6

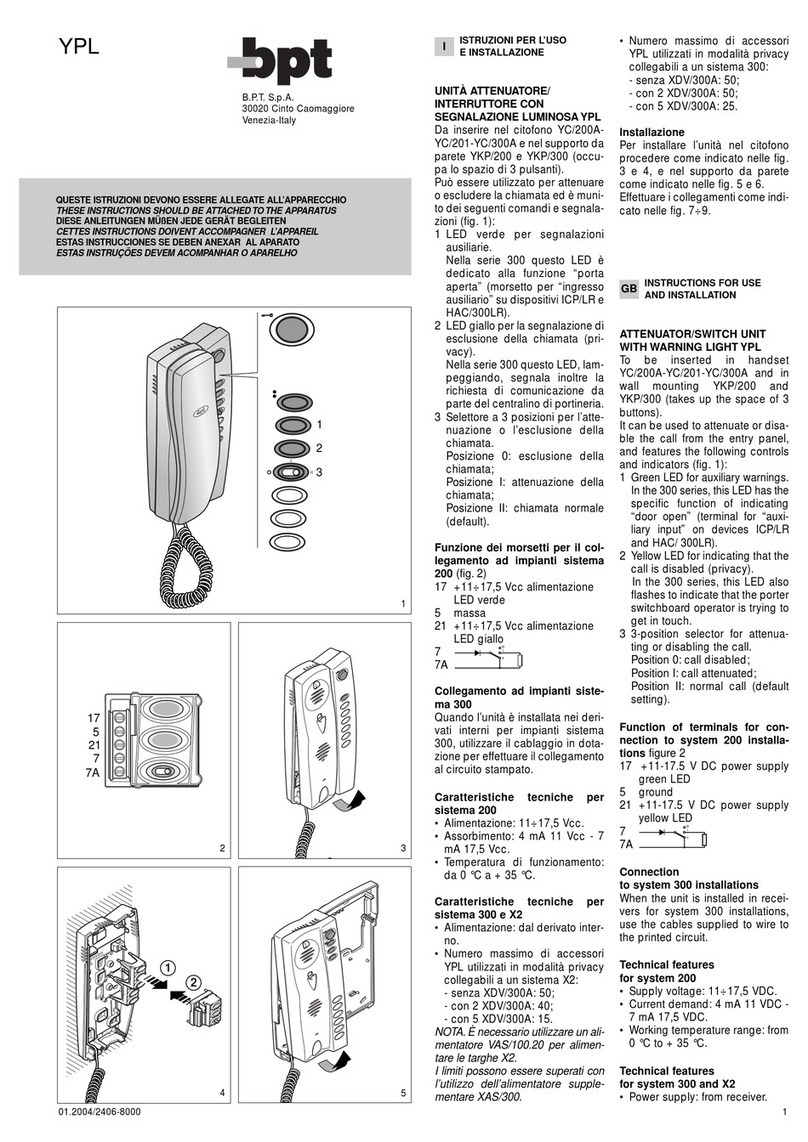

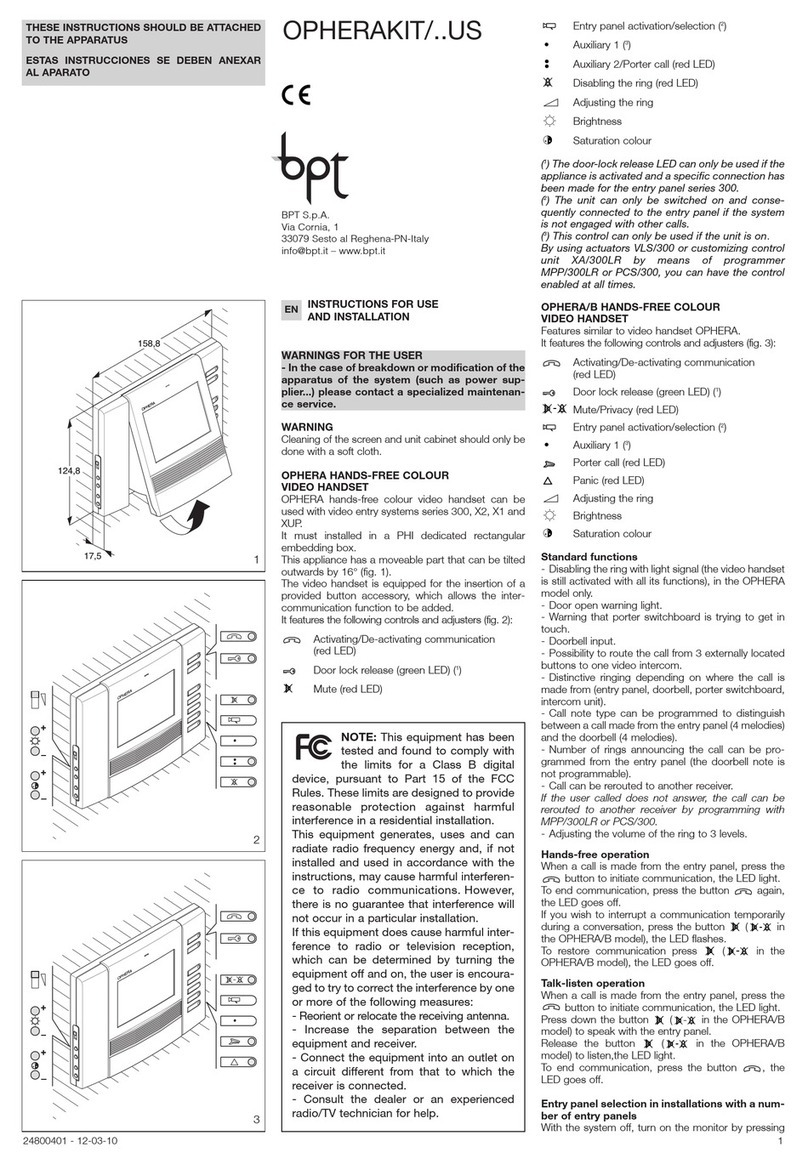

TButton for a service call (tra-

desman stair light etc.).

ENTRY PANEL OPERATING

INSTRUCTIONS

Information for visitors

The entry panel can be program-

med so that, whilst the installation

is in stand-by, information on how

to use the keypad appears on the

display in 4 languages.

These messages can be customi-

zed via programming.

Finding users stored in the

directory and making the call

Pressing and releasing pushbutton

or interrupts the informational

messages so that you can search

for the desired name (along with

the name, the display features the

customized code or, if there is

none, the call code) in alphabetical

order (scanning performed in this

order of priority: space, special

characters, numbers and letters).

Every time the button is pressed,

the next name appears whilst, if the

button is kept pressed, a fast sear-

ch is performed, quickly scrolling

through the initial letters in alpha-

betical order or reverse order

depending on whether key or

is used.

Select the initial letter desired, find

the name using the key or .

When the name desired comes up

on the display, make the call by

pressing the key.

If you know the call code already,

you can also key in the user’s code

directly via the keypad.

System busy warning

This status is indicated on the

display with the previously pro-

grammed message.

Whilst in this condition, calls can-

not be made from the entry panel.

Nonetheless, secret codes can be

sent and the programming menu

accessed.

Key P

A dedicated key for sending the

call code to the porter.

Pressing this key calls up the mes-

sage stored for this function (no

default setting).

If the installation does not feature a

porter switchboard, this code can

be used for other purposes.

Key T

A dedicated key for making a ser-

vice call (tradesman stair light

etc.).

Pressing this key calls up the mes-

sage stored for this function (no

default setting).

Sending this code does not activa-

te the installation.

Key S

This key must be pressed before

entering secret codes.

In order to send a secret code, you

must press the S key, enter the

secret number (no more than 9

numbers) and press the key.

The system features a device that

protects the secret codes from any

attempts to discover them.

Once a code that does not match

any of those stored has been ente-

red 5 times, key P’s service call

code (usually corresponding to the

porter call) is sent.

Key

•Use key in residential installa-

tions to replace the block number

with a letter or caption.

- Press key to select the caption

to be associated with the block

(e.g. A, B, Build. A etc.).

- Key in the user number and press

the key to make the call.

The block code associated with

the caption must be programmed.

•Use key to make alphanume-

ric calls.

- Key can be used to select the

letters. Once the necessary letters

have been stored, simply key in the

alphanumeric code (e.g. AZ, 1C,

A3B etc.), than make the call by

pressing .

Of course, the code entered must

fit in the customized code field in

the user menu.

Key C

Lets you delete the code keyed in.

Accessing the

programming menu

In order to access programming, key

in S 12345 (default setting) and .

Default settings

The entry panel comes with the fol-

lowing settings:

1-Help messages for finding

names in 4 languages (Italian,

English, French, German).

2-Service messages (e.g. BUSY)

in 4 languages (Italian, English,

French, German).

3-Programming menu in Italian

(with the option of selecting

English).

4-CONSTANT LIGHTING mode for

display and keypad.

5-Programming password and

deleting memory S 12345 (S

can be omitted from the memory

deletion password).

6-Block numerical call mode.

7-Block number: 00.

8-Code associated with key P:

80156.

9-Code associated with key T:

79157.

Resetting the default password

Should the customized password

be misplaced, the default setting

12345 can be reset by entering an

emergency code furnished by BPT.

To receive this code, you must

quote the ID code to be found on

the back of the front plate.

Programming button functions

Menu forward search function

Menu reverse search function

Confirms function

0÷9 None

None

CExits programming and returns

to the previous menu function

PNone

SNone

TNone

Data entry button functions

Decreases character size

Increases character size

Confirms data entered

0Enters number 0and symbols

+ - / % £ $

1Enters number 1and symbols

space , : @ ‘ “ ;

2Enters number 2and letters A

BCÅÄÆÇ

3Enters number 3and letters

D E F É

4Enters number 4and letters

G H I

5Enters number 5and letters

J K L

6Enters number 6and letters

MNOÑÖØ

7Enters number 7and letters

PQRSß

8Enters number 8and letters

TUVÜ

9Enters number 9and letters

WXYZ

Enters symbols * . ? ¿ ! ¡ & §

CDeletion of the letter, number

or symbol previously entered

and exit from parameter data

entry.

PEnters symbols # = ( ) < > _

SSelects upper or lower case

TAdvances the cursor across

the display

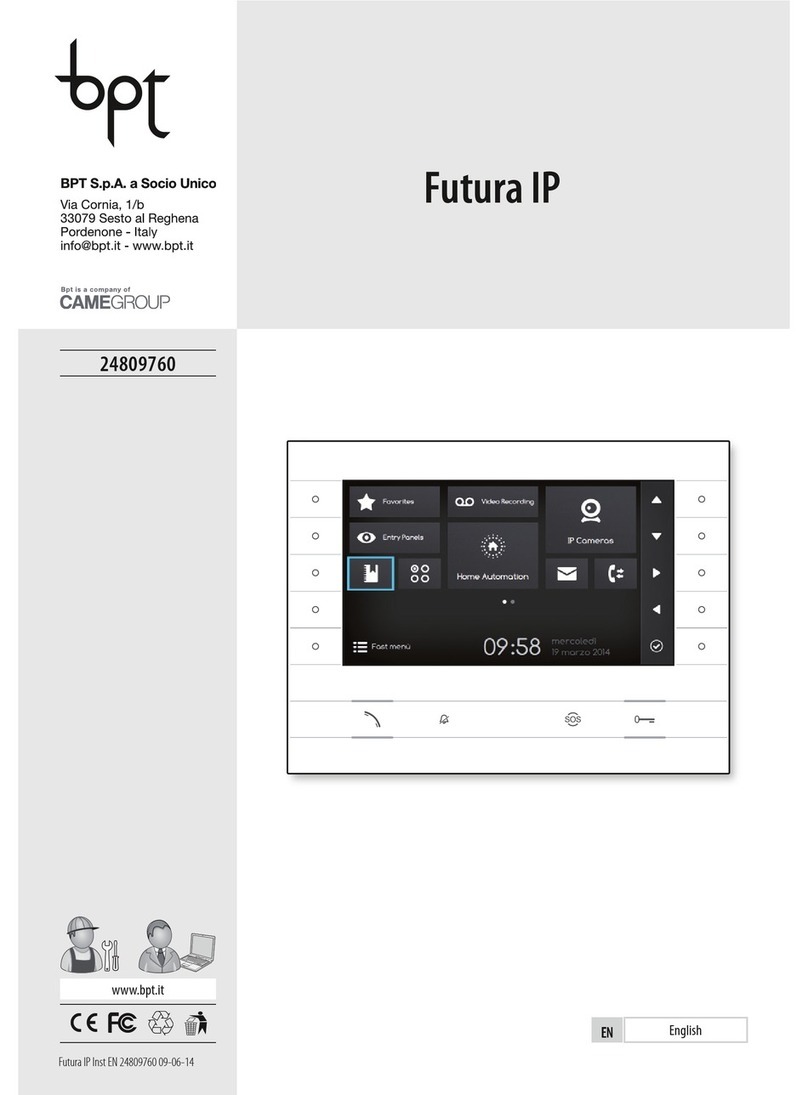

Programming

menu functions (fig.6)

Lingua/Language

Italiano

English (select the desired langua-

ge for the programming menu

messages).

The language options are Italian

and English.

Users management

Add (adds a new user).

The following parameters can be

entered for each user:

•call code (0-80155)

•customized code (max. 9 num-

bers or letters)

•user name (max. 80 letters in

small characters, max. 30 letters

in medium characters, max. 9

letters in large characters).

WARNING. If you want to enter

users in progressive call mode,

you must first edit the settings in

the relevant section.

Modify (edits the stored user).

Delete one (deletes an individual

stored user).

In the Modify and Delete one sub-

menus, you can select the user to

be edited or deleted using keys

and .

You can scroll through quickly by

keeping key or pressed.

Delete all (deletes all stored users).

In the Delete all submenu, you are

asked to confirm before all stored

items are deleted.

Call mode

Block call (call in block mode).

First two digits: 0 to 80;

Last three digits: 0 to 161.

Progressive call (call in progressi-

ve mode).

0 to 12635.

Information texts

Add (adds a new informational mes-

sage).

Informational messages are ente-

red using the alphanumeric keys

and can contain up to 80 letters and

numbers in small characters, 30 let-

ters and numbers in medium cha-

racters and 9 letters and numbers

for large characters.

Messages are displayed in sequen-

ce every 2 s.

Modify (edits the informational mes-

sage).

Delete one (deletes an informational

message).

In the Modify and Delete one sub-

menus, you can select the message

to be edited or deleted using keys

and .

P key texts

Add (adds anew portercallmessage).

Porter call messages are entered

using the alphanumeric keys and

can contain up to 80 letters and

numbers in small characters, 30

letters and numbers in medium

characters and 9 letters and num-

bers for large characters.

Messages are displayed in

sequence every 2 s.

Modify (edits the porter call messa-

ge).

Delete one (deletes a porter call

message).

In the Modify and Delete one sub-

menus, you can select the messa-

ge to be edited or deleted using

keys and .

T key texts

Add (adds a new Tradesman com-

mand message).

Tradesman command messages

are entered using the alphanume-

ric keys and can contain up to 80

letters and numbers in small cha-

racters, 30 letters and numbers in

medium characters and 9 letters

and numbers for large characters.

Messages are displayed in

sequence every 2 s.

Modify (edits the Tradesman com-

mand message).

Delete one (deletes a Tradesman

command message).

In the Modify and Delete one sub-

menus, you can select the messa-

ge to be edited or deleted using