Braun Aesculap S4 Manual

Other Braun Medical Equipment manuals

Braun

Braun Infusomat P User manual

Braun

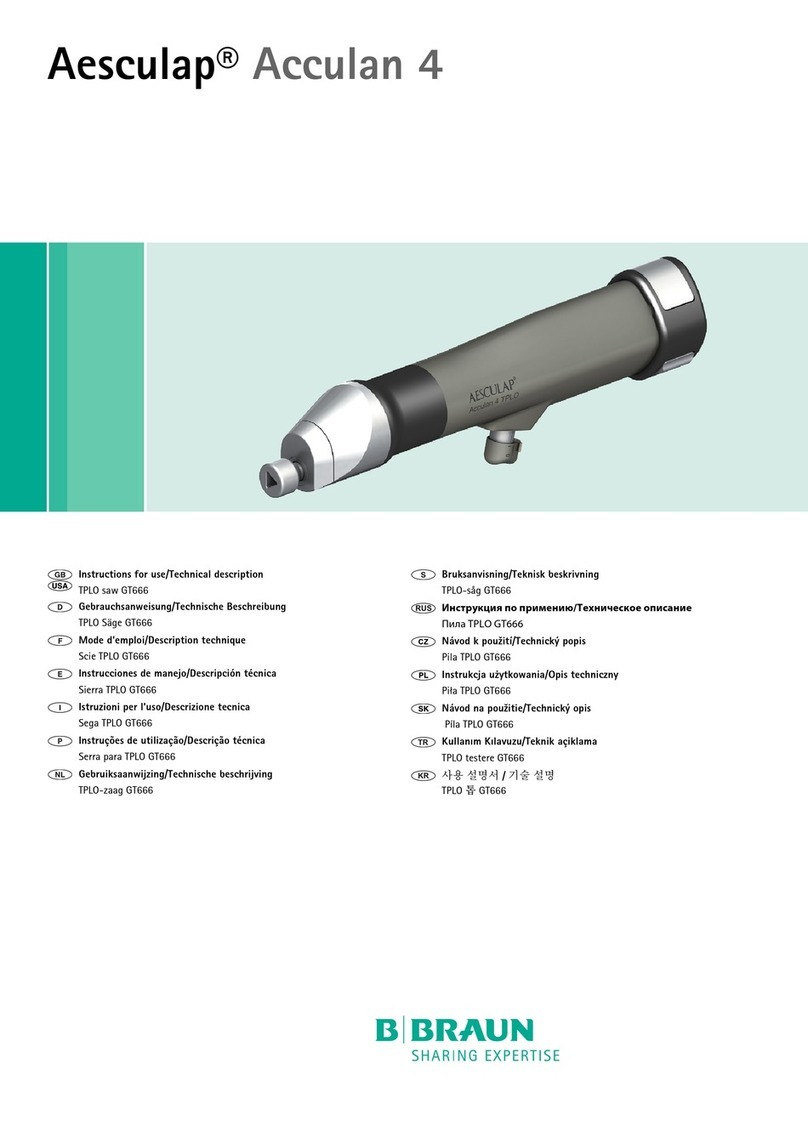

Braun Aesculap Acculan 4 Manual

Braun

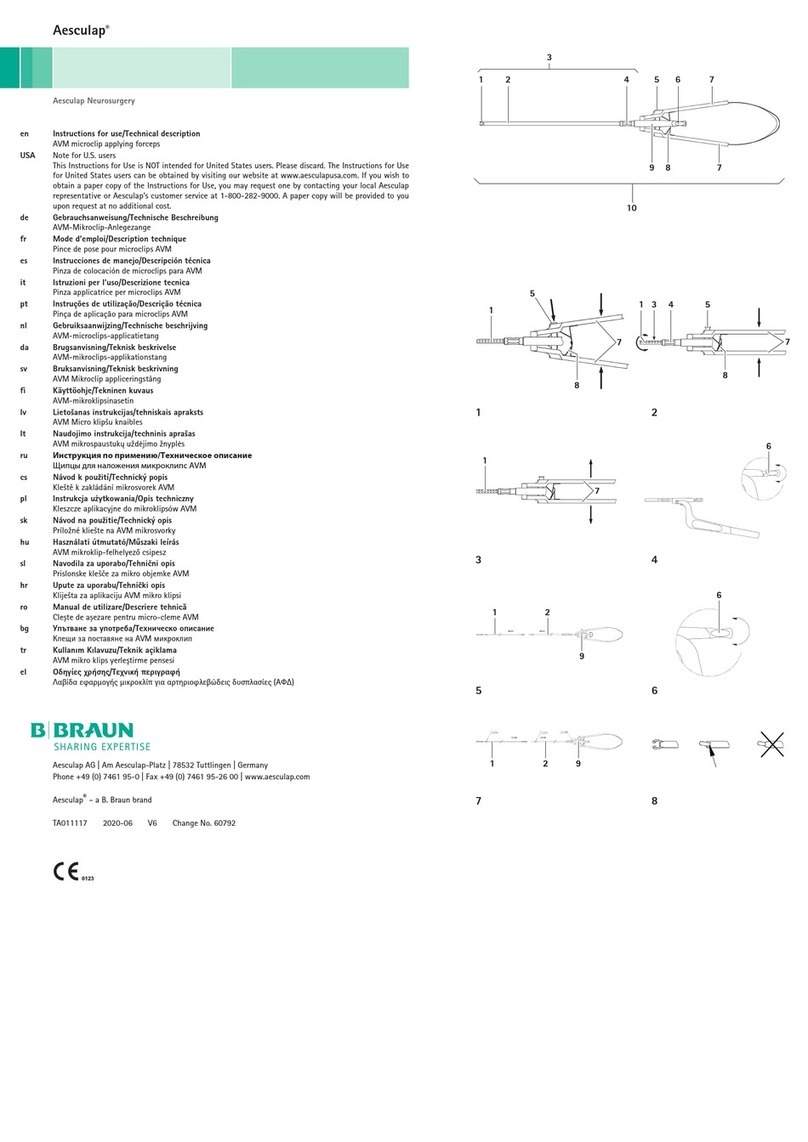

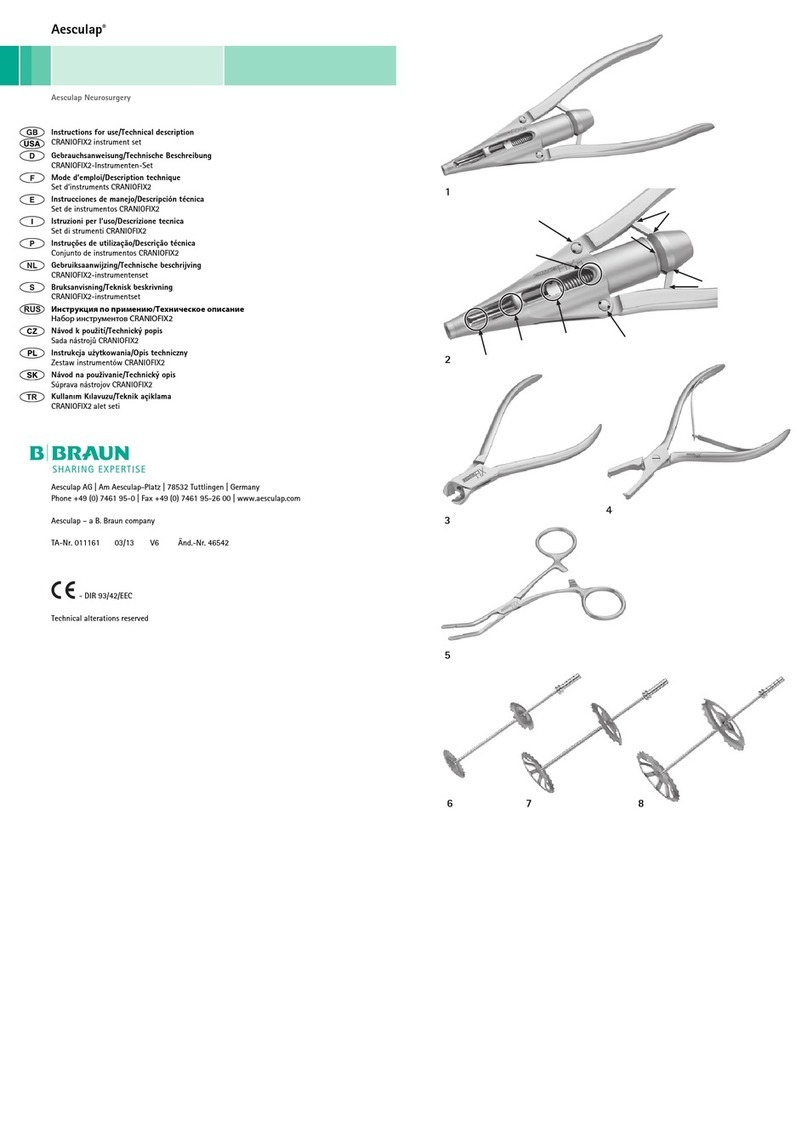

Braun Aesculap Neurosurgery Manual

Braun

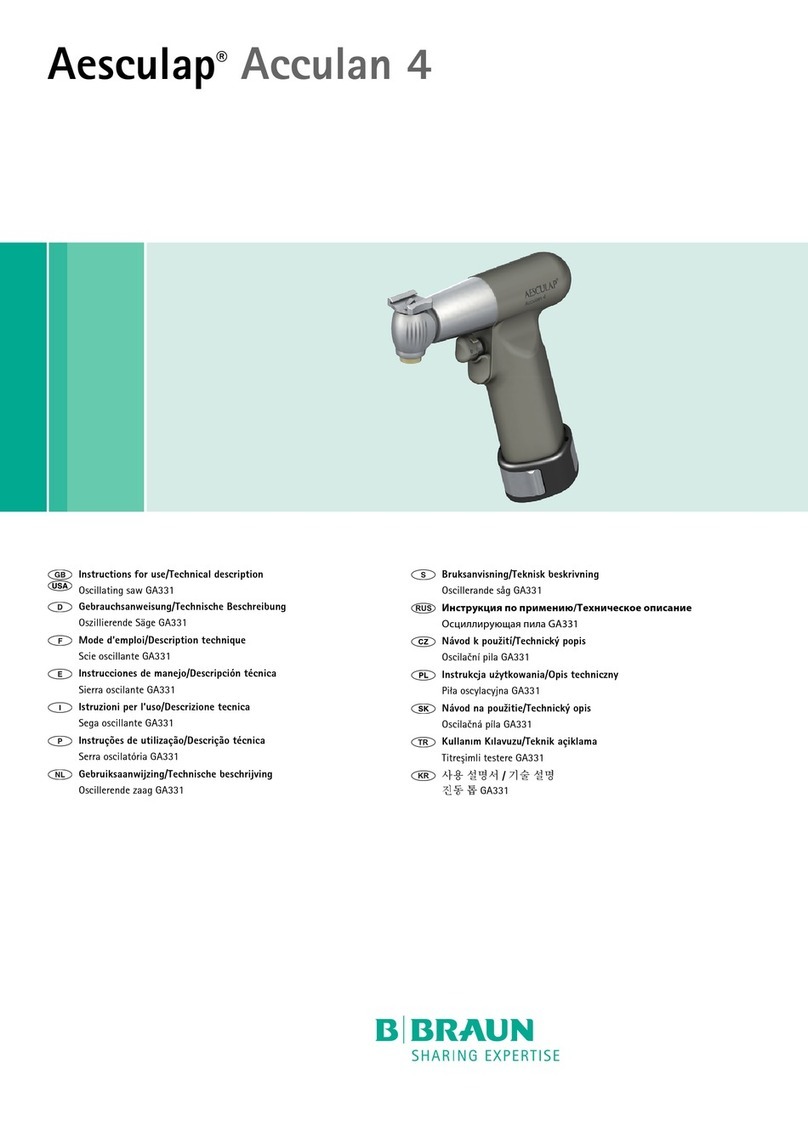

Braun Aesculap Acculan 4 Manual

Braun

Braun BPX800 User manual

Braun

Braun Aesculap ELAN 4 Manual

Braun

Braun Aesculap Neurosurgery Manual

Braun

Braun Acculan 3Ti User manual

Braun

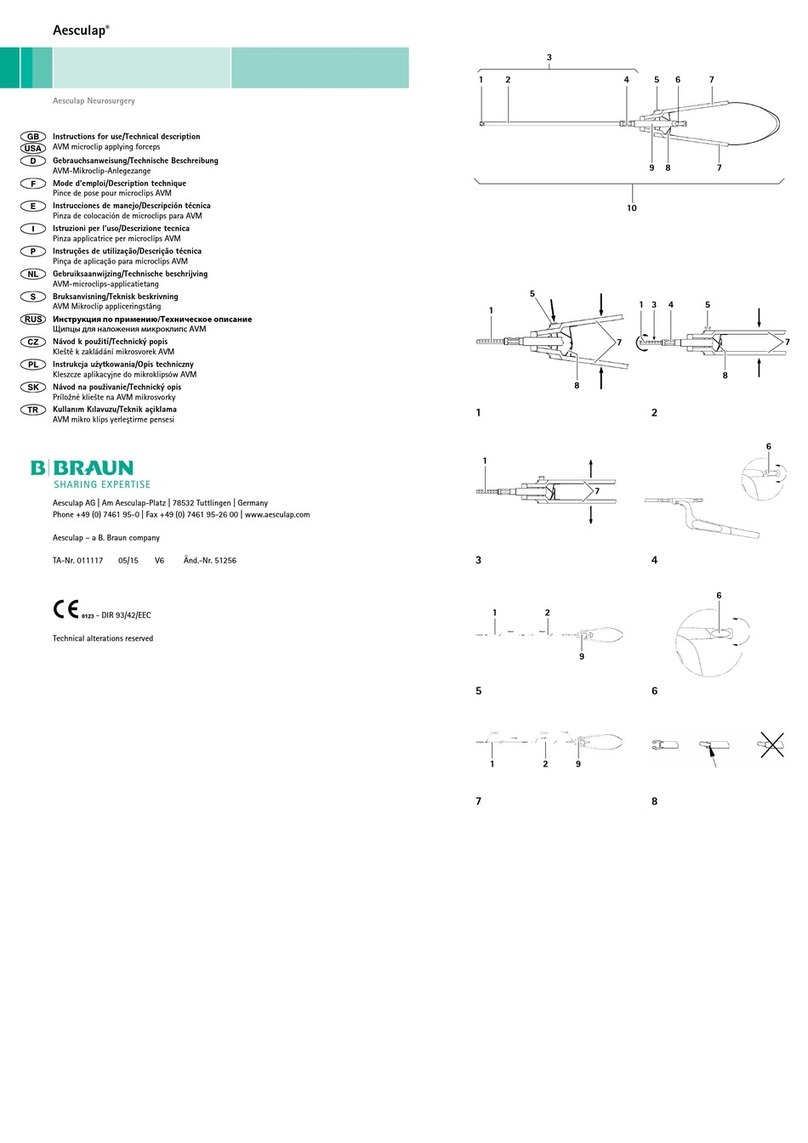

Braun Aesculap Neurosurgery Manual

Braun

Braun Draina S Large User manual

Braun

Braun Aesculap Neurosurgery Manual

Braun

Braun Infusomat Space P User manual

Braun

Braun Aesculap activ L User manual

Braun

Braun Aesculap S4 FW225R Manual

Braun

Braun Aesculap Spine User manual

Braun

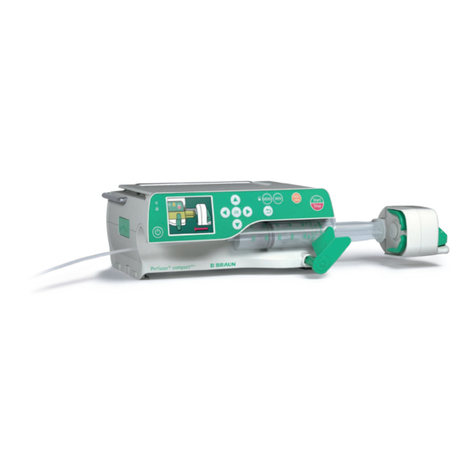

Braun Perfusor compact plus User manual

Braun

Braun Flexima 3S User manual

Braun

Braun Infusomat Space User manual

Braun

Braun BNA100US User manual

Braun

Braun Aesculap Quintex Manual