EN

ICAUTION!

fObserve all national directives for drinking water installations (e.g. DIN 1988, EN 1717) and applicable state and local regulations, general

sanitary requirements and technical data for the protection of drinking water.

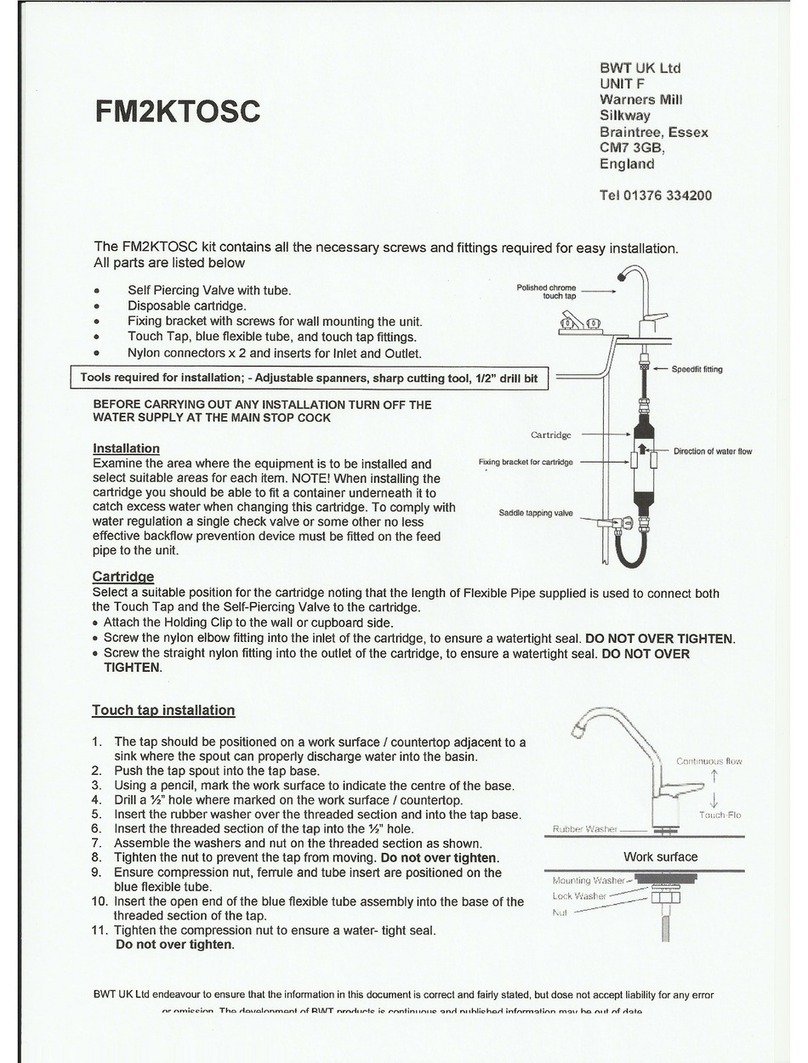

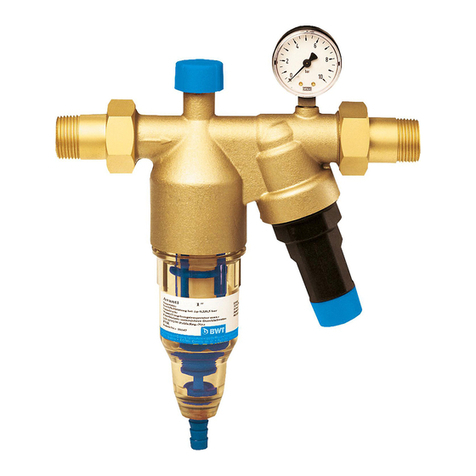

fA check (shut-off) valve upstream of the filter system must be installed.

fUse only connections with gaskets or flat seals. Conical seals damage the filter head connections and will invalidate the warranty claim.

fThe appliance needs to be connected with hoses in accordance with DVGW W 543 or NSF 42/53.

fIf the product has been stored below freezing point (0 °C), leave the unpacked product at the ambient temperature of the installation

location for a minimum of 24 hours prior to operation.

fDo not install the filter system near heat sources, open fire places or naked flames.

fChemicals, solvents and vapours must not come into contact with the filter system.

fThe installation location must be protected against freezing and direct sunlight.

NOTE!

fFor installation and operation of the filter system, the BG regulation “Rules for Safety and Health Protection When Working in Kitchens”

of the “Food and Beverages” expert committee of BGZ (BGR111) must be observed. The filter system has been hygiene tested in accor-

dance with Section 7.4 DIN 18879–1.

fThe materials are selected in accordance with the requirements of DIN 18879–1 and EN 14898.

fThe pressure resistance of the filter system conforms to DIN 18879–1.

fThe filtered drinking water conforms to liquid category 2 in accordance with EN 1717.

fClean and descale the appliance, e.g. coffee machine, before firstly installing the filter system.

fFor immunocompromised people and infants it is recommended to boil the tap water before drinking. This also applies to filtered water.

fFor the protection against microbiological growth the filter cartridge contains a small amount of silver (“bacteriostatic”)*. There might

be a harmless release of silver in concentrations below the recommendations of the World Health Organization (WHO). The term

“bacteriostatic” indicates that the system limits the passage or growth of bacteria already existing in the incoming water*. It does not

mean that the water leaving the system is safer to drink than the water entering it.

fDuring the filtering process, the magnesium content rises slightly. If a special low-magnesium diet is to be followed, BWT recommends

to seek medical advice.

4.1 Responsibility of the operator

The installation and operating instructions must be kept in the immediate vicinity of the filter

system and must be accessible at any time.

The filter system may only be operated in a technically perfect state ensuring a safe

operation.

The instructions in this installation and operating manual must be followed entirely.

4.2 Warranty and exclusion of liability

BWT warrants to the original purchaser/consumer all equipment that it munufactures to be free

from defects in material and workmanship for a period of 2 years from the date of purchase. This

warranty is subject to exclusions and limitations

The notes and recommendations listed, as well as local drinking water and recycling regulations,

must be met. All information and notes in this installation and operating manual account for

the applicable standards and regulations, state-of-the-art technology as well as our expertise

in water treatment. BWT does not assume any liability for damages or subsequent/secondary

damages arising from:

Failure to comply with the instructions in this installation and operating manual

Improper use

Improper or faulty installation

Improper commissioning, operation, maintenance

Mechanical damage of the filter system

Unauthorized modifications

Technical modifications

Use of non-certified, non-approved components

MMWPC_NeuesDesign_pink.indd 12 05.10.2018 08:43:48