4 GEOMETRY

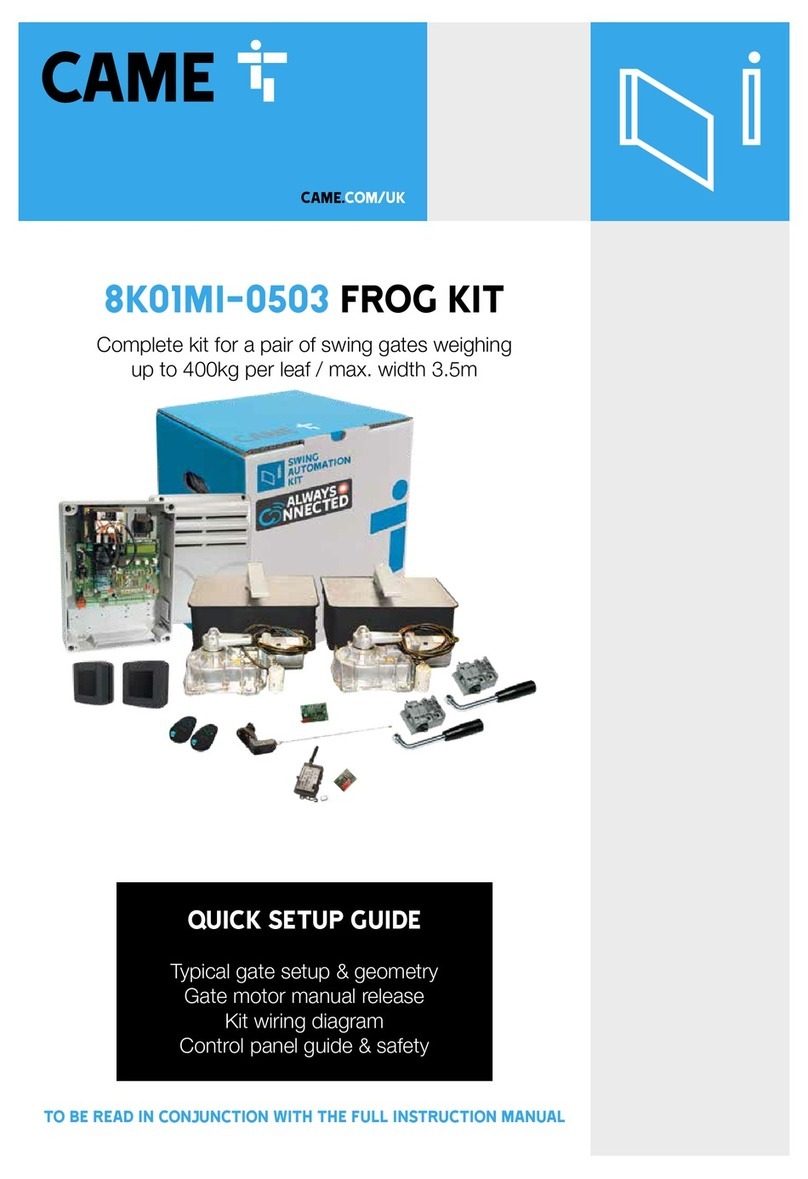

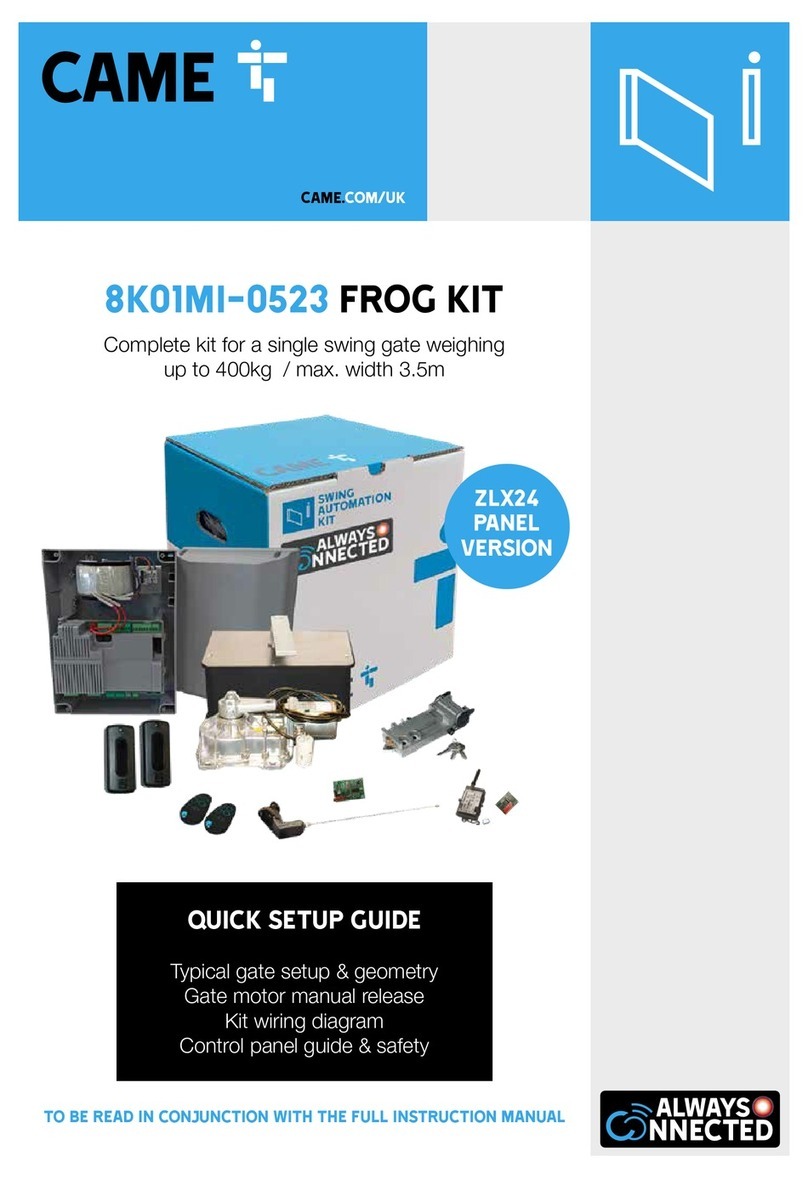

Preliminary checks

Tick

1. Check that the gate structure is sturdy enough, the hinges work efficiently and that there is

no friction between the fixed and moving parts

2. Check that the foundation box is correctly installed

3. Make sure that you have fitted opening and closing mechanical gate stops

4. Ensure that the gate corresponds with the motor limits

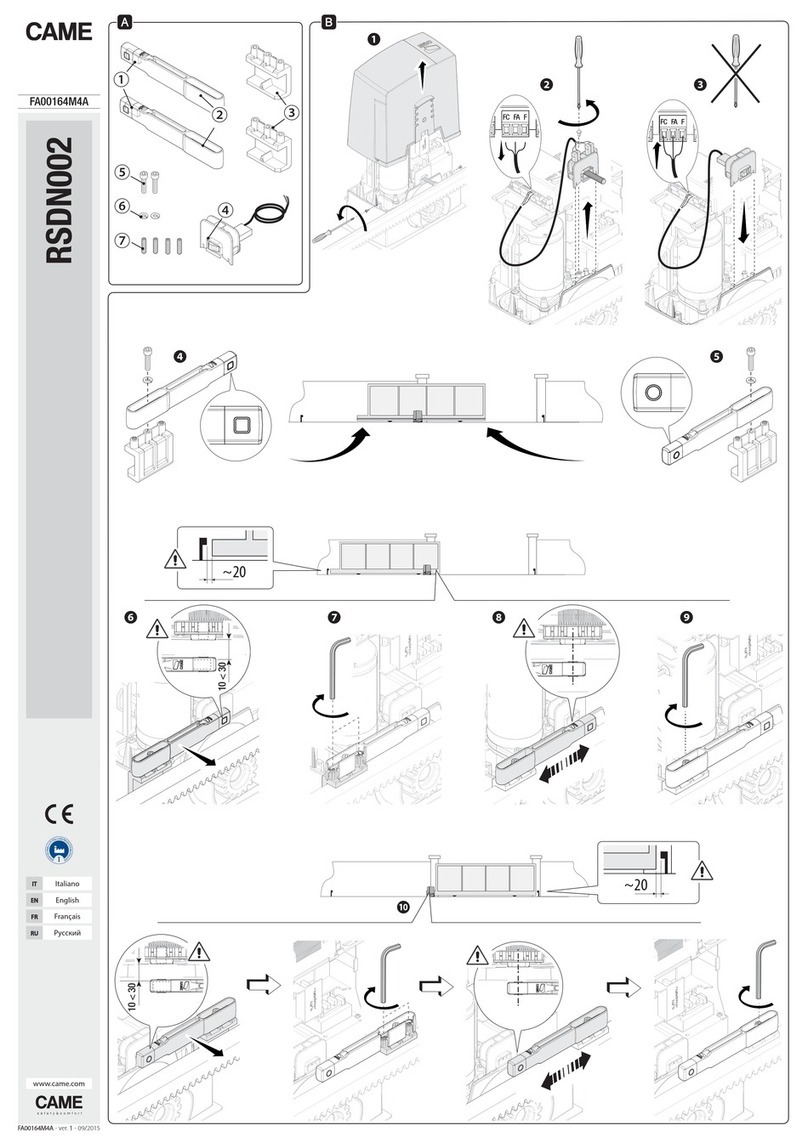

• Manually open the leaf.

• Position the gearmotor over the threaded pins

of the casing and fasten it.

• Lubricate the transmission lever.

• Fit the transmission lever as shown in the

drawings.

Page 99- Manual code: FA00597- ENFA00597-EN ver. 1105/2018 © CAME S.p.A. - The data and information provided in this manual are subject to change at any time without prior notice byCAME S.p.A.

Open the door to facilitate the placement of the gearmotor in the foundation case and its anchoring.

Secure the gearmotor using the nuts supplied.

M12 nut

UNI 5588

Fastening the gearmotor

Before fastening the gearmotors, fit the adjusting screws into the gearmotor drive arms, as shown in the drawing.

LEFT SIDE RIGHT SIDE

Page

105/2018 © CAME S.p.A. - The data and information provided in this manual are subject to change at any time without prior notice by CAME S.p.A.

Lubricate the transmission lever and fit it into the hole of the gearmotor arm and case lever.

Determining the end run points

During opening:

- Fully open the leafs (the maximum aperture is 110 °);

- loosen the screw until it makes contact with the body ;

- tighten the nut to lock the position of the screw.

During closing:

- close the leaves completely;

- loosen the screw until it makes contact with the transmission arm ;

- tighten the nut to lock the position of the screw.

105/2018 © CAME S.p.A. - The data and information provided in this manual are subject to change at any time without prior notice byCAME S.p.A.

Open the door to facilitate the placement of the gearmotor in the foundation case and its anchoring.

Secure the gearmotor using the nuts supplied.

M12 nut

UNI 5588

Fastening the gearmotor

Before fastening the gearmotors, fit the adjusting screws into the gearmotor drive arms, as shown in the drawing.

LEFT SIDE RIGHT SIDE

Page 1010 - Manual code: FA00597-ENFA00597-EN ver. 1105/2018 © CAME S.p.A. - The data and information provided in this manual are subject to change at any time without prior notice by CAME S.p.A.

Lubricate the transmission lever and fit it into the hole of the gearmotor arm and case lever.

Determining the end run points

During opening:

- Fully open the leafs (the maximum aperture is 110 °);

- loosen the screw until it makes contact with the body ;

- tighten the nut to lock the position of the screw.

During closing:

- close the leaves completely;

- loosen the screw until it makes contact with the transmission arm ;

- tighten the nut to lock the position of the screw.

105/2018 © CAME S.p.A. - The data and information provided in this manual are subject to change at any time without prior notice byCAME S.p.A.

Open the door to facilitate the placement of the gearmotor in the foundation case and its anchoring.

Secure the gearmotor using the nuts supplied.

M12 nut

UNI 5588

Fastening the gearmotor

Before fastening the gearmotors, fit the adjusting screws into the gearmotor drive arms, as shown in the drawing.

LEFT SIDE RIGHT SIDE

Page 1010 - Manual code: FA00597-ENFA00597-EN ver. 1105/2018 © CAME S.p.A. - The data and information provided in this manual are subject to change at any time without prior notice by CAME S.p.A.

Lubricate the transmission lever and fit it into the hole of the gearmotor arm and case lever.

Determining the end run points

During opening:

- Fully open the leafs (the maximum aperture is 110 °);

- loosen the screw until it makes contact with the body ;

- tighten the nut to lock the position of the screw.

During closing:

- close the leaves completely;

- loosen the screw until it makes contact with the transmission arm ;

- tighten the nut to lock the position of the screw.

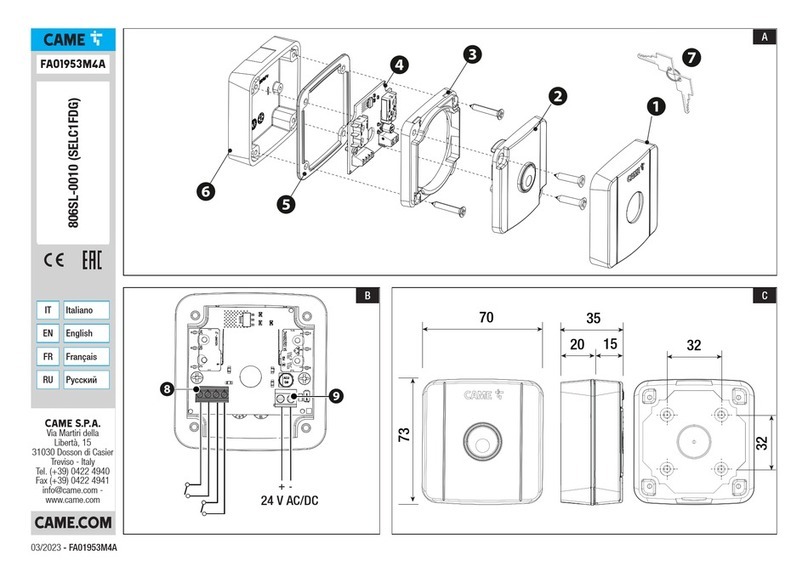

gate geometry

• It is always advisable to install an electric lock, to

ensure reliable closure of the gate.

• The installation of an electric lock is mandatory with

gate leaves longer than 2.5 m

Gate leaf length (m) 5.5 4.5 3.5 2.5 1.5

Gate leaf weight (kg) 700 900 1100 1400 1800

LIMITS TO USE

Pillar

Leaf - closed

position

Hinge

94mm*

94mm

426mm

*It is critical that the distance between the pillar

and the centre of the hinge be AT LEAST 94mm

in order for the motor to operate correctly.

For installations with gates opening outwards please refer to the main manual