiliary pump motor relay. Follow this procedure to

protect dispenser and console operation:

1. Use an RC Network on the coil circuit and across

the contacts of each submerged pump motor

control relay (typical Red Jacket style box.)

2. Check local code requirements concerning

complete disconnect of submerged pump

voltages. RC Networks will allow voltage to be

present at all times.

3. Turn off all related circuit breakers when servicing

submerged pumps or dispensers.

DATA COMMUNICATION WIRING FOR

USE WITH A CONSOLE

Data wires are required for operation of each fueling

position with a control console. The data wires can be

put in the same conduit as the other pump wiring.

Each side (fueling position) of a dispenser requires

two 18-gauge, or larger, data wires.

CAUTION: Data wires (two 18-gauge per

fueling position) are dedicated to a particular

fueling position. To prevent damage to the

electronic circuit boards, do not mix the data

wires or connect them to any other data wires.

CAUTION: DO NOT USE WIRE NUTS OR

SPLICES ON DATA WIRES. FAILURE OF THE

SYSTEM WILL OCCUR.

11